Wax extruder head 2015

A wax extruder head

To be used to print honey combs for bees to live in.

In brief, my current research is about understanding cities as microbiological organisms. In order to do so, we have been doing preliminary analysis on Langstroth beehives around cities and have discovered a surprising amount of microbes in them. We understand that there is a microbial baseline within hives, and the differences are due to the immediate surrounding. Because beehives could only travel in a two mile radius, we can effectively create hyperlocal 'microbe maps', and understand the city in ways that we have never been able to visually see before. The world view in this project is both to discover what the invisible microbe world would look like, and also rethink the role of the hive in cities, beehive as a sensor. The next stage of the project might involve analyzing feral hives. I propose to extrude honey combs on top of structures that allow faral bees to make it their home, and allow us to collect their debris. The first step in this project will be to design an effective method for extruding wax, a material which they can consider to be their home.

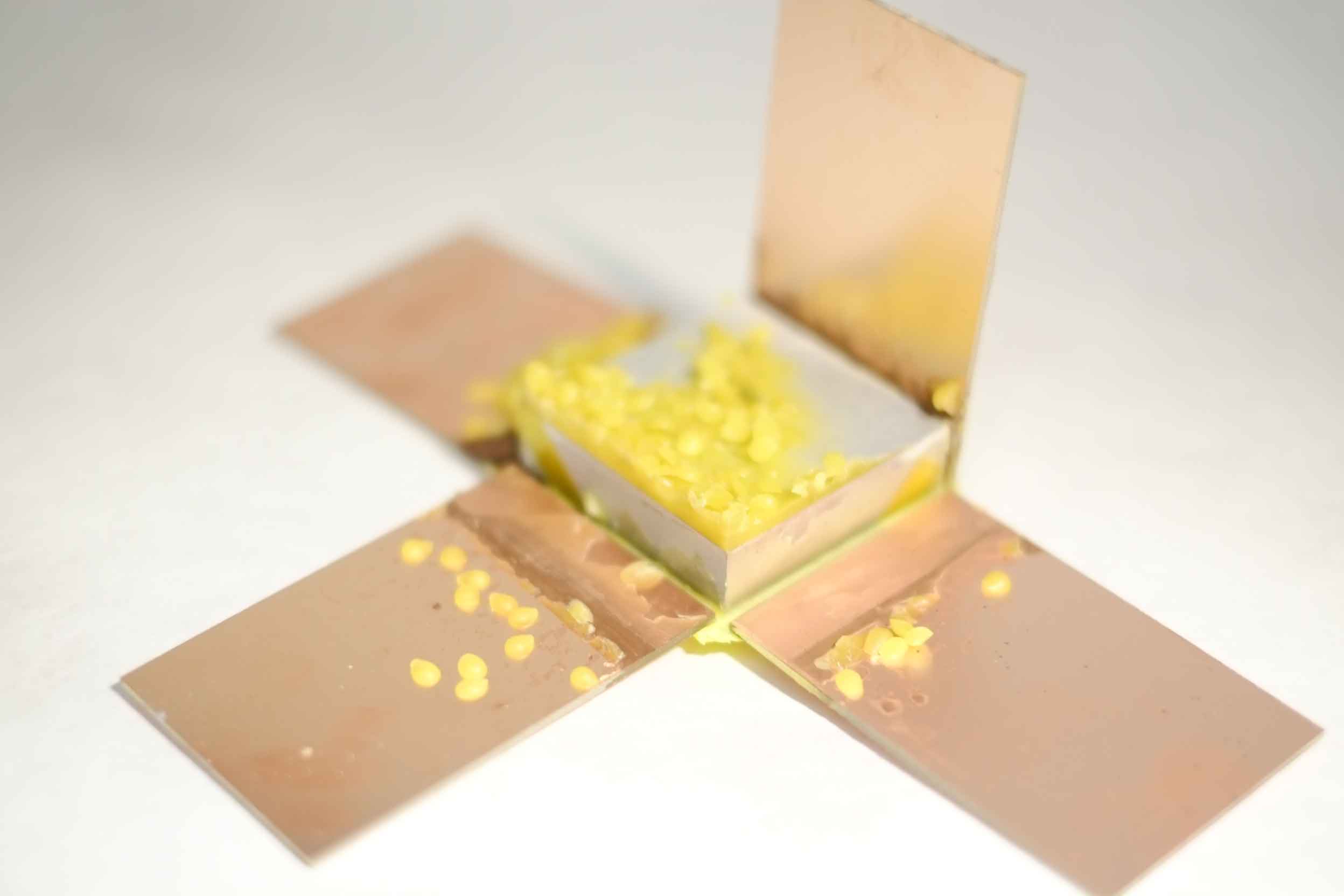

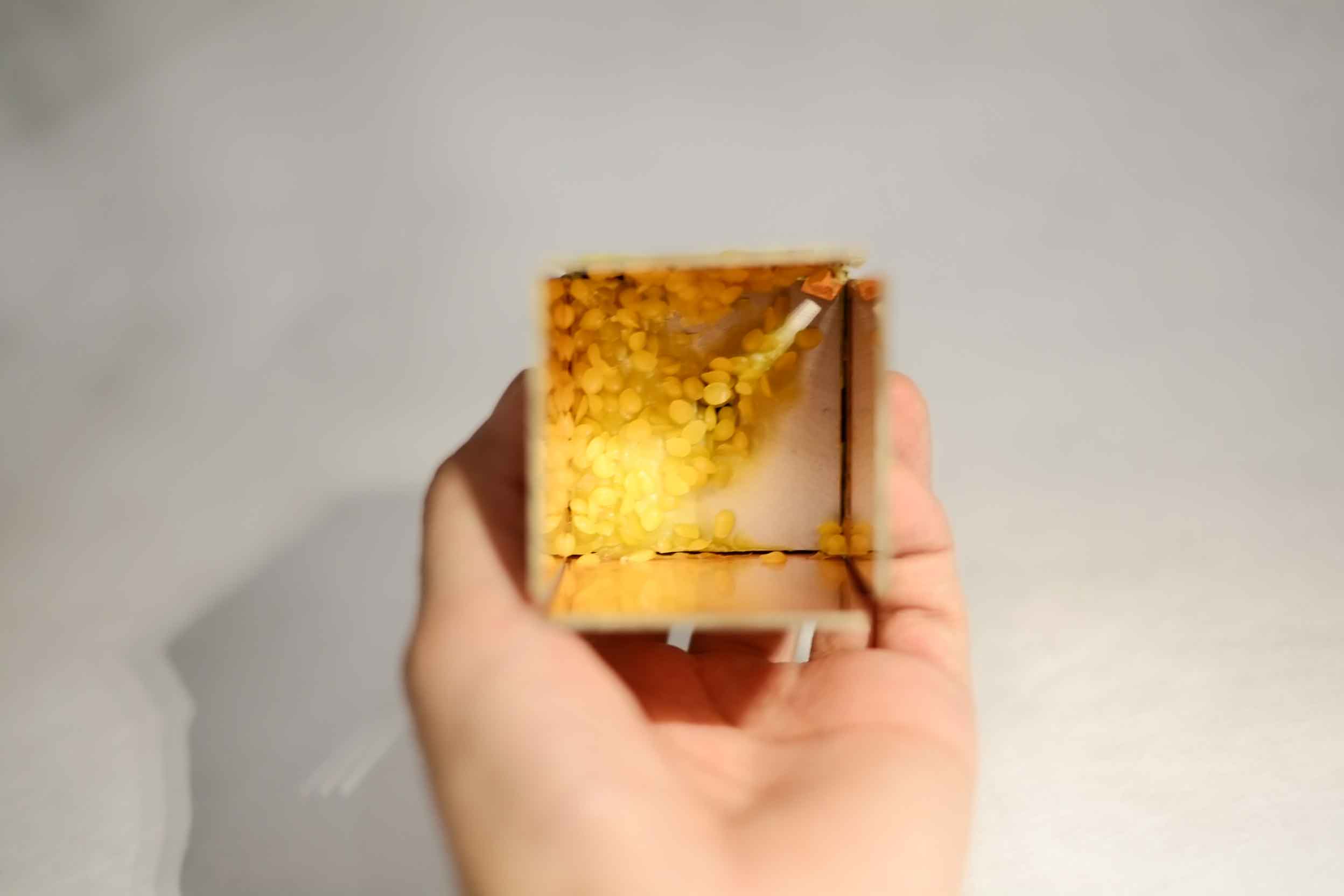

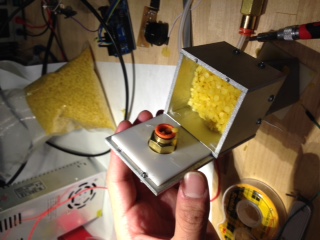

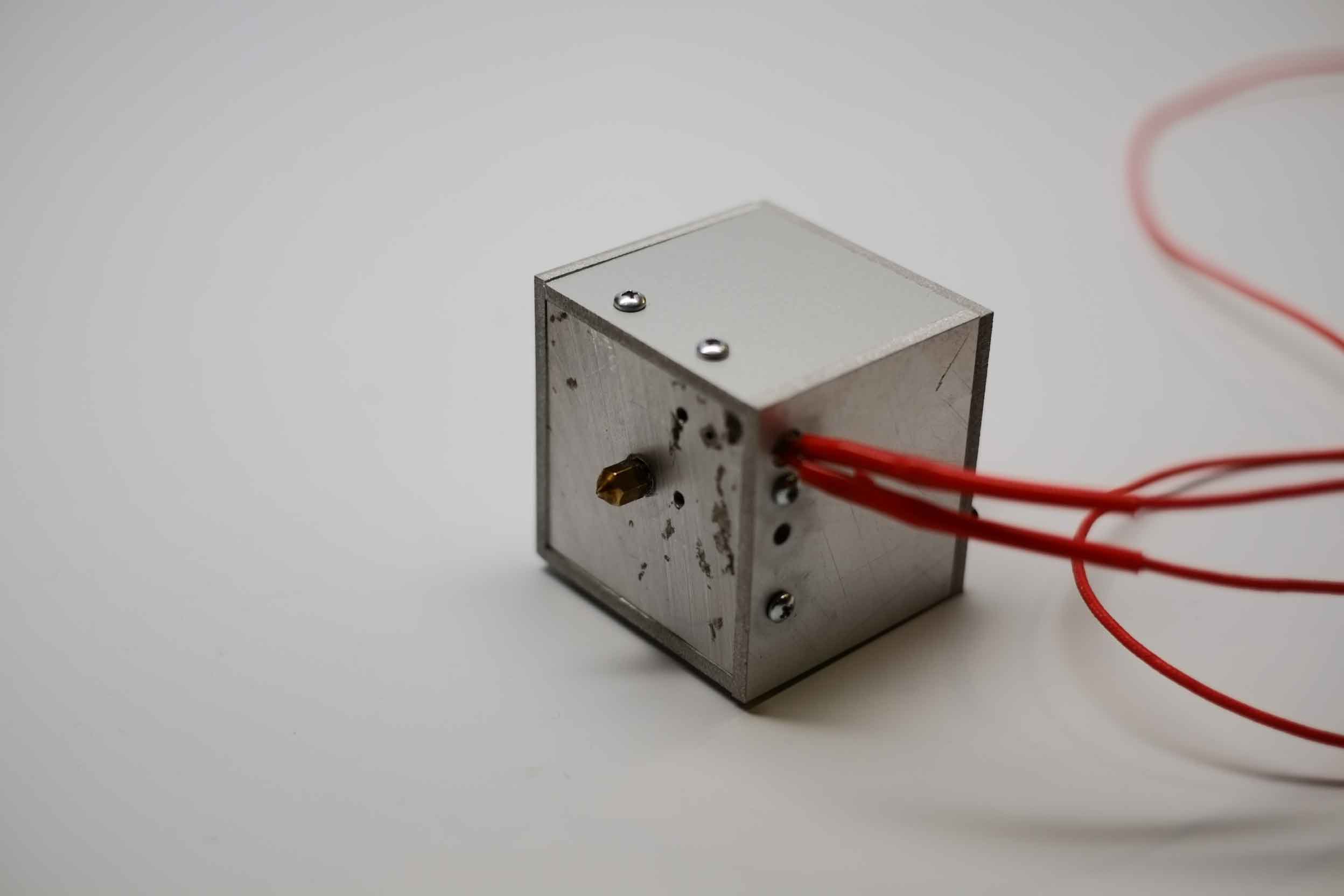

I began by heating an aluminum block using a heating element and see at which rate can it melt wax.

