electronics production

fabISP

milling+soldering+programming

class tutorial

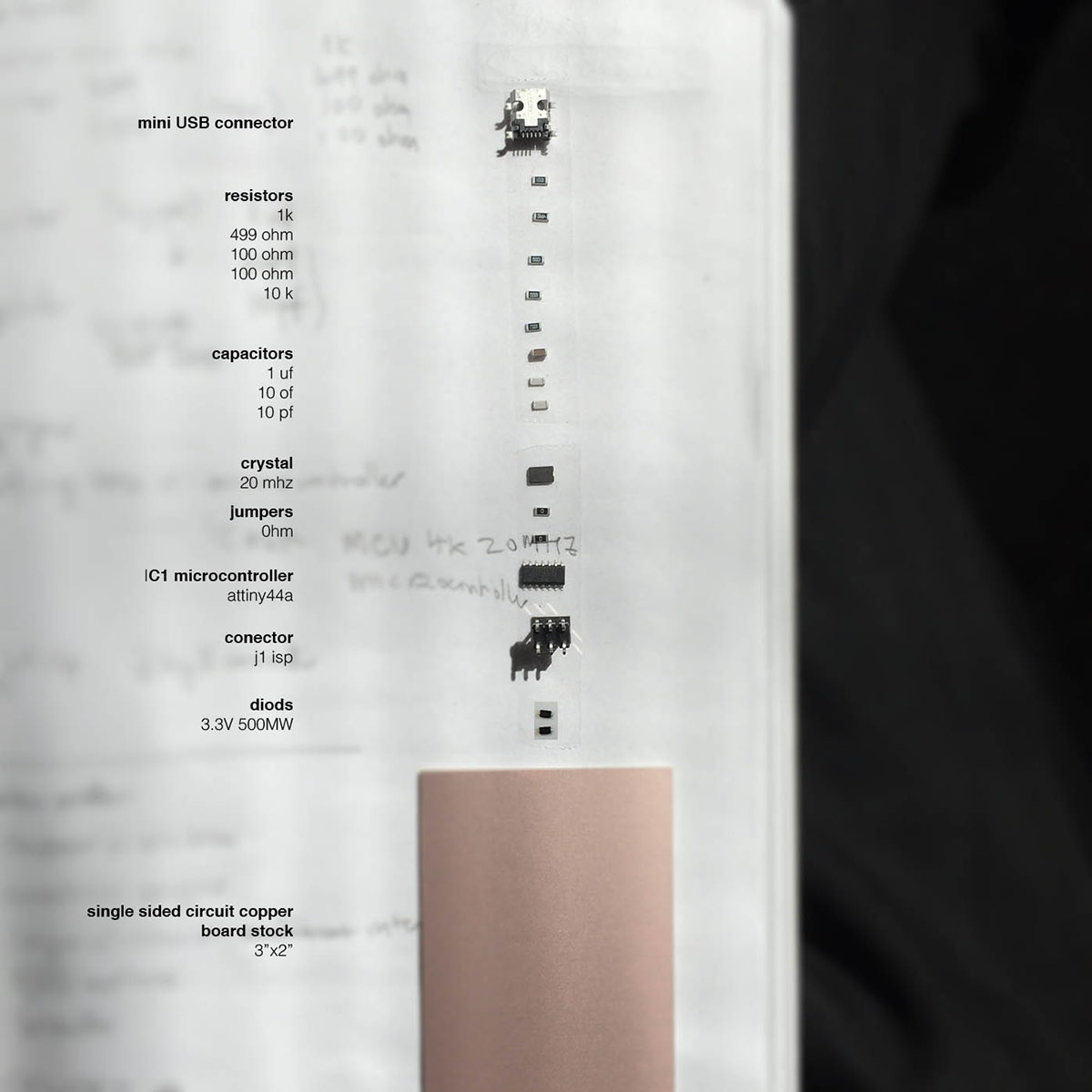

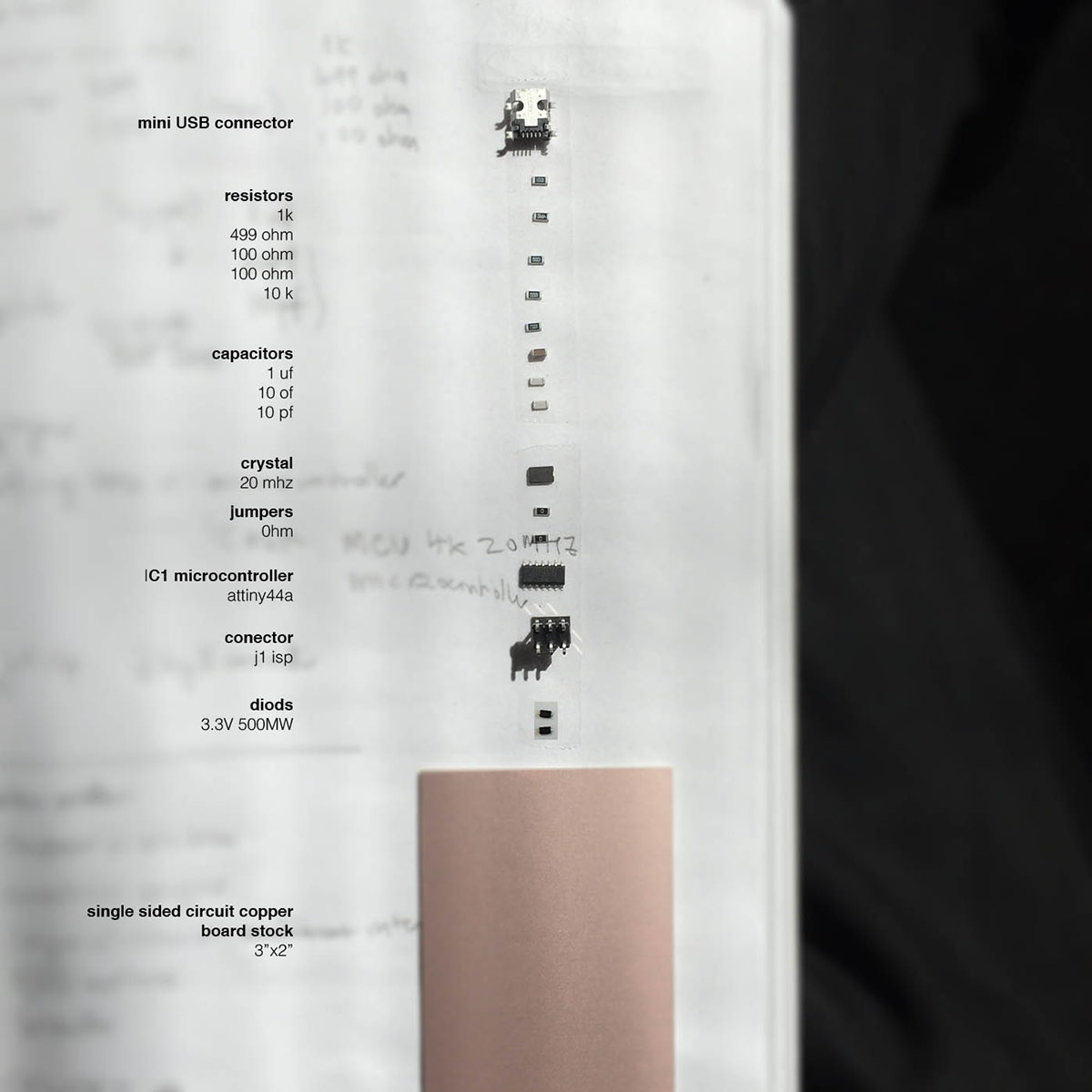

fabISP components: mini USB connector; resistors (5): 1k, 499 ohm, 100 ohm, 100 ohm, 10 k; capacitors (3): 1 uf, 10 of, 10 pf; crystal: 20 mhz; jumpers: 0hm; IC1 microcontroller: attiny44a; conector: j1 isp; diods (2): 3.3V 500MW; single sided circuit copper board stock: 3”x2”

