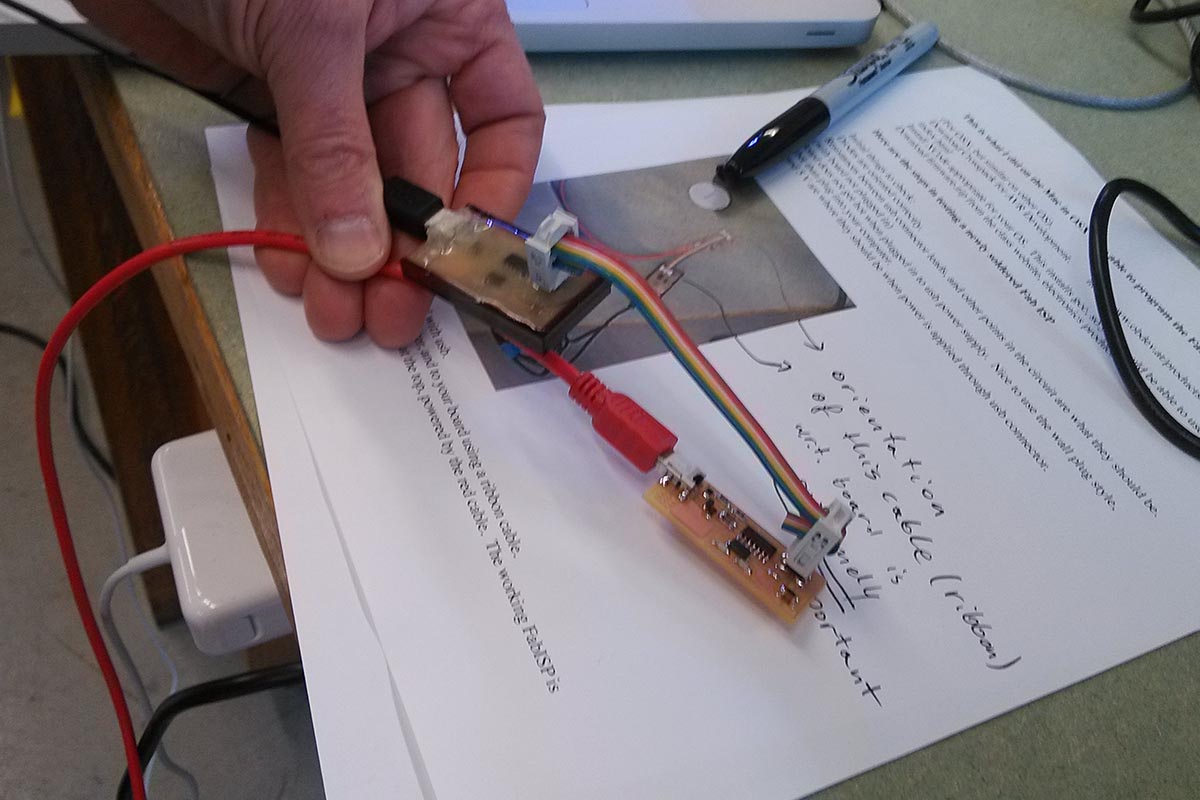

The finished board.

