Editing the GUI to show two sensor readings

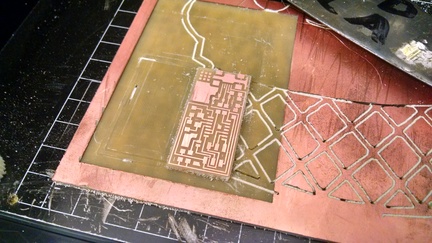

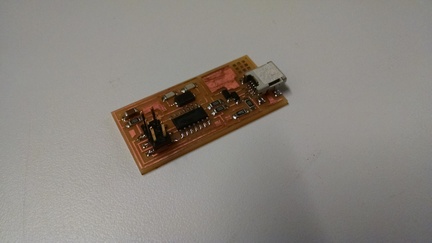

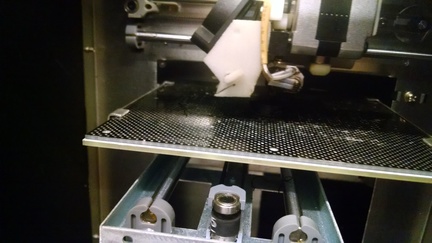

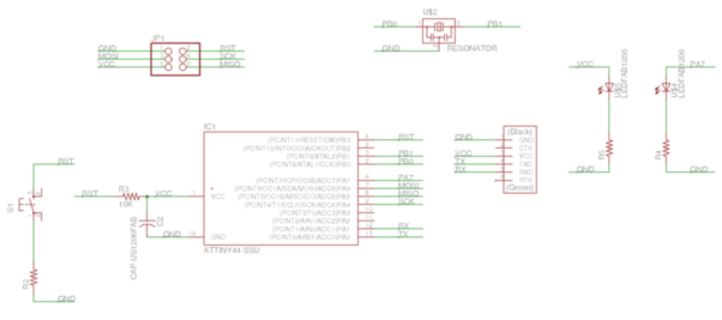

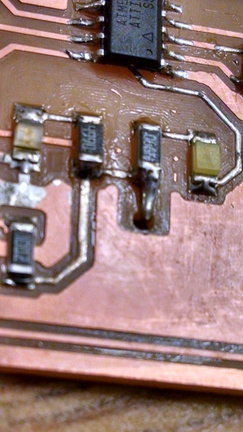

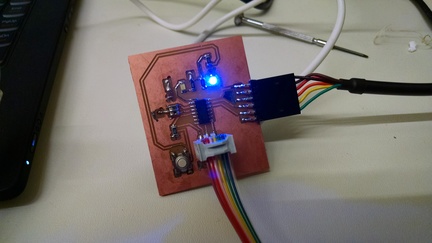

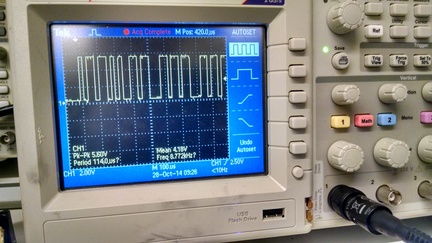

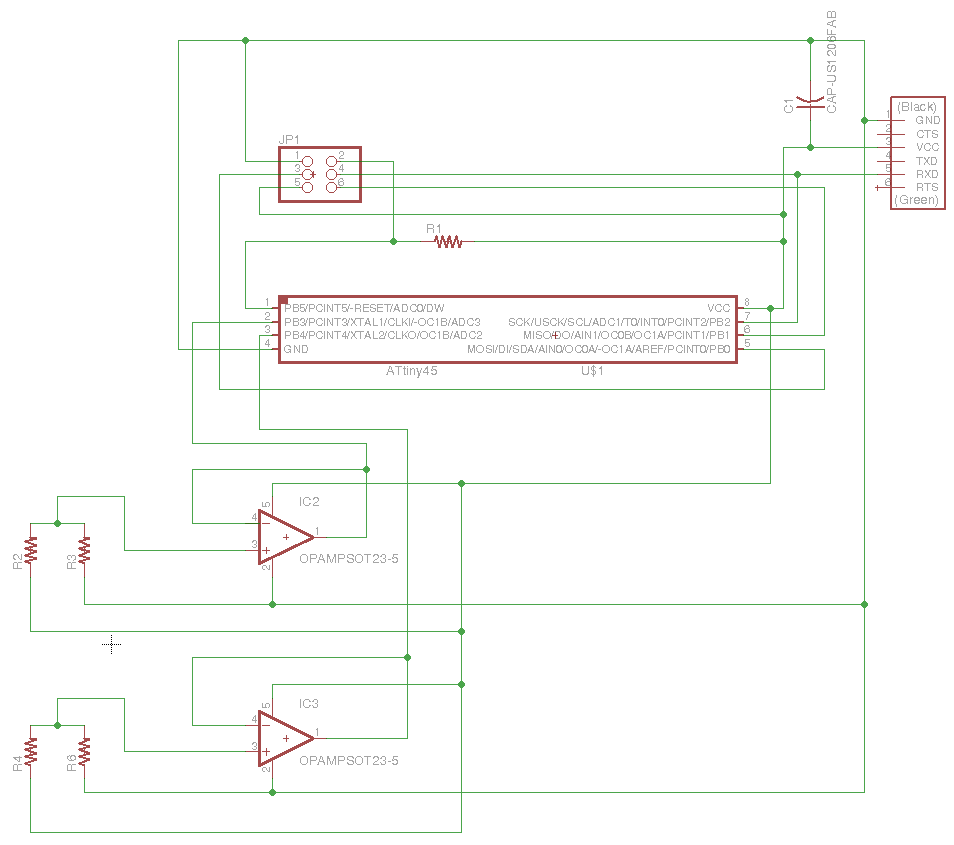

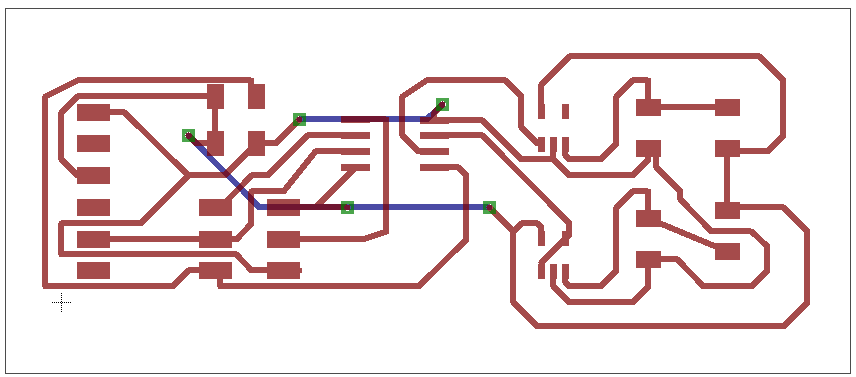

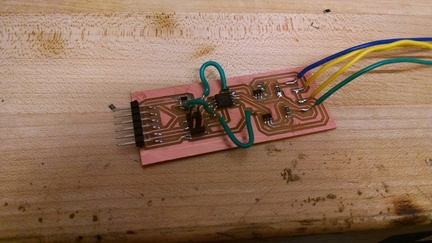

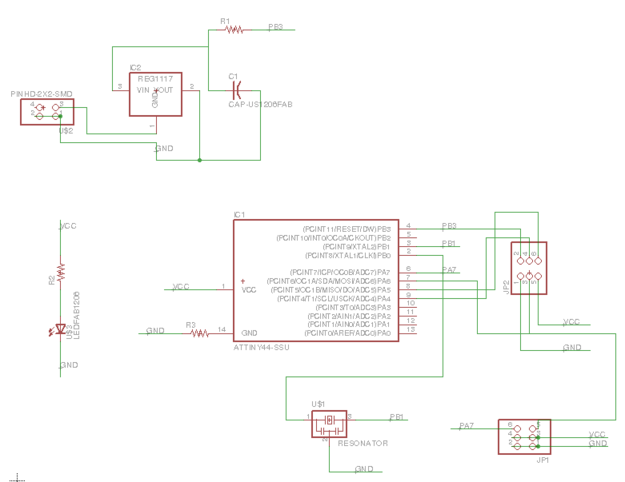

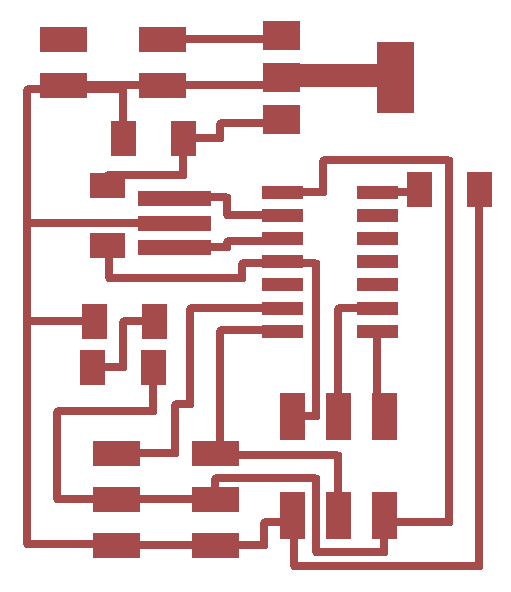

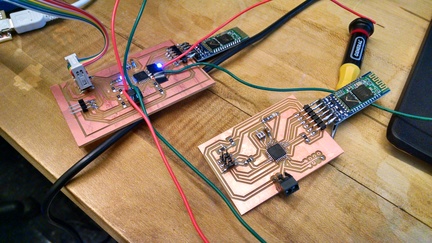

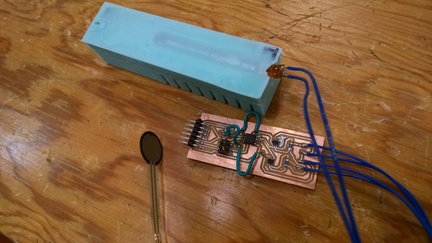