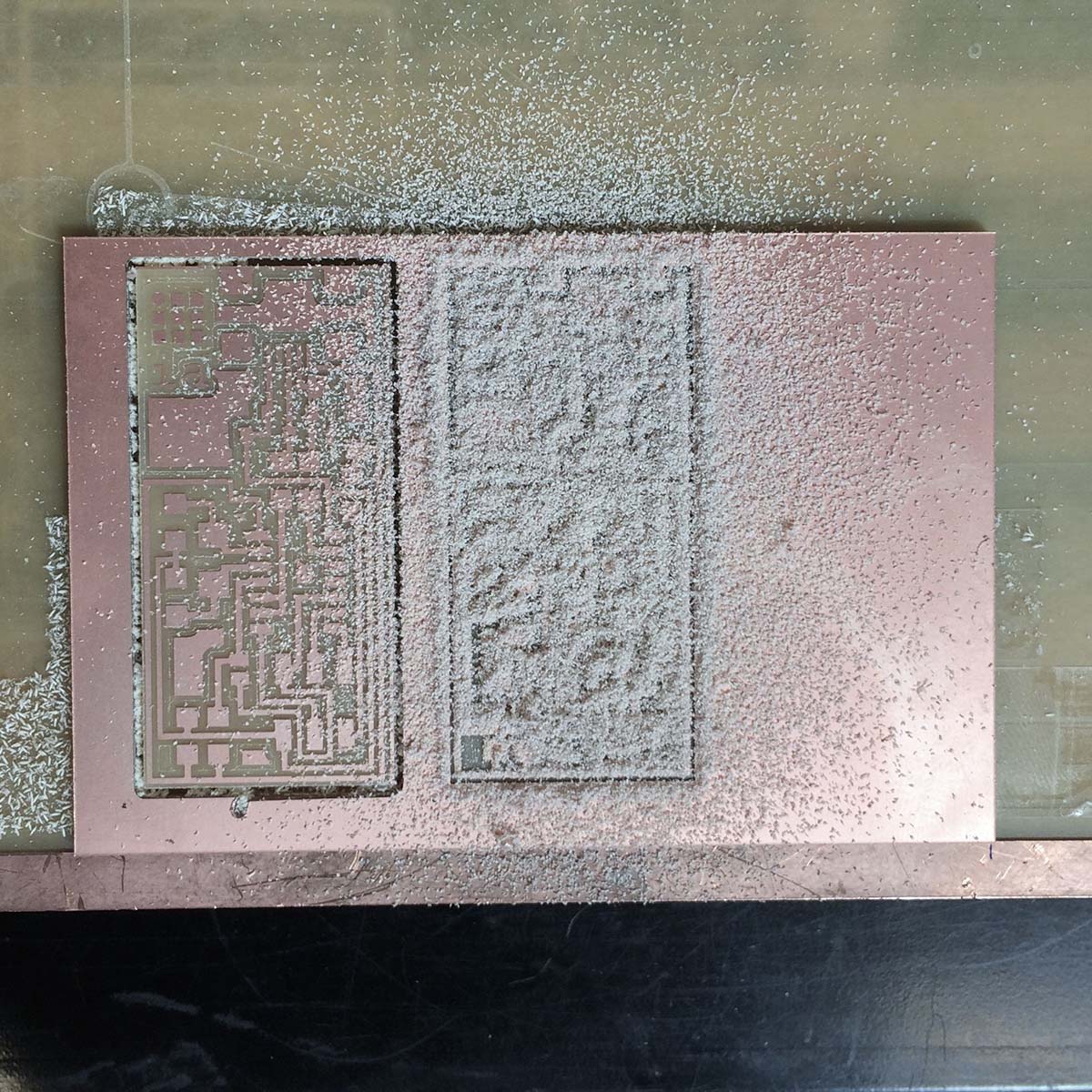

milling

output: ROLAND MODELA MDX-20

output controller: http://mod.cba.mit.edu/index.html

guide:

- use double-sided tape to attach the board tightly to bed (it might float during milling if you don't)

- use shiny bits for milling (1/64 interior, circuits, traces + 1/32 exterior, outline)

- set origin visually using 'x' and 'y' fab module controller (write down this numbers!)

