Geoff Tsai

MAS.863 How to Make (Almost) Anything, Fall 2013

Project 03: Electronics Production

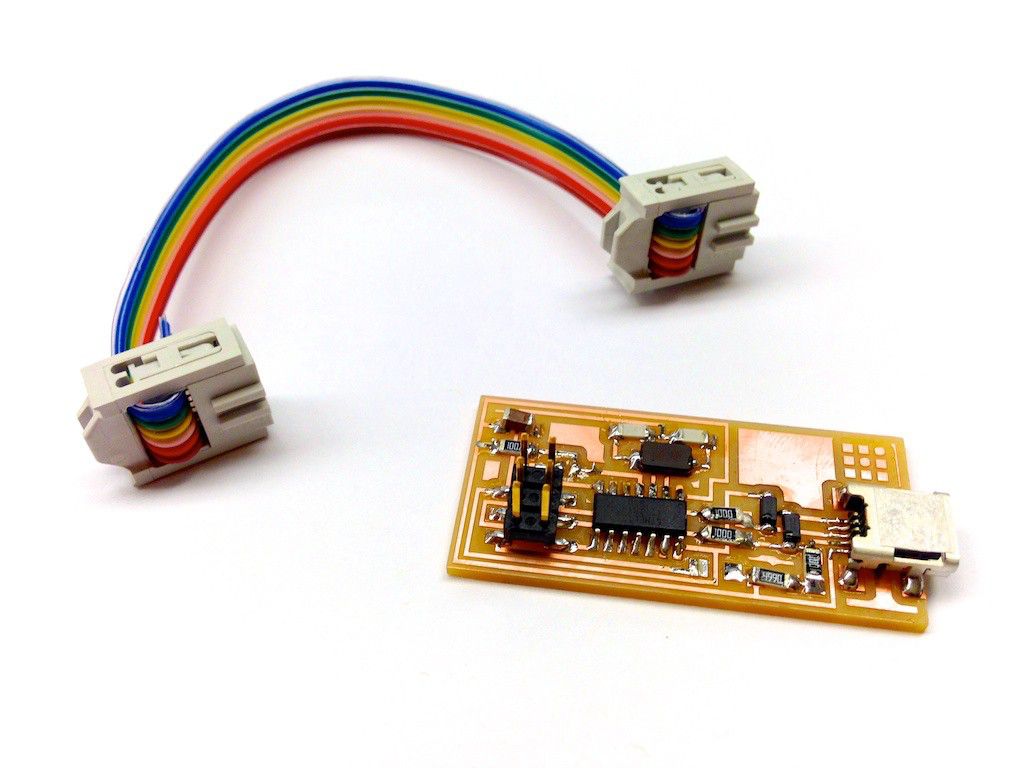

The assignment for this project was to create the FabISP in-circuit programmer. I've never done circuit board milling before, so this was a fun, new experience.

