computer-controlled machining

flat to form column

scketching and modeling + cutting + assembling

scketching and modeling + cutting + assembling

i've had this idea of a 'flat to form' column for a while so this week's assignment was a good opportunity to start testing it out.

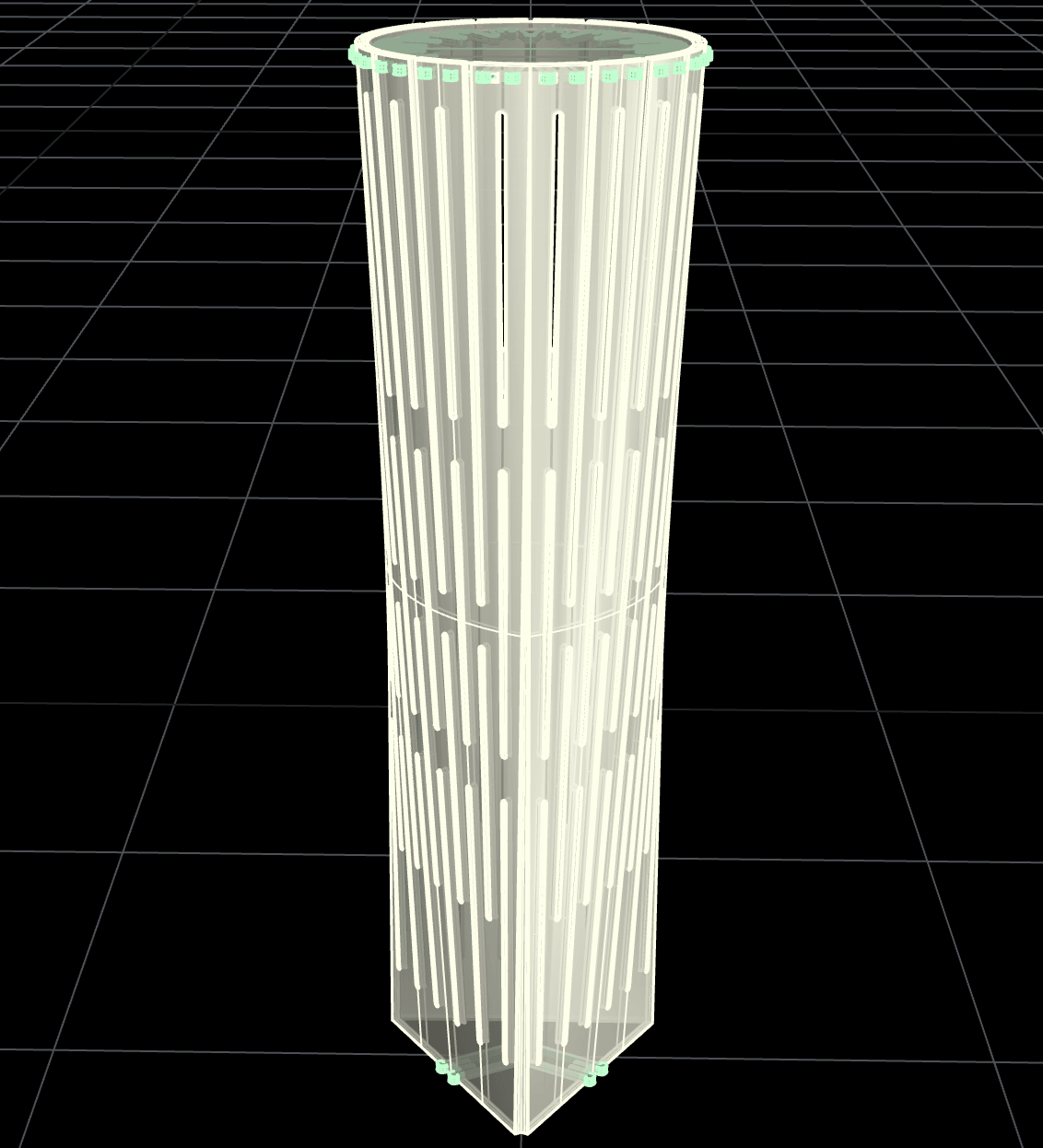

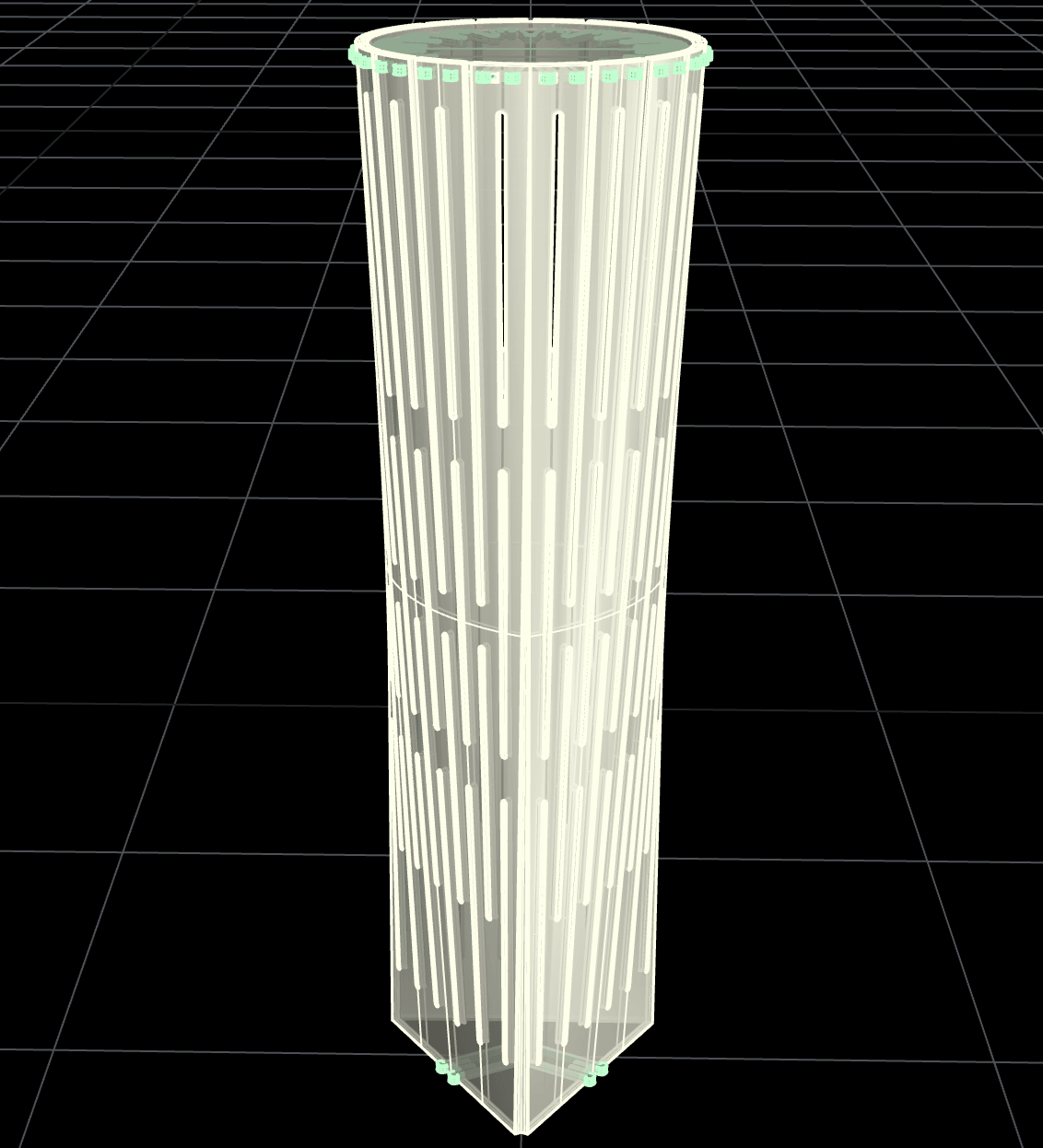

sketching + modeling

i started sketching out basic shape transformations for the sake of Geometry (triangle > circle; square > circle; square > boulléean plan; etc.), everything looks possible on graphite. rhino model took a little bit longer. i spent some time understanding how snap locks work. i decided to use this joint technique for the column disregarding the material properties of OSB which caused a fatal error (OSB has any internal plasticity at all, see cutting section for details).