- set origin height using 'up' and 'down' output controller

- upload (customized!) traces file: .png or .svg formats

- calculate path

- send path to output (check % during progress!)

- mill two boards if you are new to this process (next step's needed skills might surprise you)

true story:

in my first milling the board wasn't enough secured to the bed. traces were milled perfectly but during outline milling (1/32, deeper) the board started to float. i had to stop the machine (worrying moment), attach the board again and then start outline milling from the beggining again.

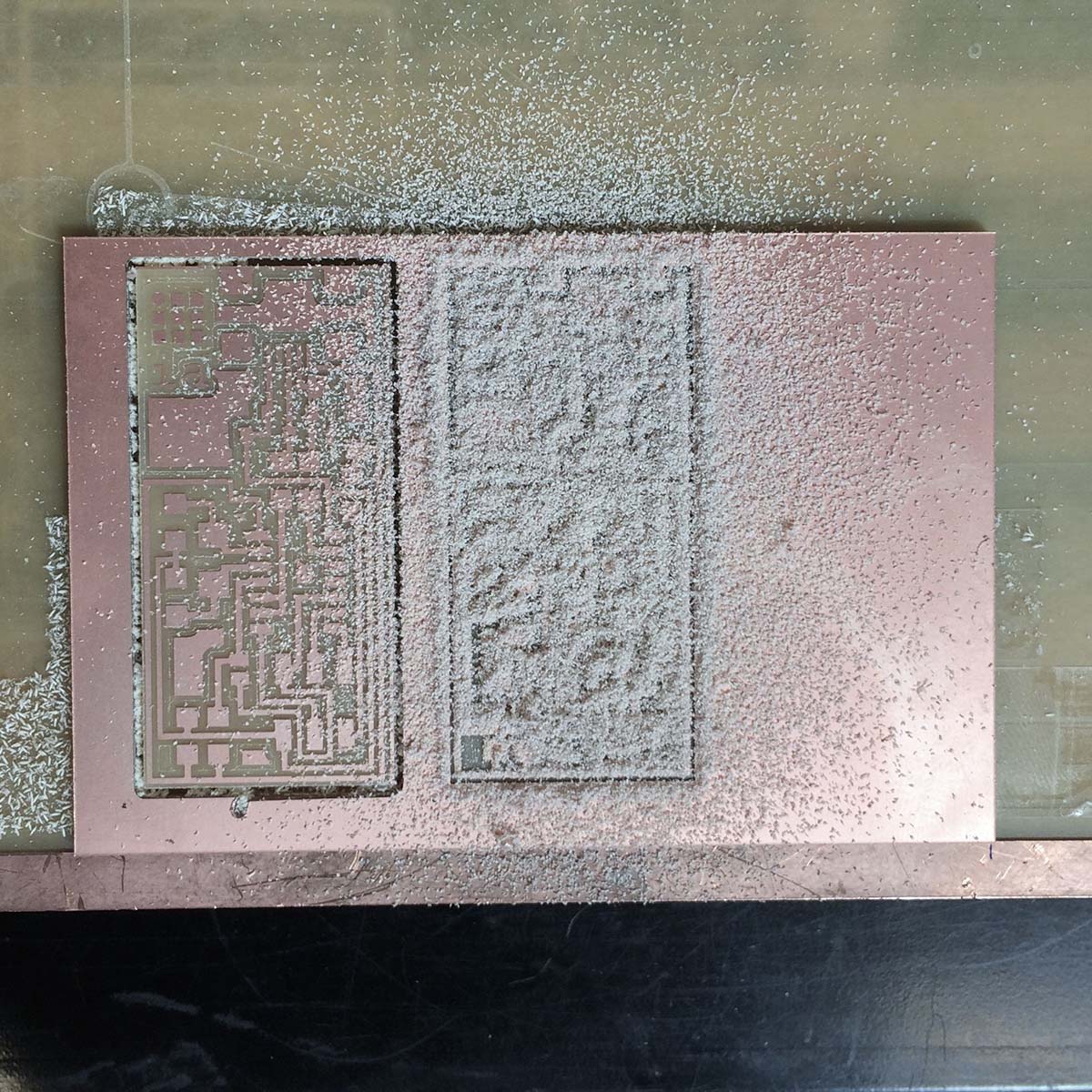

results:

soldering

stuffing:

- microcontroller (pins shouldn't touch each other)

- resistors (no specific direction, work either way)

- capacitors (no specific direction, work either way)

- diods (specific orientation: thin line to the right)

- jumpers (no specific direction, work either way)

- crystal (specific orientation: dot upper left)

- usb (tiny! pins shouldn't touch each other)

- conector (too big: leave it for the end)

