final project

unimorph skin module

parts

1. composite module

2. control board: sensor + MCU

3. power supply

composite

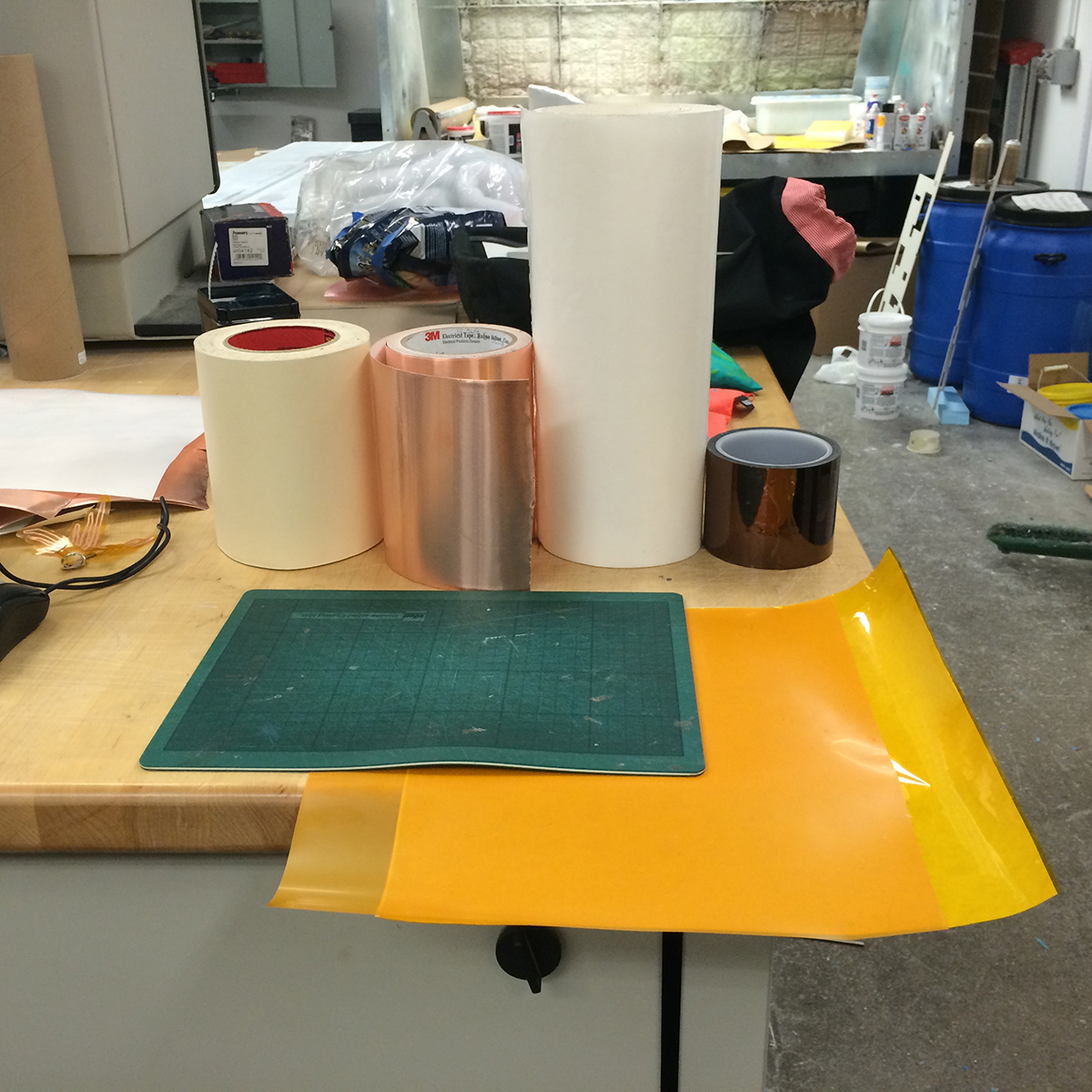

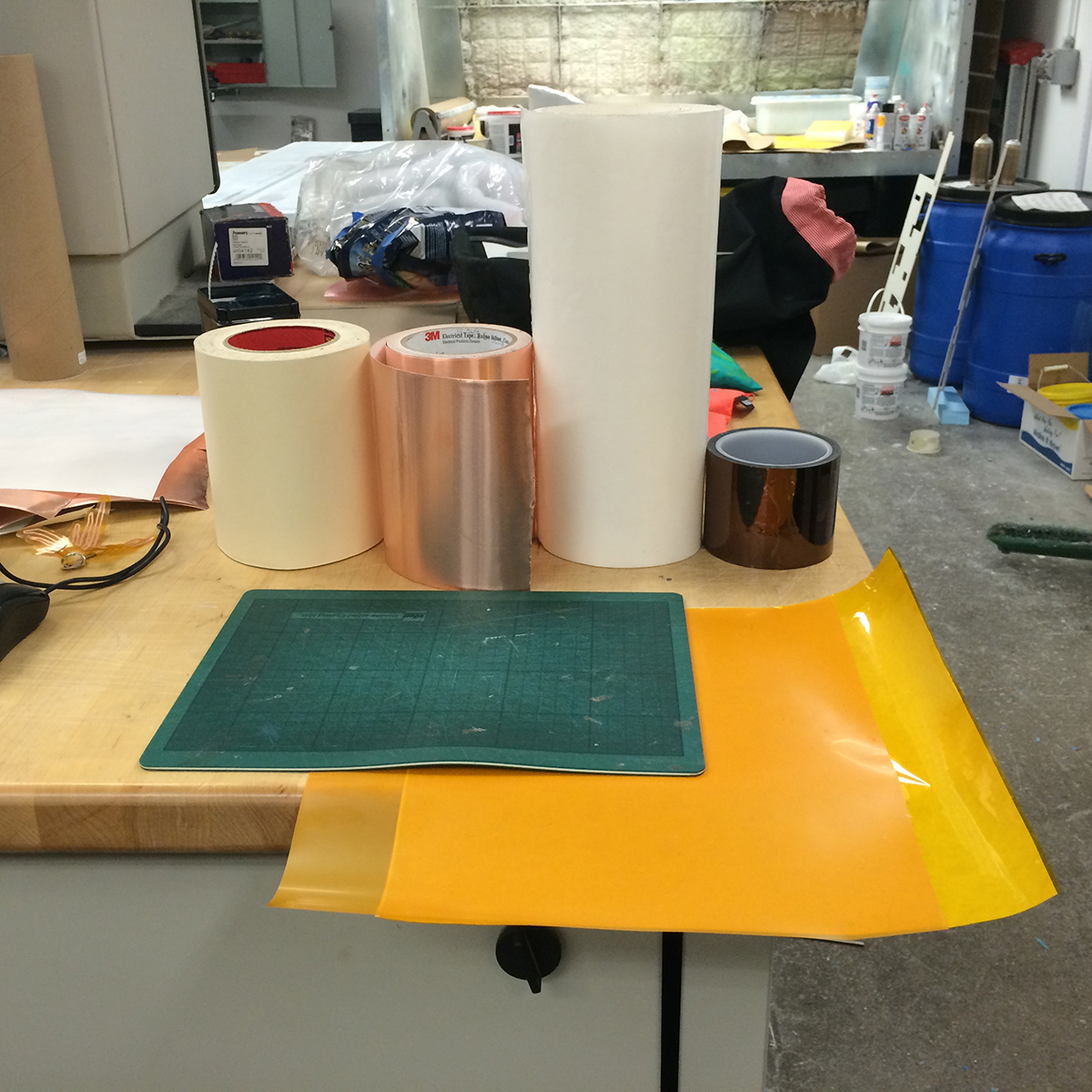

- materials -

1.2mil kapton tape ordered from Amazon, Kapton (R) Polyimide Film .001" Thick ordered from McMaster-Carr; 3M #1126 copper tape with conductive adhesive available from the fab lab inventory, UHMW polyethilene ordered from Amazon.

- costs -

1.2 kapton (R) tape = 19.95 usd / roll 3"x36yard (aprox 4 yard used / 2.21 usd)

Kapton (R) Polyimide Film .001" Thick = 10.95 usd / 12" X 12" 3M copper tape = 321.83 usd / roll 5.67"x36yard (aprox 5.5 yard used / 45 usd)

UHMW polyethilene = 10.84 usd / 1 sheet 12"x12"

parts

1. composite module

2. control board: sensor + MCU

3. power supply

composite

- materials -

1.2mil kapton tape ordered from Amazon, Kapton (R) Polyimide Film .001" Thick ordered from McMaster-Carr; 3M #1126 copper tape with conductive adhesive available from the fab lab inventory, UHMW polyethilene ordered from Amazon.

- costs -

1.2 kapton (R) tape = 19.95 usd / roll 3"x36yard (aprox 4 yard used / 2.21 usd)

Kapton (R) Polyimide Film .001" Thick = 10.95 usd / 12" X 12" 3M copper tape = 321.83 usd / roll 5.67"x36yard (aprox 5.5 yard used / 45 usd)

UHMW polyethilene = 10.84 usd / 1 sheet 12"x12"

