|

|

MAS.863 How To Make (Almost) Anything

– Fall 2014 Richard Li Final Project – The Smart

Ukulele Week 14 The integration of topics covered in this class: The goal is to make a proof of concept high tech

stringed instrument such as the ukulele that can help you learn how to play

by using LEDs to display the chord shapes directly on the frets. In the

spirit of increasing the tech level of the traditional ukulele, this ukulele

combines virtually all the topics we covered in this class. Here are the

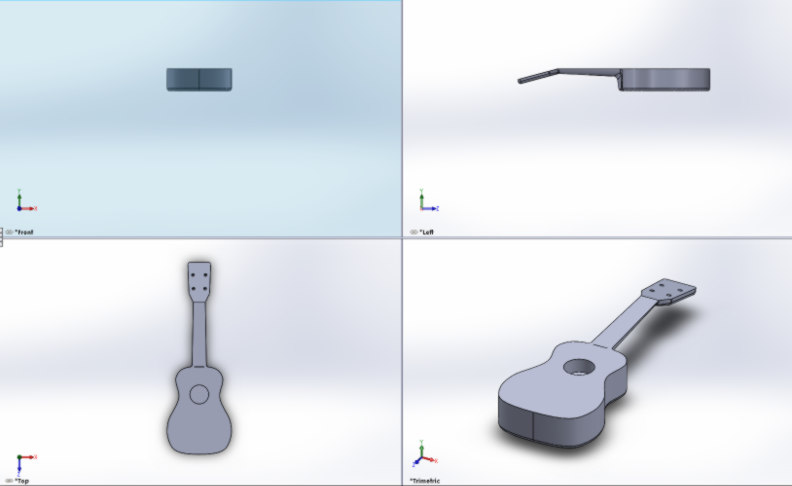

breakdowns of topics covered for instance: CAD – Solidworks CAD

of composites and casting molds Computer controlled cutting/machining – Waterjet for soundboard and headstock, Vinyl cutter for

prototyping Electronics Production – Vinyl cutting and

Roland MDX milling of boards, stuffing boards etc. 3D Printing – bridge/saddle, nut, molds for

casting fretboards Embedded programming – programming boards to

light up chord shapes on LEDs Composites – CFRP Body, Neck and Headstock Input / Output Devices – LED charlieplexing, LCD screen and future input of mic for VU meter capabilities Communications – capability on board to talk

through Bluetooth serial module (HC-05) Why

ukulele and carbon fiber you might ask? First, I donŐt have one yet and been

meaning to want to pick one up and learn it for a while. Secondly, my

ambition is to build more complex structures out of carbon fiber and get

better at doing lay-ups especially with high performance materials to

eventually build something like a carbon acoustic guitar or bike frame. The

ukulele is nice in that itŐs an ambitious starting point, but it wonŐt burn

through a ton of material in case the layup goes horribly wrong and doesnŐt

have the mechanical intricacies such as truss rods in large guitars. As for the carbon argument, IŐve heard some amazing

sounds coming from carbon instruments before – such as when I went to

my good friendŐs cello recital where she played with a carbon fiber cello.

Carbon fiber reinforced plastics (CFRP) are also incredibly durable yet have

high strength and stiffness to weight ratios – which is highly desired

for an ultraportable instrument such as the ukulele. Wood properties change

drastically with moisture and ambient conditions, whereas the carbon fiber

can be played casually on the humid Hawaiian beaches without a worry. WhatŐs been done before: A group of three students at Tufts had started and

documented a fabrication of CFRP Ukulele, but did not end up finishing the

end product. In the end, their molding process is similar to what I had

planned, except they used a vacuum assisted resin infusion approach: http://www.tuftl.tufts.edu/musicengineering/research/CarbonFiberUke.pdf Also there is a company that sells LED embedded

guitars also as a learning tool (itŐs cool to see others independently saw

the potential in this too!). No design yet on ukulele, and cheaper versions

limited to only first 5 frets: Design, materials, components, and costs: As mentioned in my

composites page, this is modeled off of a Soprano ukulele, but designed to be made of three pieces with the body made of

one single composite piece, and the soundboard/neck cover as another separate

piece. Here is the solidworks part I modeled for

this body:

The idea

is that the fretboard would be a separate unit that

can be cast out of clear epoxy with an LED array embedded within it so that

light can shine through. The bridge and nut would be 3D printed out of harder

plastic like ABS. Strings, tuners would just be commercial off the shelf. One

additional neat feature I wanted to add was the capability to swap out fretboards quickly using magnets underneath the neck. I purposely also embedded disc

magnets within the fretboard conveniently shaped as

fret markers so that the board would be held down onto the neck. In terms of the cost, the

boards and circuits are only really a few dollars each. The tuners are about

8 dollars from amazon, and 3D printed material my amount to about 10 dollars.

The dominant cost is the carbon fiber, which I made with extra fabric lying around my laboratory. In general, you can buy the

carbon fiber fabric in bulk at >25ft at 10 dollars per food at 50Ó wide

(http://www.cstsales.com/carbon_fabric.html). In the end, the estimate cost

here using those numbers come out to < $~80 and factor in another ~$20 for

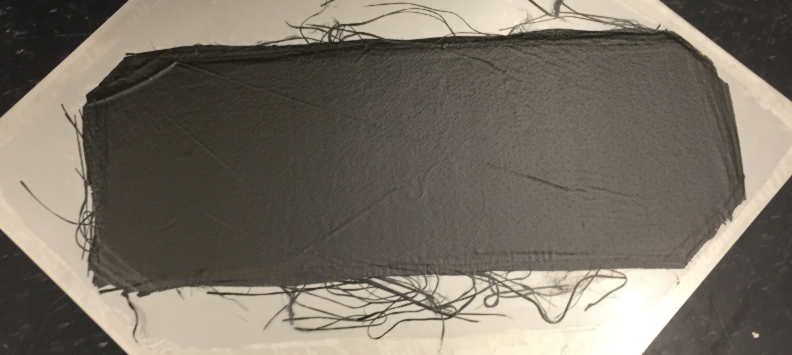

the total epoxy and hardener used up during the layup. Ukulele composite fabrication: Read more in my composites

page for more information on the mold design and layup tutorial: http://fab.cba.mit.edu/classes/863.14/people/richard_li/assign8.html But that was only the

beginningÉ Here are

all the post processing steps for fabricating the ukulele. First take apart

the vacuum bagging:

Here is a video depicting

the satisfaction you gain from peeling apart of the your peel ply to see what

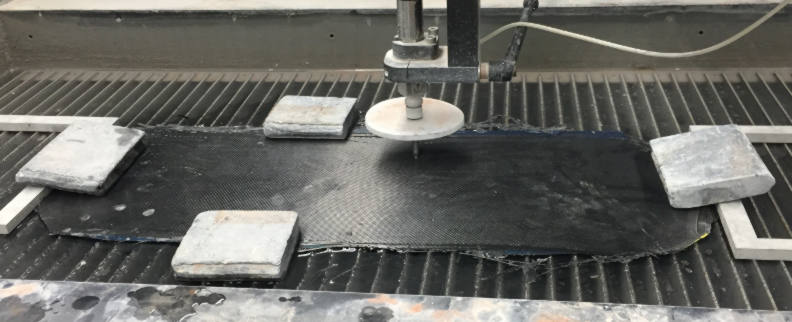

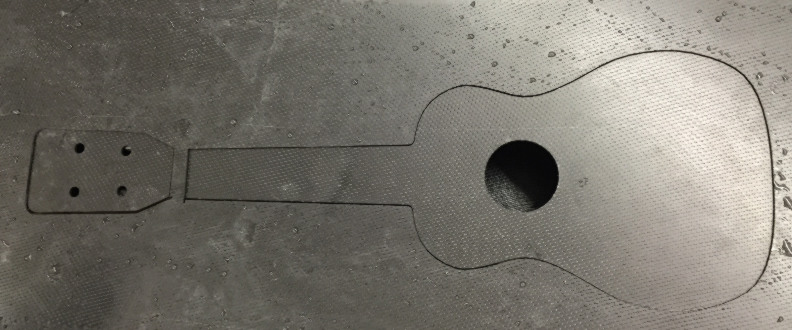

present awaited underneath: IMG 2437 from Rich Li on Vimeo. Then waterjet

the outline of the soundboard and headstock onto the flat plate. For the

soundboard waterjet file, in Solidworks,

I just opened my part, went to save as .dxf, and

then selected the front face as the object to be exported as dxf. One key thing for good mating is to purposely offset