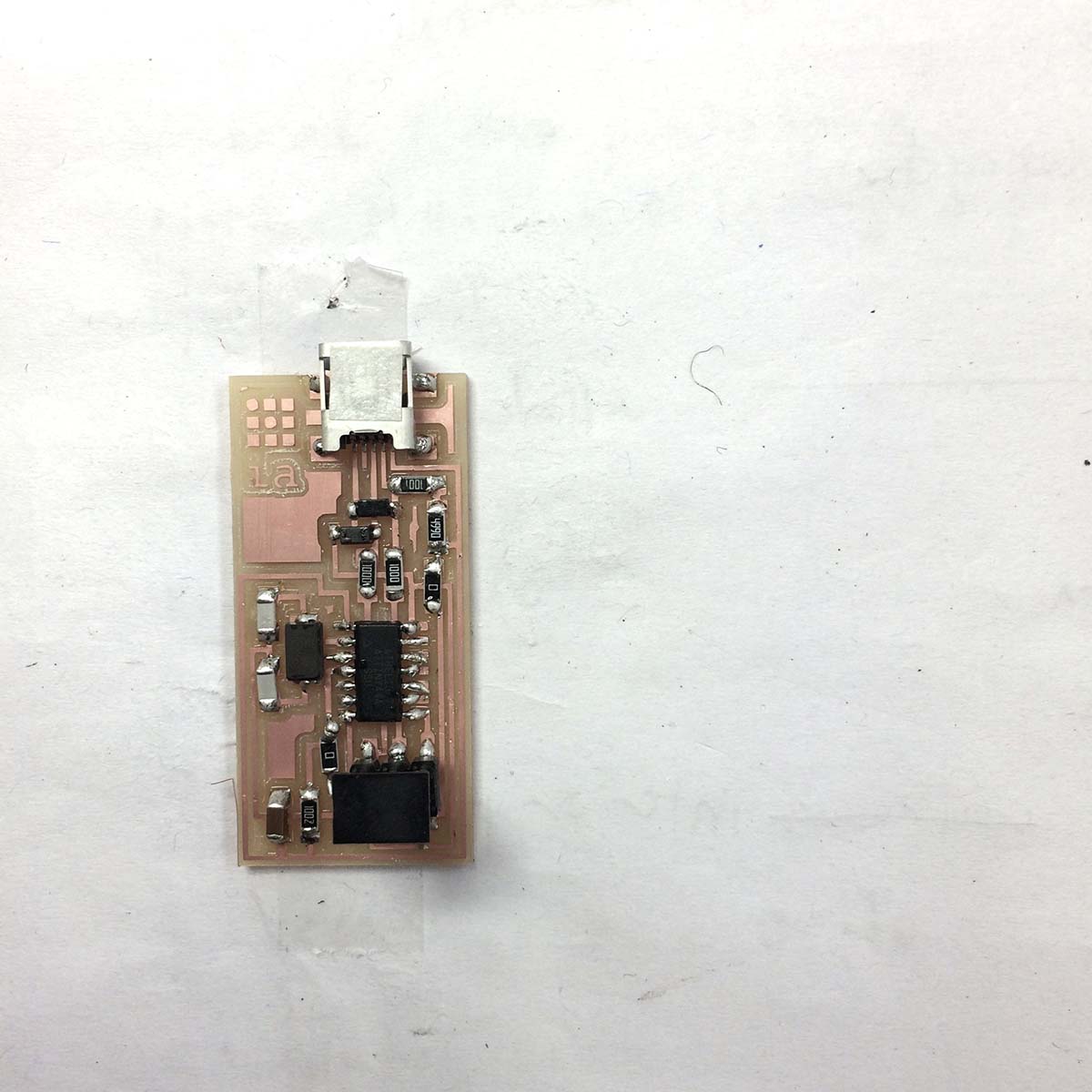

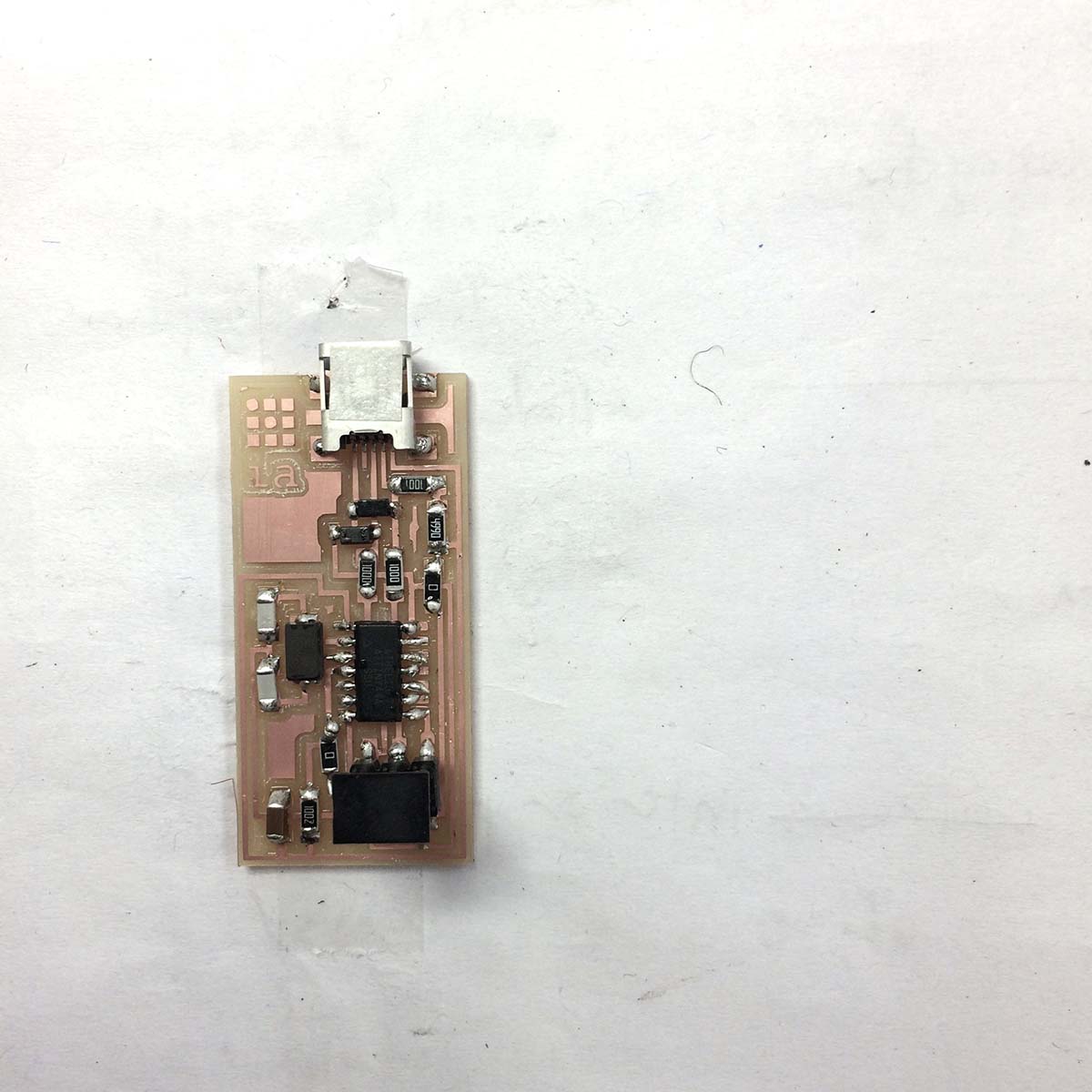

first result:

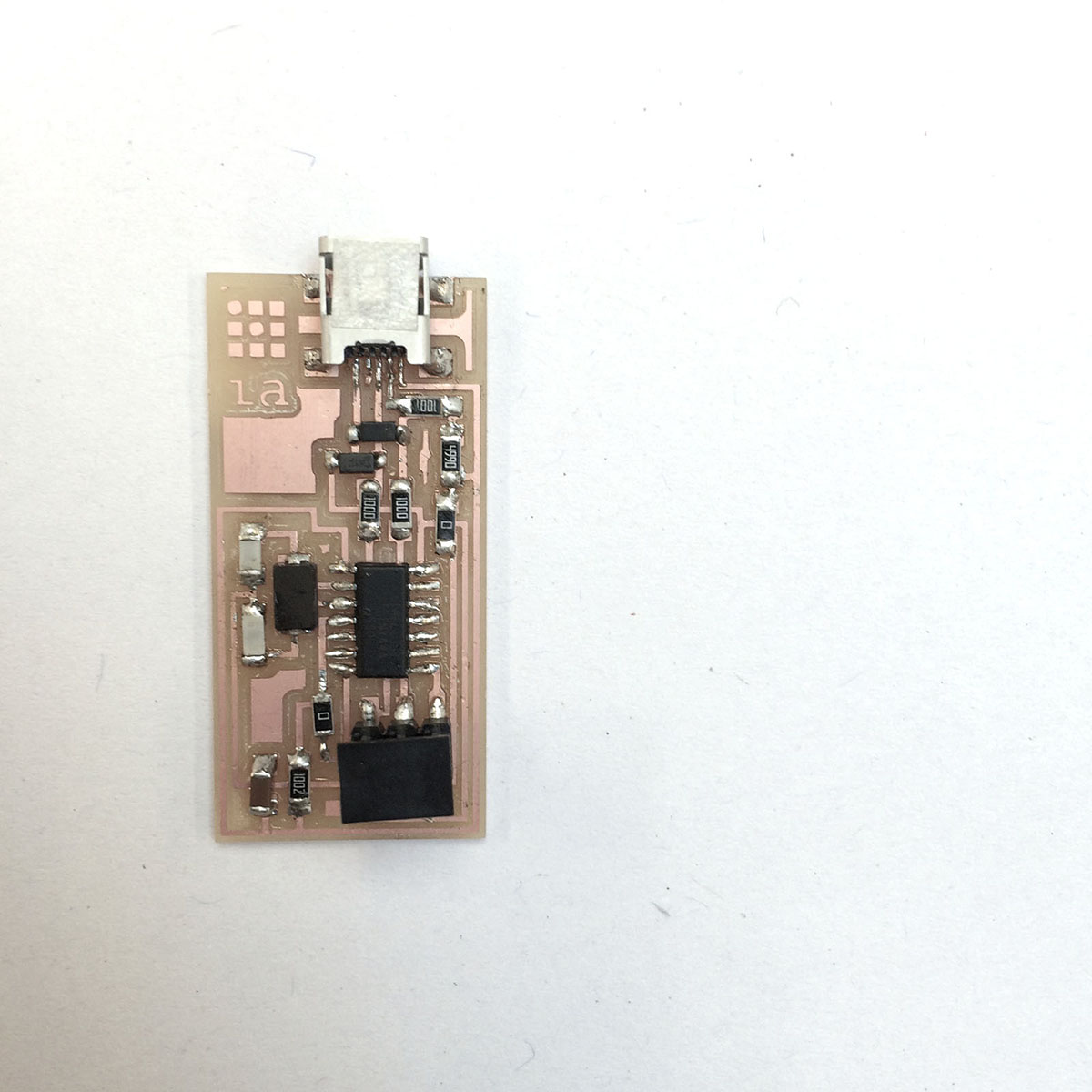

retouching:

milling+soldering+programming

class tutorial

fabISP components: mini USB connector; resistors (5): 1k, 499 ohm, 100 ohm, 100 ohm, 10 k; capacitors (3): 1 uf, 10 of, 10 pf; crystal: 20 mhz; jumpers: 0hm; IC1 microcontroller: attiny44a; conector: j1 isp; diods (2): 3.3V 500MW; single sided circuit copper board stock: 3”x2”

milling

output: ROLAND MODELA MDX-20

output controller: http://mod.cba.mit.edu/index.html

guide:

- use double-sided tape to attach the board tightly to bed (it might float during milling if you don't)

- use shiny bits for milling (1/64 interior, circuits, traces + 1/32 exterior, outline)

- set origin visually using 'x' and 'y' fab module controller (write down this numbers!)

- set origin height using 'up' and 'down' output controller

- upload (customized!) traces file: .png or .svg formats

- calculate path

- send path to output (check % during progress!)