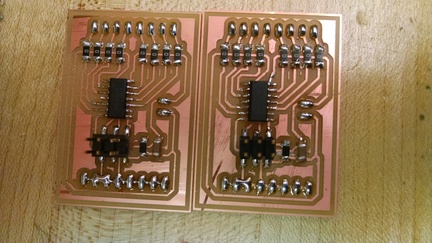

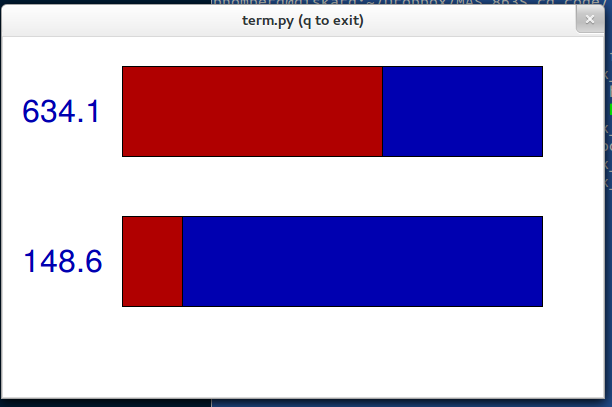

During input devices week, I made a board with two sensors. In order to view both sets of data, I switched the serial output between the two relevant pins in the program and reprogrammed the ATiny44 in order to see the other sensor output. This week, I edited the code on the board and edited the GUI to show both data points at once. I tested it by activating each sensor independently and seeing the response. It took a little fiddling with parameters and figuring out how Tkinter works, but ultimately was relatively straightforward.