the soundboard dimensions outwards so that when we go to mate it with the

body, excess material will be there from which we can then trim down and sand

down flush. In the waterjet, be sure to use the

composite setting in OMAX:

Next remove the body from

the mold and then hot-glue the lips to a vertical mount that can pass the

body through a band saw and cut it down to the right height. Note, I had

trouble removing mine, and ended up having to take apart my mold because I

didnŐt seal the mold properly prior to putting on mold release or paste wax.

The result is that the sides of the body stuck very well to the foam. This

will require quite some patience and elbow grease to chip off eventually.

Also itŐs crucial that the band saw you use has a hard abrasive coating on it

such as diamond grit band saw which is normally used

for cutting composites with ceramic fibers. Any other ones will ruin the

tooling quickly, and also result in very poor surface finish since it doesnŐt

cut gradually with an abrasive pass. Be sure to feed it through slowly.

After itŐs been cut down

to the right height:

You can use any two-part

epoxy and clamp down the soundboard to the body. Be sure to adhere (no pun

intended) to the cure times of the epoxy.

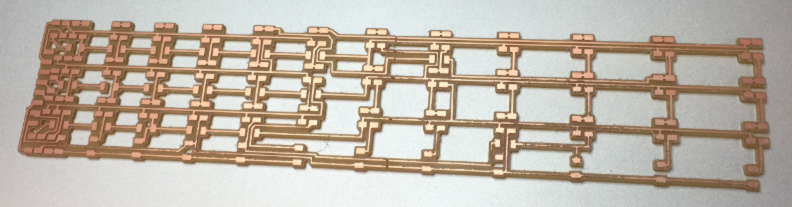

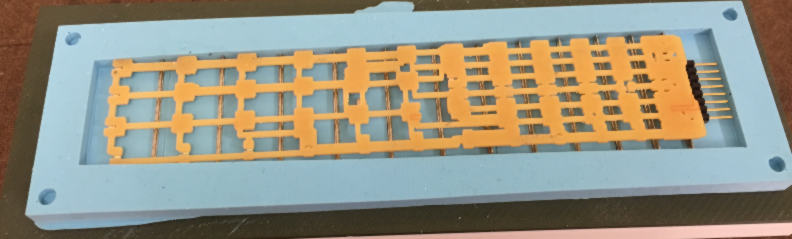

Ukulele Circuit Design This is probably where I

spent the most of my time this past week. I wanted to implement charlieplexing as that would

save a lot of pins. With 48 LEDŐs, I need 8 pins (up to 56 supported) in a 8X6 array for me. My straightforward charlieplex

diagram was like this at first:

However, the real issue is

that I have 12 frets and 4 strings. Thus the challenge was getting it to route

to a high aspect ratio rectangle (took at least a day to figure out)! Note

the interesting thing is that the schematic here below and above are

electrically identical. The only difference is that I installed a LOT of

jumpers (shows up as resistors on the bottom schematic) in order to get rows

to weave between each other.

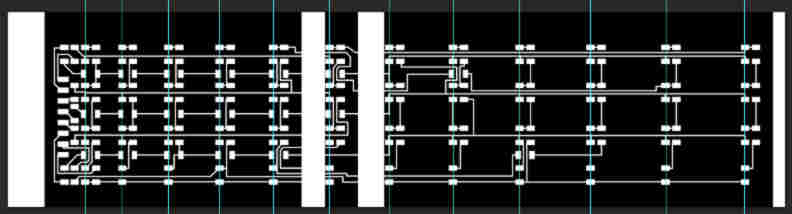

After some back and forth,

the neatest routing I can get is this. As you cans see, the 8 pin header are

all together on the left, and those spread out to each pin connected to a row

of 6 placed either in the left half or right half of the circuit board.