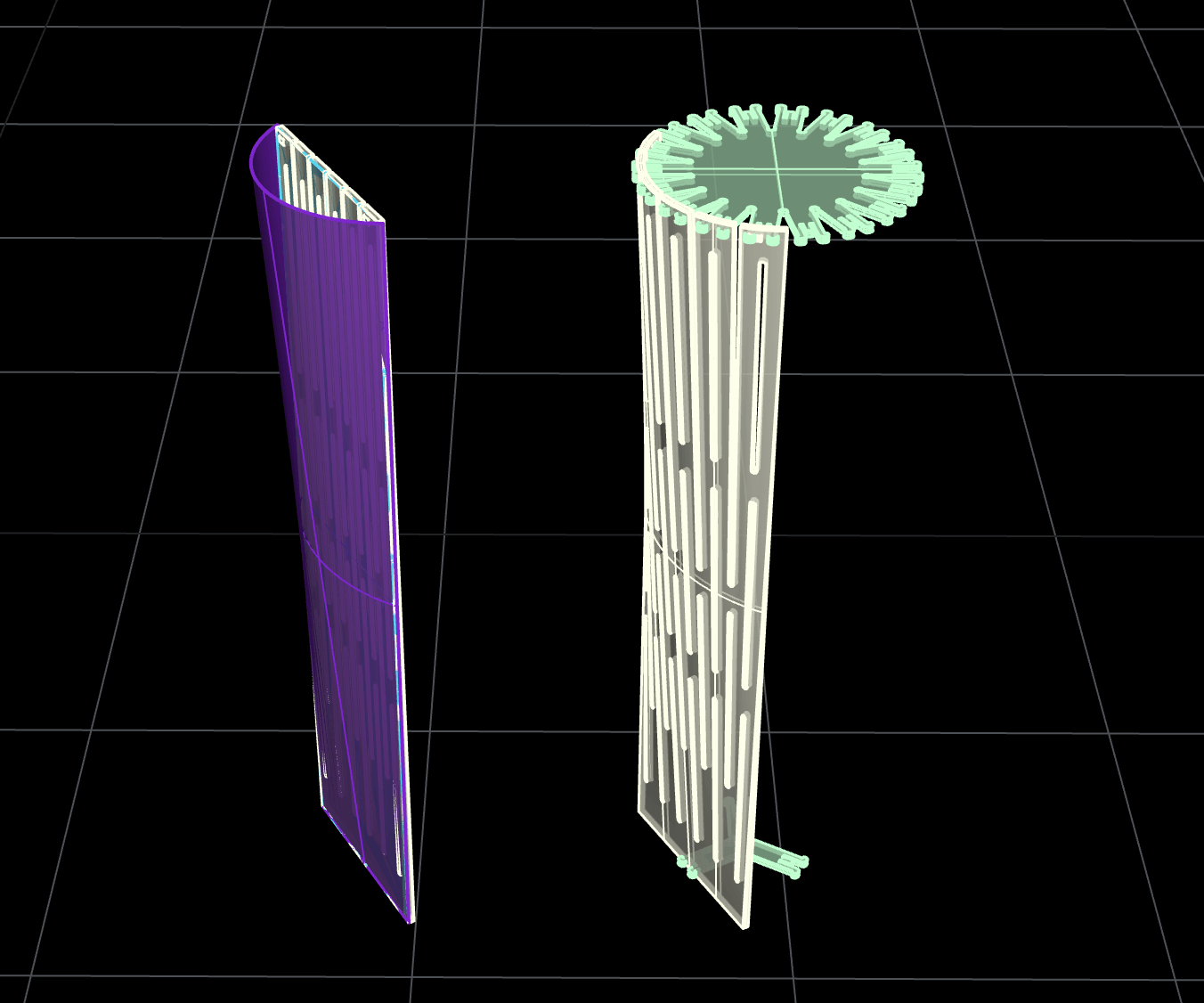

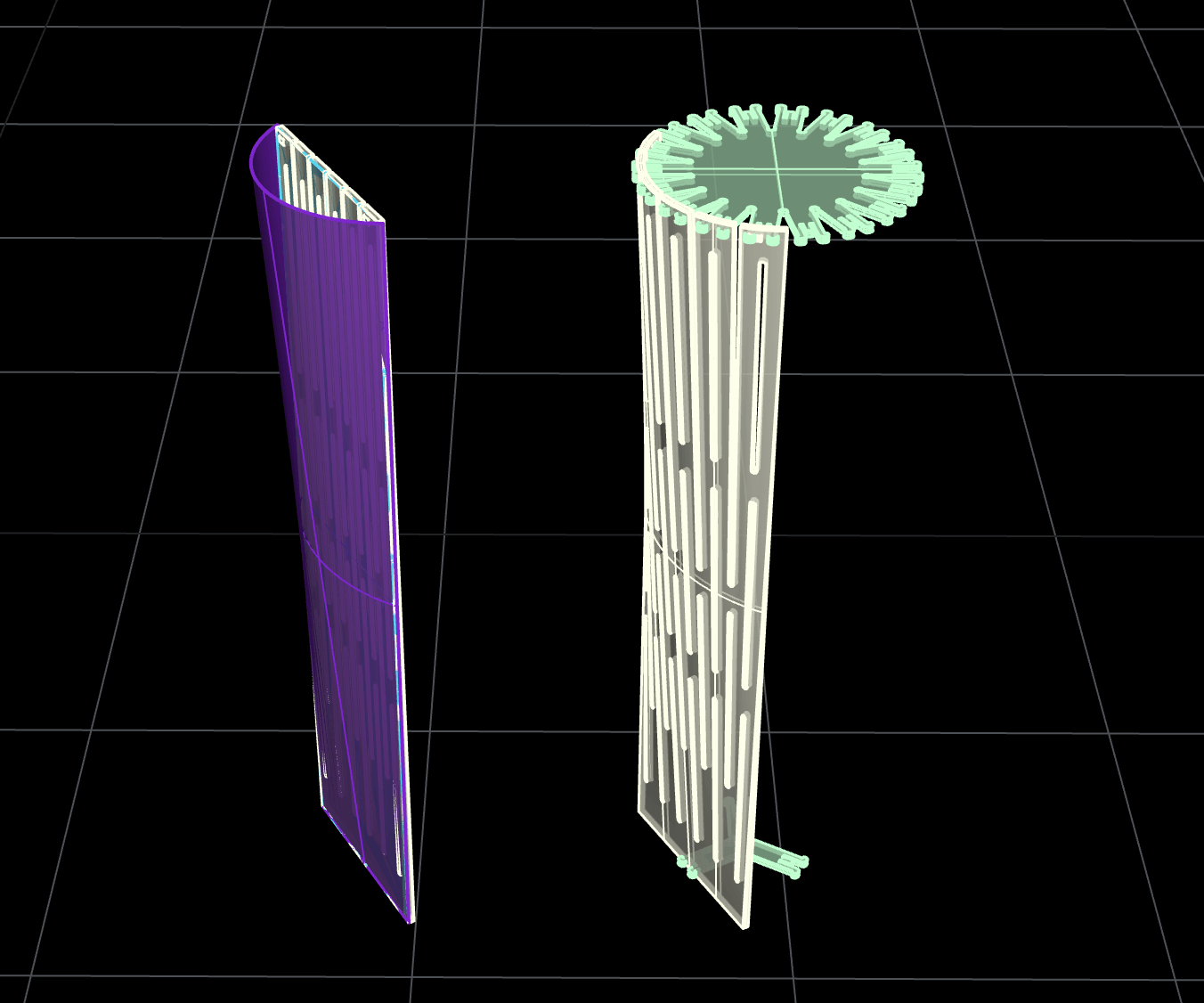

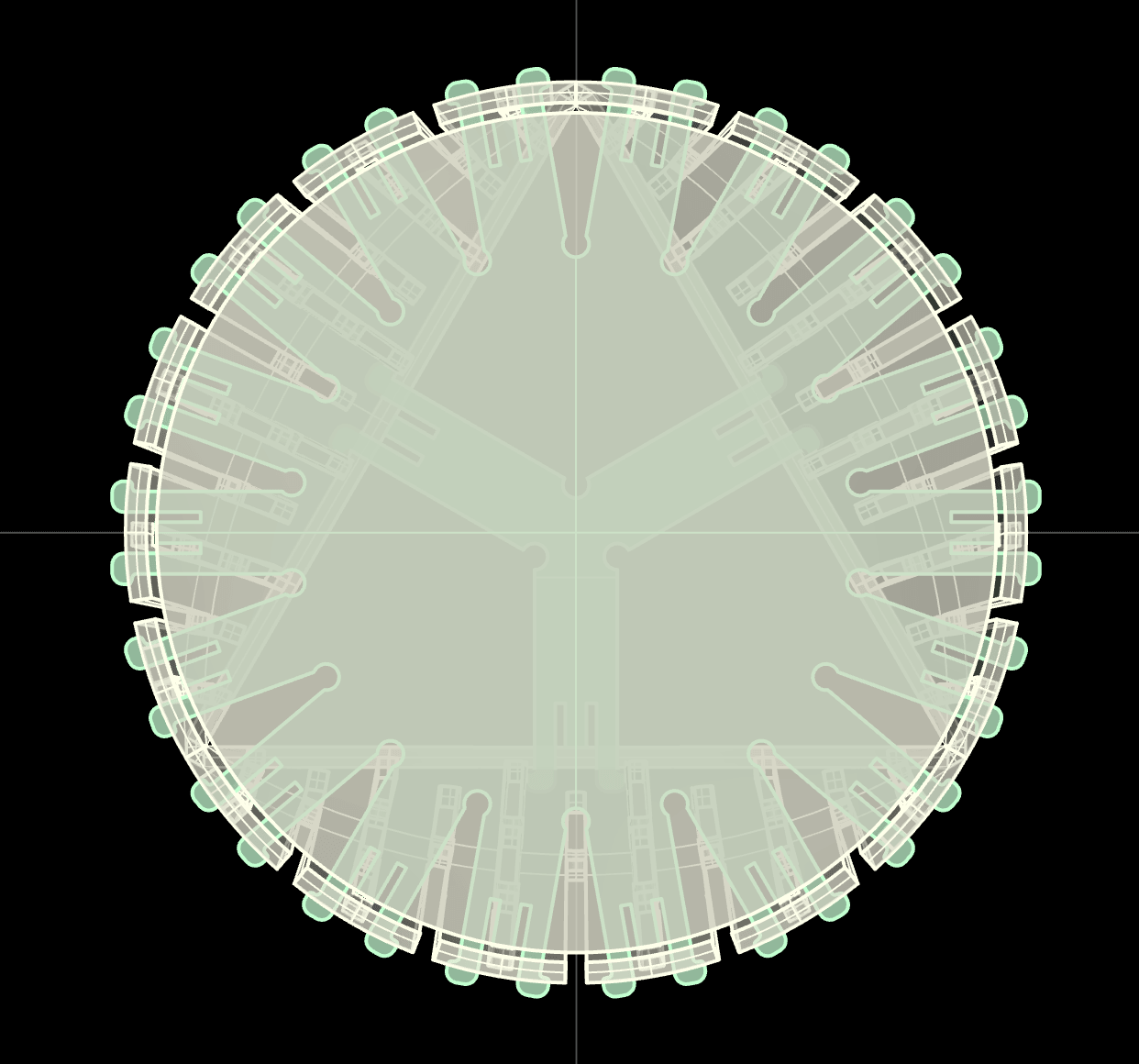

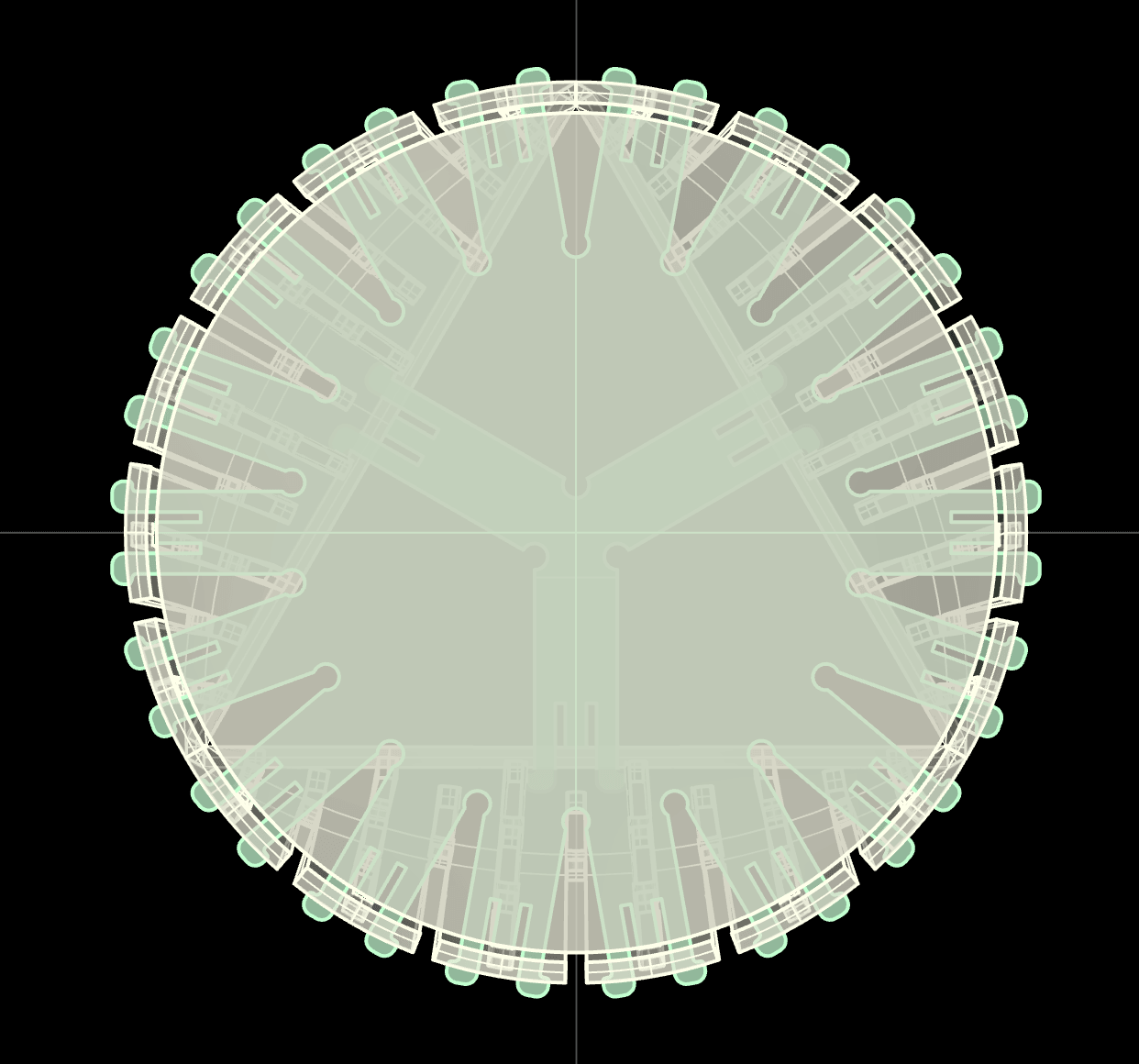

lower and upper sections

flow along curve command for deformation

view

CNC cutting

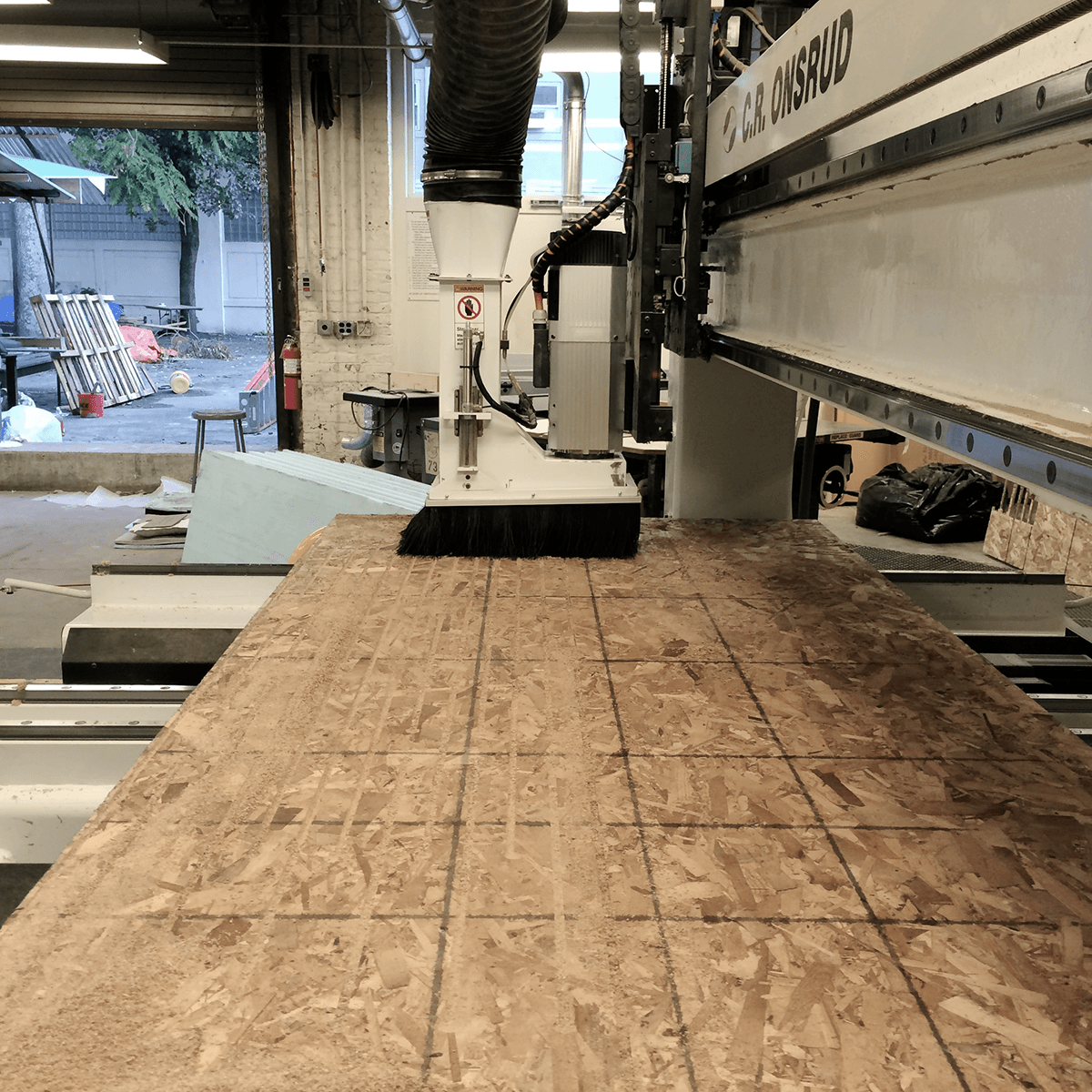

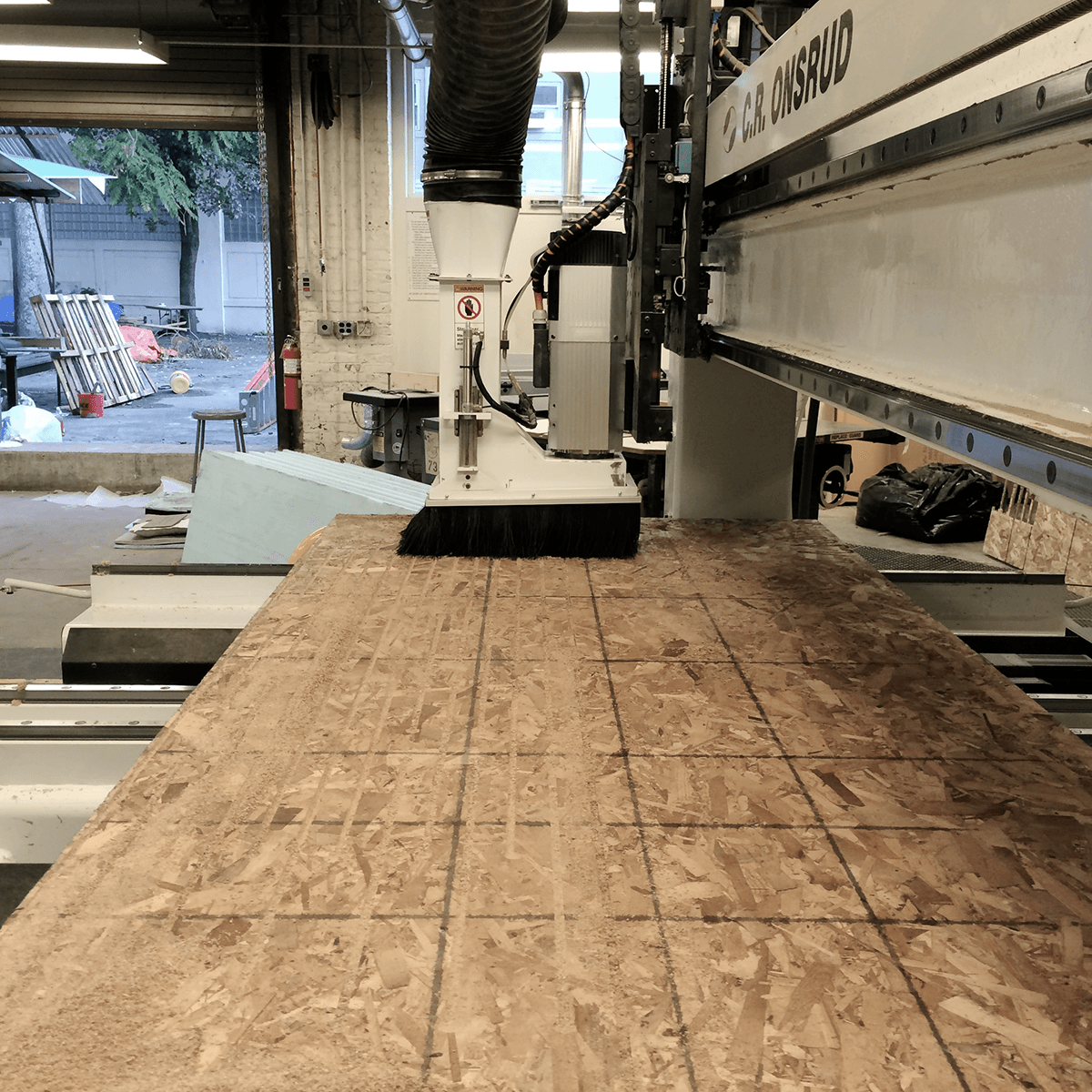

output: CR Onsrud 4’ x 8’ CNC router

output controllers: Mastercam + Onsrud-OSAI Control

steps for outputting:

00_sample

01_2D drawing (rhino) .3dm

02_toolpaths (mastercam) .mcx-7