composite materials

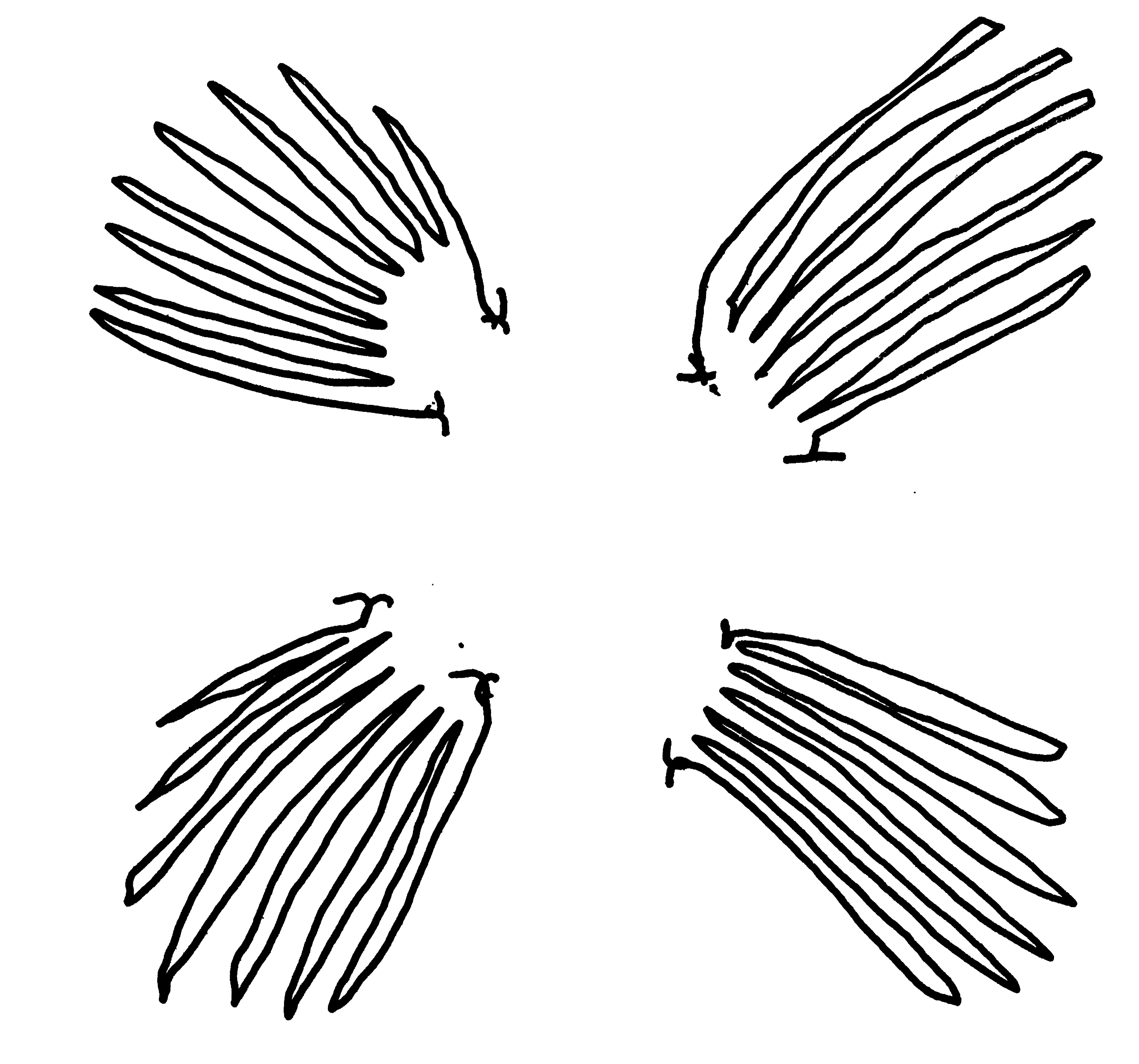

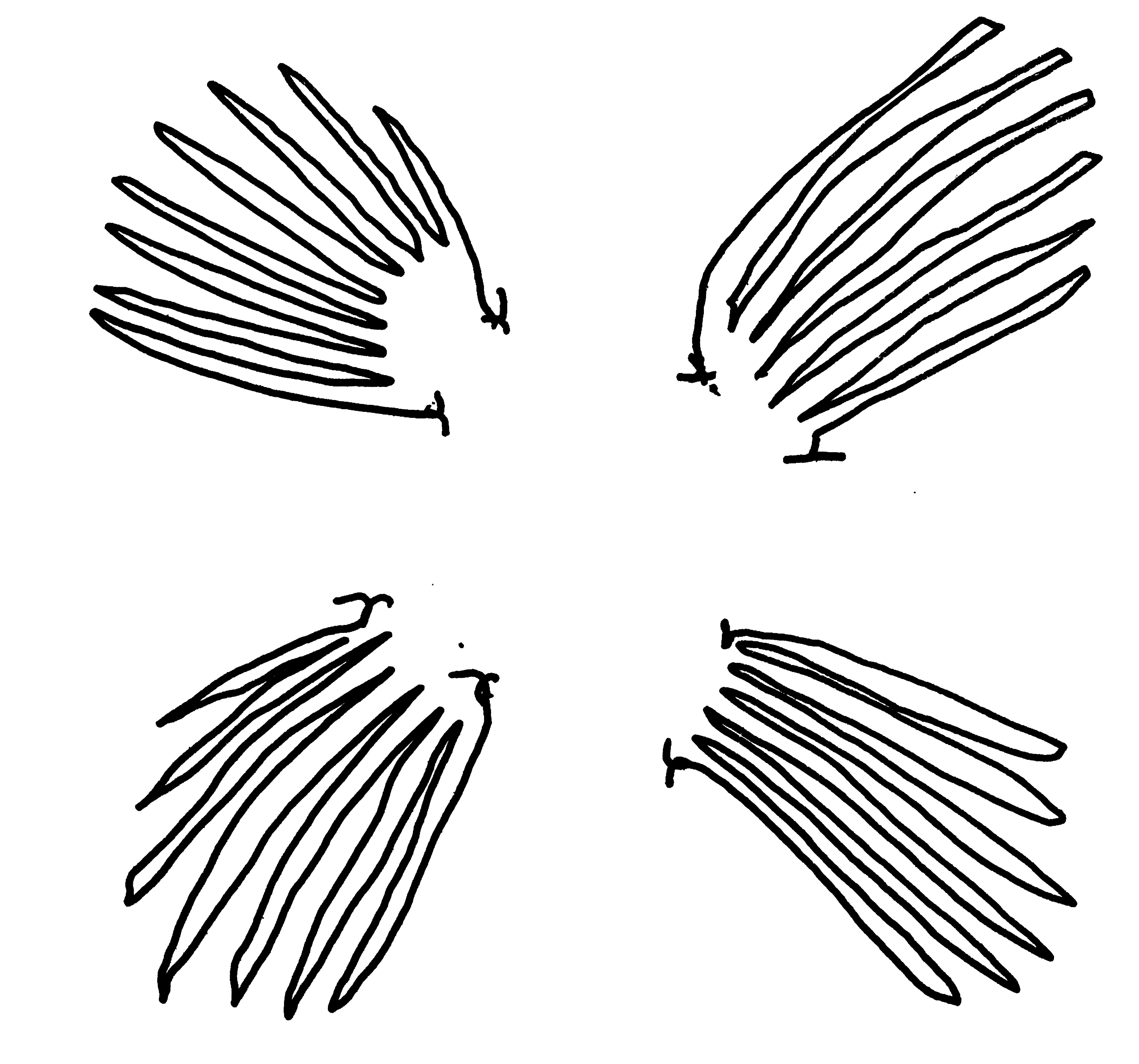

- design -

process: scanned hand-drawing, post-processed in Photoshop for black and white png output (levels parameters)

- design -

process: scanned hand-drawing, post-processed in Photoshop for black and white png output (levels parameters)

hinge variation relative to density, distribution, direction and quantity of hinges.

- fabrication -

>vinyl cutter<

output: Roland CAMM-1 Servo GX-24

software: fab modules

tutorial!

- fabrication -

>vinyl cutter<

output: Roland CAMM-1 Servo GX-24

software: fab modules

tutorial!

input files for fab modules

the most important information given by the fab module was the total dimension of each piece. the rest of the parameters were not modified. the pen force is manually controlled in the vinylcutter