Additionally, the LED

driver board was designed as follows with capabilities for multiple outputs

such as for LCD display, pins for Bluetooth serial, and then pins (on the 2X2

header) for futureproofing when I come around to

hooking up a mic/opamp circuit which can turn my LED array into a VU meter. Given

the number of pins totally needed, I ended up needing to use an atmega 328p. This schematic does have one mistake, and

that is I hooked up two LED pins to ADC 6 and ADC 7 which

will not do outputs. ThatŐs a rookie mistake, and for the purposes of moving

forward I just soldered on jumper cables, but have not updated this schematic

below.

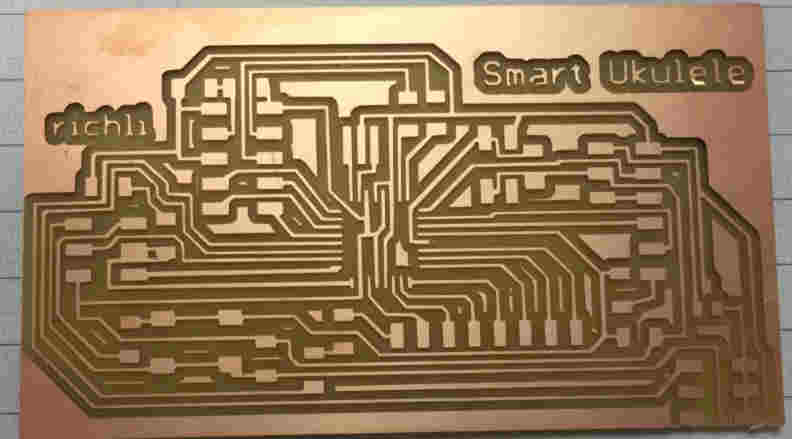

The board

layout for this circuit looks likes this, again heading the above warning on

pins ADC 6 and 7. I ended up using PB1 and ADC5 instead for two of the LED

pin outs instead.

The other issue is that

free Eagle has a size limit. Thus I had to use Photoshop and split the LED

board into small strips and stretch out the sections to match the coordinates

of the frets. Using the guide tool was super helpful to make sure I had the

right fret spacings.

