Machine Building

a lazybartender

The Arch Section

Meeting of the mind

The Arch section quickly agreed alcohol was the only answer to "What machine should we make"

After a couple hours of discussion, we decided on a basic concept and divided the tasks betweeen hardware, software, rack, and pouring mechanism.

The Pouring Mechanism

drip, drip, drip

To pour the different liquids from different resevoirs into the target cup, the mechanism team tried out several passive pour mechanisms.

They tried a "hamster" drip method in which pushing up on a water stop would allow water to flow.

They tried a syringe injection method.

They settled for a simple method of adjusting the height the alcohol resevoirs and allowing gravity to pull the liquid into the target cup.

Your browser does not support the video tag.

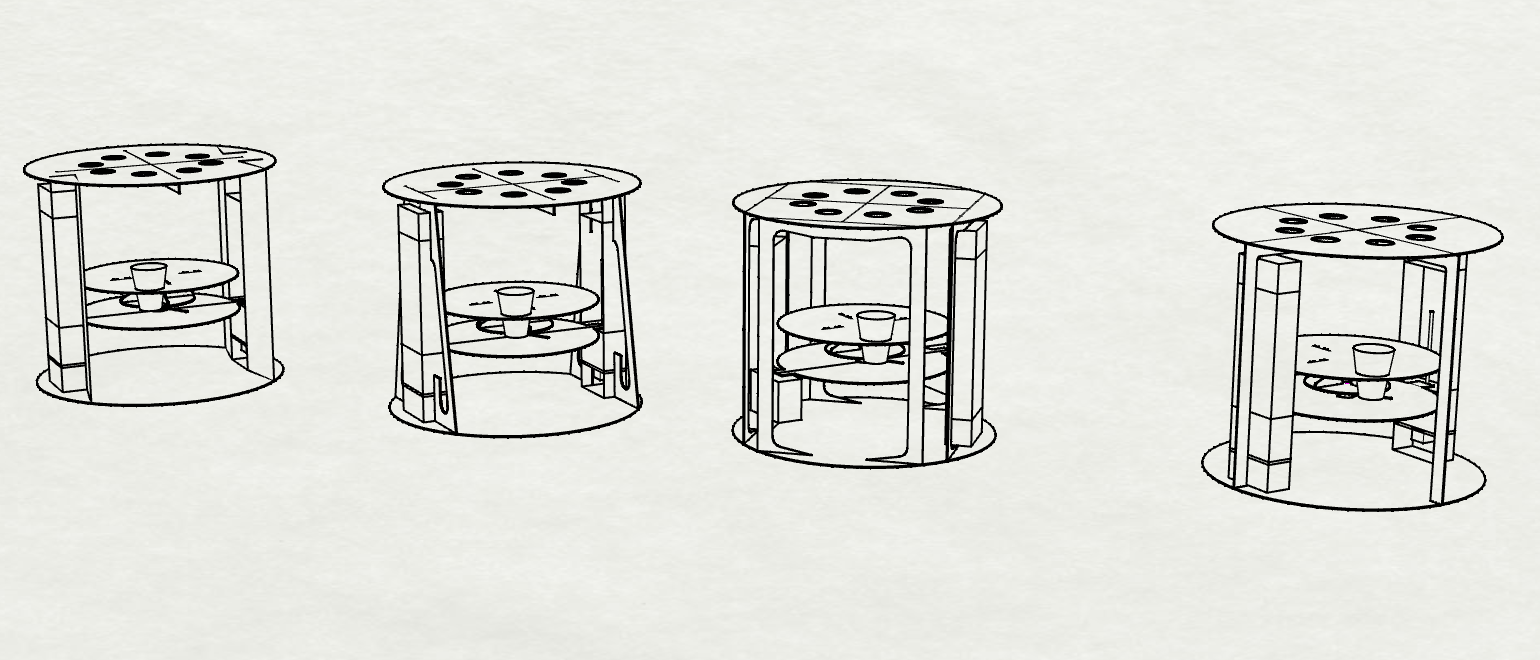

Sam (below) led the team in designing a pressfit rack design.

The Rack

building the thing to hold the alcohol.