03_GCode (exported from mastercam to ONSRUD controller) .nc

00_sample:

before going into the cutting phase a made a handmade sample of the joint: it wouldn't work. so i made a few adjustments to the model: i cut the unnecessary "ears" and brang the matching holes closer.

plan

but this model didn't go any further...

CNC cutting

output: CR Onsrud 4’ x 8’ CNC router

output controllers: Mastercam + Onsrud-OSAI Control

steps for outputting:

00_sample

01_2D drawing (rhino) .3dm

02_toolpaths (mastercam) .mcx-7

03_GCode (exported from mastercam to ONSRUD controller) .nc

00_sample:

before going into the cutting phase a made a handmade sample of the joint: it wouldn't work. so i made a few adjustments to the model: i cut the unnecessary "ears" and brang the matching holes closer.

OSB ≠ HDPE

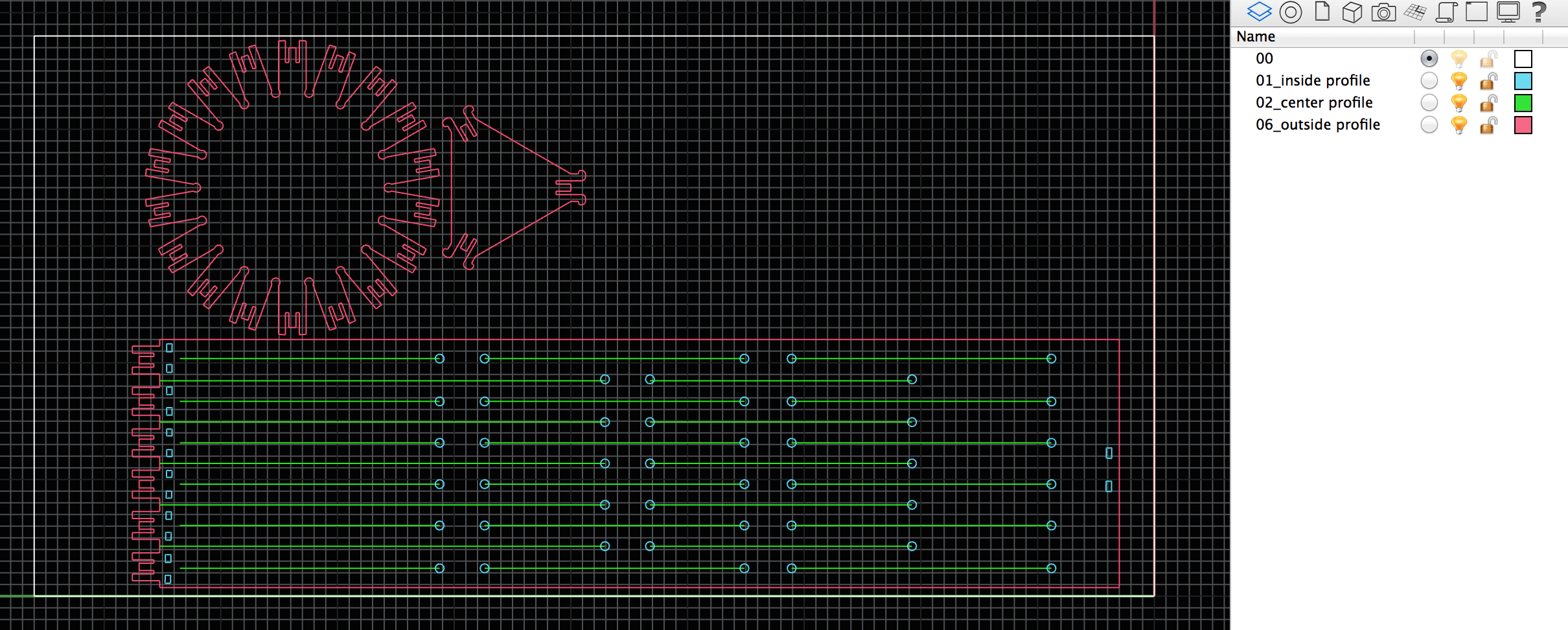

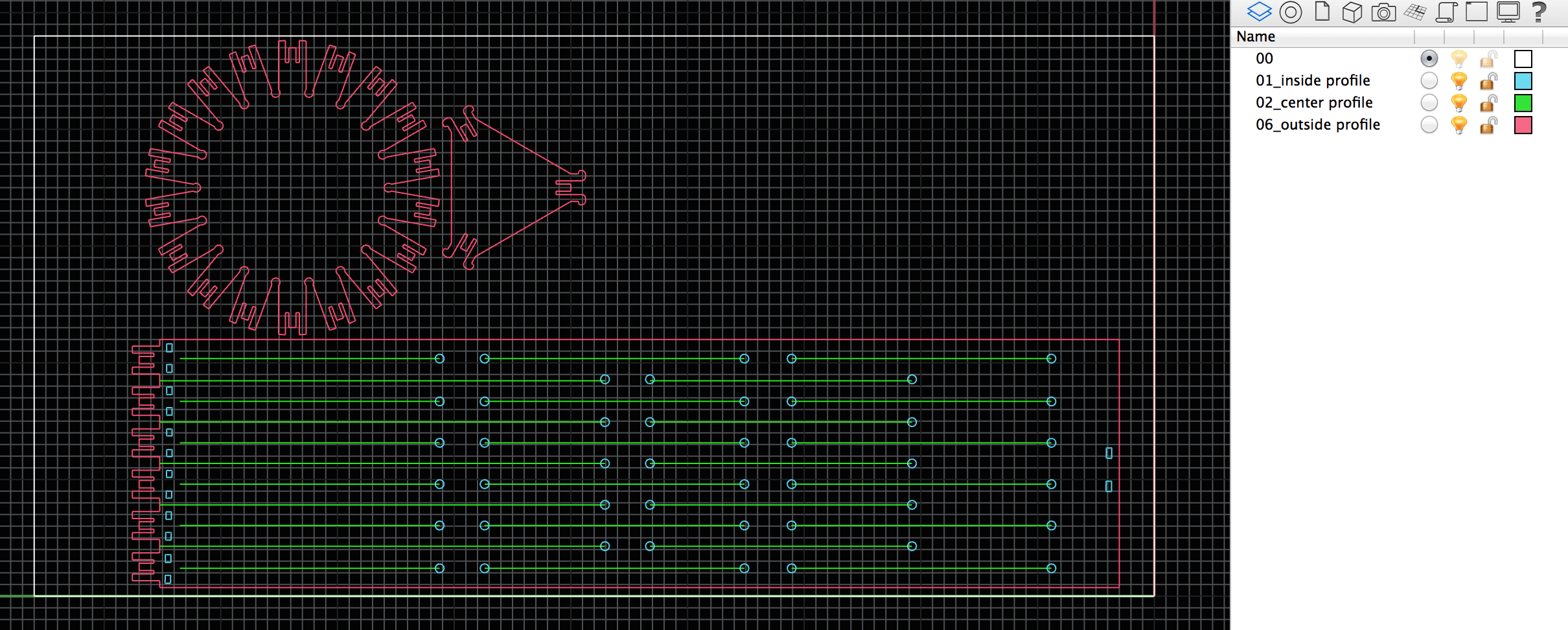

01_2D drawing:

01_2D drawing:

given the 2D initial nature of this project, i used a 2D drawing to go into mastercam. here, rhino model and layers ready to go.