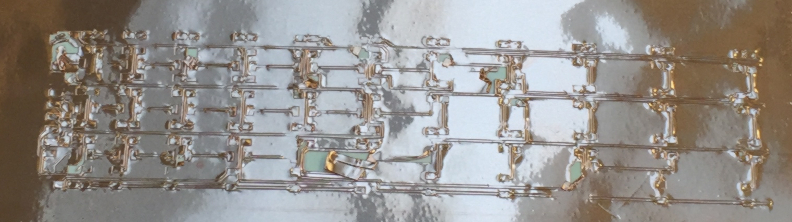

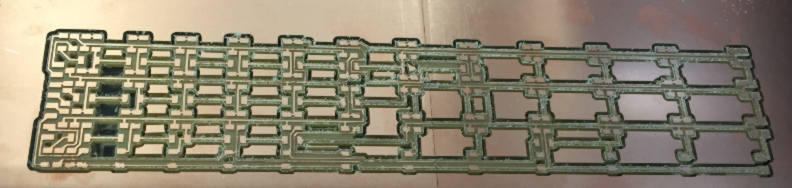

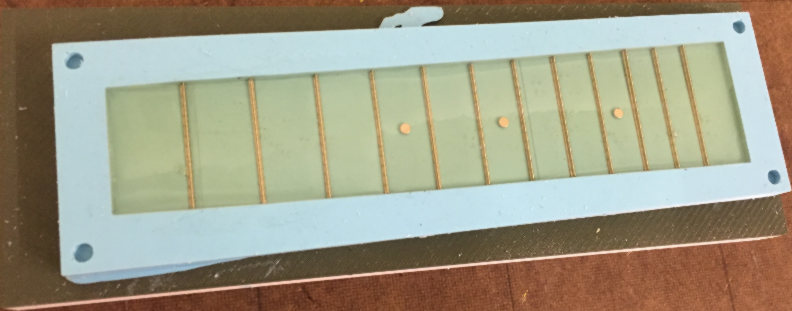

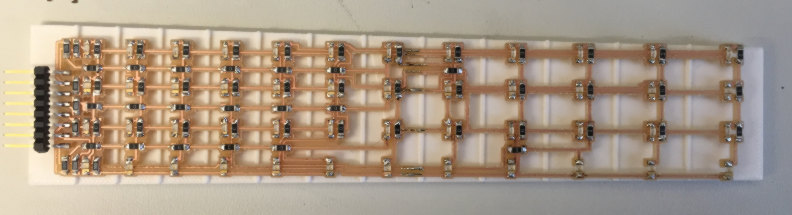

Circuit Fabrication Due to the desire to have

a transparent fretboard, I originally envisioned

vinyl cutting copper tape and adhering that to a fretboard

and then stuffing it. Toolpaths were generated once again using the fab module by Neil Gershenfeld, more information of which can be found from

my previous weeksŐ documentation. However, it quickly became clear

that the vinyl cutter was not suited for this operation as the result would

either drag apart my traces

or just not cut hard enough. ItŐs a difficult balance

to play between force applied and the trace resolution you can get without

tearing it apart.

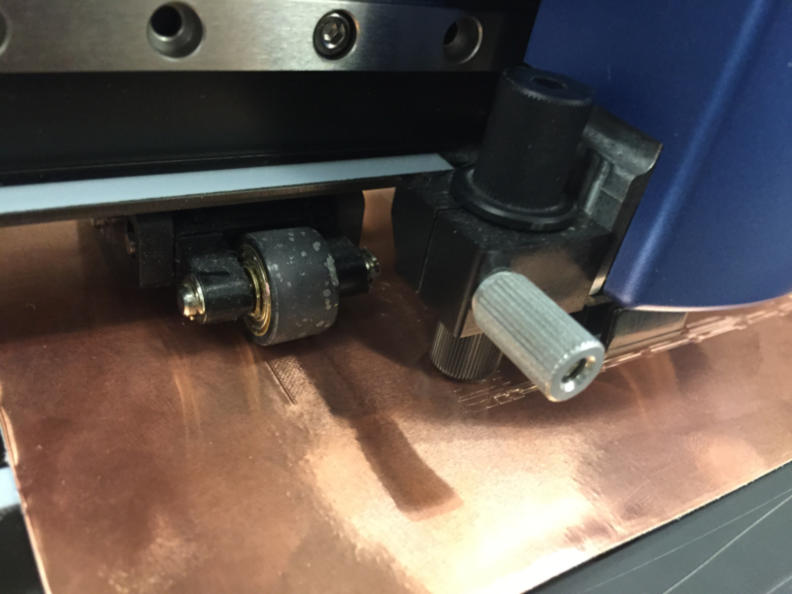

After an all-nighter in

the shop a winner became clear. It seems another way I can get transparency

while still using a method that can do high resolution trace cutouts (i.e.,

the Roland MDX) is to cut away any interior geometry all the way through the

thickness of the board. The shop didnŐt have long enough copper boards so I

ended up putting two next to each other prior to milling on the MDX 20.

It was a great success:

the traces came out very cleanly, and the in between sections were fully cut

all the way. The way I achieved this using the fab module is to import my

trace file, select the milling method to be 1/32Ó outline cut (which cuts

through the full board thickness), and then adjusting the tool diameter to be

1/16Ó so it would go in to cutting the island traces out from the rest of the

board but would still mill out bigger contiguous in between regions.

The milling of the driver board

proceeded without a hitch after quite a bit of practice over the past weeks.

Programming

- CharliePlexing The order of operations

for charlieplexing consists of three steps: 1. Set all

8 pins to high impedance, 2. Set the pin connected to LED anode you want to

light up to high, and 3 set the pin connected to the LED cathode you want to

light up to LOW and have that be in a loop until you want another LED state.

