Week 6: Electronics Design

There's this amazing fact about "how to make almost anything" weekly assignments: you get faced to a problem which you are completely unfamiliar with - and there is no way you can actually and completely learn it. However, you spend one week, desperately jumping from this tutorial to that tutorial - this book to that book, etc. To understand something, and after that one week, you find yourself able to "solve" that problem- just like that!

I started my week by reading different materials to get myself familiar with electronic design. For the starter, the first chapter of "art of electronic" is a great source for getting familiar with basics of electronic PCB design. Reading the data sheet for ATTiny is also very important to understand the hello-world PCB design, and any other programmable PCBs.

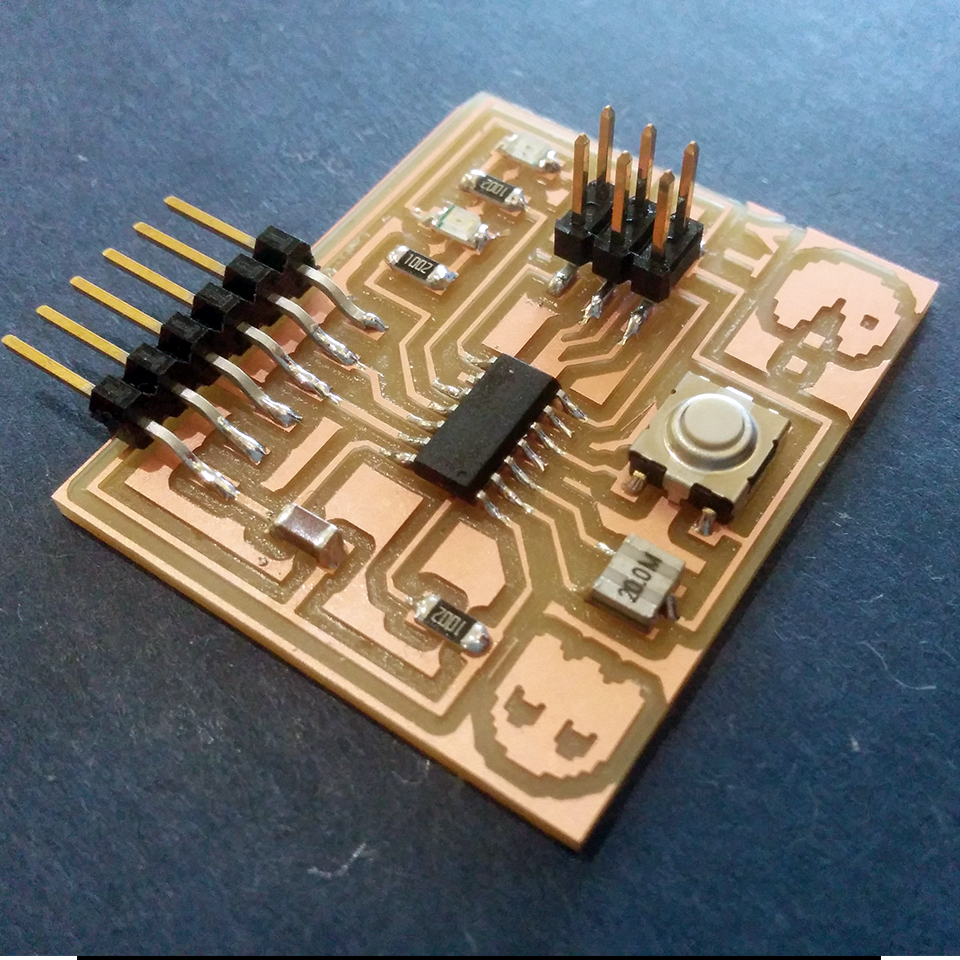

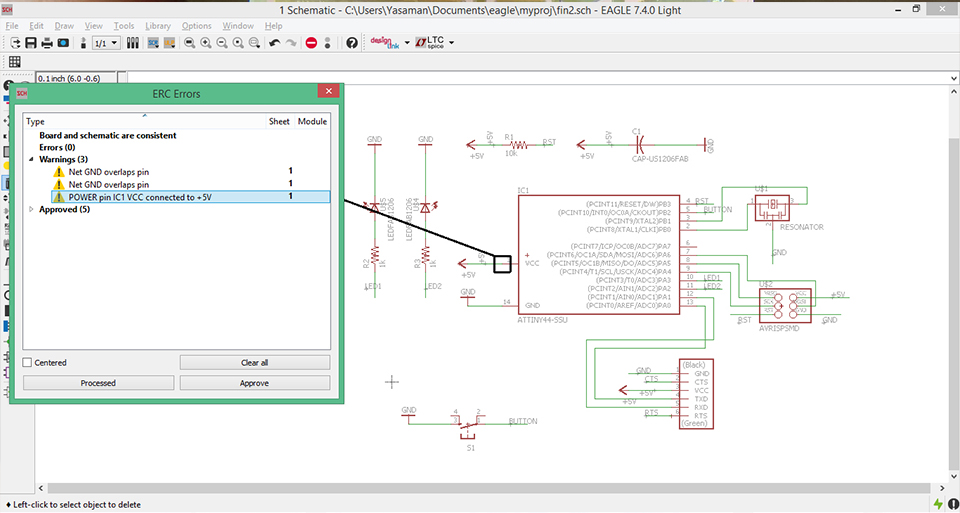

Design in EAGLE: Schematic Design

It's not easy to design a PCB in EAGLE, but it's a completely amusing job - like solving a puzzle! It starts by choosing the components from the library, and making the connections between these components. There are a lot of things you learn just by designing in EAGLE's interface, understanding the errors that it gives and trying to solve them. I started my schematic EAGLE design from the scratch for more than 6 times!! First attempt looks absolutely ridiculous right now, but final design was done in less than 30 minutes!!! That's the improvement you achieve by sticking with something!