>assembly<

>assembly<

before getting to the right settings to control the vinyl cutter alternative methods of fabrication were tested! here: hand cut vinyl

vinyl cut base > tape > kapton > peel off > UHMW > final outline

material before heat tests

>material testing<

>material testing<

tests

unimorph skin test

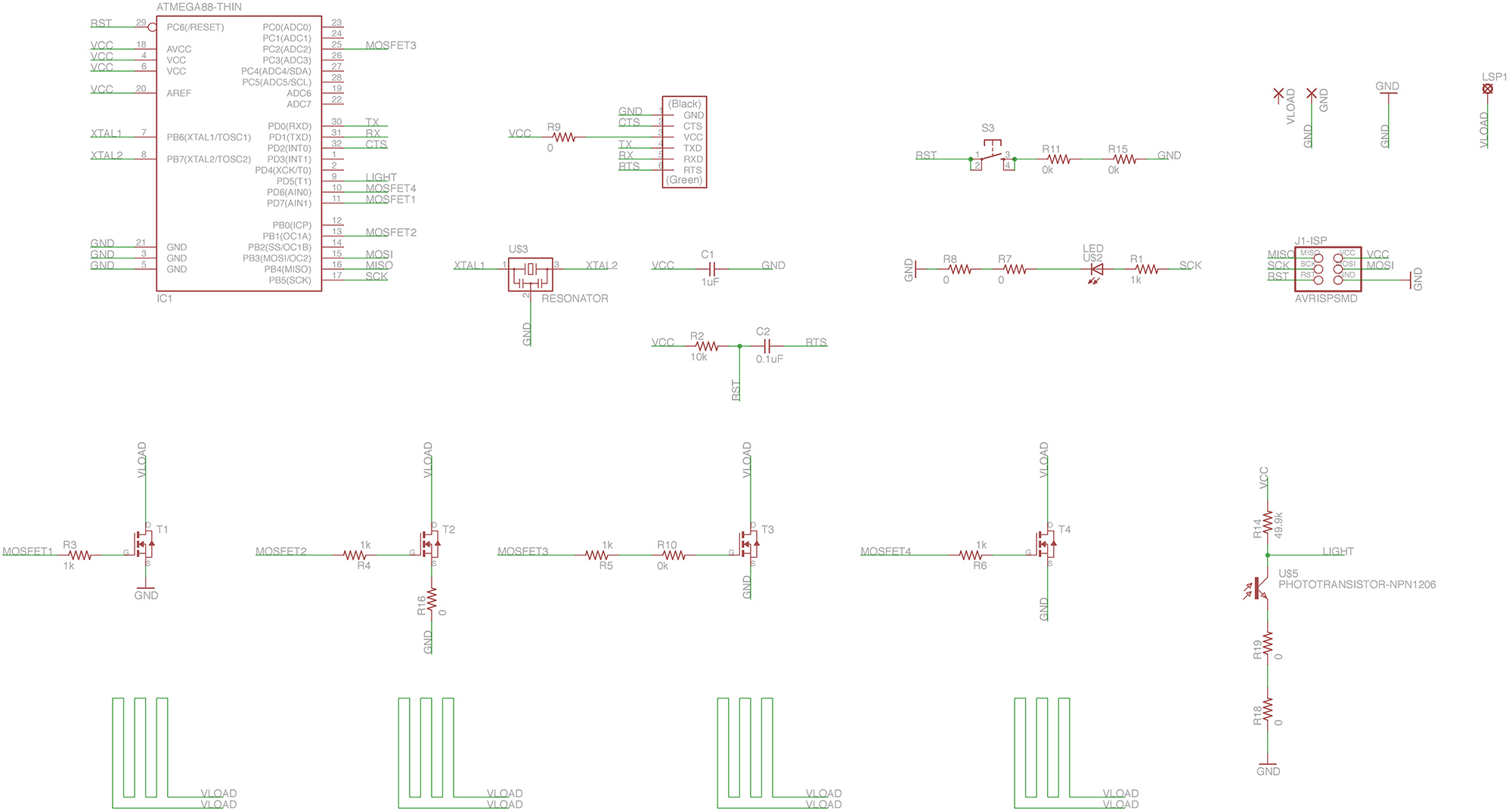

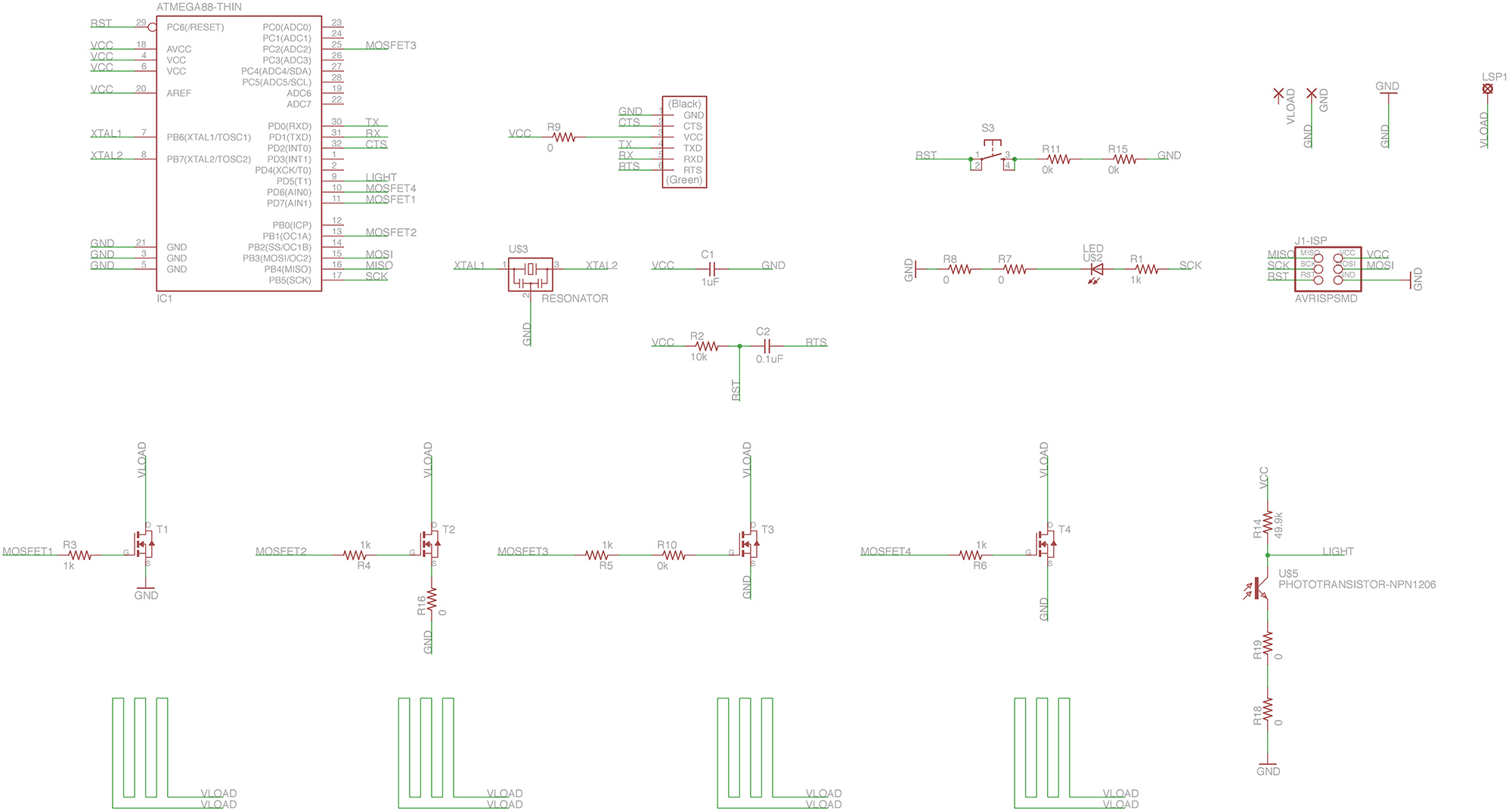

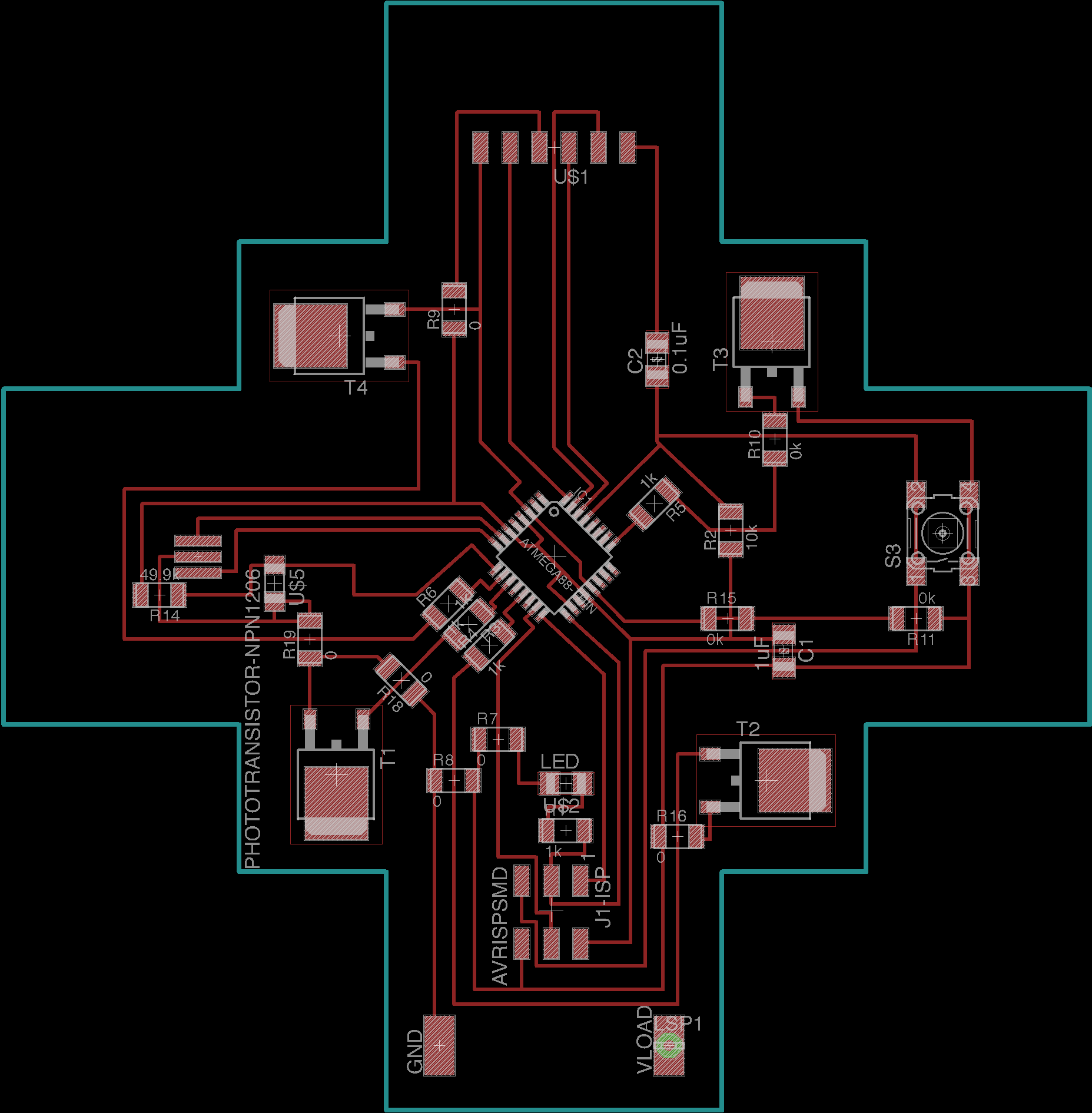

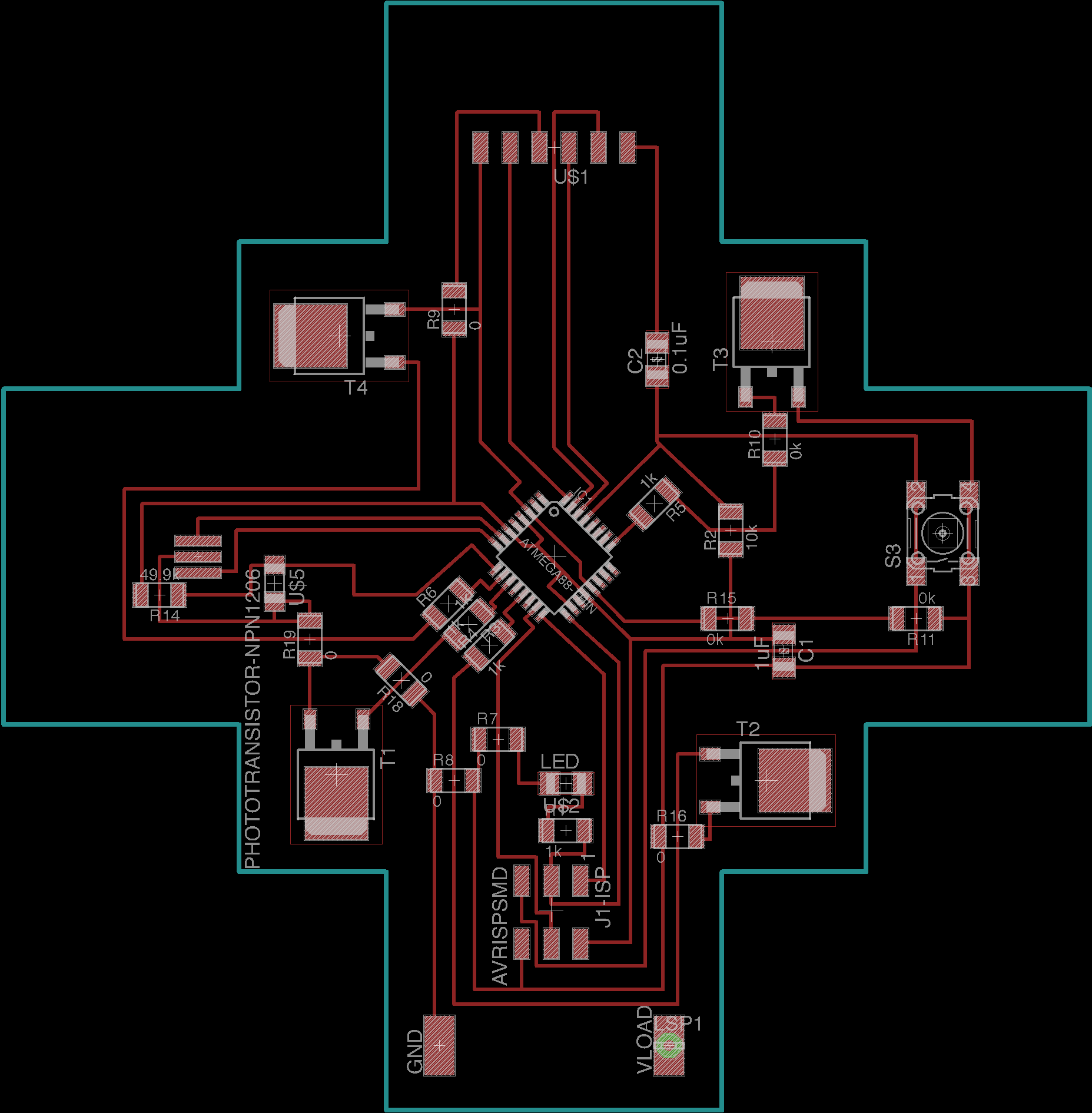

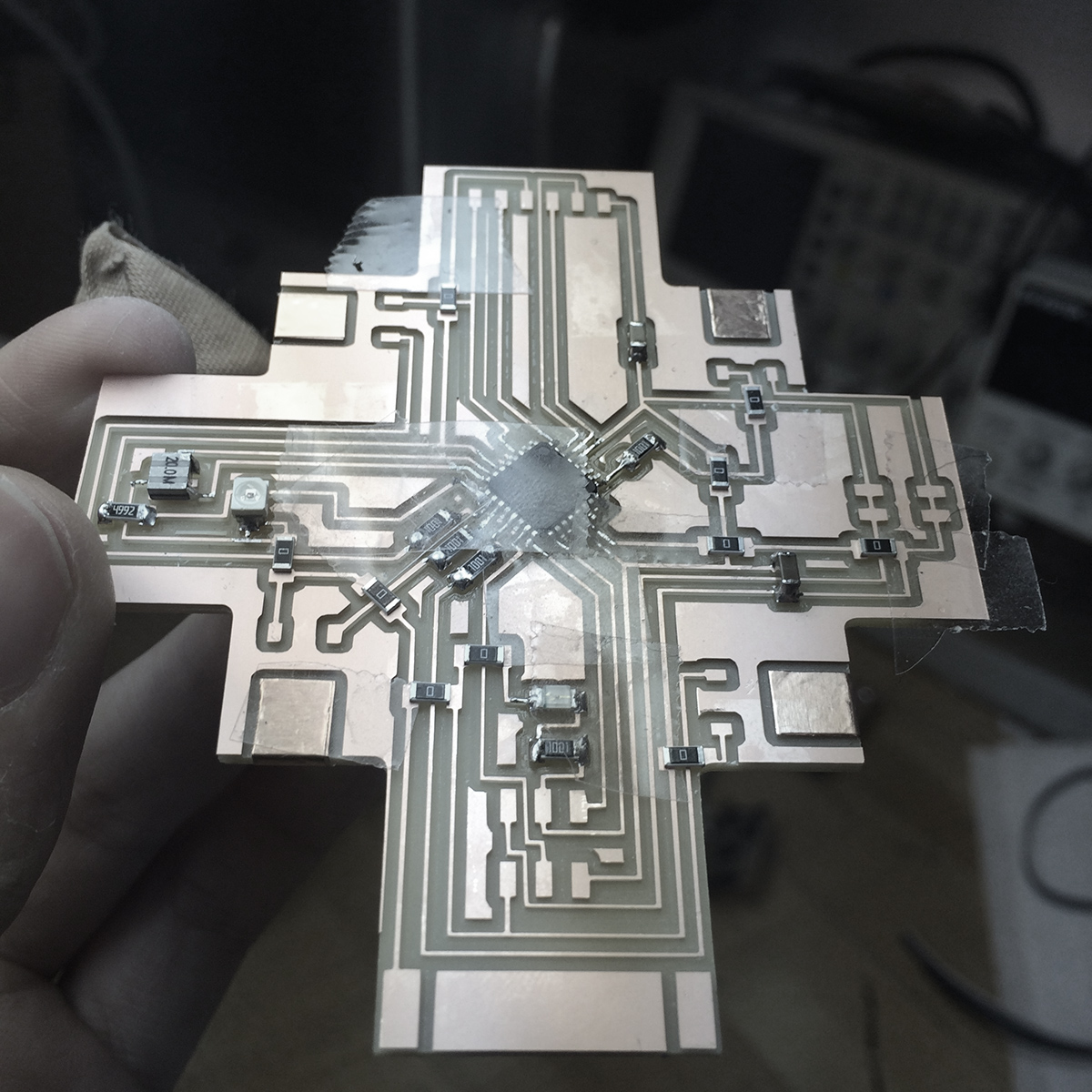