ItŐs a lot of lines of code over time to set this up. Good thing Arduino has a Charlieplex

library that works with these three steps. Below is the Charlieplexing code I wrote and modified from an online Charlieplex arduino library.

Several things should be noted. First is the assignment of 2D arrays called highpin and lowpin, which maps

the anode and cathode pins respectively to the real life coordinate of a

specific LED. Say for instance, I want to turn on the LED for first fret at

first string, the index of [1][1] would be used for highpin

and lowpin to give me the anode and cathode pins

for that LED to actually turn that on. I found a pattern in the mapping and

wrote that in as a for loop in the beginning of the

code. Next, to light multiple

lights with a chord, charlieplexing actually turns

only one LED in the chord on at a time but cycles through it so quickly that

through persistence of vision, makes it seem like theyŐre all on at the same

time. Thus youŐll see that for the chords programmed in, I have a while loop

just cycling through the LEDs that define the code shape. If I want to have a

chord for a certain time interval and then move onto another chord, the key

trick I used here is the Ňmillis()Ó function which gives me a starting time stamp for when

I enter the chord loop, and then current time stamp through each loop

iteration, and have it exit the loop once the time interval for that chord is

up so it can move onto another chordŐs looping through its own LEDŐs. That

pretty much the core of how this code works: //#include <Arduino.h> #include <SoftwareSerial.h> SoftwareSerial mySerial(6,4); #include <Charlieplex.h> #define NUMBER_OF_PINS 8 #include <LiquidCrystal.h> LiquidCrystal lcd(4, 3, 5, 6, 7, 8); //define pins in the order you want to adress them byte pins[] = {A3, A1, A5, 9, A4, A2, A0, 10}; int highpin[13][5]; // 2D array of the anode pins

corresponding to the index in the [][] int lowpin[13][5]; // 2D array of the cathode pins

corresponding to the index in the [][] int s = 0; int f = 0; //initialize object Charlieplex charlieplex = Charlieplex(pins,NUMBER_OF_PINS); boolean singleOn =

false; int starttime

= millis(); int endtime = starttime; void setup(){ // initialize serial communication at 11500 bits per second: mySerial.begin(11500); lcd.begin(16,1); // Start LCD screen output //Map

the indices for highpin and low pin to the actual

pin numbers. for(int row=1;row<=8;row++){ int column = 1; // for the column address for (int c=1; c<=6;c++){ if (column == row){

column++; } if (row <=4){

s = row;

// if row<= 4

f = 6-c+1; // } if (row >4){

s = row-4; // if row >= 4

f = 12-c+1; // } highpin[f][s] = column-1; lowpin[f][s] = row-1; column++; //c++; }

} } /* void Cchord(int dur){

//This is a function that would spit out a C chord on your fretboard

starttime = millis();

endtime = cstart;

while ((endtime-starttime)

<= dur) {// do this loop for up to 3000 mS

charlieplex.clear();

charliePin ledtemp5

= {highpin[1][2], lowpin[1][2]};

charlieplex.charlieWrite(ledtemp5,HIGH);

charlieplex.clear();

charliePin ledtemp6

= {highpin[2][1], lowpin[2][1]};

charlieplex.charlieWrite(ledtemp6,HIGH);

endtime = millis(); } } */ void loop(){ if (singleOn){ charlieplex.clear(); } //Cchord(5000); //charlieplex.clear(); //delay(1000); // Light

up all frets int gstart

= millis(); int gend

= gstart; while ((gend-gstart) <= 5000)

{// do this loop for up to 5000 mS

int row = 1; // for the row address = for printing every light

for(int

row=1;row<=8;row++){ //int c = 1; //

counter for where along the row it's printing - want it to print across each

which is 6 int column = 1; // for the column address for (int c=1; c<=6;c++){ if (column == row){

column++; } charlieplex.clear(); charliePin ledtemp

= {column-1, row-1}; charlieplex.charlieWrite(ledtemp,HIGH); column++; }

} gend = millis(); } charlieplex.clear(); delay(2000); // C

Chord lcd.clear(); lcd.setCursor(0,0); lcd.print("C Chord"); int cstart

= millis(); int cend

= cstart; while ((cend-cstart) <= 3000)