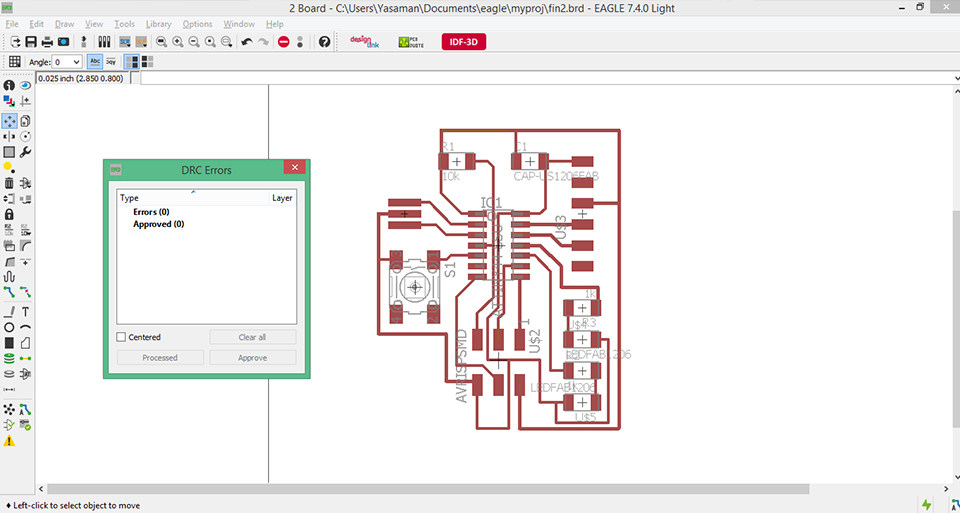

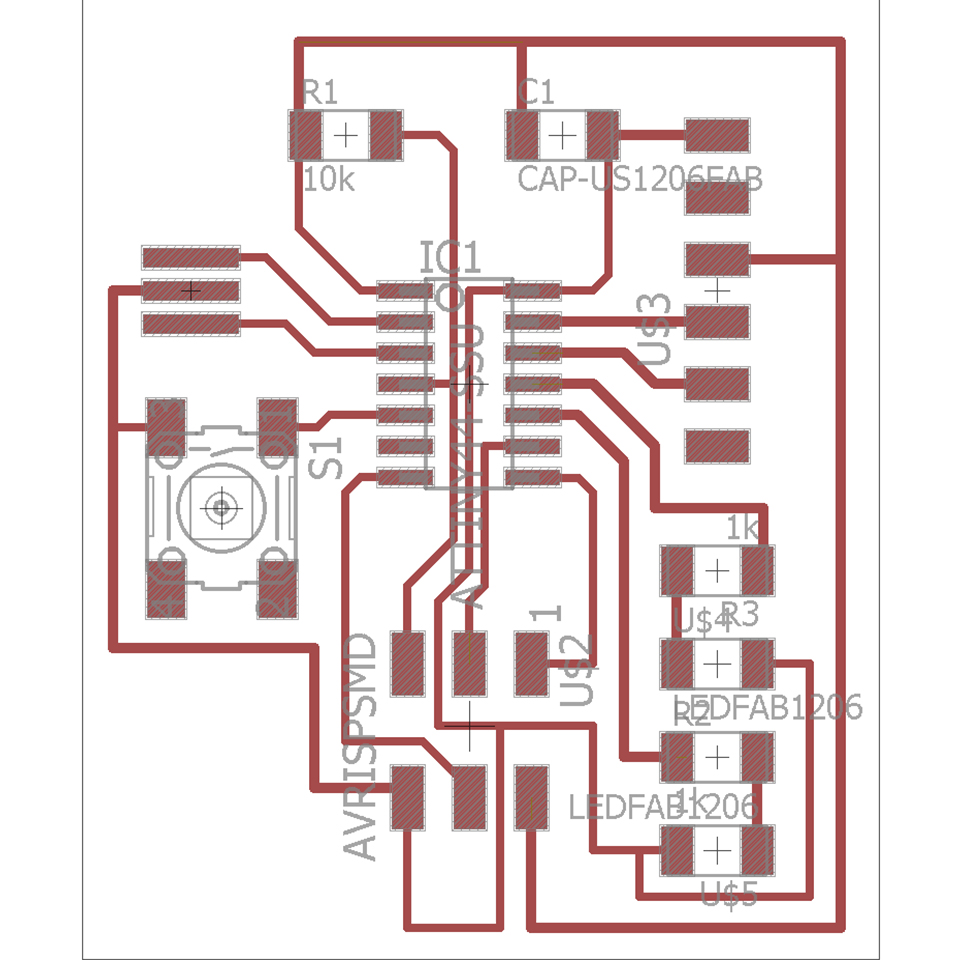

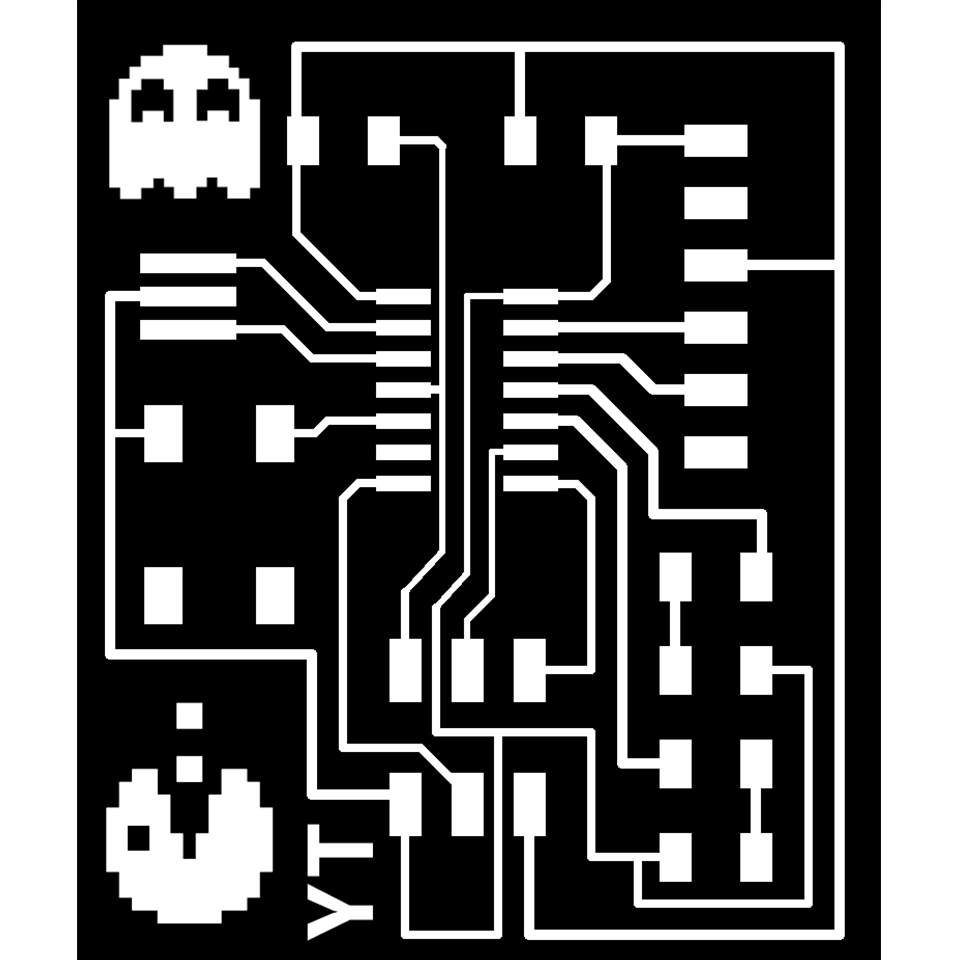

Design in EAGLE: Board Design

Board design is the stage in which you turn your schematic connections into roots - the ones to be exported as image to the milling machine. The locations and rotations of components are very important for preventing overlapping roots, need for using jumpers and etc. After finishing up with turning net too routes, and checking in for the errors and debugging them, I exported two image files: one of components, their values, connections and basically everything in design, and the second one only consisting of traces, as a monochrome image to be the input for FabModules and Roland milling machine.

