This week I explored and began development of a graphical user interface for my previous kiln controller board. So far I have built up the functionalities required to run the heaters and read the temperature. For my final project, I'll be combining these alogn with an interface, implemented with the actual glass kilns we use. For this week, my goal was simply to generate a control system that could write to the board through the usb serial connection. Now that I have a feel for the programming, it should be possible to build a more complex digital control board with more of the functionalities we require for the glass kiln heating package.

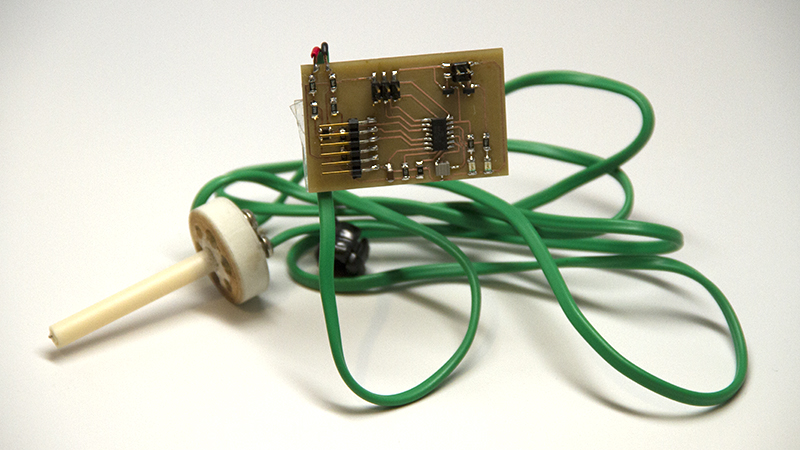

A previous project of mine involved a simple digital controller for solenoids in a pressure actuated extrusion system. Jorge Duro, who made the system, pointed me in the direction of a Processing library called controlP5, which contained a huge variety of customizable buttons, sliders, drop down menus, etc. I explored the library and ran the test with the board using a control knob set up. Initially I used these knobs to control the output for the indicator LEDs which run in parallel to the heating elements circuits. It was convient to just use them like indicators but later, the code can be much more complex, involving more commands and taking into account the thermocouple reading, which still needs to be calibrated.