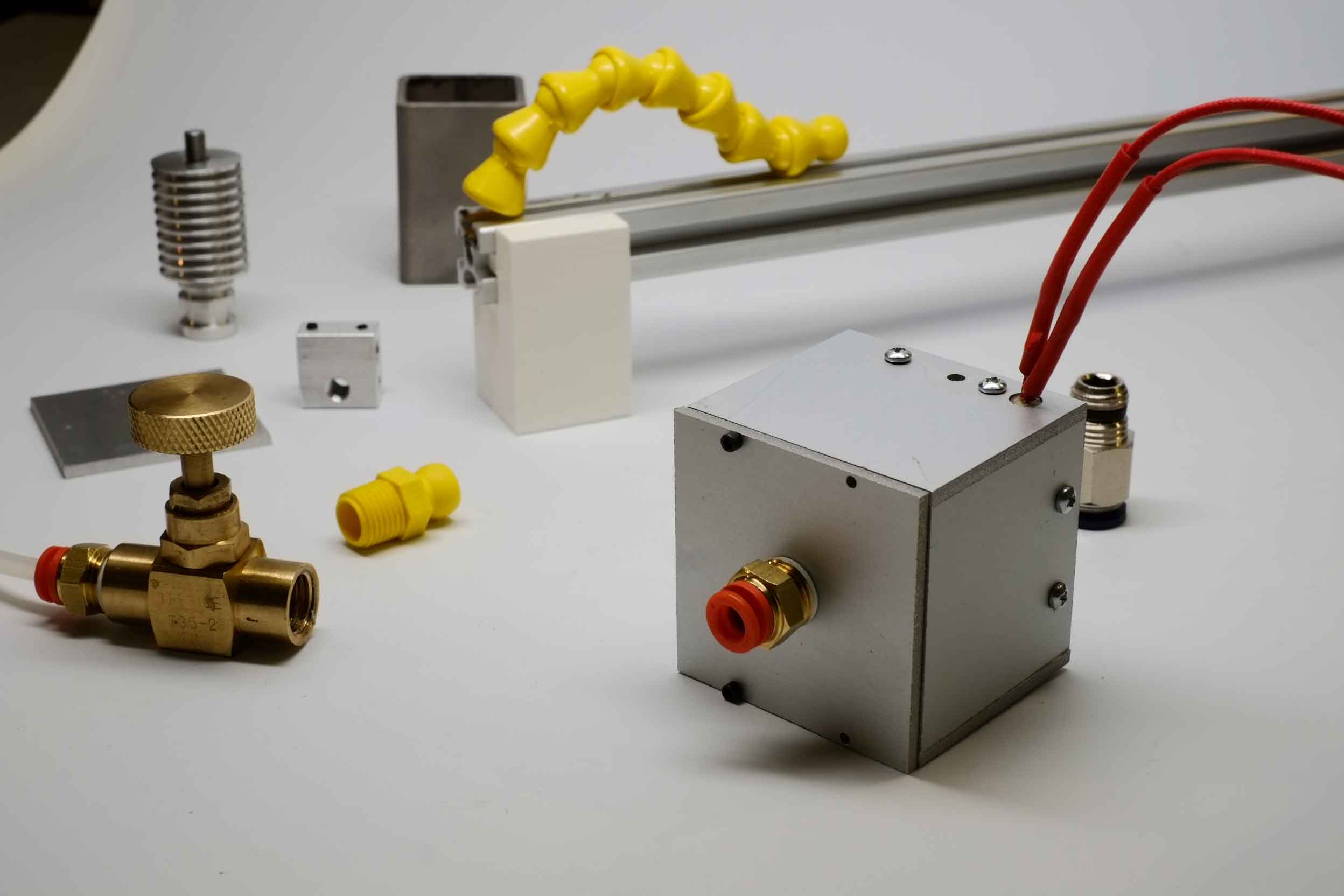

The core was milled to hold the heating element , thermistor, and extruder nozzel. I then waterjet walls to isolate the wax and distribute the heat more effectively.

The extruder nozzle was not flowing properly, so I drilled a larger diameter using a mill

Finally, I had to use a compressor to pump air through the nozzle. I added a 1/4" adapter for a compressor on the top lid.

Finally, I had to use a compressor to pump air through the nozzle. I added a 1/4" adapter for a compressor on the top lid.

There was a bit of air leakage, so I casted a gasket out of silicone thanks to Jon Bobrow.

There was a bit of air leakage, so I casted a gasket out of silicone thanks to Jon Bobrow.

