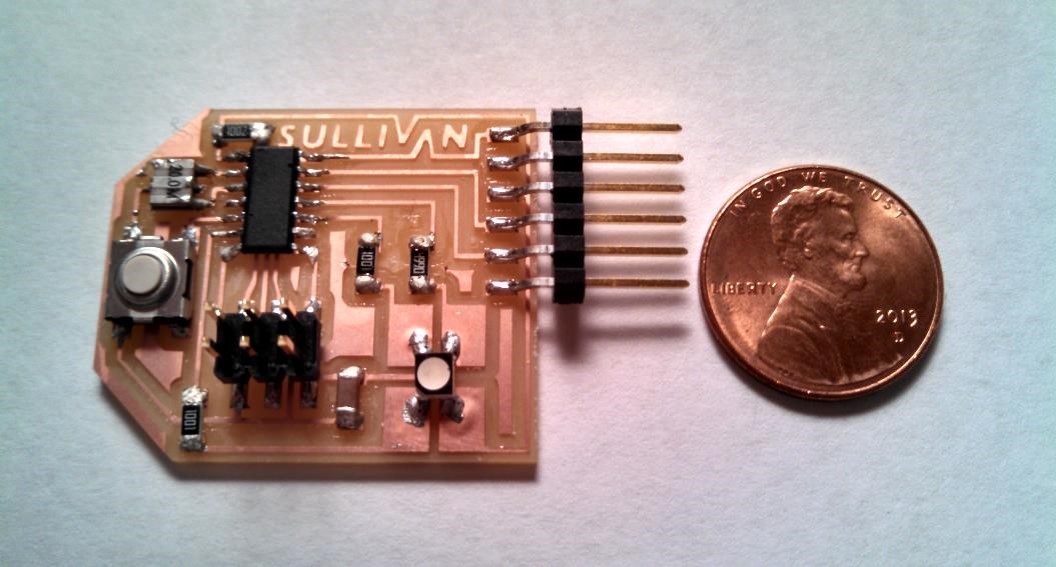

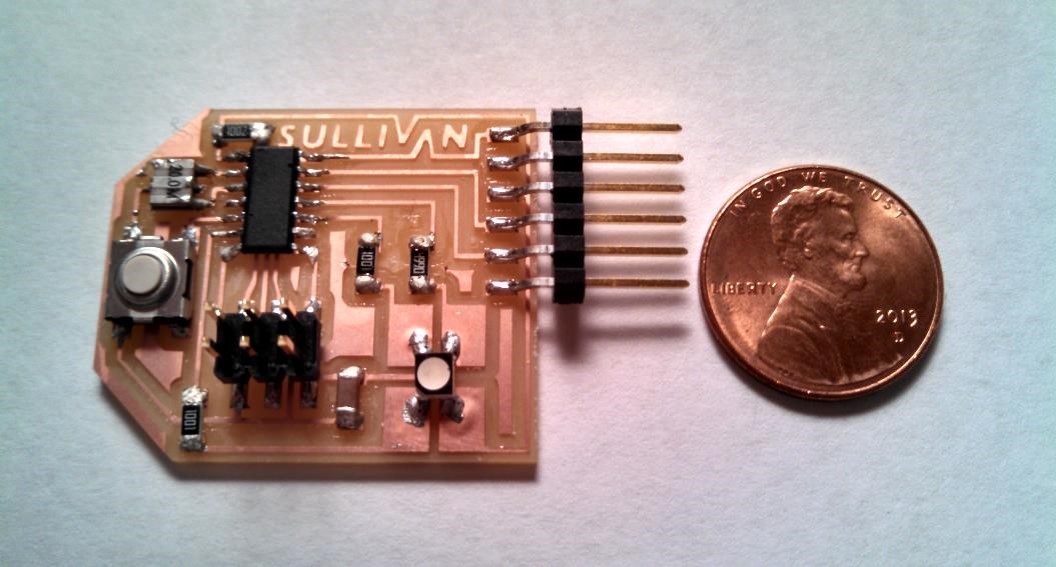

The objective for this week was to make a circuit board

with at least one button and one LED. I chose to use an RGB LED

allowing me to create a spectrum of colors.