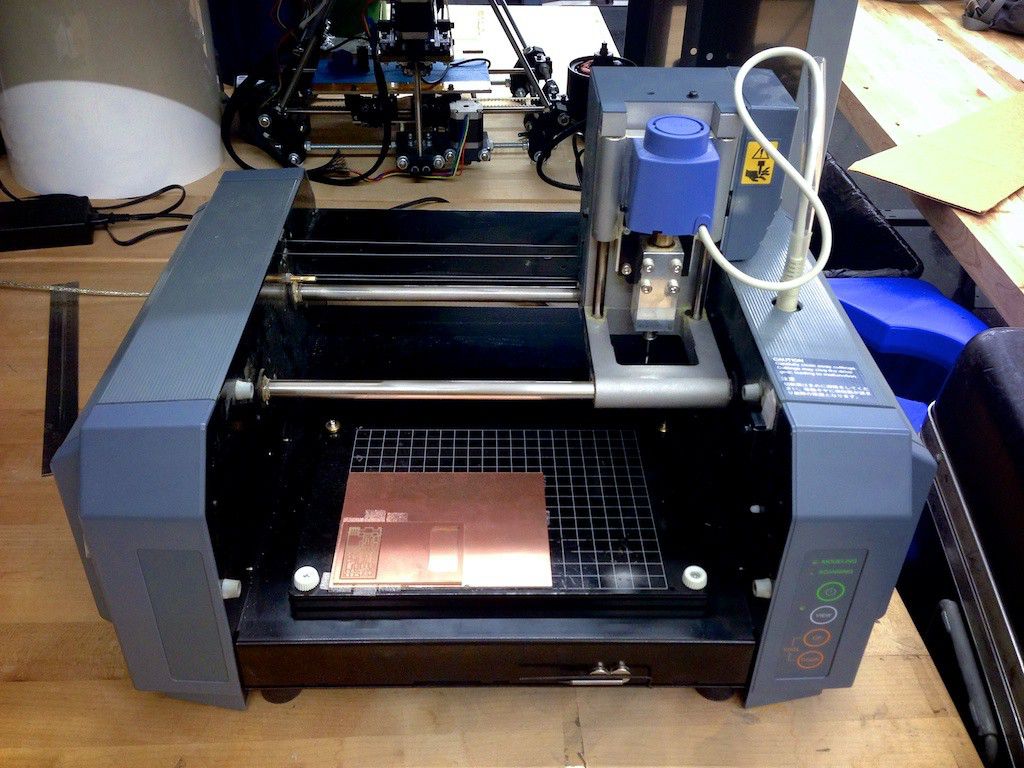

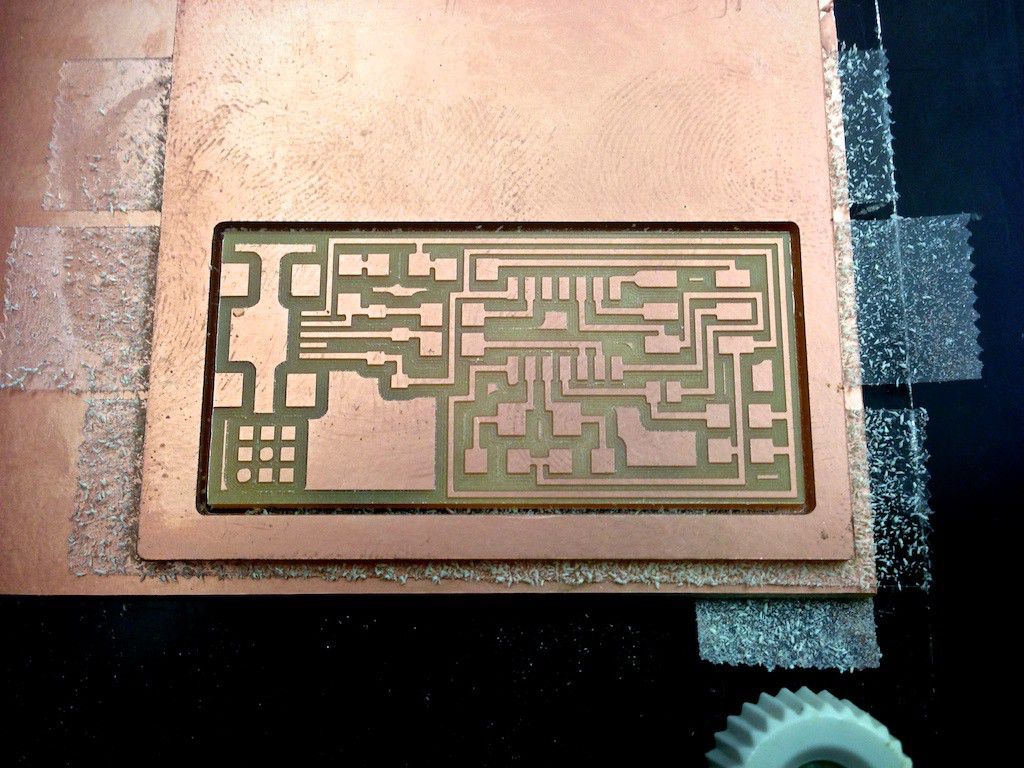

There were a few different ISP designs available, but I opted for the traditional HelloISP. In order to actually make the PCB, I started with a blank sheet of FR1 and loaded it into the Modela mill.

The circuit traces (interior of the board) were cut with the tiny, 1/64" end mill; the PCB outline was cut with the 1/32" end mill, separating the completed PCB from the rest of the copper-clad FR1 sheet.