{// do this loop for up to 3000 mS charlieplex.clear(); charliePin ledtemp

= {highpin[3][4], lowpin[3][4]}; charlieplex.charlieWrite(ledtemp,HIGH); cend = millis(); } // G

Chord lcd.clear(); lcd.setCursor(0,0); lcd.print("G Chord"); gstart = millis(); gend = gstart; while ((gend-gstart) <= 3000)

{// do this loop for up to 3000 mS charlieplex.clear(); charliePin ledtemp1 = {highpin[2][4], lowpin[2][4]}; charlieplex.charlieWrite(ledtemp1,HIGH); charlieplex.clear(); charliePin ledtemp2 = {highpin[2][2], lowpin[2][2]}; charlieplex.charlieWrite(ledtemp2,HIGH); charlieplex.clear(); charliePin ledtemp3 = {highpin[3][3], lowpin[3][3]}; charlieplex.charlieWrite(ledtemp3,HIGH); gend = millis(); } // F Chord lcd.clear(); lcd.setCursor(0,0); lcd.print("F Chord"); cstart = millis(); cend = cstart; while ((cend-cstart) <= 3000)

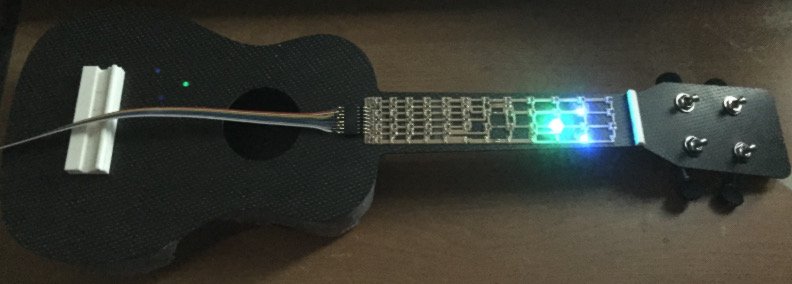

{// do this loop for up to 3000 mS charlieplex.clear(); charliePin ledtemp5 = {highpin[1][2], lowpin[1][2]}; charlieplex.charlieWrite(ledtemp5,HIGH); charlieplex.clear(); charliePin ledtemp6 = {highpin[2][1], lowpin[2][1]}; charlieplex.charlieWrite(ledtemp6,HIGH); cend = millis(); } } Here is an example of the

G chord shape lit up!

Here is a video of the LED

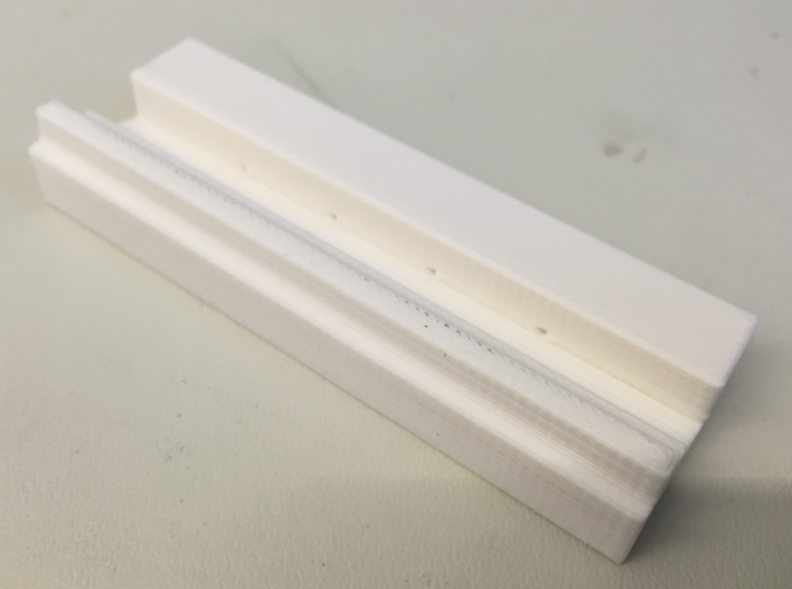

board first working on its own: IMG 2851 from Rich Li on Vimeo. Molding/Casting the Fretboard: With the electronics up

and running, it was time to make the fretboard. Fretboard postive molds were

designed in solidworks and 3D printed on the

Dimension. I then cast oomoo into these 3D printed

molds to get the negative molds, within which I can case

my clear epoxy to get my fretboard. To embed

components within the epoxy, I first cut low/narrow fretwire

(which can be ordered from a guitar parts supply store such as stewart macdonald online).

