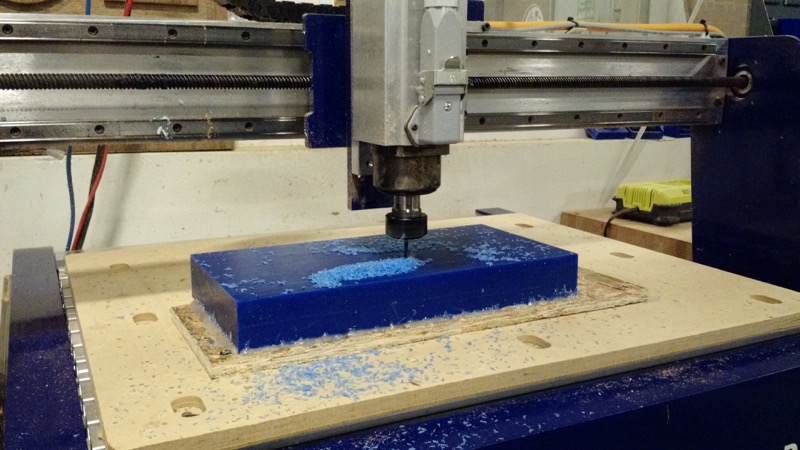

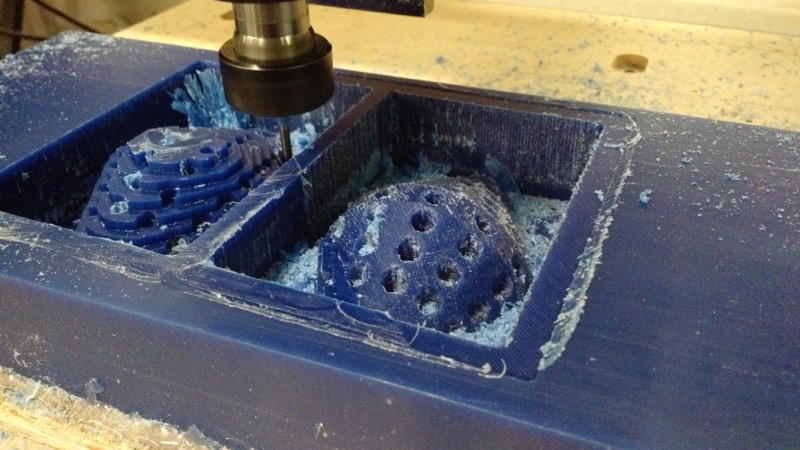

design a 3D mold, machine it, and cast parts from it

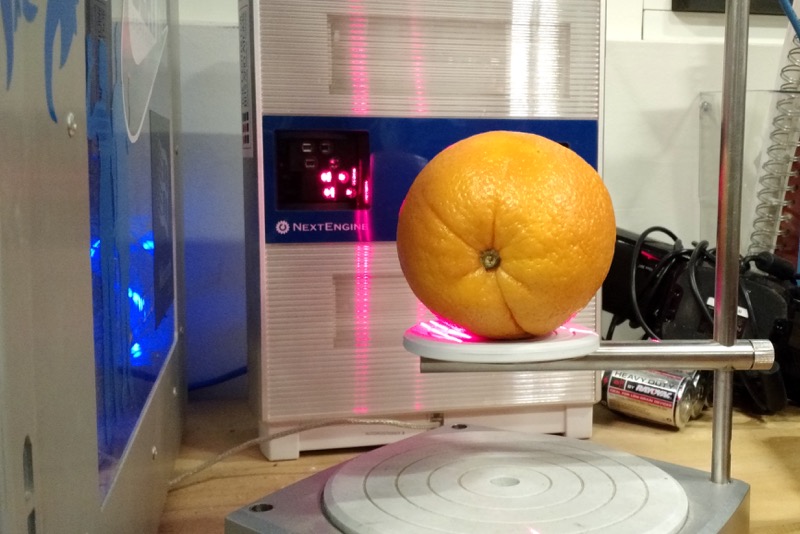

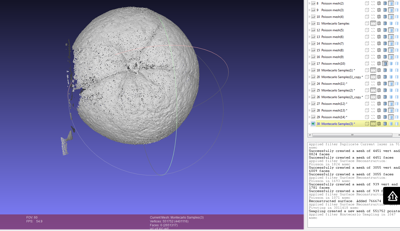

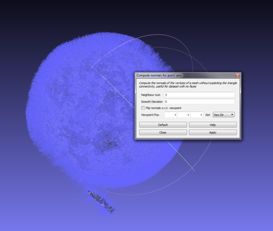

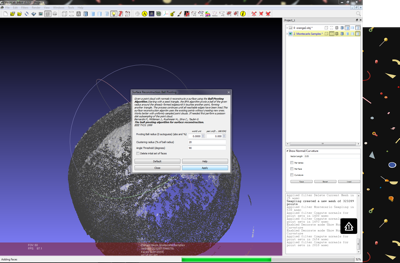

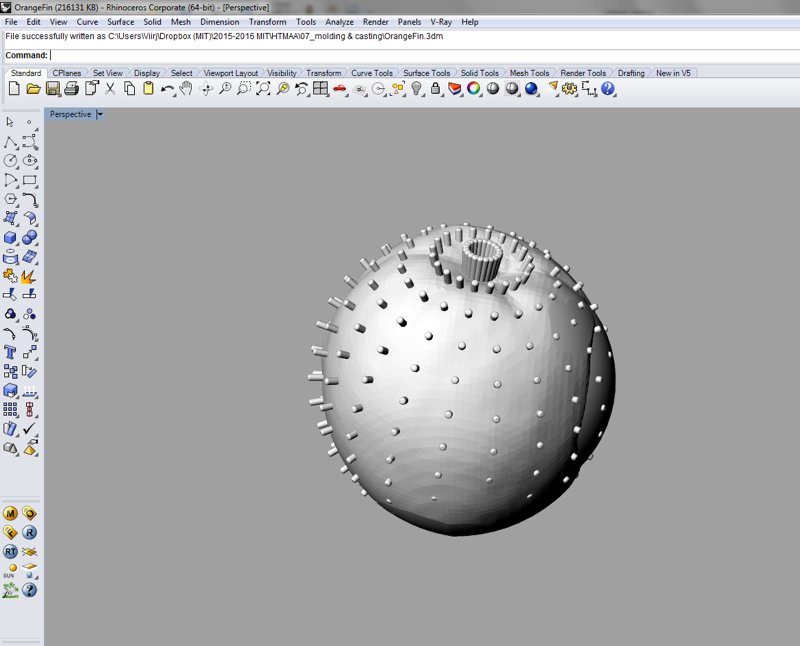

The object of my choice for molding was an orange for this assignment. I first used the NextEngine 3D scanner to scan my orange. Because the mesh that was generated from the 3D scan had a bunch of holes, I used MeshLab to reconstruct it. I did this by first importing the .OBJ file NextEngine generated. Then, using MonteCarlo Sampling, I extracted the points from the mesh. Hiding the layer of the original .OBJ, I selected to Compute Surface Normals from Points and then Poisson Surface Reconstruction to generate my final closed mesh.

Because the mesh that was generated from the 3D scan had a bunch of holes, I used MeshLab to reconstruct it. I did this by first importing the .OBJ file NextEngine generated. Then, using MonteCarlo Sampling, I extracted the points from the mesh. Hiding the layer of the original .OBJ, I selected to Compute Surface Normals from Points and then Poisson Surface Reconstruction to generate my final closed mesh.

Tools:

NextEngine 3D scanner > MeshLab > Rhino > Shopbot WAX > Mold silicone > cast

![How to make [almost] anything class Viirj Kan](img/logo.png)