The objective for this week was to make a circuit board

with at least one button and one LED. I chose to use an RGB LED

allowing me to create a spectrum of colors.

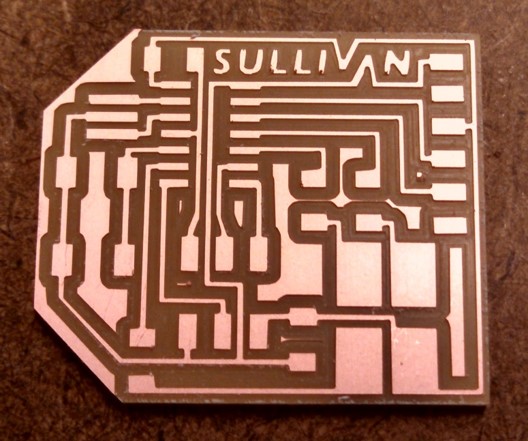

The picture on the left shows the corresponding Eagle board. I used a wire thickness of 0.012 inch which worked ok but they're very fragile. Also the length of the pads for the 20 MHz resonator seemed a bit too short. The pads were only slightly longer than the resonator making it very difficult to solder. Everything else seemed to work out great.

The biggest mistake I made was making the wires too small. I would

suggest a minimum wire thickness of 0.016 inches. Also when I was

designing my board I wanted to make it as compact as possible but in

hindsight that made milling and soldering much more difficult.

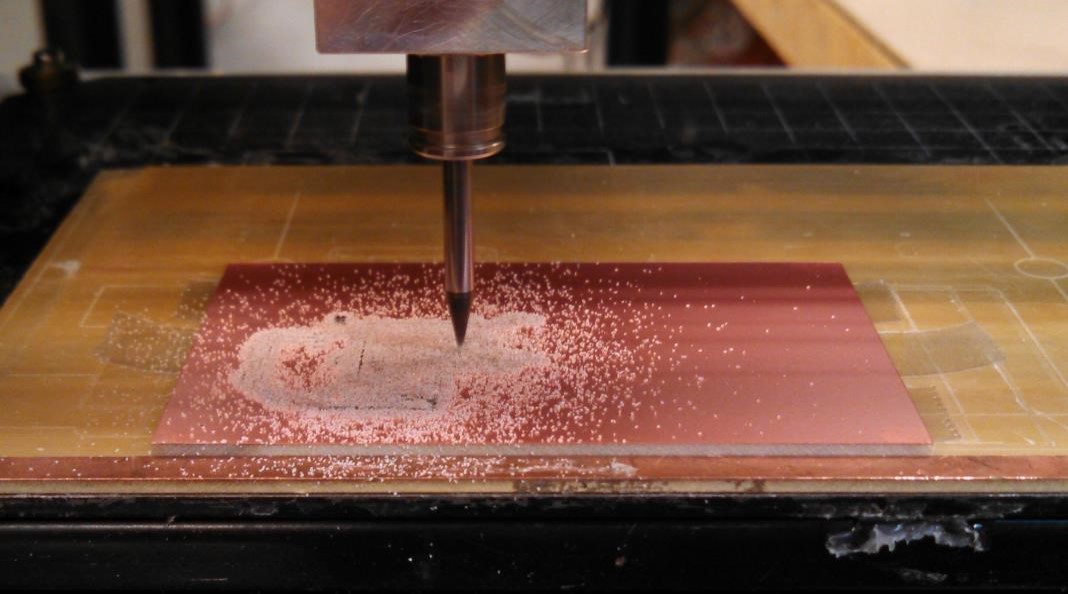

Another thing I noticed a little too late is that I think I may have

used a dull 1/64th inch bit in the mill because I realized

that it had cut really crooked lines especially when they were

diagonal. I didn't notice this until after I had soldered the board

and looked through the pictures I had taken.