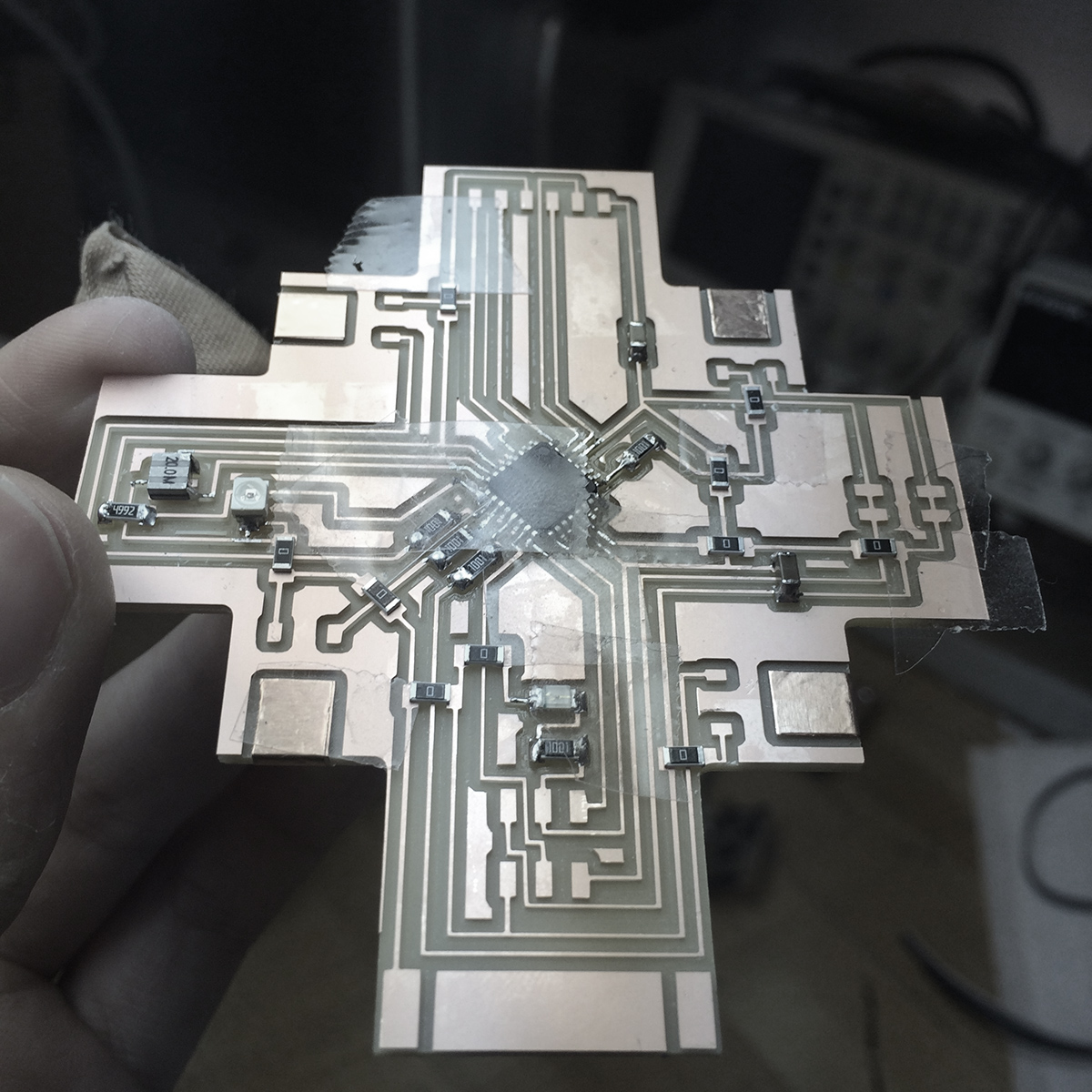

control board

software: eagle

-design-

skin modules ideas

hand drawing of board design before going into eagle

-materials-

MCU ATmega328; header 2x3, resistors x16, capacitors x3, LED, switch, crystal 20 Mhz, phototransistor, NMOSFETs x4, FTDI connector

-materials-

MCU ATmega328; header 2x3, resistors x16, capacitors x3, LED, switch, crystal 20 Mhz, phototransistor, NMOSFETs x4, FTDI connector

schematic

routing

soldering methods finally acquired!