Code on the ATiny44:

#include

#include

#define output(directions,pin) (directions |= pin) // set port direction for output

#define set(port,pin) (port |= pin) // set port pin

#define clear(port,pin) (port &= (~pin)) // clear port pin

#define pin_test(pins,pin) (pins & pin) // test for port pin

#define bit_test(byte,bit) (byte & (1 << bit)) // test for bit set

#define bit_delay_time 102 // bit delay for 9600 with overhead

#define bit_delay() _delay_us(bit_delay_time) // RS232 bit delay

#define half_bit_delay() _delay_us(bit_delay_time/2) // RS232 half bit delay

#define char_delay() _delay_ms(10) // char delay

#define serial_port PORTB

#define serial_direction DDRB

#define serial_pin_out (1 << PB2)

void put_char(volatile unsigned char *port, unsigned char pin, char txchar) {

//

// send character in txchar on port pin

// assumes line driver (inverts bits)

//

// start bit

//

clear(*port,pin);

bit_delay();

//

// unrolled loop to write data bits

//

if bit_test(txchar,0)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,1)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,2)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,3)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,4)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,5)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,6)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

if bit_test(txchar,7)

set(*port,pin);

else

clear(*port,pin);

bit_delay();

//

// stop bit

//

set(*port,pin);

bit_delay();

//

// char delay

//

bit_delay();

}

int main(void) {

//

// main

//

static char chr;

//

// set clock divider to /1

//

CLKPR = (1 << CLKPCE);

CLKPR = (0 << CLKPS3) | (0 << CLKPS2) | (0 << CLKPS1) | (0 << CLKPS0);

//

// initialize output pins

//

set(serial_port, serial_pin_out);

output(serial_direction, serial_pin_out);

//

// init A/D

//

ADMUX = (0 << REFS2) | (0 << REFS1) | (0 << REFS0) // Vcc ref

| (0 << ADLAR) // right adjust

| (0 << MUX3) | (0 << MUX2) | (1 << MUX1) | (1 << MUX0); // ADC3 1 0 for ADC4, 1 1 for ADC3

ADCSRA = (1 << ADEN) // enable

| (1 << ADPS2) | (1 << ADPS1) | (1 << ADPS0); // prescaler /128

//

// main loop

//

while (1) {

//

// send framing

//

put_char(&serial_port, serial_pin_out, 1);

char_delay();

put_char(&serial_port, serial_pin_out, 2);

char_delay();

put_char(&serial_port, serial_pin_out, 3);

char_delay();

put_char(&serial_port, serial_pin_out, 4);

char_delay();

ADMUX = (0 << REFS2) | (0 << REFS1) | (0 << REFS0) // Vcc ref

| (0 << ADLAR) // right adjust

| (0 << MUX3) | (0 << MUX2) | (1 << MUX1) | (1 << MUX0); // ADC3 1 0 for ADC4, 1 1 for ADC3

//

// initiate conversion

//

ADCSRA |= (1 << ADSC);

//

// wait for completion

//

while (ADCSRA & (1 << ADSC))

;

//

// send result

//

chr = ADCL;

put_char(&serial_port, serial_pin_out, chr);

char_delay();

chr = ADCH;

put_char(&serial_port, serial_pin_out, chr);

char_delay();

ADMUX = (0 << REFS2) | (0 << REFS1) | (0 << REFS0) // Vcc ref

| (0 << ADLAR) // right adjust

| (0 << MUX3) | (0 << MUX2) | (1 << MUX1) | (0 << MUX0); // ADC4 1 0 for ADC4, 1 1 for ADC3

//

// initiate conversion

//

ADCSRA |= (1 << ADSC);

//

// wait for completion

//

while (ADCSRA & (1 << ADSC))

;

//

// send result

//

chr = ADCL;

put_char(&serial_port, serial_pin_out, chr);

char_delay();

chr = ADCH;

put_char(&serial_port, serial_pin_out, chr);

char_delay();

}

}

The relevant change in the Arduino code is the resetting the value of ADMUX and sending the second result each cycle.

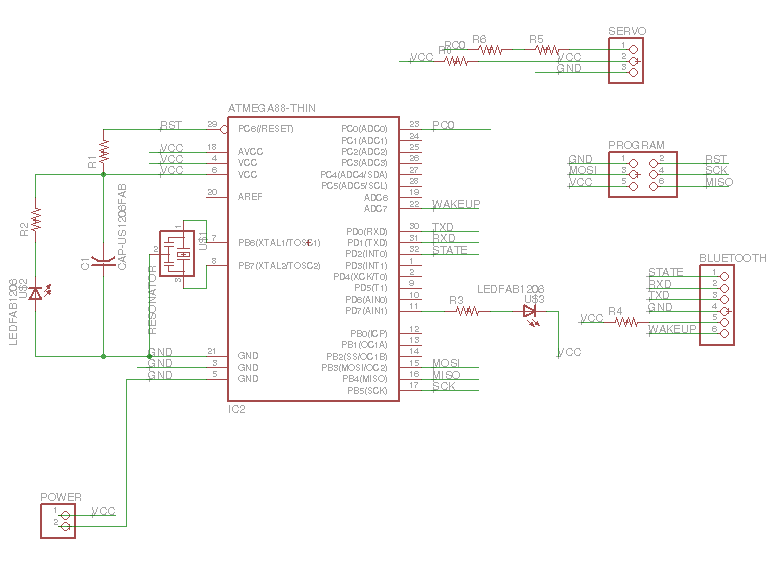

For the python output program, it appears as follows:

from Tkinter import *

import serial

WINDOW = 600 # window size

eps1 = 0.5 # filter time constant

filter1 = 0.0 # filtered value

eps2 = .5

filter2 = 0

def idle(parent,canvas):

global filter1, eps1

global filter2, eps2

#

# idle routine

#

byte2 = 0

byte3 = 0

byte4 = 0

ser.flush()

while 1:

#

# find framing

#

byte1 = byte2

byte2 = byte3

byte3 = byte4

byte4 = ord(ser.read())

if ((byte1 == 1) & (byte2 == 2) & (byte3 == 3) & (byte4 == 4)):

break

low = ord(ser.read())

high = ord(ser.read())

value1 = 256*high + low

filter1 = (1-eps1)*filter1 + eps1*value1

x = int(.2*WINDOW + (.9-.2)*WINDOW*filter1/1024.0)

low = ord(ser.read())

high = ord(ser.read())

value2 = 256*high + low

filter2 = (1-eps2)*filter2 + eps2*value2

y = int(.2*WINDOW + (.9-.2)*WINDOW*filter2/1024.0)

canvas.itemconfigure("text1",text="%.1f"%filter1)

canvas.coords('rect1',.2*WINDOW,.05*WINDOW,x,.2*WINDOW)

canvas.coords('rect2',x,.05*WINDOW,.9*WINDOW,.2*WINDOW)

canvas.itemconfigure("text2",text="%.1f"%filter2)

canvas.coords('rect3',.2*WINDOW,.3*WINDOW,y,.45*WINDOW)

canvas.coords('rect4',y,.3*WINDOW,.9*WINDOW,.45*WINDOW)

canvas.update()

parent.after_idle(idle,parent,canvas)

#

# check command line arguments

#

if (len(sys.argv) != 2):

print "usage: command line: python term.py serial_port"

sys.exit()

port = sys.argv[1]

#

# open serial port

#

ser = serial.Serial(port,9600)

ser.setDTR()

#

# set up GUI

#

root = Tk()

root.title('term.py (q to exit)')

root.bind('q','exit')

canvas = Canvas(root, width=WINDOW, height=.6*WINDOW, background='white')

canvas.create_text(.1*WINDOW,.125*WINDOW,text=".33",font=("Helvetica", 24),tags="text1",fill="#0000b0")

canvas.create_rectangle(.2*WINDOW,.05*WINDOW,.3*WINDOW,.2*WINDOW, tags='rect1', fill='#b00000')

canvas.create_rectangle(.3*WINDOW,.05*WINDOW,.9*WINDOW,.2*WINDOW, tags='rect2', fill='#0000b0')

canvas.create_text(.1*WINDOW,(.5-.125)*WINDOW,text=".33",font=("Helvetica", 24),tags="text2",fill="#0000b0")

canvas.create_rectangle(.2*WINDOW,.3*WINDOW,.3*WINDOW, .45*WINDOW, tags='rect3', fill='#b00000')

canvas.create_rectangle(.3*WINDOW,.3*WINDOW,.9*WINDOW,.45*WINDOW, tags='rect4', fill='#0000b0')

canvas.pack()

#

# start idle loop

#

root.after(100,idle,root,canvas)

root.mainloop()

The relevant change is to duplicate the filtered value calculation and the rectangle creation.