- mill two boards if you are new to this process (next step's needed skills might surprise you)

true story:

in my first milling the board wasn't enough secured to the bed. traces were milled perfectly but during outline milling (1/32, deeper) the board started to float. i had to stop the machine (worrying moment), attach the board again and then start outline milling from the beggining again.

results:

soldering

stuffing:

- microcontroller (pins shouldn't touch each other)

- resistors (no specific direction, work either way)

- capacitors (no specific direction, work either way)

- diods (specific orientation: thin line to the right)

- jumpers (no specific direction, work either way)

- crystal (specific orientation: dot upper left)

- usb (tiny! pins shouldn't touch each other)

- conector (too big: leave it for the end)

first result:

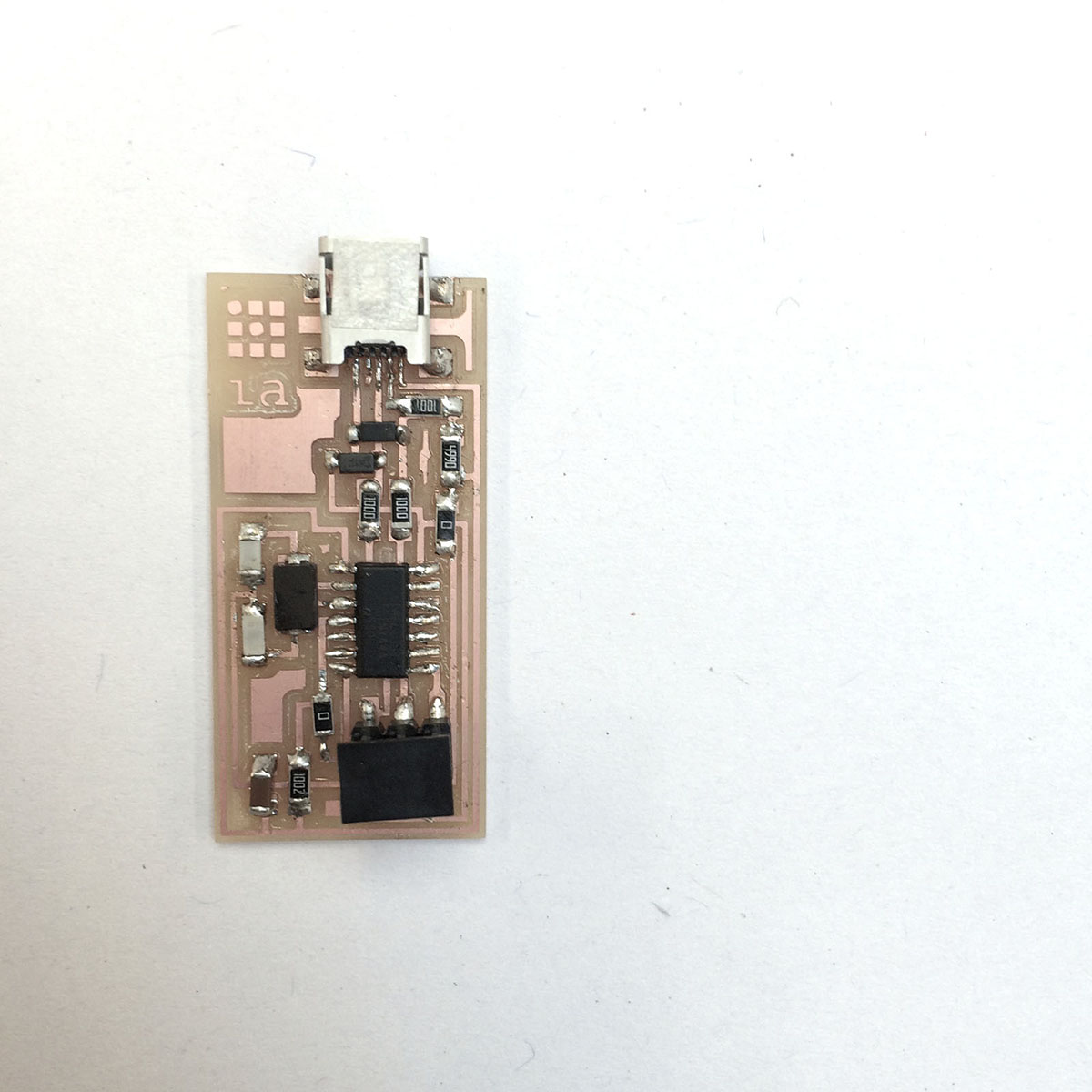

retouching:

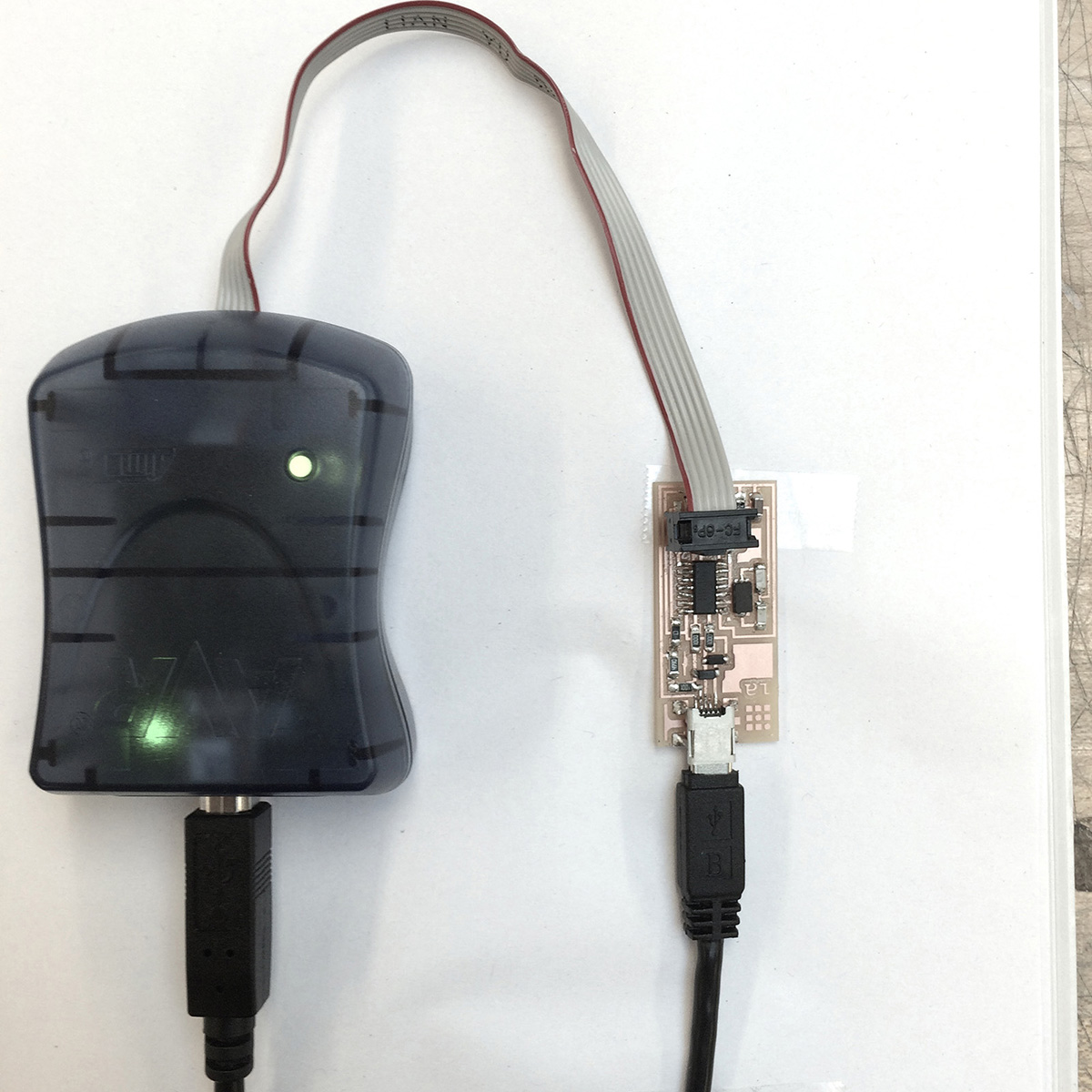

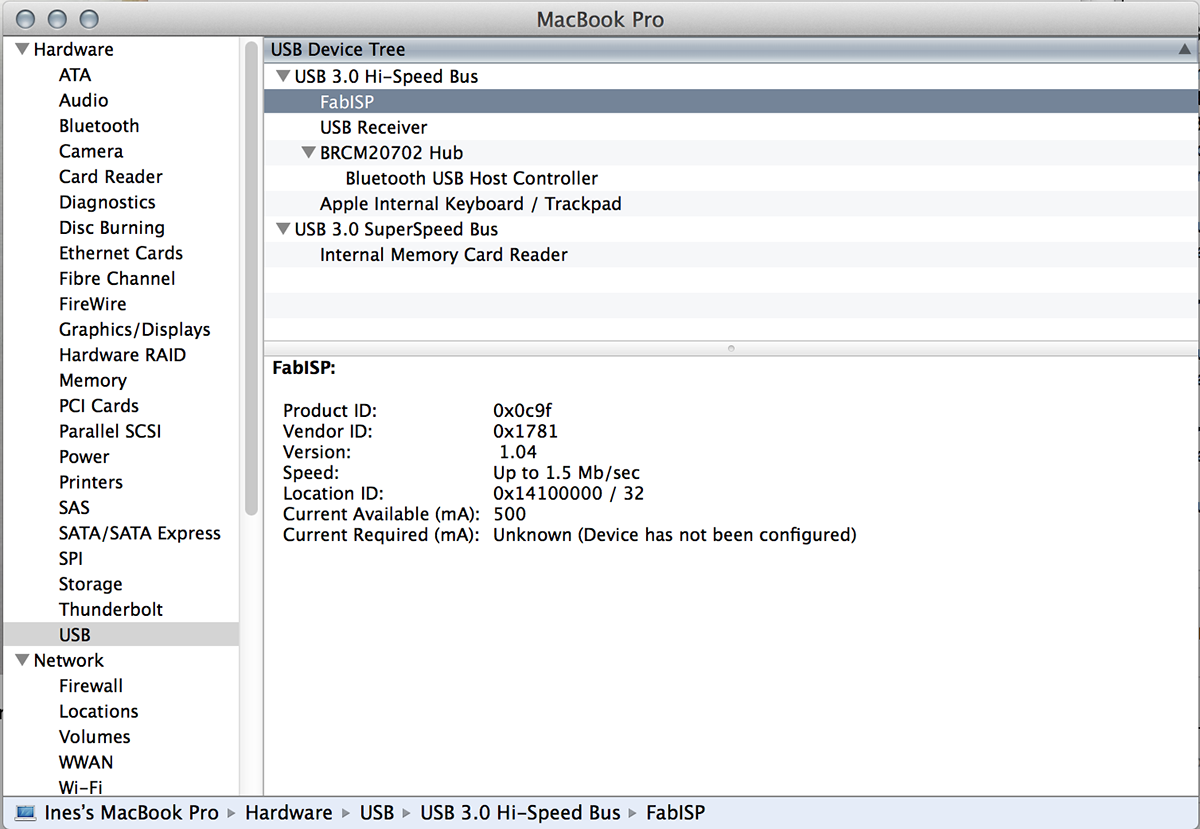

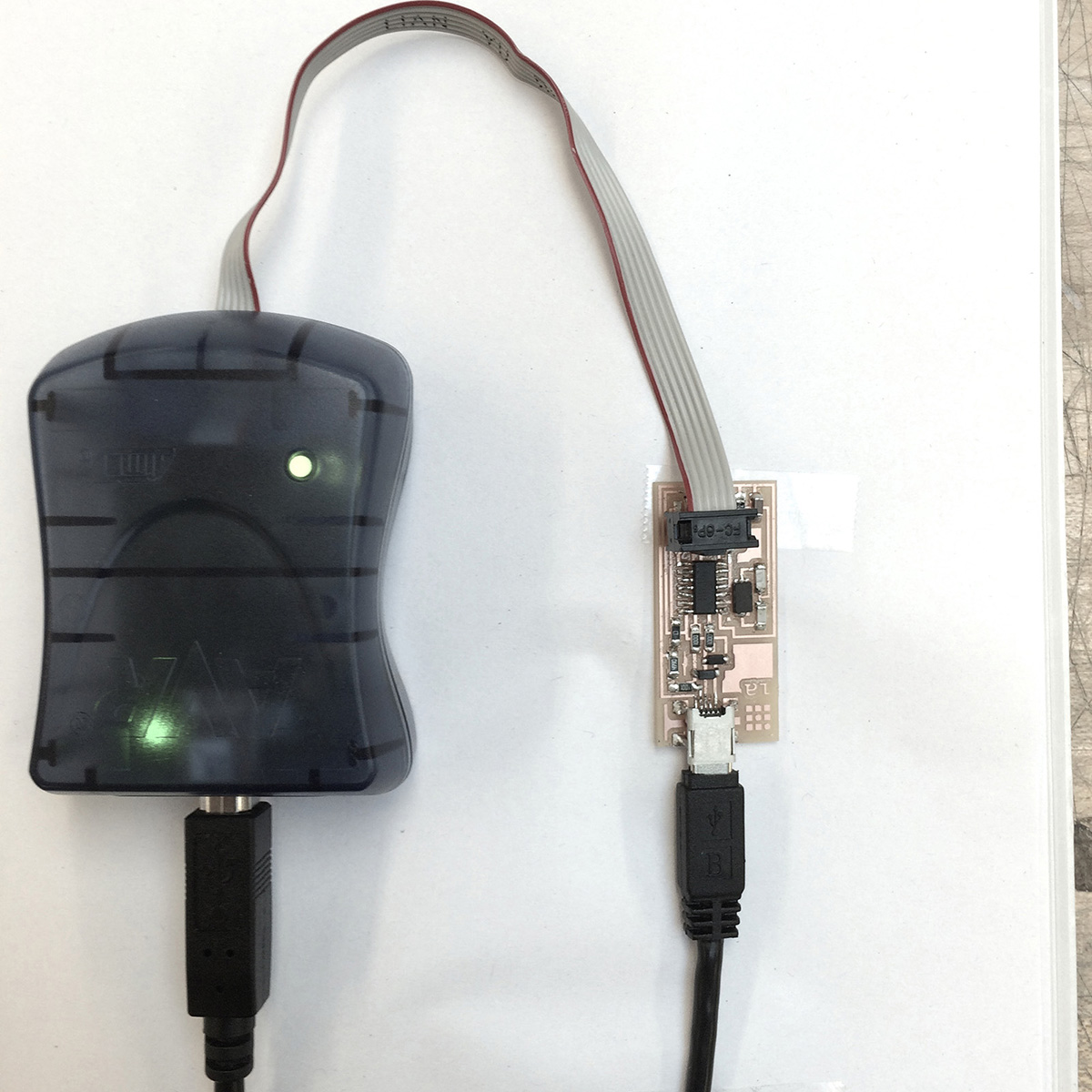

programming

- smoke test

- install AVR programming software

- download and unzip firmware

- give power to fabISP (check lights!)