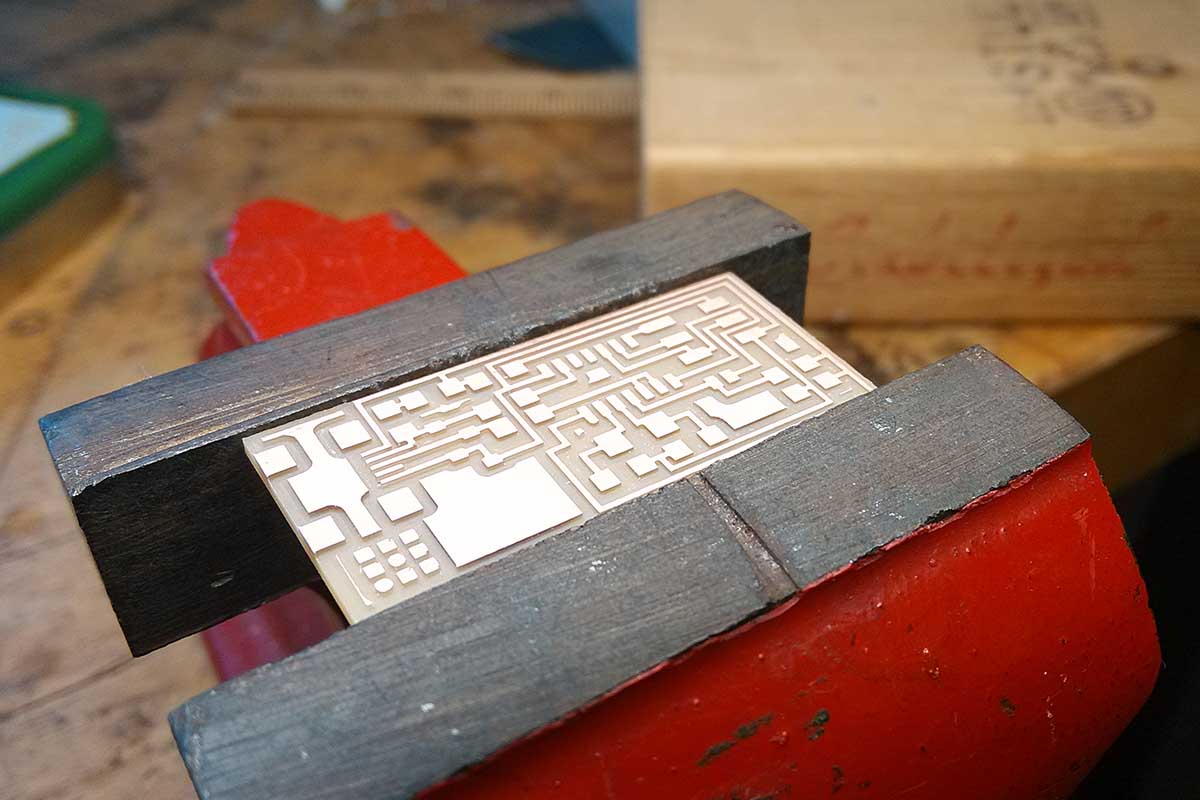

Milling the board from the stock. The fab module considers the origin (X,Y,Z) to be wherever the tool is when the tool path is sent.

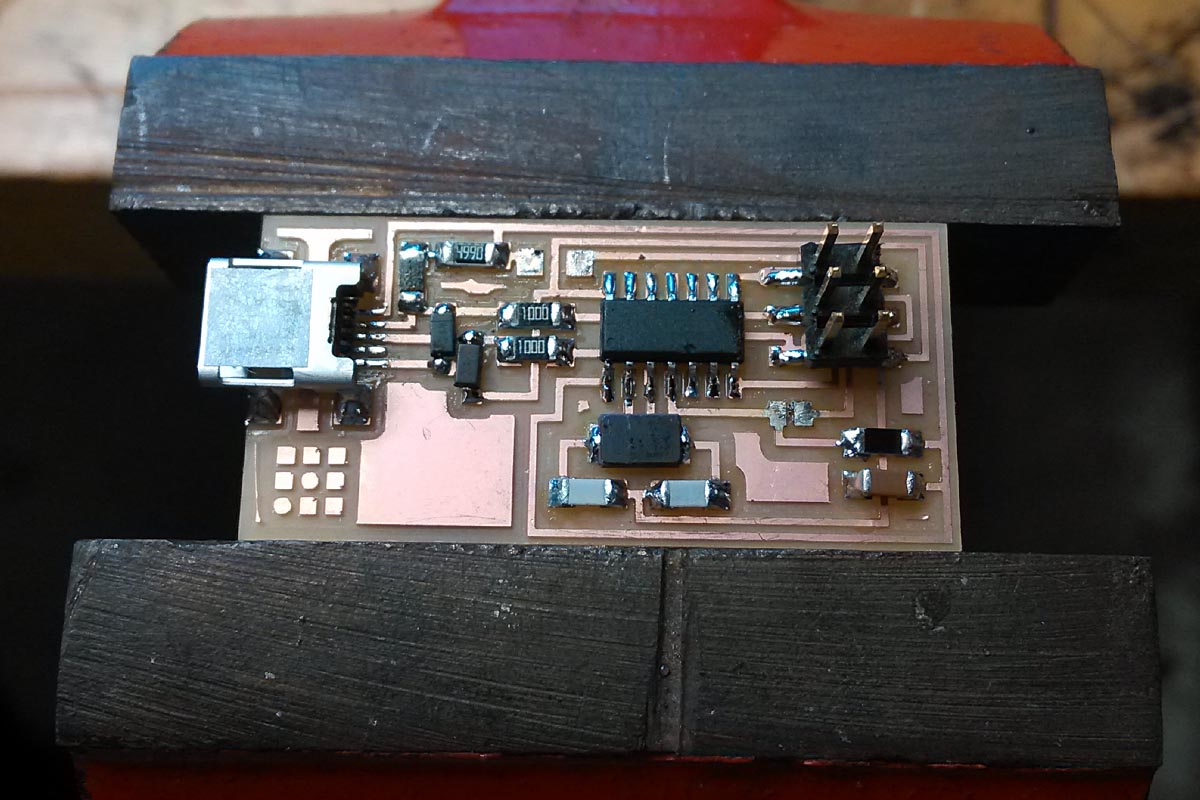

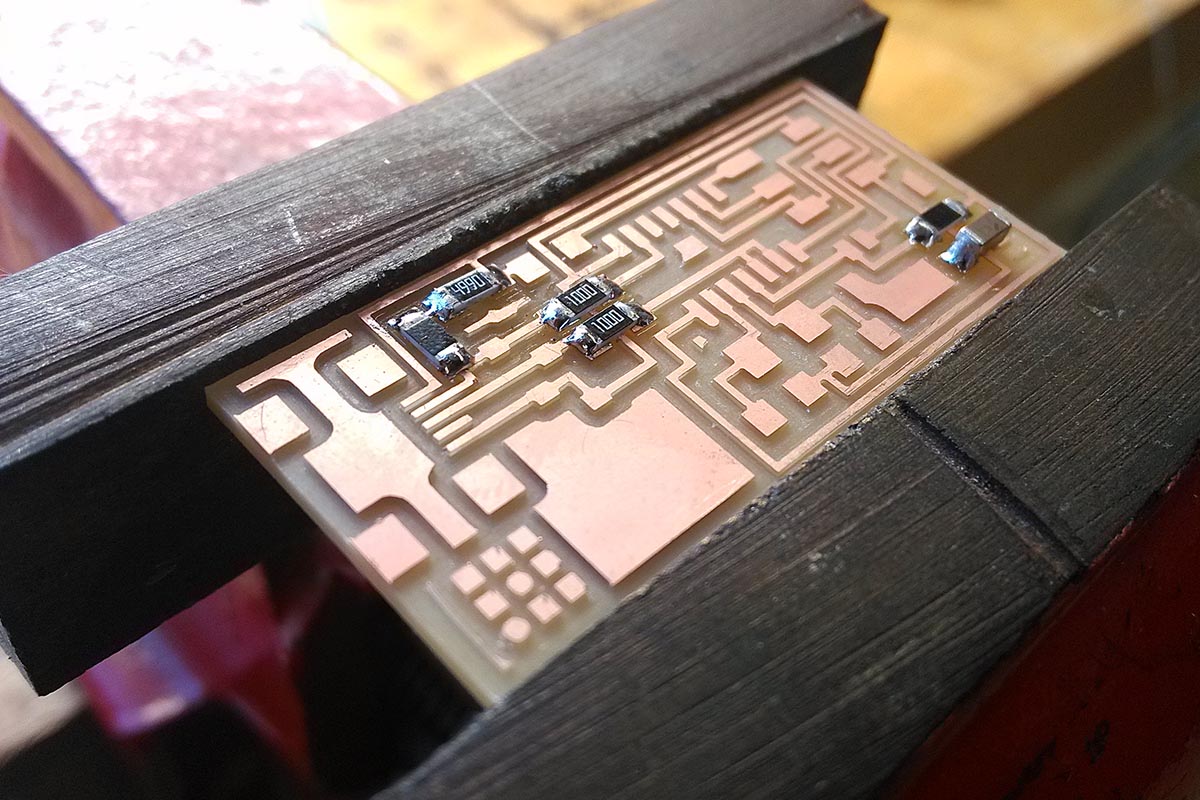

The milled board, held in a clamp for surface-mount soldering.

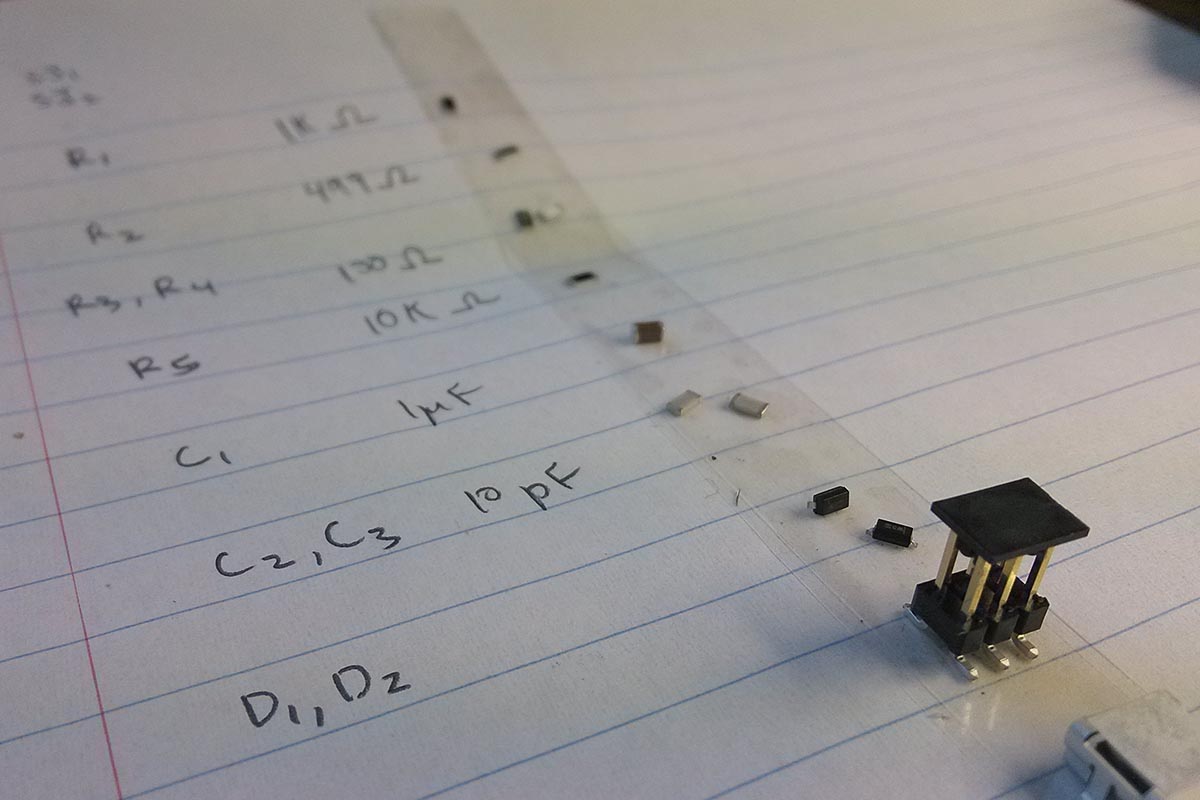

A parts list was written out and the required components were collects and attached with tape.

Surface mount soldering was a new experience, and required much more time and trials than conventional soldering.