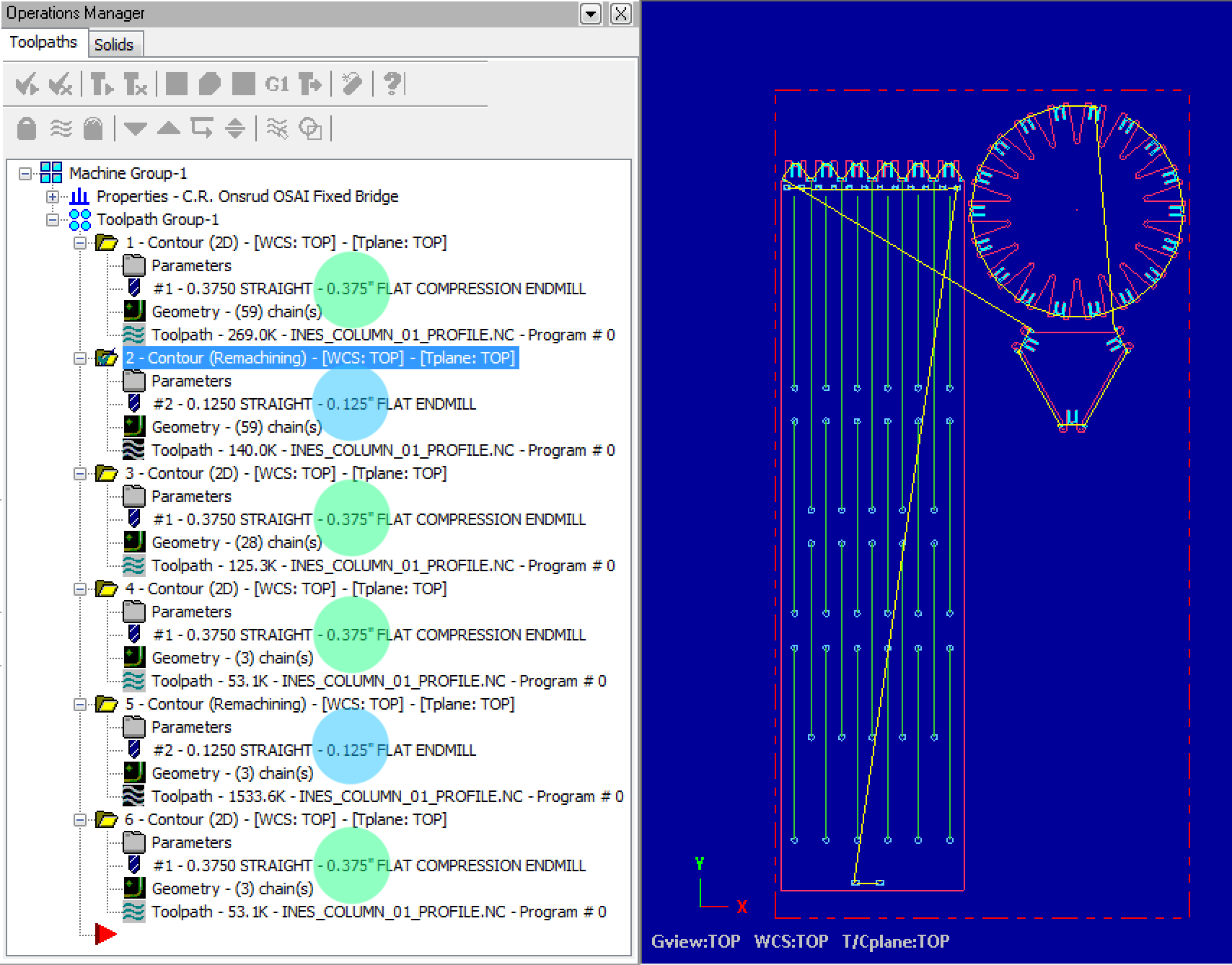

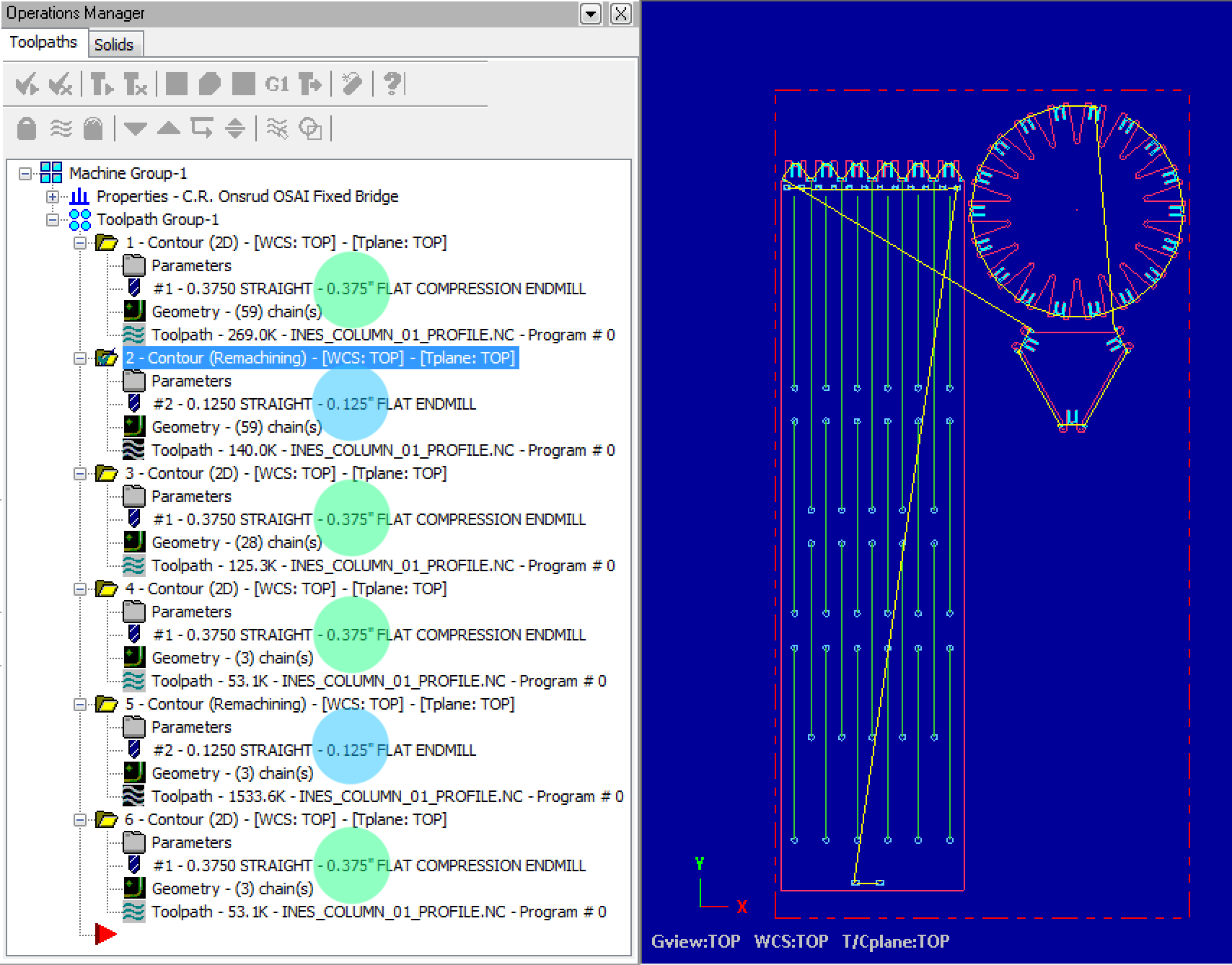

02_toolpaths:

02_toolpaths:

6 contour steps, 4 3/8'' contours (1 for each geometry) and 2 remachining with a smaller endmill (1/8'')

