I must say, at the first mention of soldering, electronics and programming I had a small panic attack. This was my first project working with electronics and I still have a long way to go to truly understand what I've just put together. I do feel much more comfortable with the practical skills and now perhaps the understanding will follow...eventually.

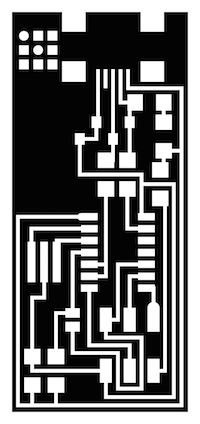

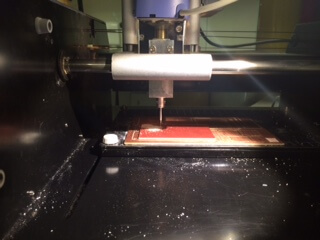

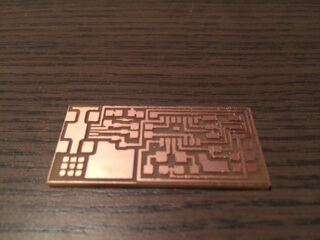

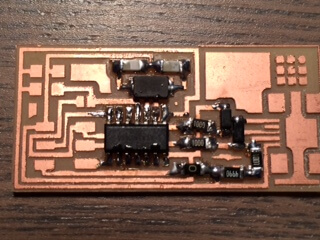

The first part of this project was working with the Roland table top mill. I've used full scale mills before so I felt pretty comfortable understanding the necessary steps. The first, of course, was to load the correct settings on fab modules and load the traces. Setting the origin was a little bit difficult as I was not sure how close the traces would be to the edge. I conservatively decided to put the origin for the traces path about double the width of the interior path into the material. Above are the regular designs for the FabISP board.

I first milled the traces (with a depth of 0.12" as opposed to the automatic 0.10") and then pressed View on the machine to clean up the dust and make sure the cutting depth seemed consistent. There were no issues so I proceeded to load the interior toolpaths. Again the milling went smoothly, just had to pull my part up and get rid of the double stick tape that was holding it down.

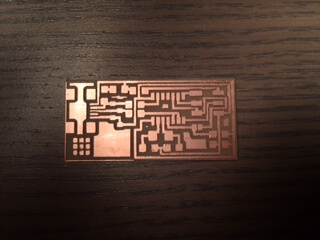

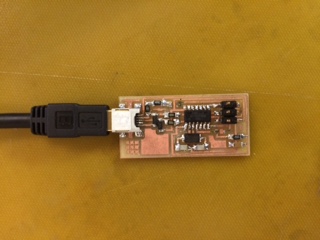

This is what the fully milled PCB board looked like. Some of the traces are still a little fuzzy even after scoring it with a straight edge and cleaning it thoroughly. I double checked to make sure there weren't any bridges though so really it's just an aesthetic issue at this point. Perhaps it was the speed of the tool or how sharp/blunt the 1/64" end mill was when I used it.

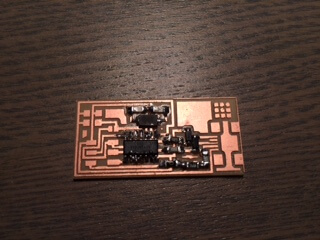

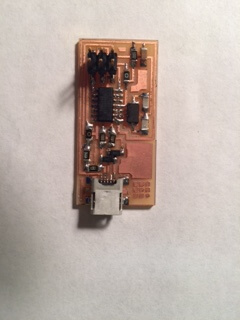

And so the adventure began. I never knew how shakey I was until I tried to solder. The resistors went okay except for my first try which turned out wonky and diagonal (another aesthetic issue, hopefully more practice will fix this), but the rest of the resistors were okay. Unfortunately, my first try on the microchip was a big solder mess. I also didn't know that copper wick existed at this point so I was worried I'd have to start over. Thankfully, my classmates told me of the magical copper braid that pretty much saved my life this week! Turns out slower application of solder especially on parts with little prongs is a useful skill to have... I will have to practice.

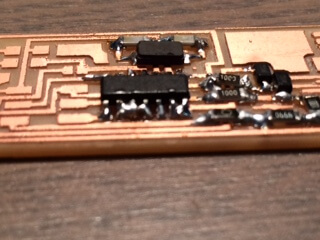

Yay! My microchip got cleaned up and I could finish up the rest of the components. I tried to solder in an order that would not make certain components too difficult. It sort of happened like that but some were a little harder than others.

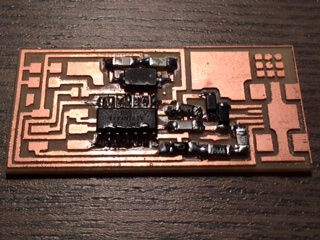

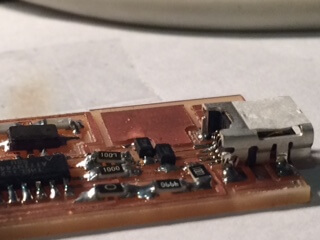

The bigger components, especially the usb connector, were pretty difficult to solder. Again it required a few tries and some copper wick to make sure none of the pads were bridged. I must say I was shocked when I found out I had to solder those tiny little connections in the back of the usb connector, but it happened and I have minimal PTSD. But all components were soldered successfully and I did a few full checks of the schematic and the board to make sure I hadn't accidentally connected traces.

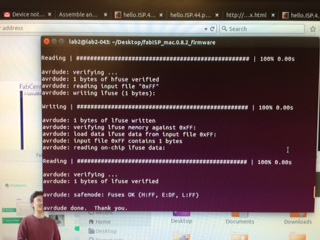

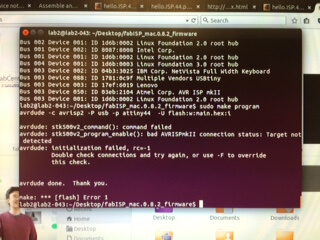

Programming was interesting as well. The first 10 minutes I was sitting in front of the computer lost. It was a little late and I finally tracked down a tutorial. Unfortunately, I was a bit tired and read the instructions too quickly. I was using the AVRISP programmer but I had changed the Makefile to USBtiny instead of keeping it using the AVRISP. The first series of tries of course then said I had an error because there was no USBtiny.... oops. Finally, thanks to Calvin's moral support and Nadya's most obvious question "why are you using usbtiny?", the programming went through without a hitch. Make clean, make hex, sudo make fuse, sudo make program... SUCCESS!

Even better... the usb was recognized by the computer! I unsoldered the jumper resistors and then plugged the board back in. Nadya explained that once the jumpers were gone, I could try to program something (knowing there was nothing connected to program) the computer also knows this and told me "Target not detected". Apparently, this confirms that my programee is now a programmer.WOOHOO!