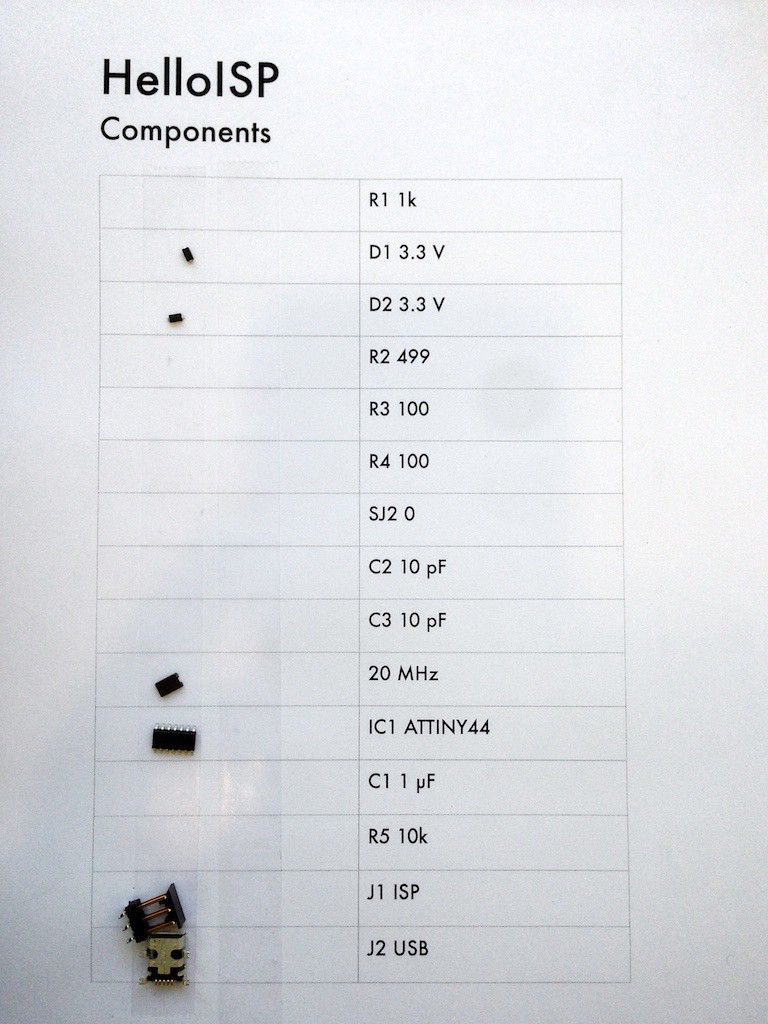

During the training for this Fab module, I learned a really useful tip which was to write down the list of components (create a BoM), add a strip of double-sided tape, and stick the small components onto the sheet adjacent to each line item. I found this incredibly helpful to keep track of the components and not lose them. Thanks for the tip, Rob!

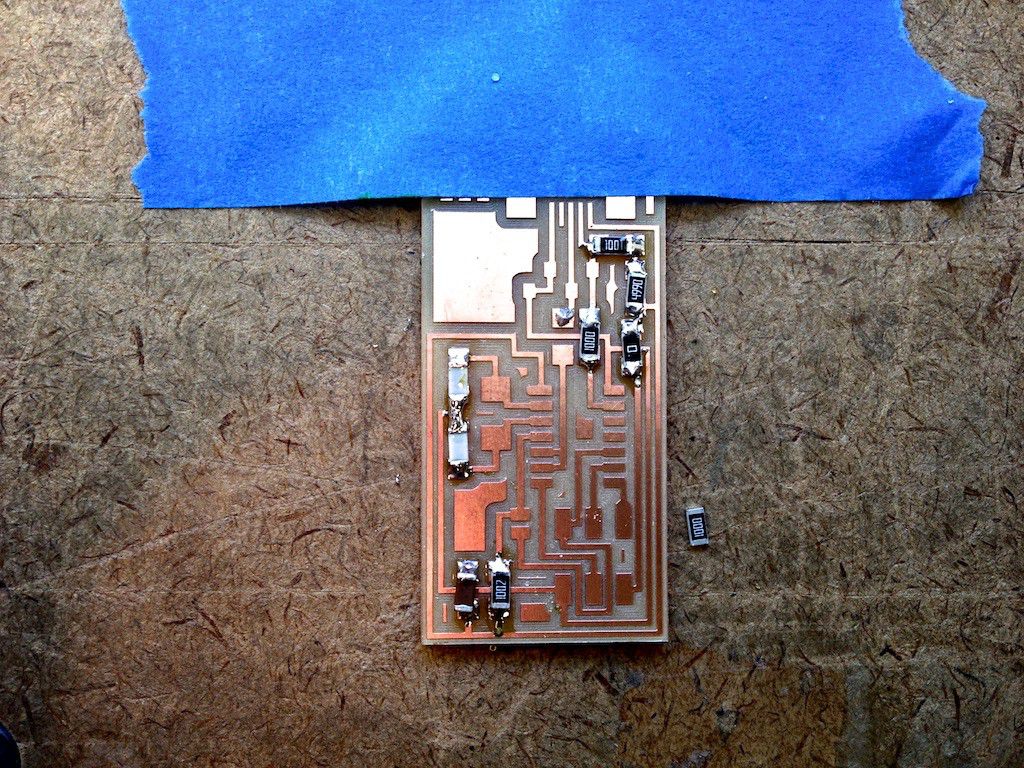

I have some soldering experience, but I haven't worked much with components this small. Soldering to the PCB was challenging at first, but I eventually got a little more comfortable with the setup. The fine-tip soldering iron was essential for soldering the small legs on the ATtiny44 and mini-USB connector. I also found holding down the entire PCB with a piece of tape was really helpful to prevent it from sliding around.