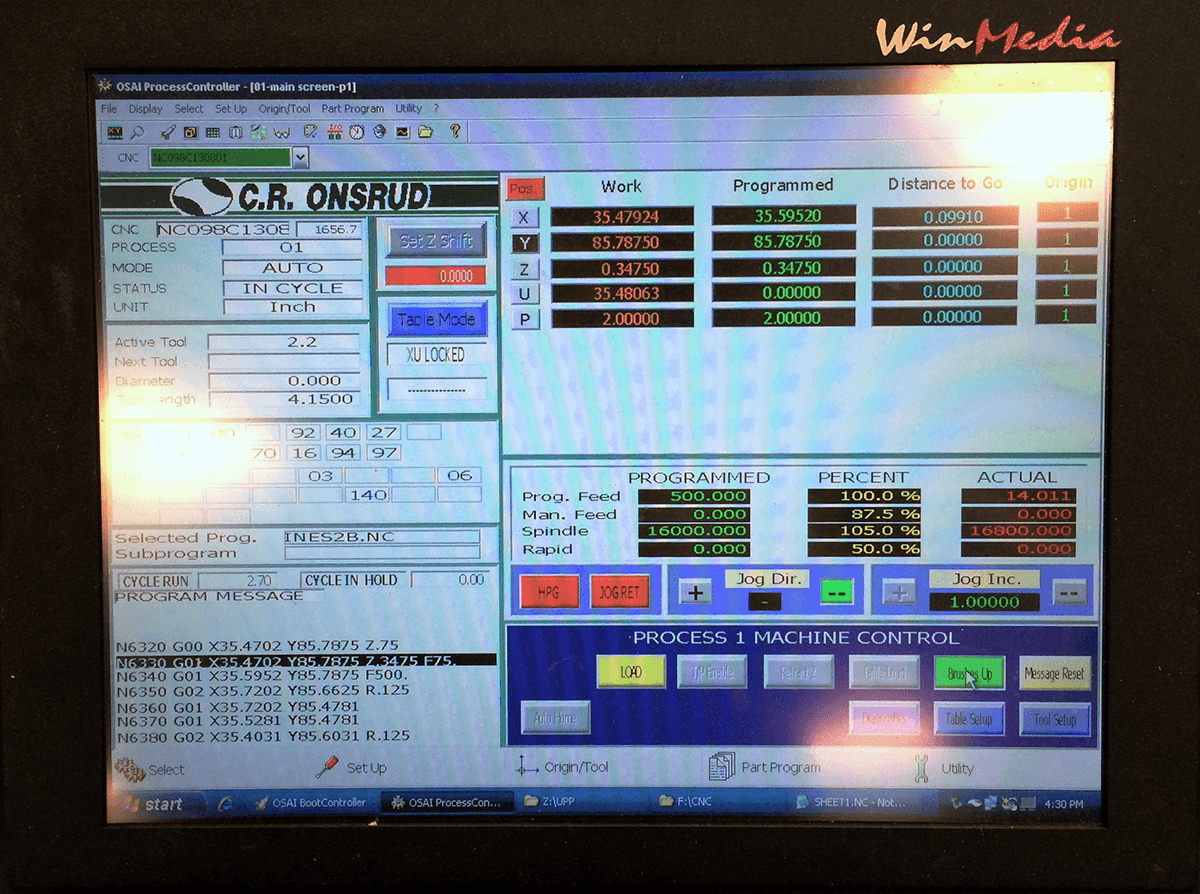

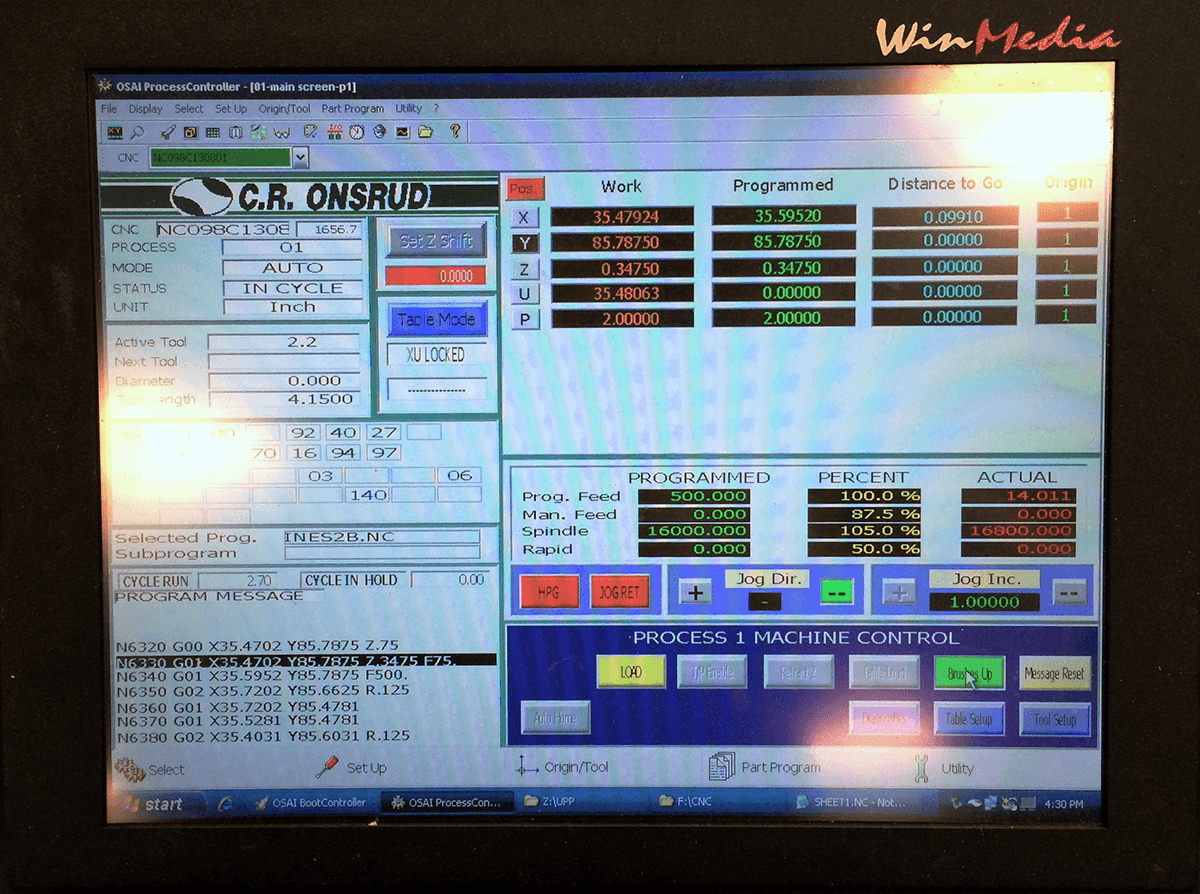

03_GCode into ONSRUD controller:

03_GCode into ONSRUD controller:

load .nc file and go!

onsrud alive. everything was going fine until the second 1/8'' remachining: the endmill broke. for this diameter a 3 pass toolpath is needed >> new .nc with toolpaths 5 & 6 (depth cuts = 0.125 added)!