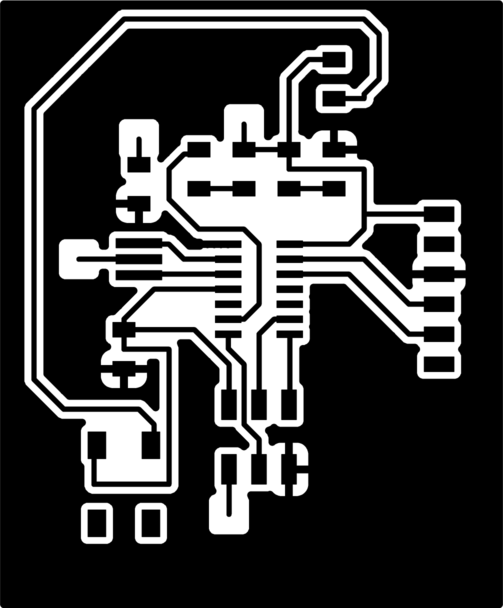

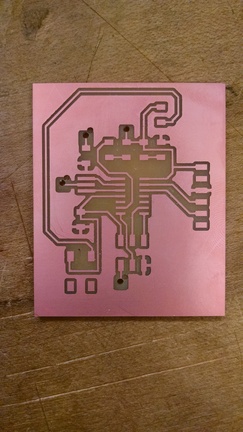

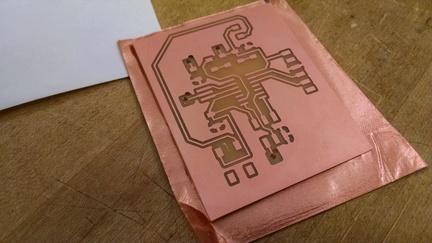

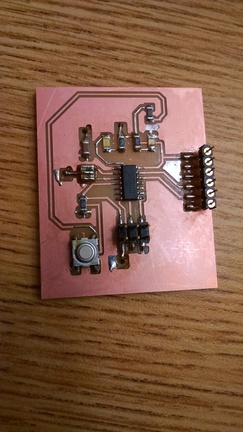

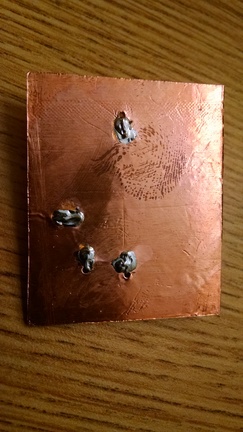

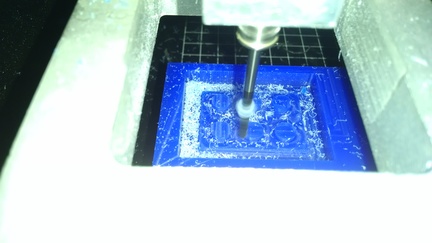

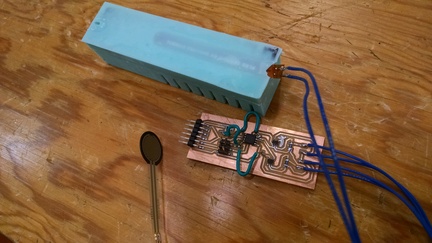

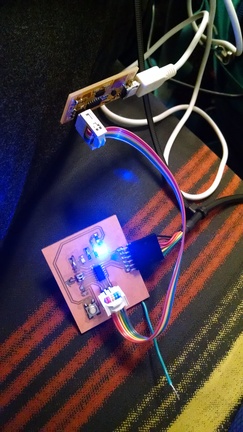

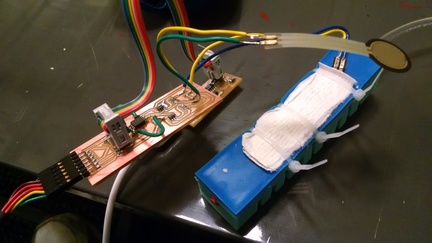

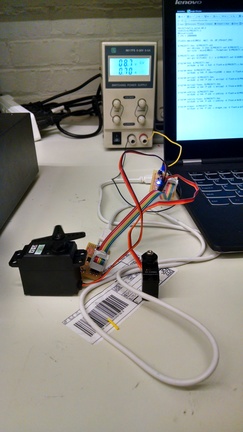

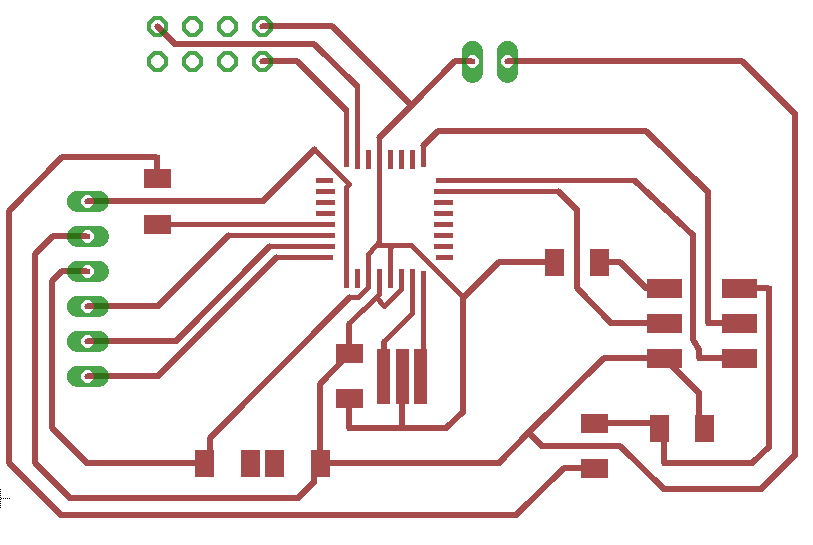

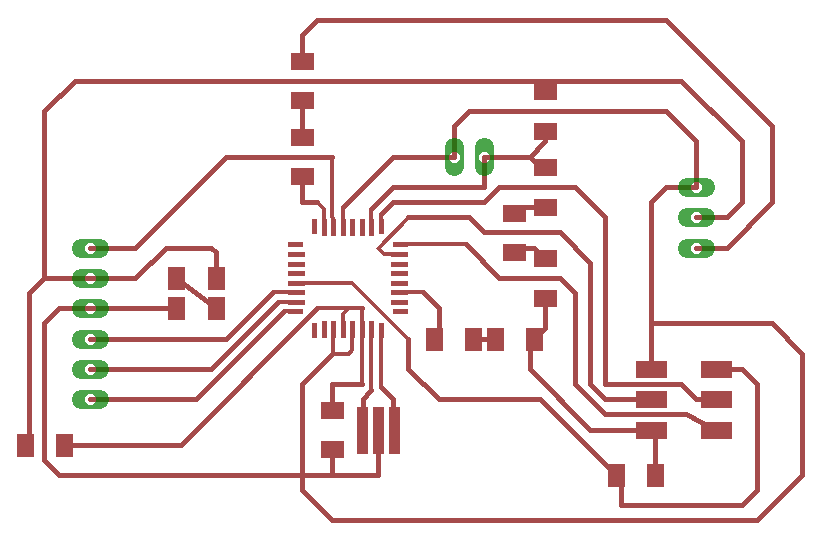