I then

placed the frets individually down into the grooves of the negative mold, as

well as the magnets used as the fretmarkers and the attachment to the neck. Next, I can place my

electronic board on tome, and then cover the mold with the top half before

pouring epoxy in through the top. As this was my first trial run, I actually

didnŐt throw in my LED board into the mold this time just in case the casting

didnŐt work out.

It was a good thing I

didnŐt. One thing I notice was that the holes I for pouring were too small,

and I found a lot of air entrapment as I added epoxy:

As a result, I took off

the top mold, and just did a simple open one part mold instead, which seemed

to work very well in distributing the epoxy.

This

process seems to work, and once I can confirm the playability of this

fretboard, IŐll embed my LED board into the epoxy with the next casting I do. 3D Printing as a tool for mold making and

prototyping Being able to 3D print the

fretboard first was incredibly helpful to verify

the position of my LED fret lights. A big thanks to Athina

P and Anna Young for their help in printing on the dimension printer on the IDC which worked seamlessly.

The saddle and nut of the

ukulele was 3D printed successfully as well.

And of course the casting

positive molds I mentioned earlier.

Test run: With the board mounted to the

neck of the ukulele, the final effect that can be achieved is shown in this

video: IMG 2878 from Rich Li on Vimeo. In the meantime, the board

is outputting the chord names to the LCD screen so a person playing this can

not only see the chord shape on the fretboard, but

also learn the names through the screen.

Questions, insights, and implications: Lots of challenges and

uncertainties appeared in this project that covered virtually the full range

of units in HTMAA. In just the composites part alone,

there was uncertainty in using foam as the mold. Would the blue foam be too

compliant and not be able to hold its shape during vacuum layup? Would the

piece stick to the mold given the lack of a draft angle? Turns out the foam

did a good job at holding shape, but not so much at allowing an easy release.

The key issue is not the draft angle as much as the surface seal of the foam.

After milling out my foam mold, I noticed the sides were extremely fuzzy. I

placed only one thin coat of entropy 100 epoxy onto the

surface, but not enough of that stuck on. The application of paste wax

was not enough to fill in the pores and completely seal the surface, thus

epoxy was able to penetrate into the foam when I did my layup, and cause

anchoring of my part. Even after removal of my part, itŐs still hard to chip

away at the pieces of epoxied foam from the surface, indicating an

anchoring/adhesive effect rather than a mold geometry effect. In the electronics design,

there were questions about how I can stretch out a board given my limitations

on size for developing it eagle. I found a workaround which

is to squeeze everything under the limits, generate the trace .png file and then use photoshop

or some image editing software to stretch it out to the right spacing. In the electronics

fabrication, there were questions about vinyl cutting the traces that small.

Indeed, that process wasnŐt successful, but using the roland

MDx20 router, and then milling through the whole board to get a transparent

effect off the traces worked very well. The next steps will be

embedding the LED into the fretboard now that the

electronics and epoxy casting were shown to work. The next iteration will

have to decide on the best wiring and positioning for playability of the

ukulele so electronic wires donŐt interfere. With the infrastructure

built, there are lots of fun things that can be built on the software and

hardware end. IŐd like to code something that would allow the importing of

tablature found online, parsing it into LED light coordinates and turning it

on so I can start learning songs. Bluetooth serial can also be connected to

the driver board pins to allow wireless serial communication to the computer

or phone sending the parsed LED light coordinates. Of course, an enclosure

will be designed to have a smaller footprint, and easy mounting to the

ukulele while being powered by a 9V battery (via bottom right pins of the

board and voltage regulator). Definitely lots of fun things to try out in

version 2.0! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|