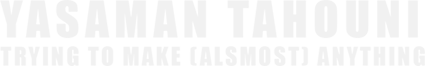

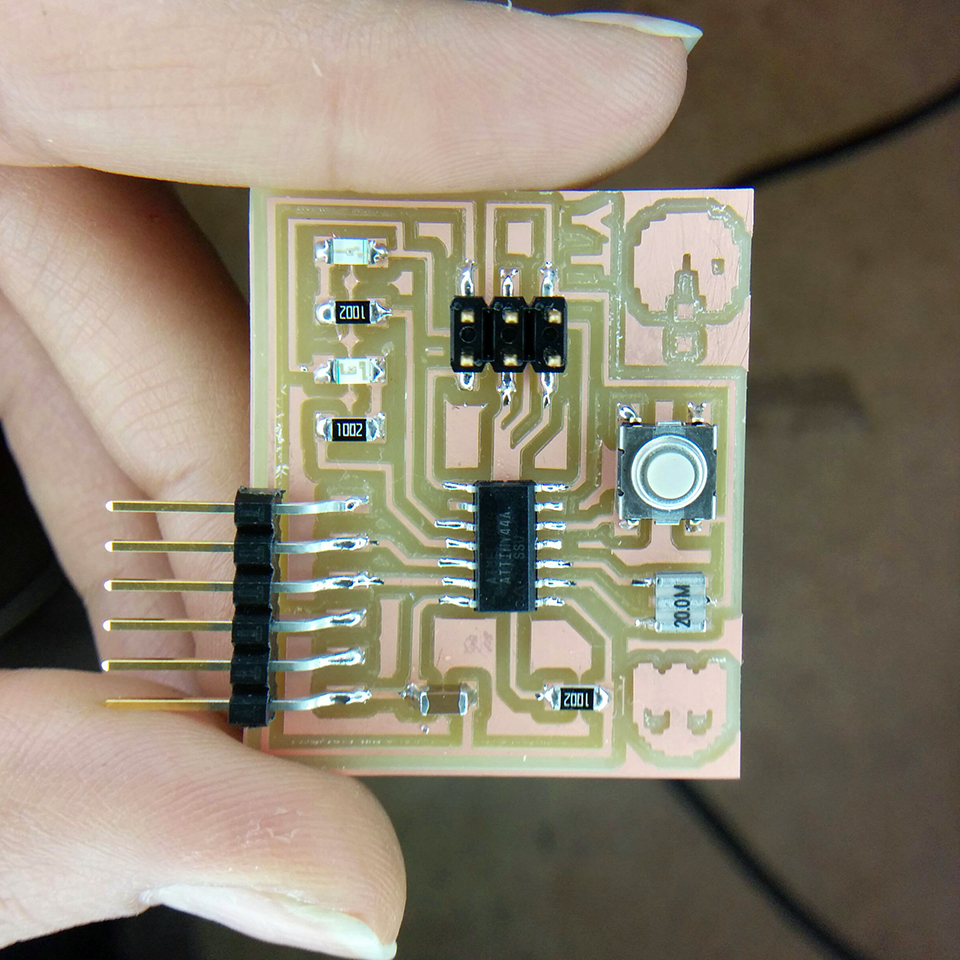

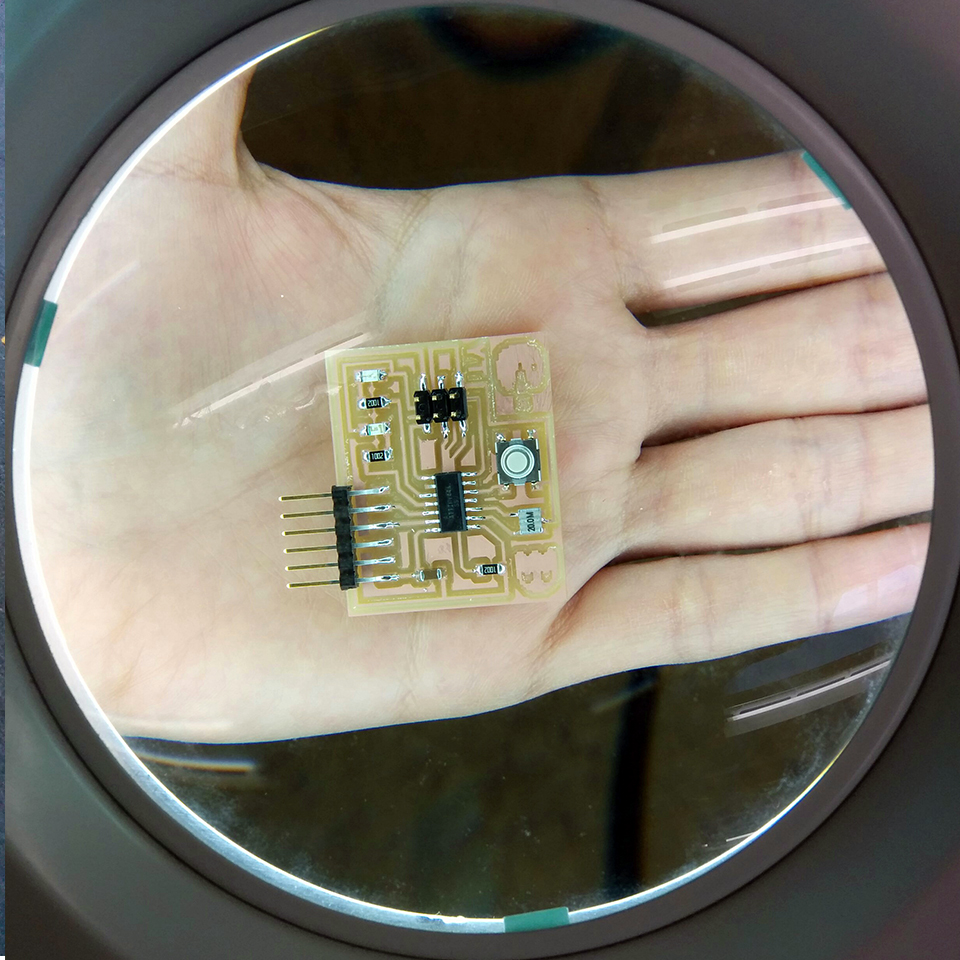

Fabrication

Fabrication process was exactly the same at Week 3ís assignment, so nothing new! But still, amusing and amazing.

Board design is the stage in which you turn your schematic connections into roots - the ones to be exported as image to the milling machine. The locations and rotations of components are very important for preventing overlapping roots, need for using jumpers and etc. After finishing up with turning net too routes, and checking in for the errors and debugging them, I exported two image files: one of components, their values, connections and basically everything in design, and the second one only consisting of traces, as a monochrome image to be the input for FabModules and Roland milling machine.