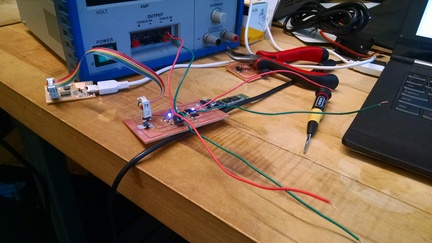

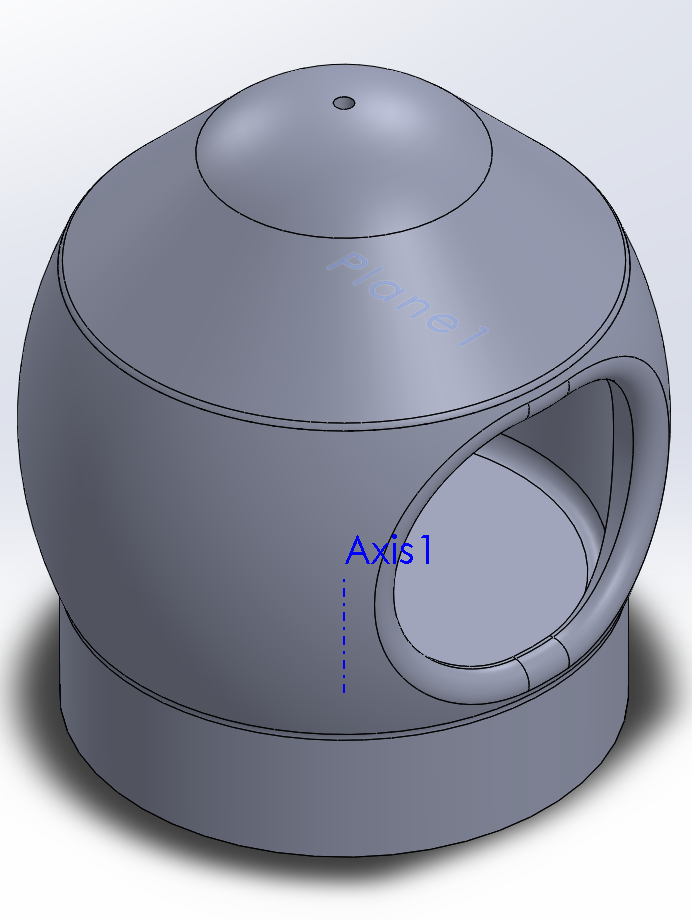

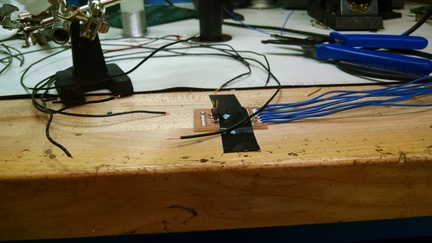

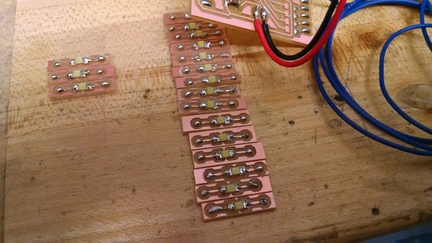

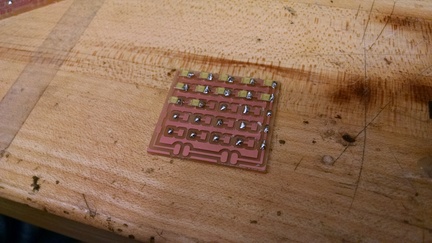

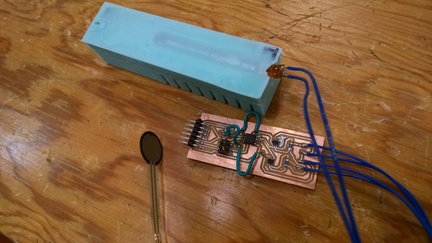

A picture of the sensor setup with the soft robotic finger:

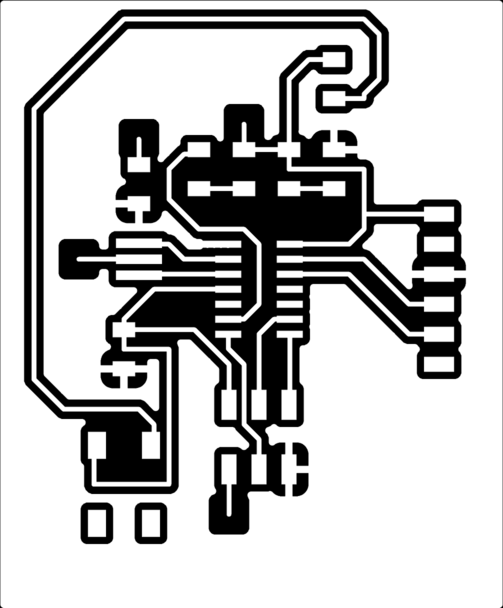

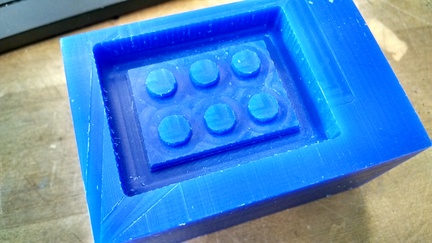

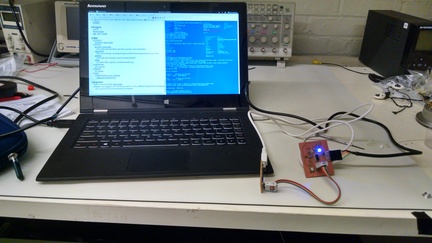

A screenshot of the edited GUI:

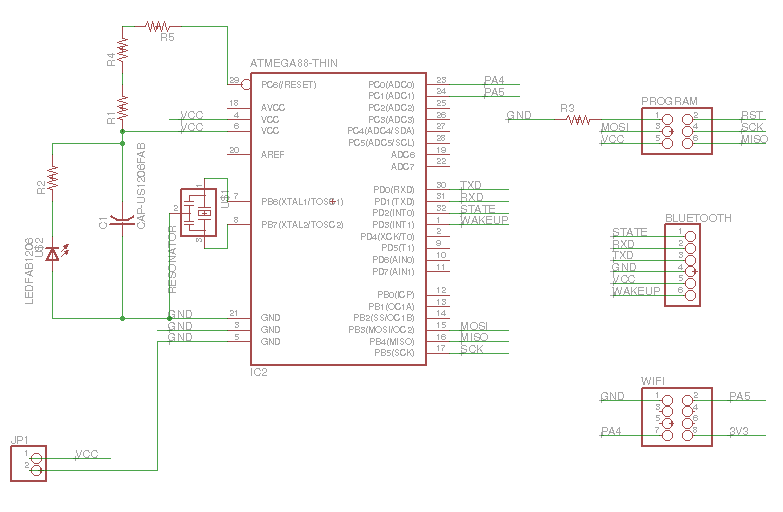

ROS integration

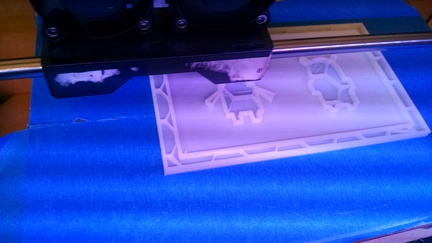

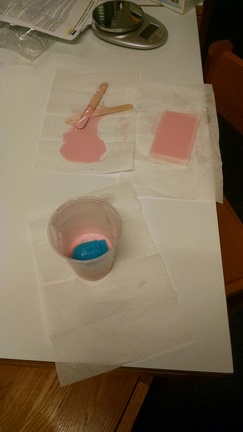

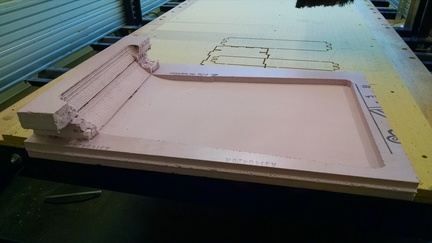

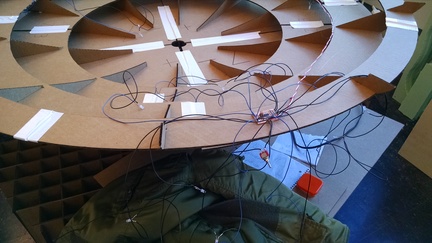

My goal with this input device is to get data back from the flex sensor to determine the curvature of a soft robotic finger. Towards this end, I have embedded the flex sensor in a prototype gripper. The next step is to create a ROS* node which will run on my computer to read in the serial input through the FTDI cable and publish the data as a custom ROS message. There are two options here: rosserial would run a rosserial_client node directly on the Arduino, communicating with a rosserial_server on the computer. This seems overkill, however. My current plan is to user a serial class to interface with the Arduino, read in the serial data, and then simply publish ROS messages independently.

I got this working using rospy and the Python serial class. (I ran into issues with the C++ serial class I downloaded -- it didn't seem to be reading the data correctly, and I kept getting strange values instead of the numbers I was expecting. Python made it a lot easier to deal with strings/ints/etc). I created a publisher node based on the code that read in data that Neil provided. Then, I published the sensor value in a custom message type to a new topic. And out came the data! Here is the code:

#!/usr/bin/env python

# license removed for brevity

import rospy

from std_msgs.msg import String

from test_code.msg import SerialMsg

import serial

eps1 = 0.5 # filter time constant

filter1 = 0.0 # filtered value

def go_publish():

ser = serial.Serial('/dev/ttyUSB0', 9600)

ser.setDTR()

pub = rospy.Publisher('flex_sensor_vals', SerialMsg)

rospy.init_node('serial_publisher_py', anonymous=True)

r = rospy.Rate(10) # 10hz

while not rospy.is_shutdown():

global filter1, eps1

global filter2, eps2

#

# idle routine

#

byte2 = 0

byte3 = 0

byte4 = 0

ser.flush()

while 1:

#

# find framing

#

byte1 = byte2

byte2 = byte3

byte3 = byte4

byte4 = ord(ser.read())

if ((byte1 == 1) & (byte2 == 2) & (byte3 == 3) & (byte4 == 4)):

break

low = ord(ser.read())

high = ord(ser.read())

value1 = 256*high + low

filter1 = (1-eps1)*filter1 + eps1*value1

msg = SerialMsg()

msg.type = 1

msg.value = filter1

rospy.loginfo("got filter value!")

pub.publish(msg)

r.sleep()

if __name__ == '__main__':

try:

go_publish()