For the temperature regulation, I made a circuit board that reads the current core temperature, and once the wax is molten,

it turns off the heating element using an N-MOSFET. ILL ADD A PIC OF THE PCB SOON!

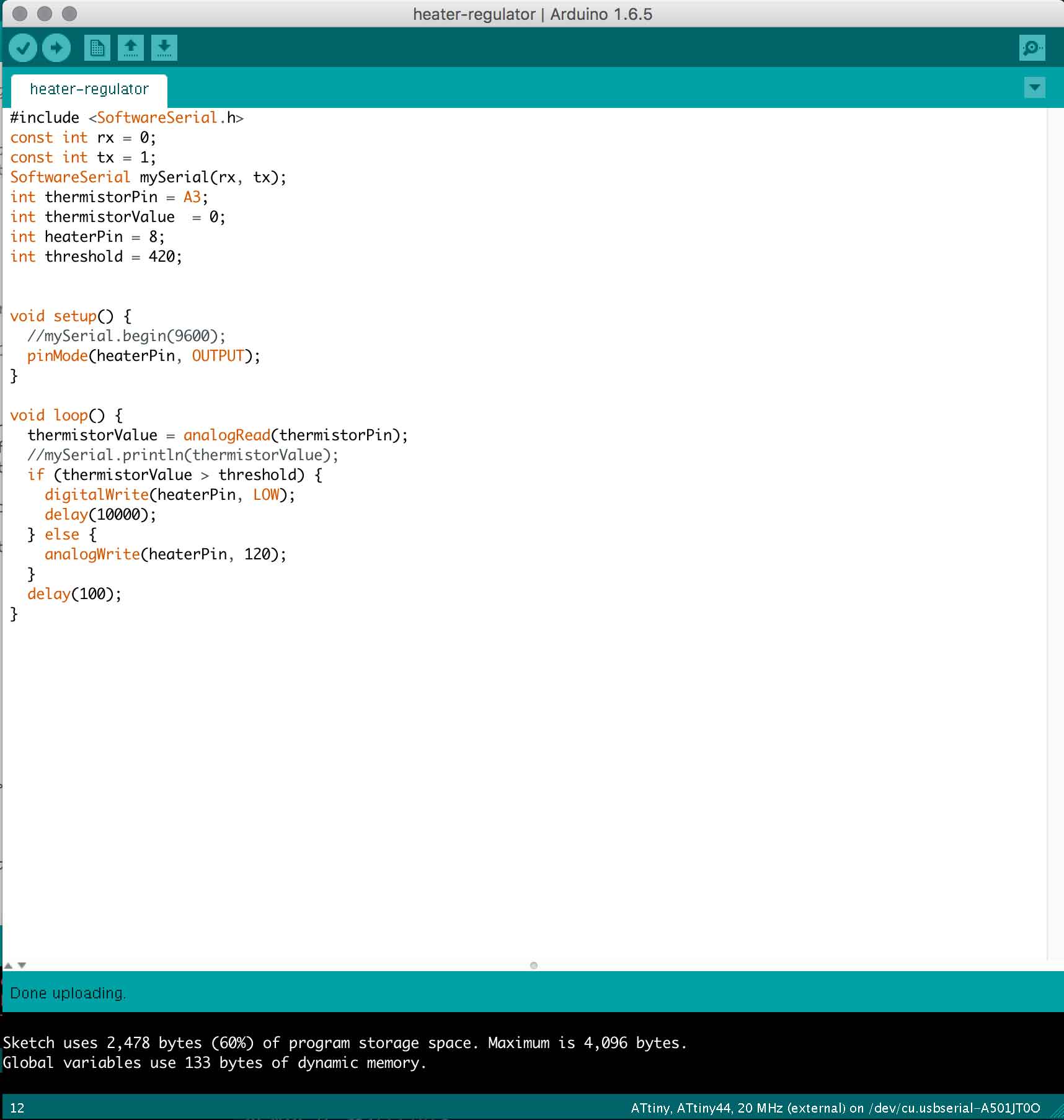

I used the Arduino IDE and Bootloader to write the code.

For the temperature regulation, I made a circuit board that reads the current core temperature, and once the wax is molten,

it turns off the heating element using an N-MOSFET. ILL ADD A PIC OF THE PCB SOON!

I used the Arduino IDE and Bootloader to write the code.