- program the fabISP: make clean; make hex; sudo make fuse; sudo make program

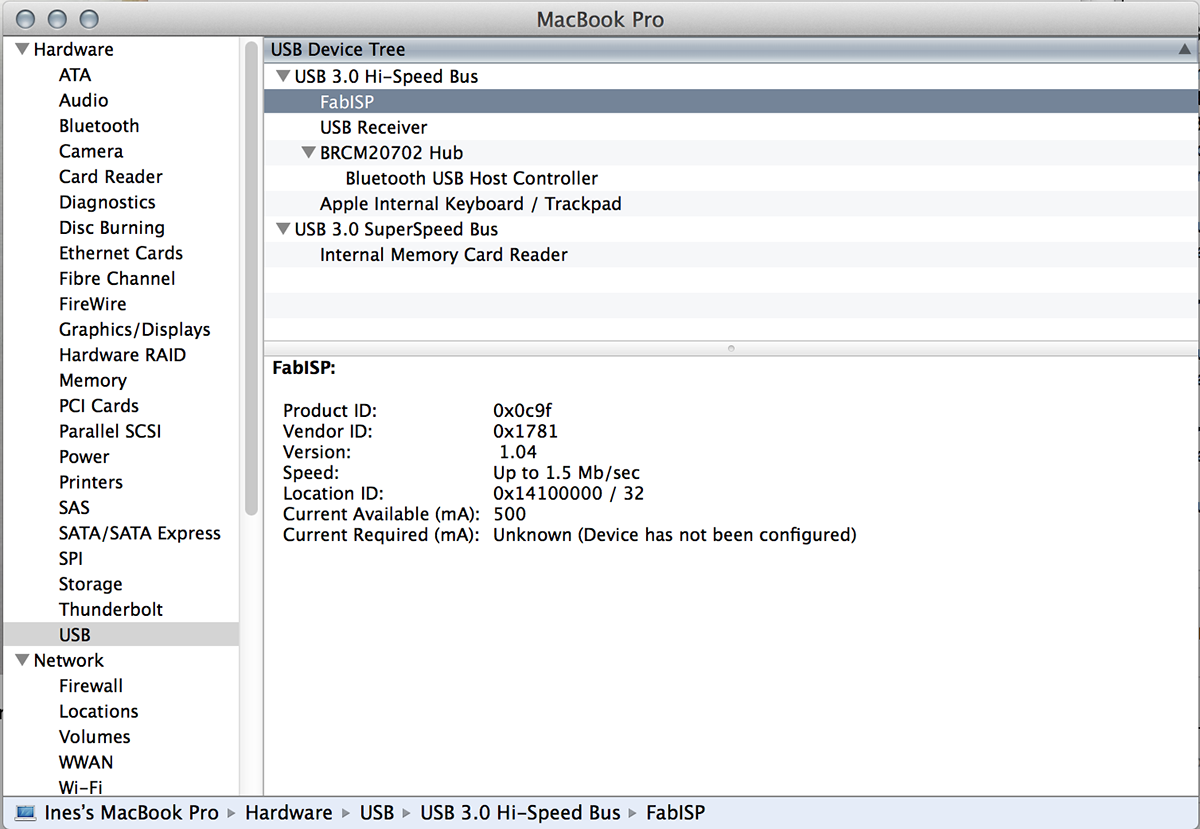

results:

- smoke test

- install AVR programming software

- download and unzip firmware

- give power to fabISP (check lights!)

- program the fabISP: make clean; make hex; sudo make fuse; sudo make program

results: