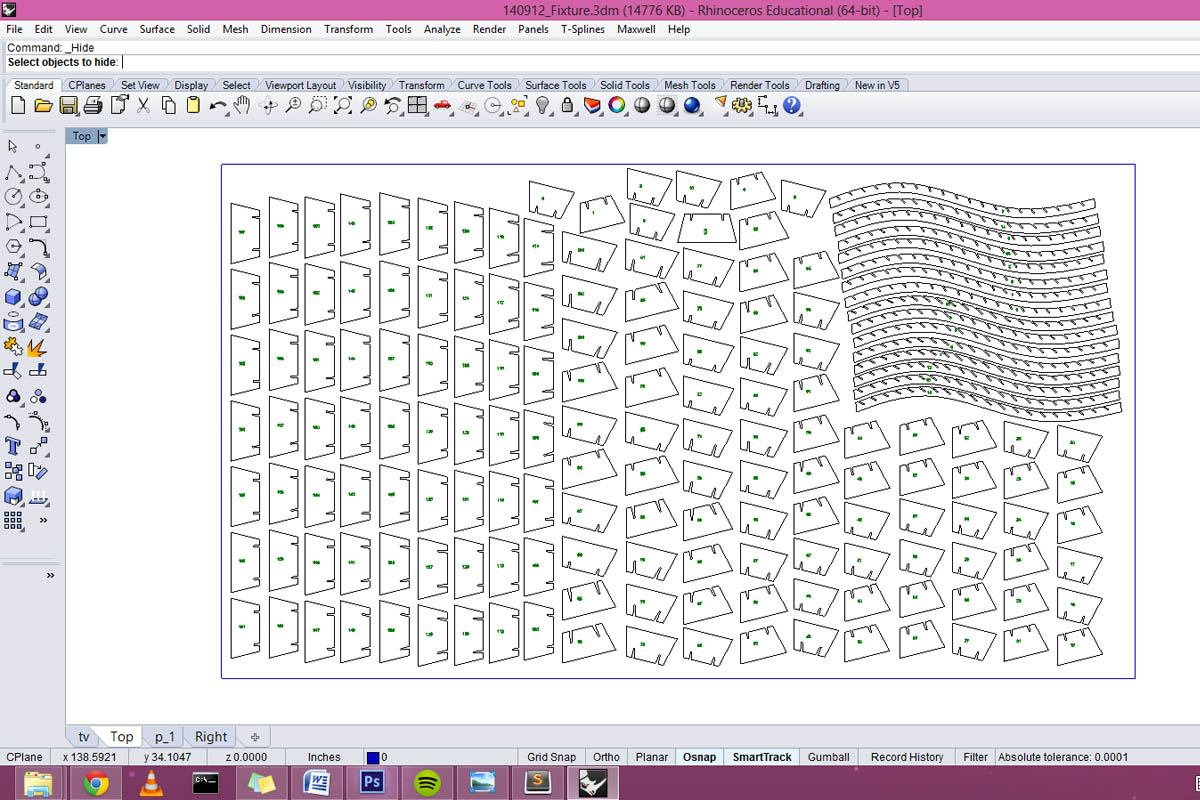

The numbering system seems to follow no pattern whatsoever, but at least remains consistent between the 3D model and the 2D cutsheet.

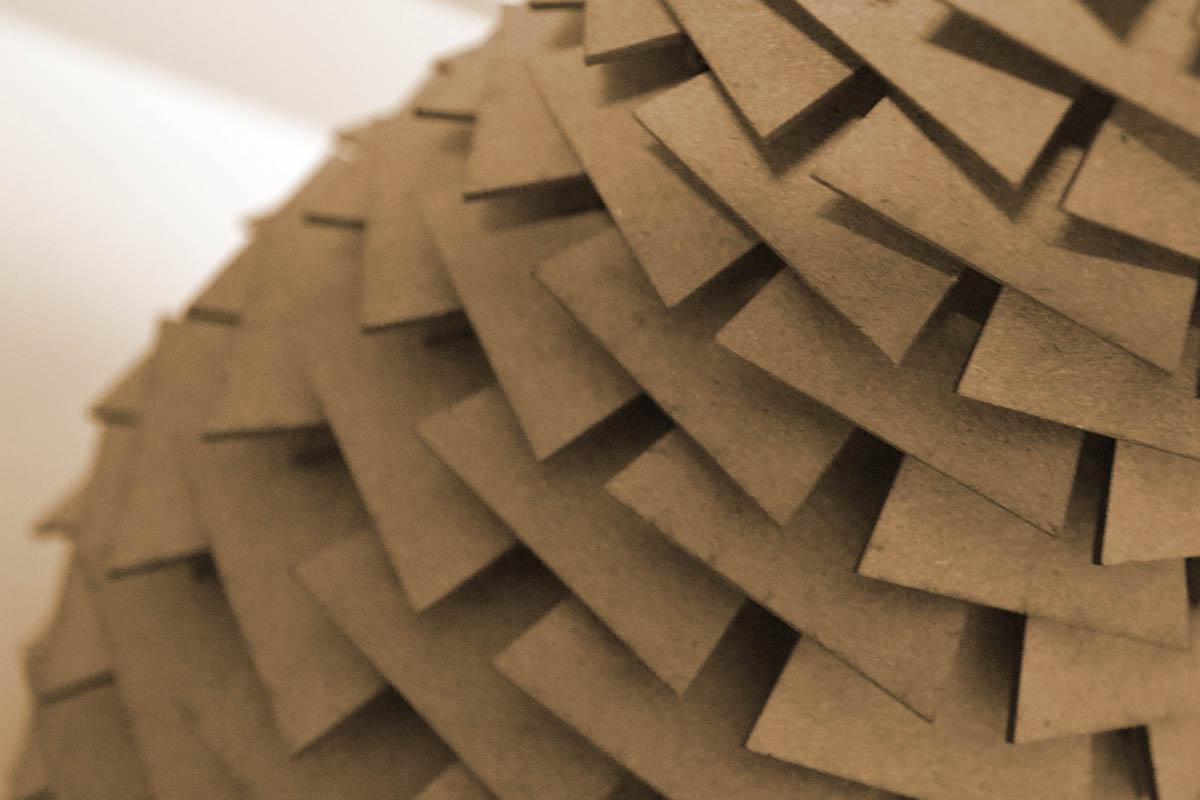

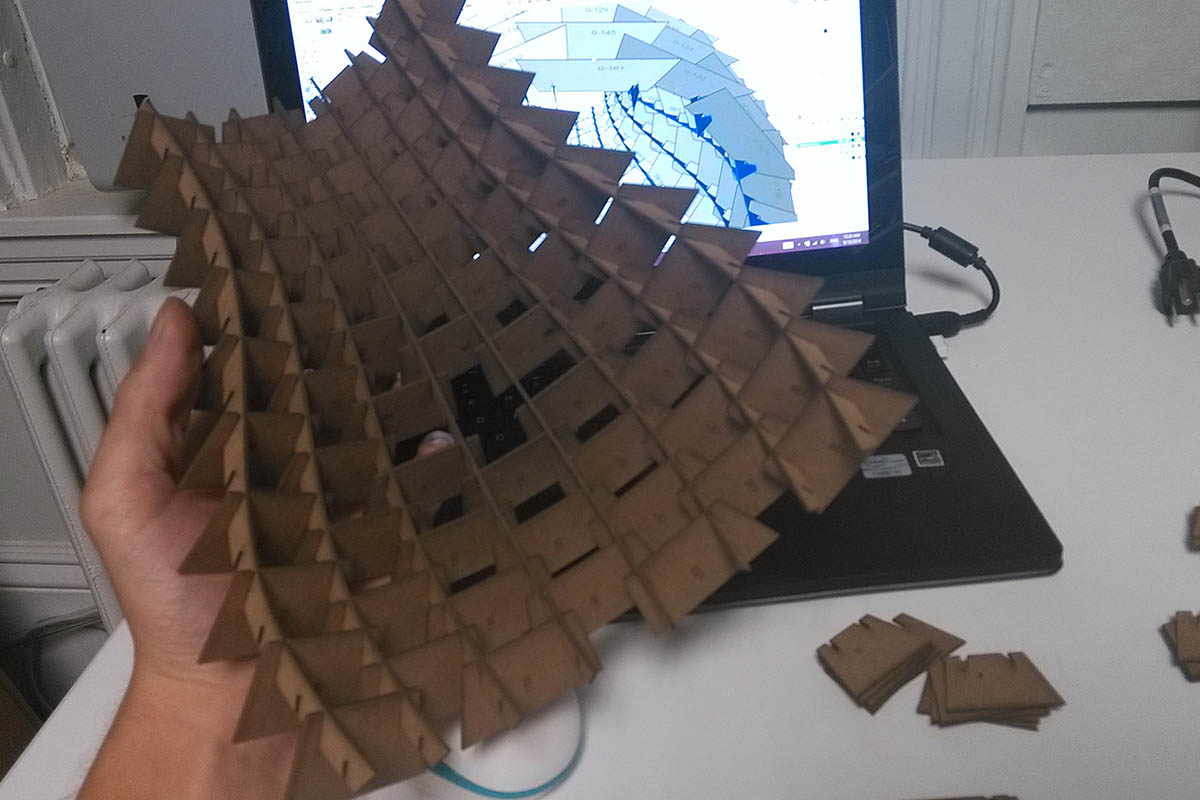

The lamp shade can be rotated along its axis, or flipped upside down for varying lighting conditions.

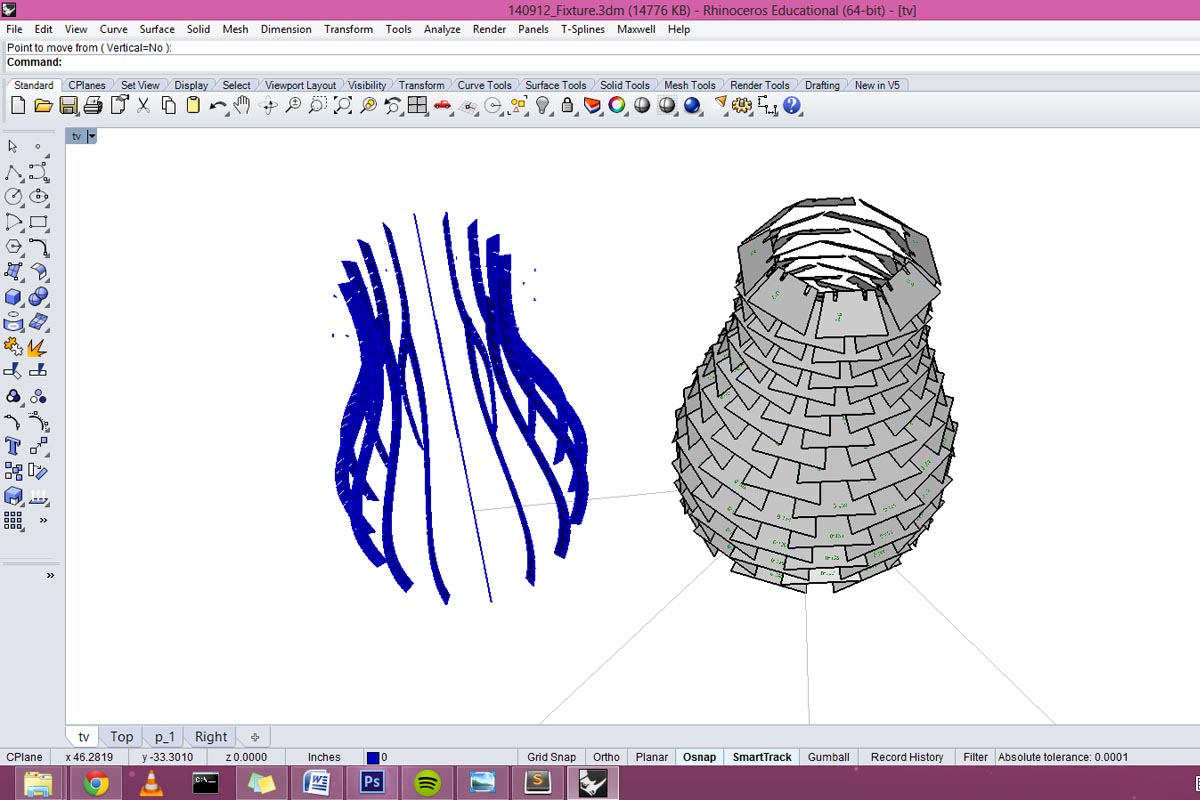

The overall form of the lamp shade as well as paneling and intersections were generated using Grasshopper for Rhino

The scale and density of the paneling was adjusted so as to occupy an entire 18x32" cut sheet.

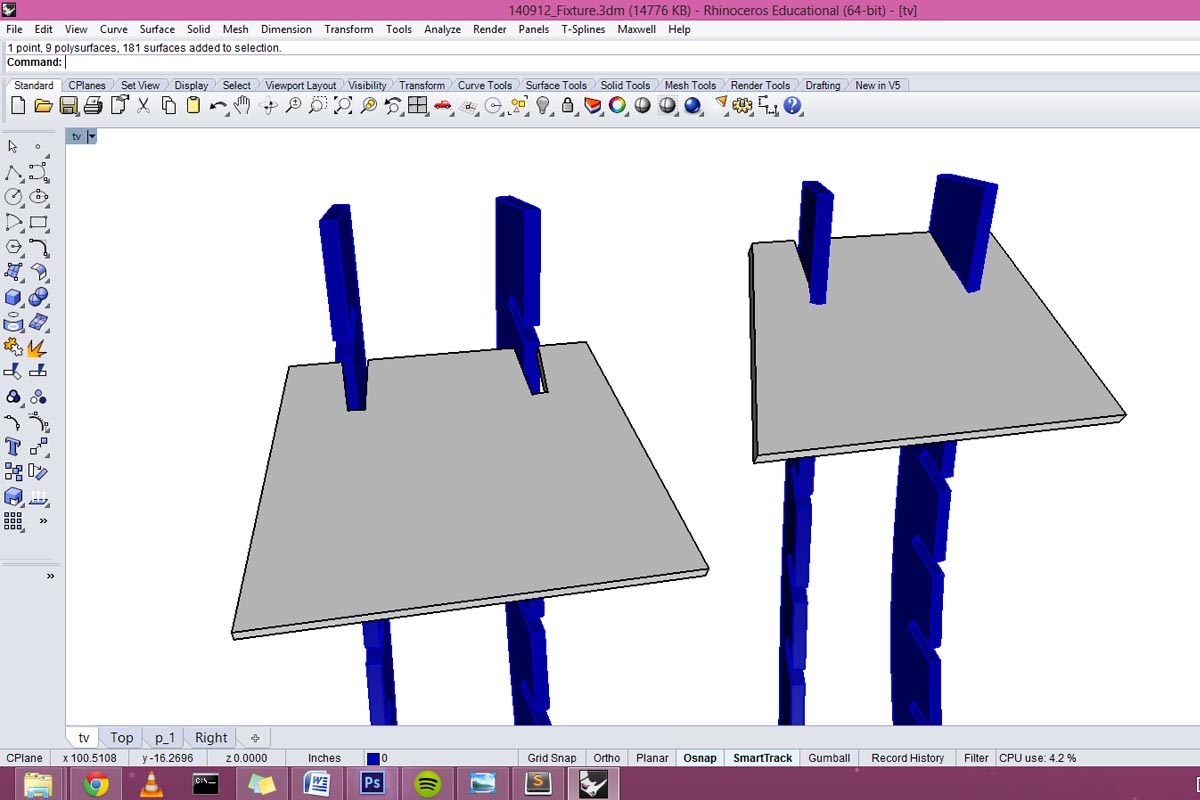

Because of the radial nature of the intersections, it was necessary to cut wedge-shaped notches in all of the horizontal panels. Otherwise they would not be able to slide between two verticals.

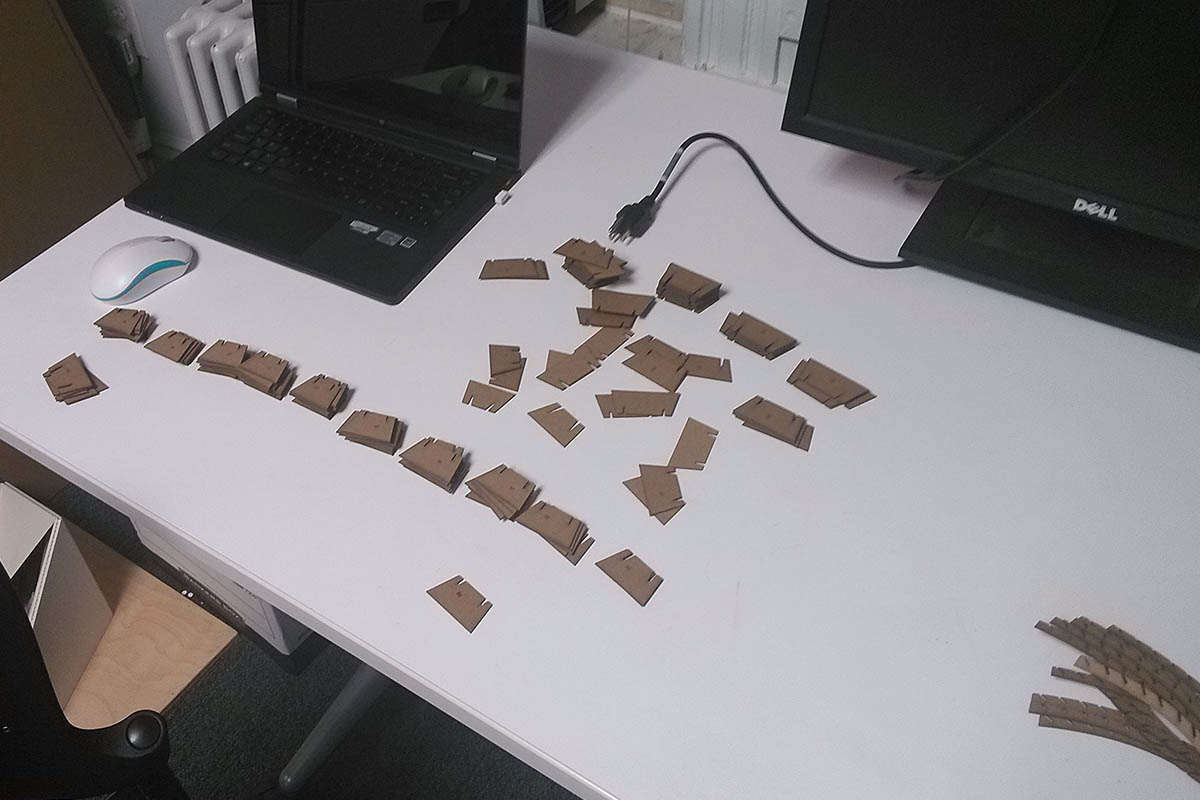

A total of 180 pieces were laser cut and organized for assembly.

The intention was to assemble the entire 360 degree form row by row. However, it turned out to be easier to assemble two halves.

Assembly of the first half (I found the missing piece later)

Completed assembly, after stitching both halves together with the remaining pieces. Fabrication and assembly time, including laser cutting, sorting and assembly, was about 3 hours.