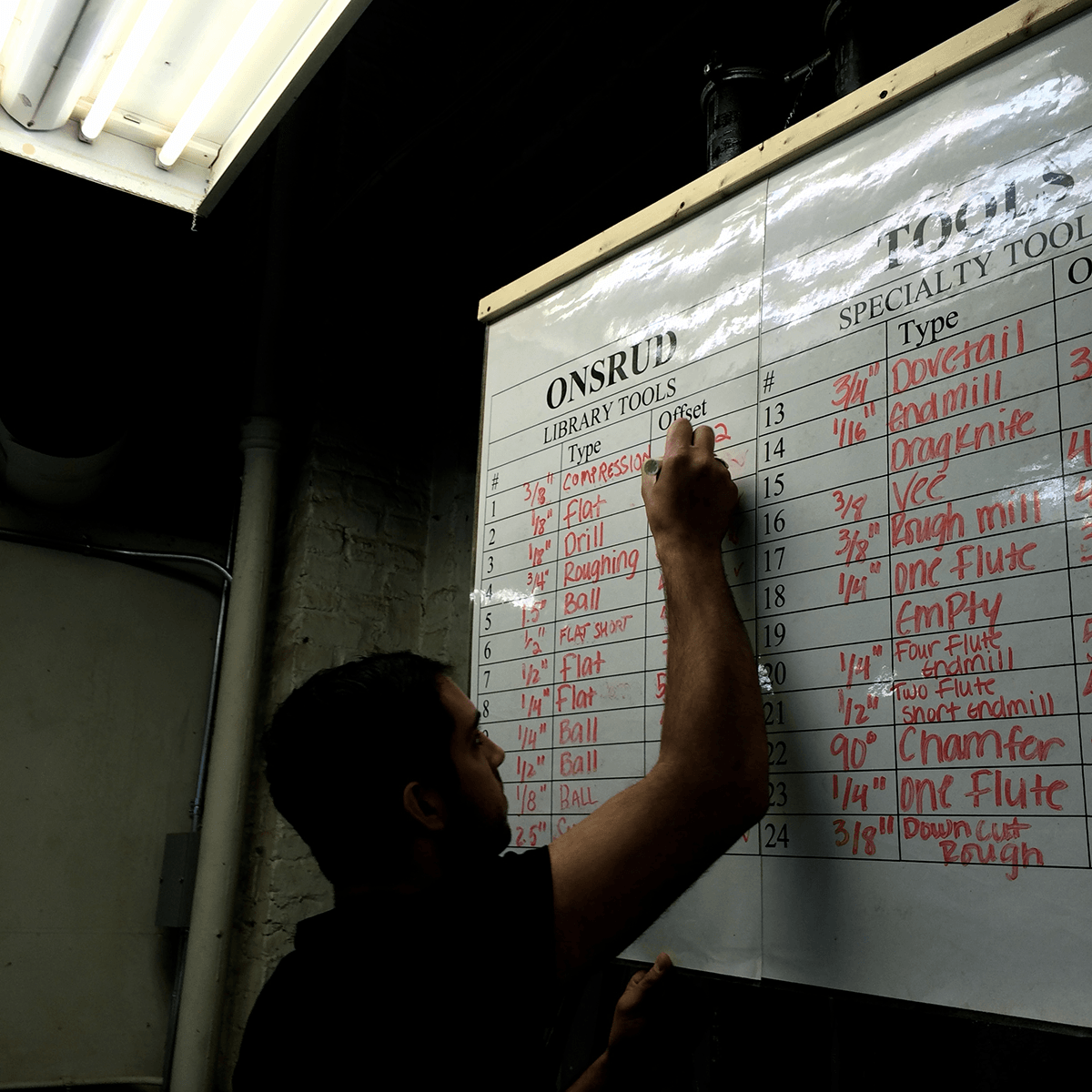

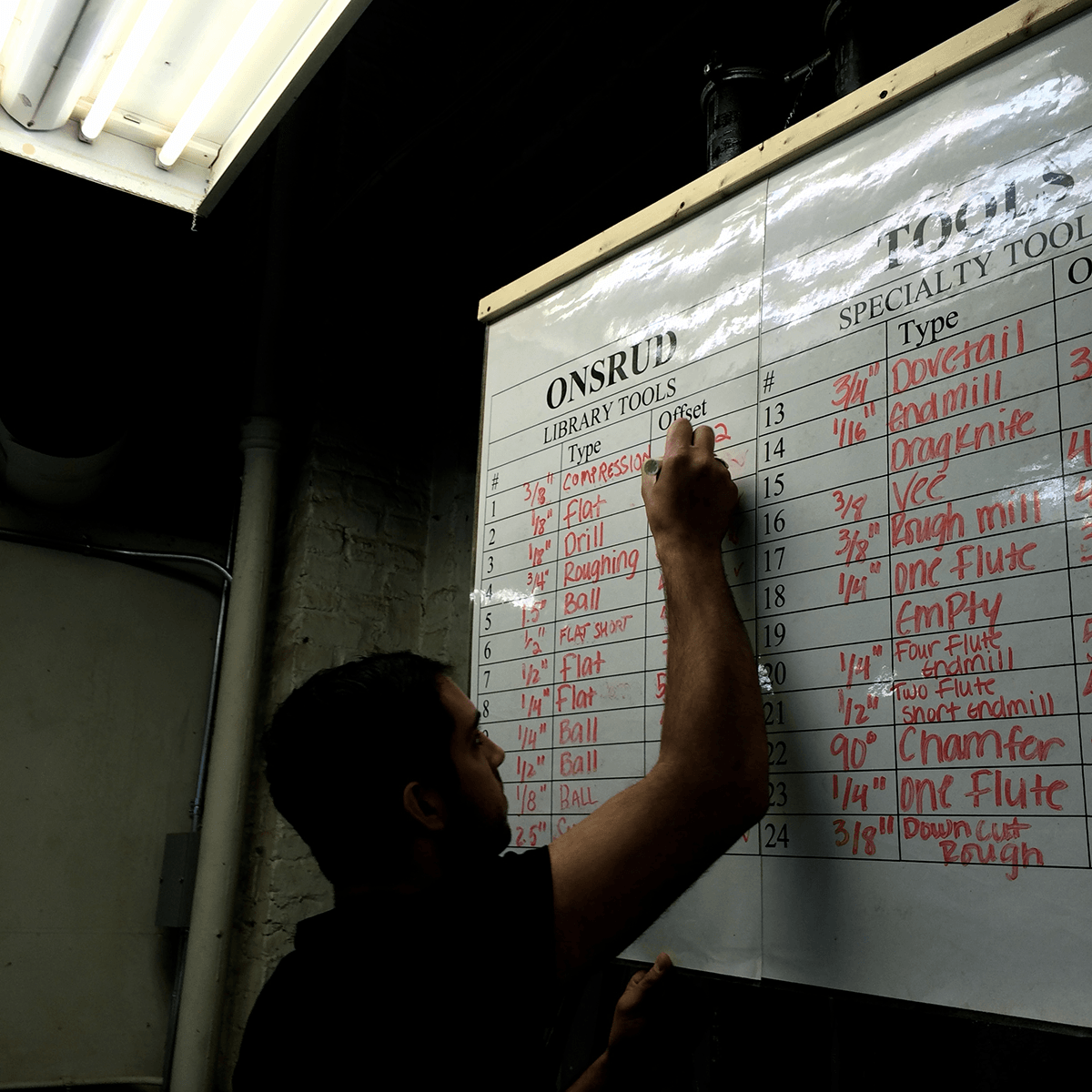

updating new endmill parameters into ONSRUD controller and tool sheet (thank you costanza!)

assembling

assembling

this part was a little distressing (no pictures of this awkward moment). the resulting parts were rough and long. with a lot of difficulty i manage to assemble the base and the three sheets. for the upper circle i had to ask for help.