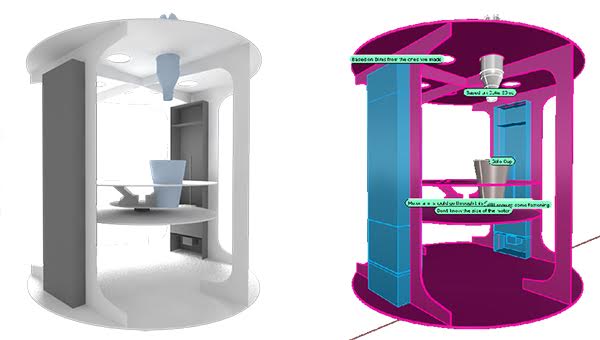

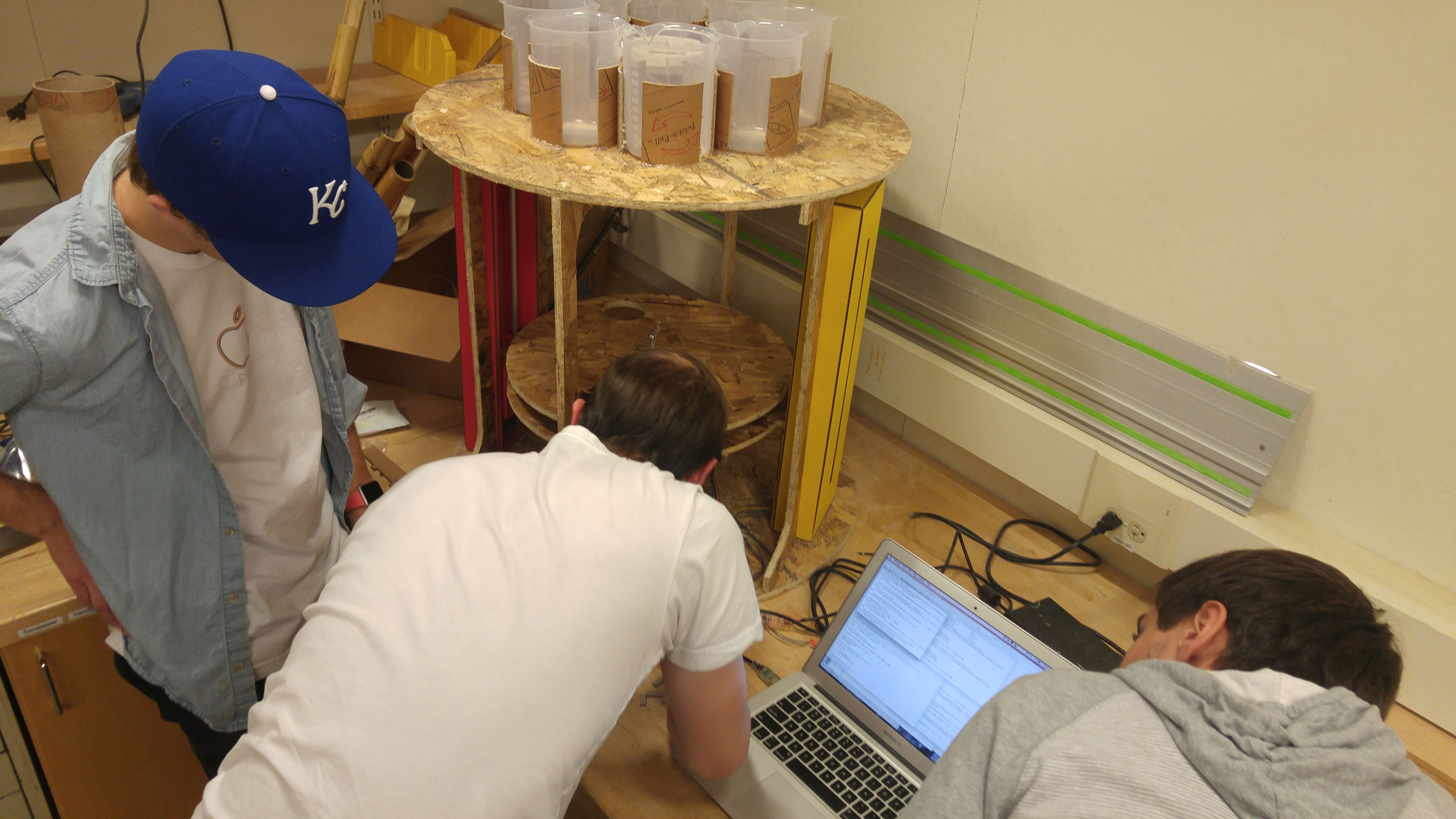

The rack team was tasked with designing something to hold the alcohol and the recieving cup. Over the course of several weeks the rack slowly took form beginning with CAD, laser cutting a prototype, making alterations, milling a full scale rack, and then a series of improviations to secure the motor to the spinnning tray.

The rack team consisted of a motor subteam that needed to figure out a way to attach the motor to make the tray spin around. More info here!