final board

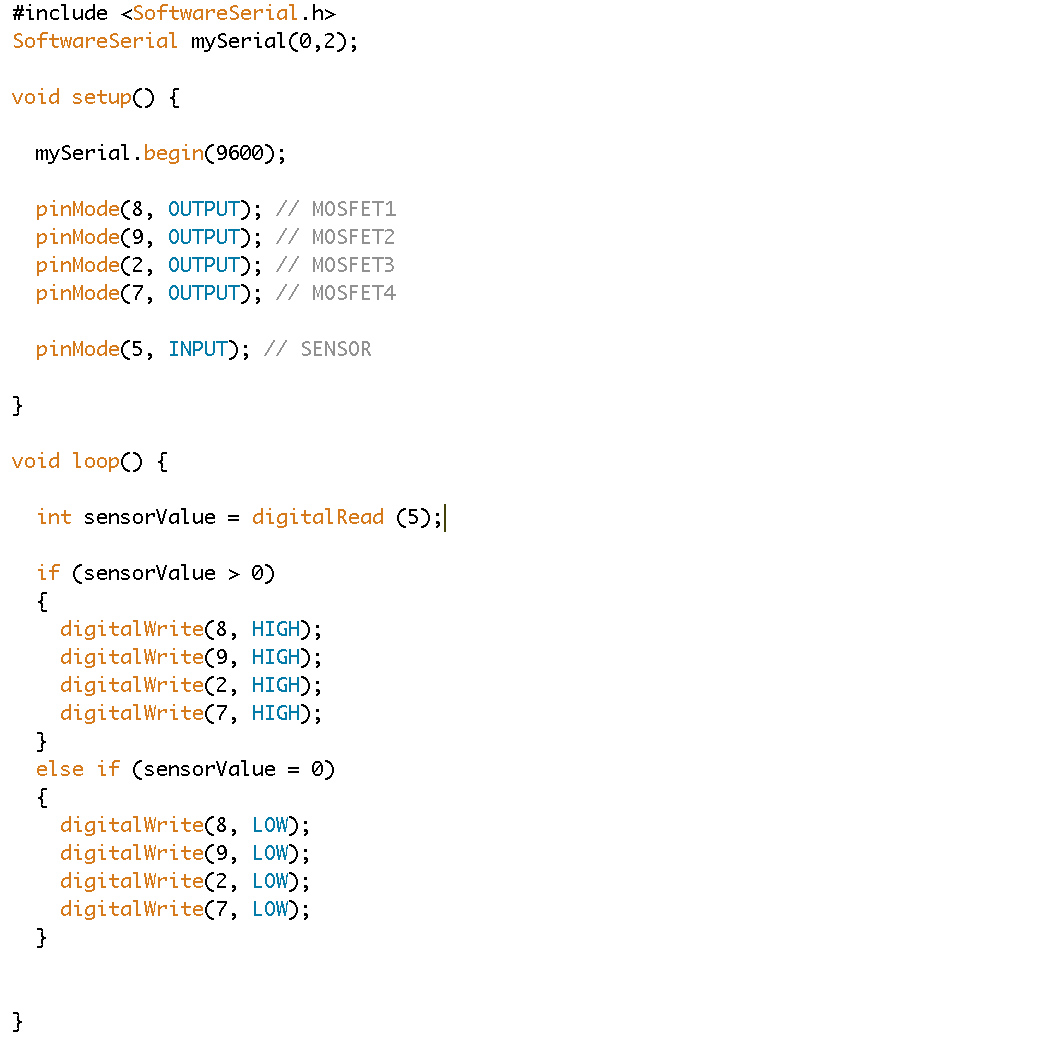

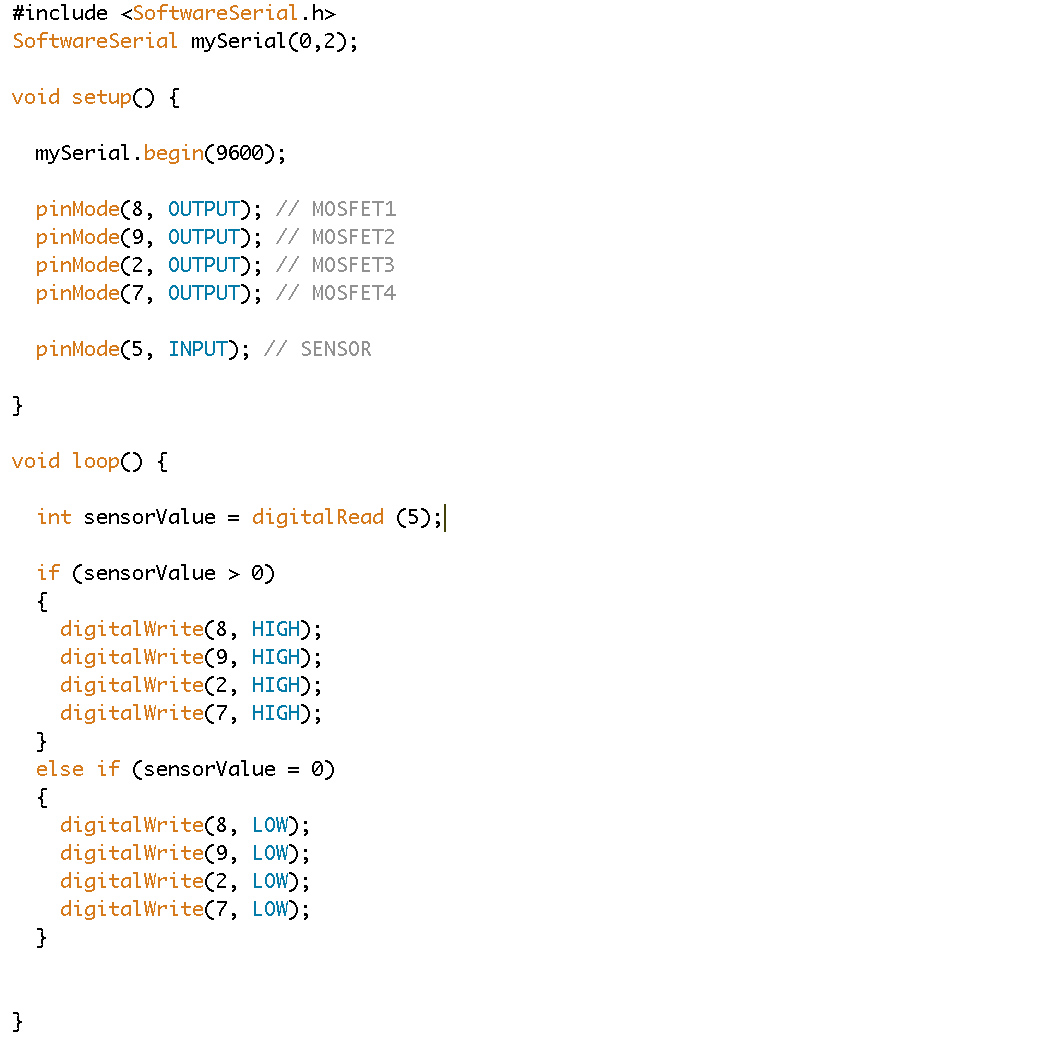

arduino code reading digital input (should have read analog to control values and each mosfet individually!)

special thanks to felix heibeck for his patience guidance into the unimorph and PCB worlds.

special thanks to felix heibeck for his patience guidance into the unimorph and PCB worlds.