except rospy.ROSInterruptException: pass

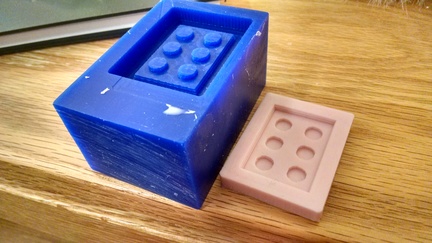

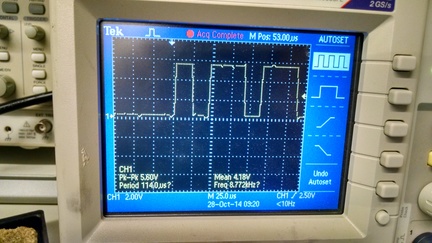

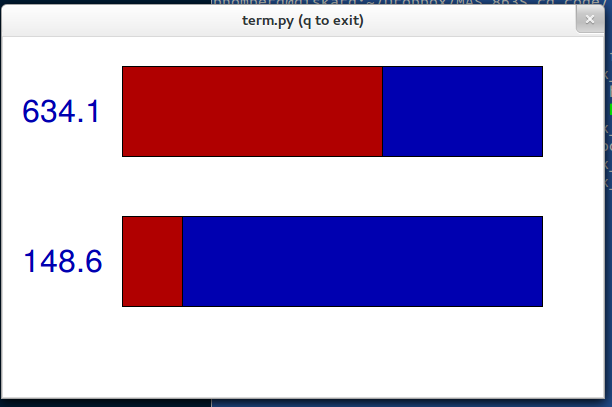

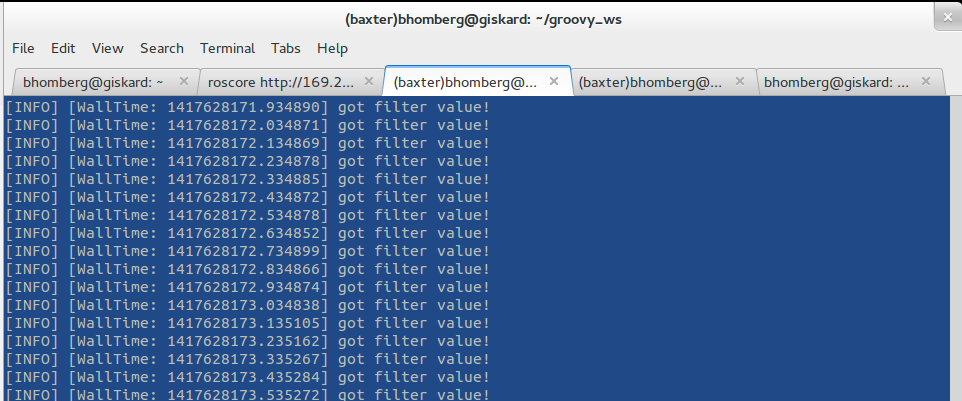

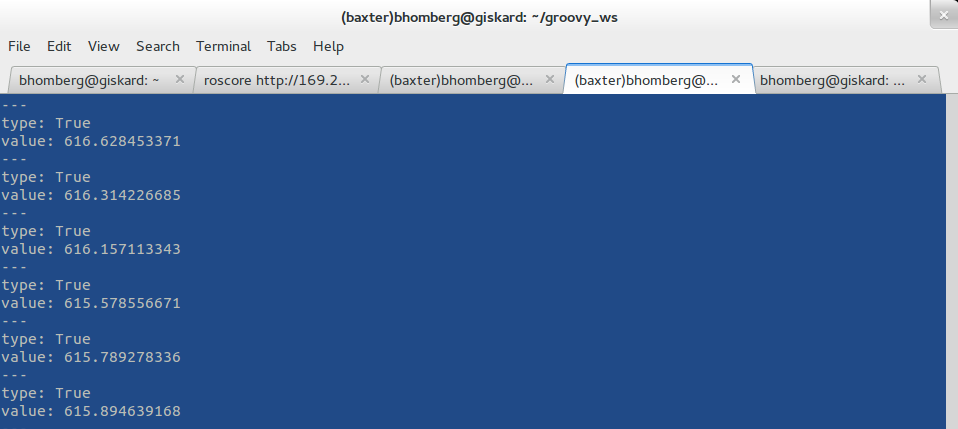

A screenshot of a rostopic echo of the data:

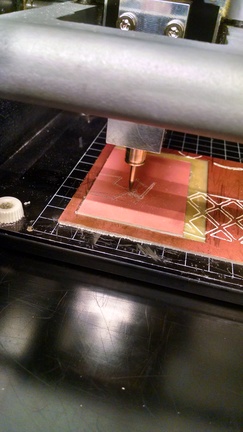

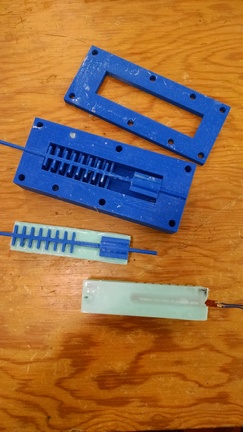

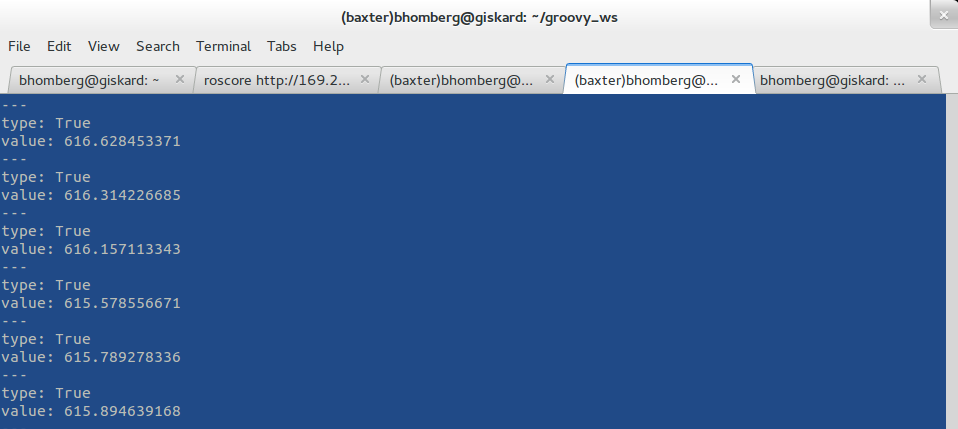

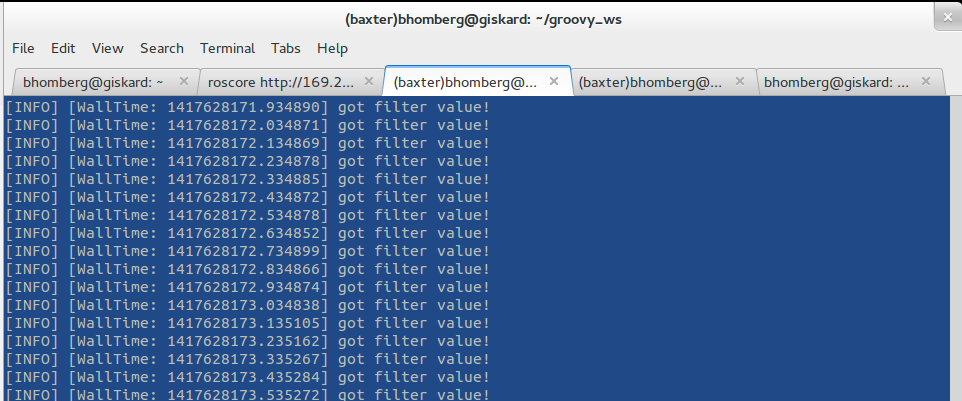

A screenshot of the debugging output:

* What is ROS? See

www.ros.org. ROS stands for the Robotic Operating System, an open source, modular tool for programming robots. It runs as a series of distinct nodes which pass messages between themselves. So long as the master node is running, any other node can be instantiated to send and receive messages and control a robot system.