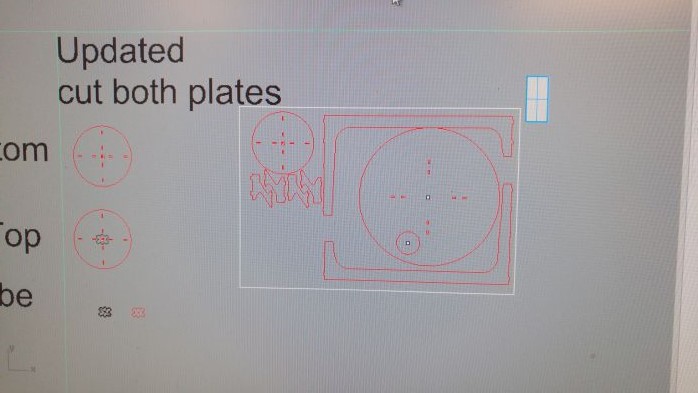

Laser cutting a 1/2 size prototype of the rack.

The Software

one line at time

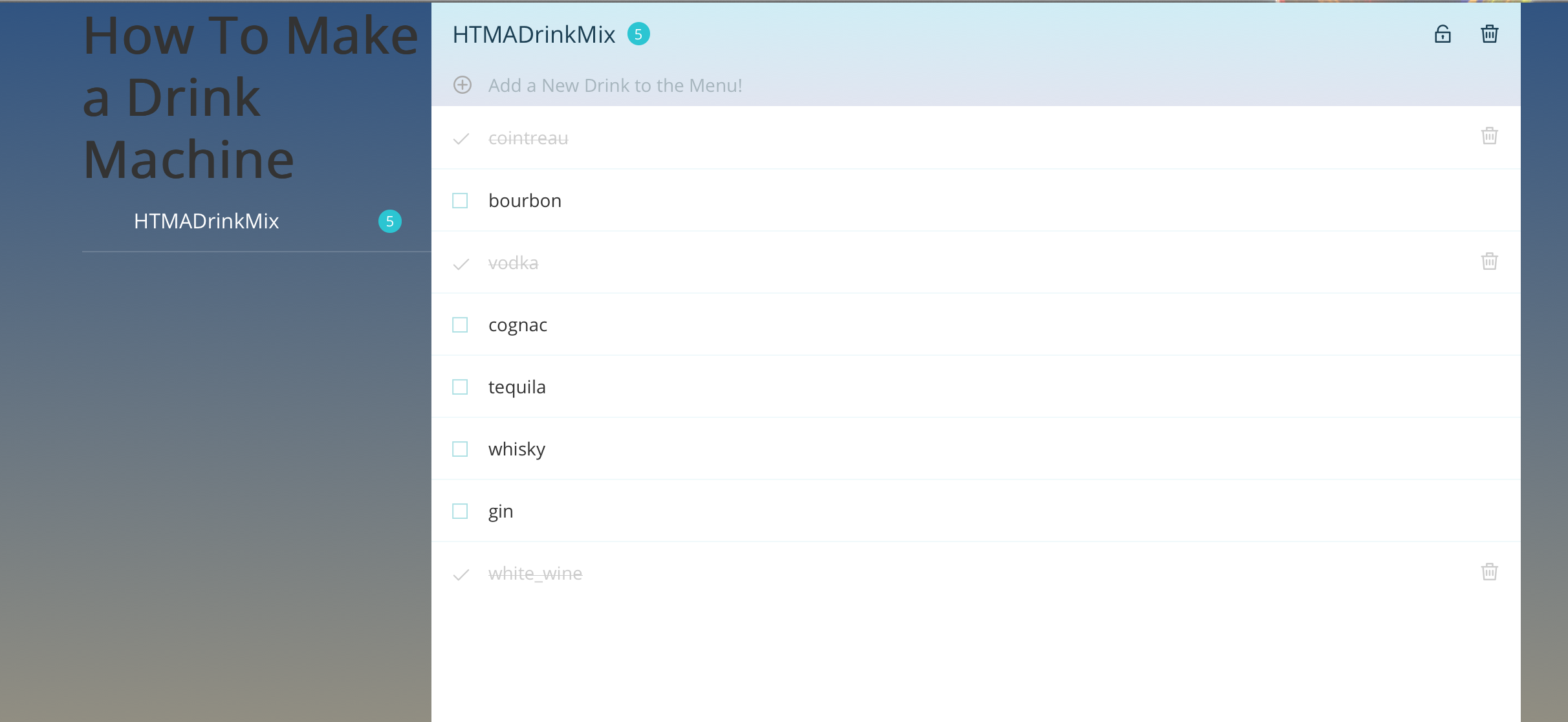

The software team came out of a mix of several different teams. In the end came down to those doing the backend programming to move the alchohol tray up and down and to spin and a team that built the frontend interface for people to order a drink online via a webpage. More info here!

The Assembly and Trials

Integration of the different parts revealed some issues that required troubleshooting:

the tray didn't spin, too much friction

need to develop a ram that raised the elevation of the alchol resevoirs

The Final Product!

Taaadaaaa!

Presenting

Neil about to imbibe before we start the machine