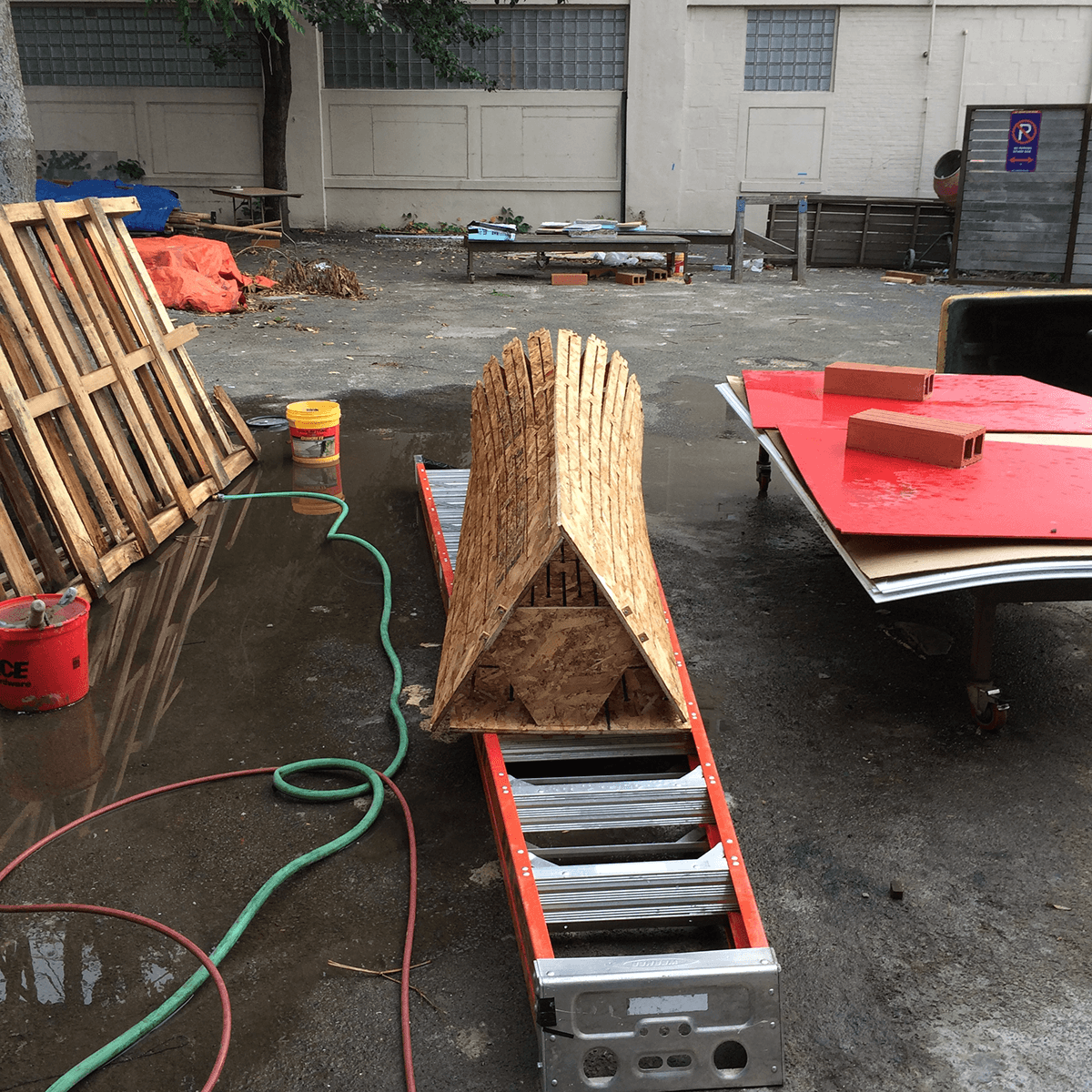

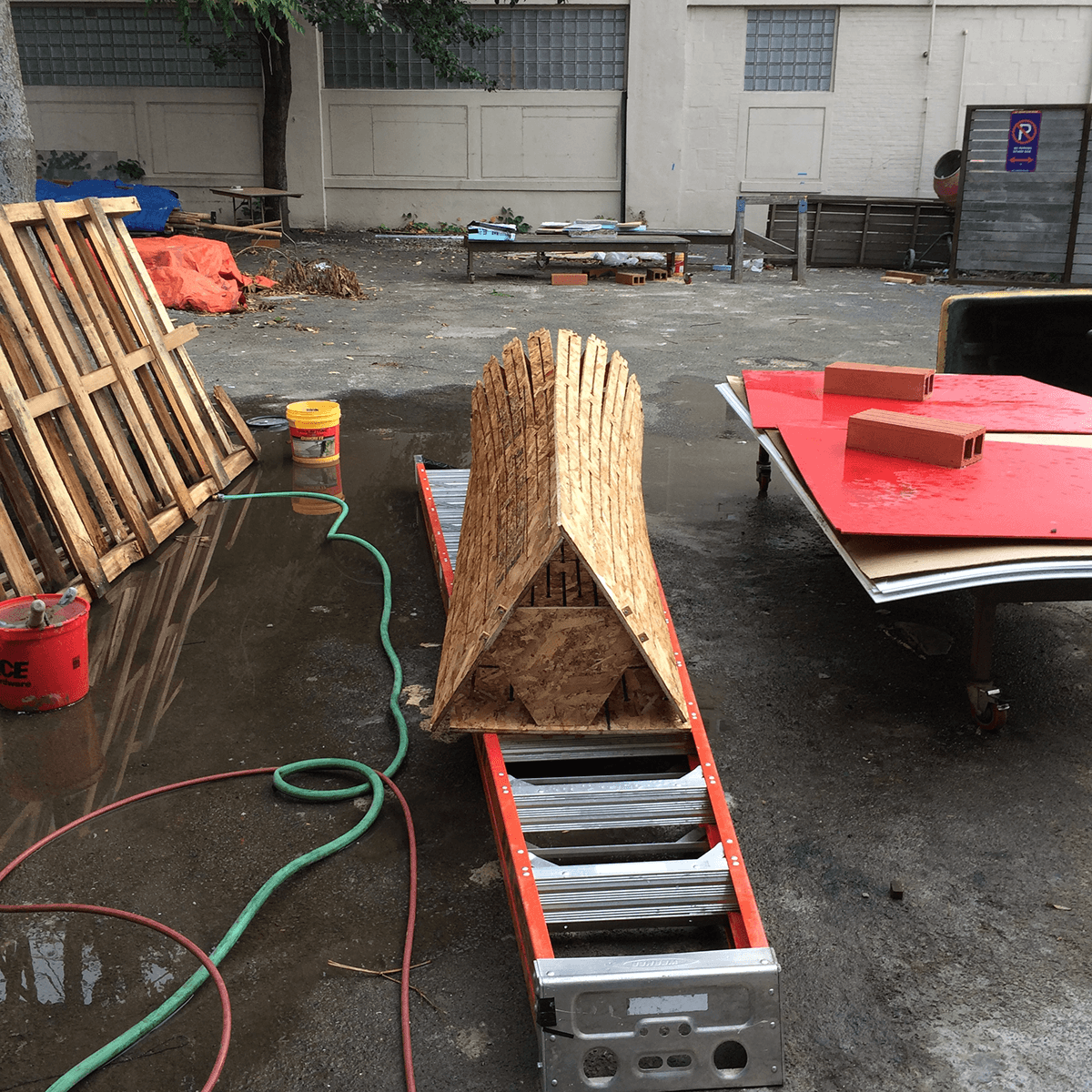

standing still

i soaked the most stressed sections, they wouldn't flex enough otherwise

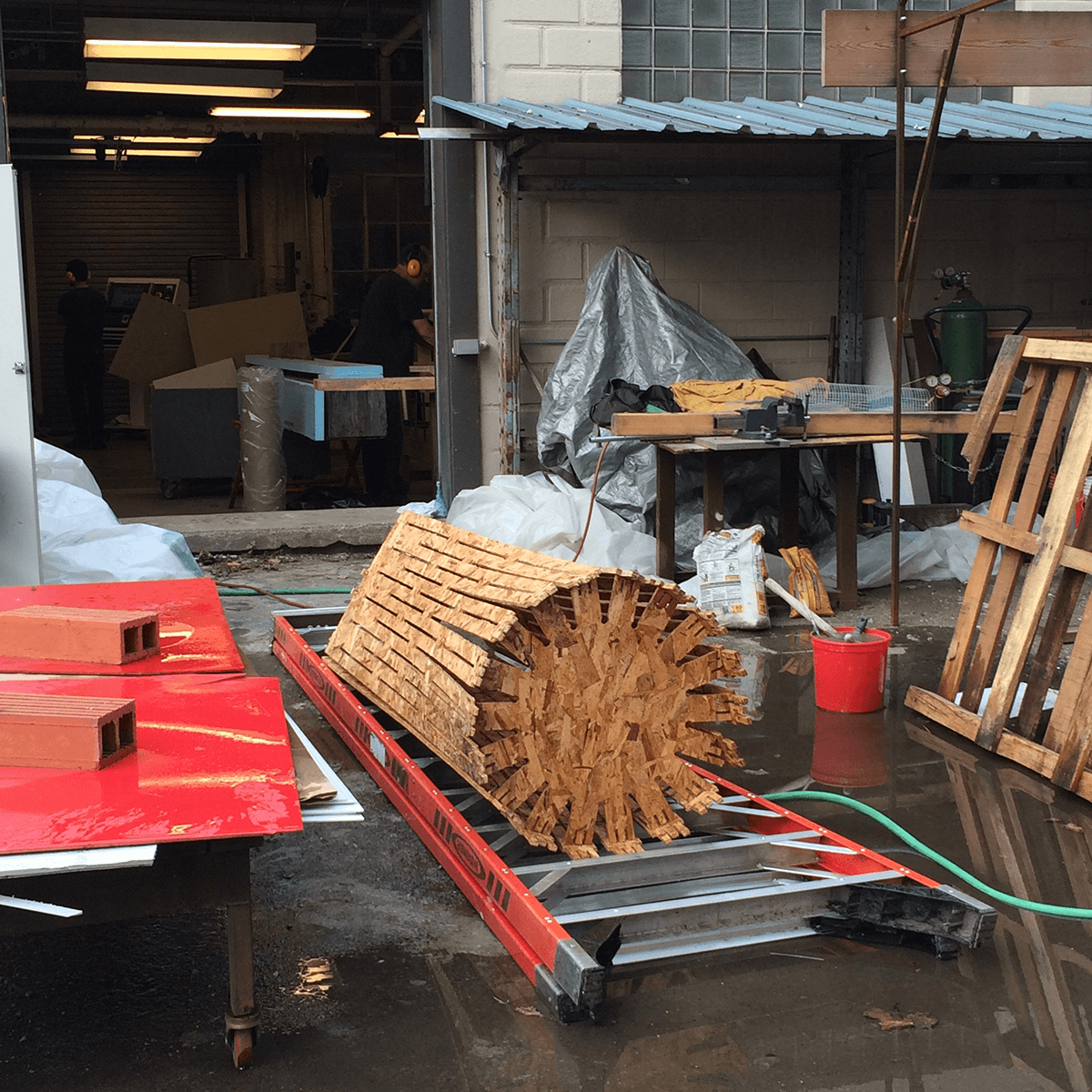

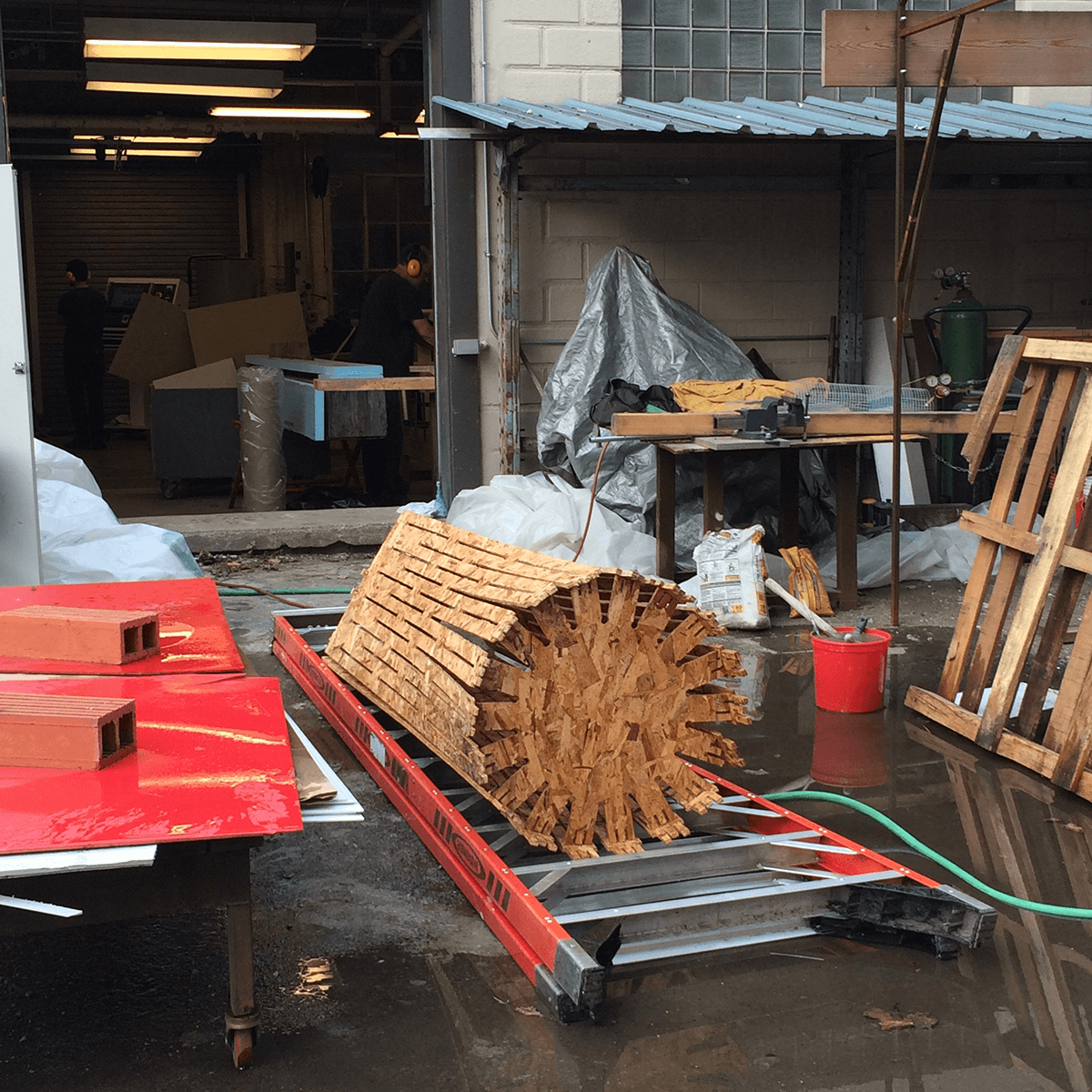

almost finished. i soaked it all over again and added some (a lot of invisible) nails to keep all the sections together.

flat to form column!