Molding and Casting 2015

Hydrostone Coffee Drip

A coffee drip made from hydrostone and wax.

This week we were to CNC an object that we wish to create multiple copies of by pouring material into a mold. I wanted to make a coffee drip and I knew what the design early on, so I began by sketching what the outcome should be.

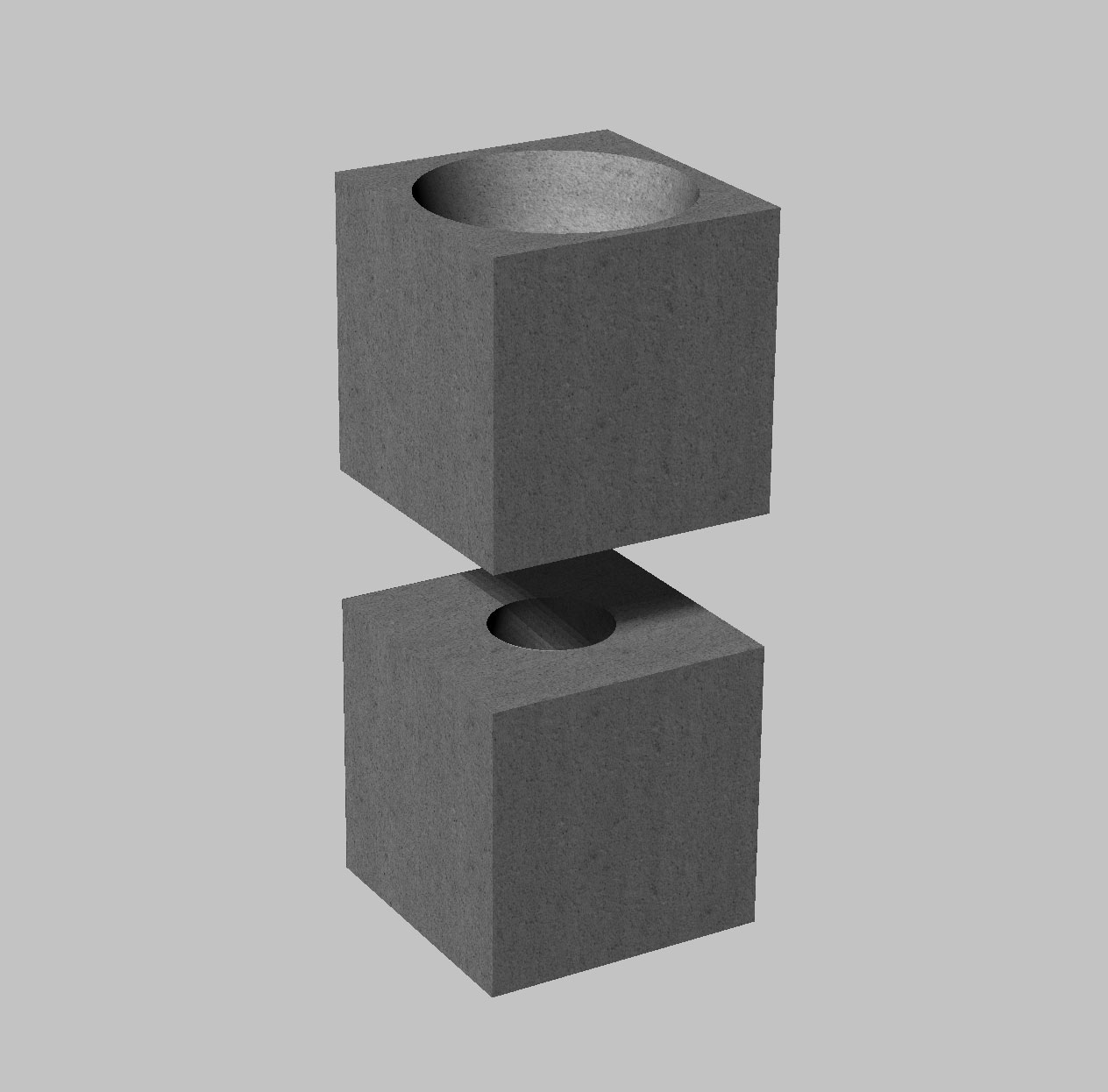

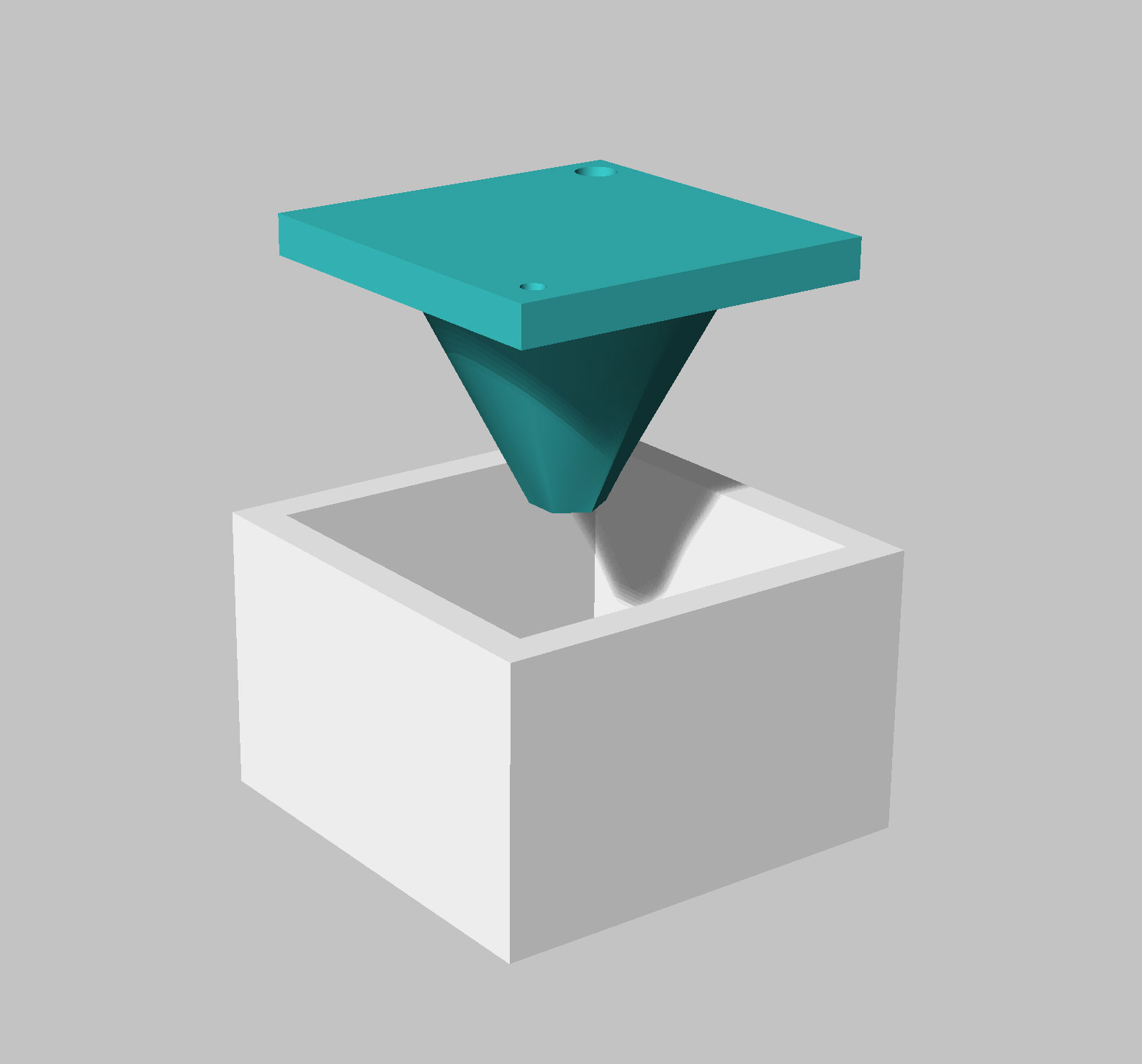

Because we are limited by the length of the bit and needed to complete this assignment during a heavy time of jetlag, I decided to cut some corners and make myself more efficient by casting components that already exist and minimize error from the machine (like seams if it were a three part mold). I decided to make a plate that would hold the existing coffee drip so that I can cast the negative portion of the drip and have extra space to then rest it onto the second part of the mold. There would be a puring hole and an air hole to allow the material to flow on the inside of the second part. Here is what I believed the negative mold should look like:

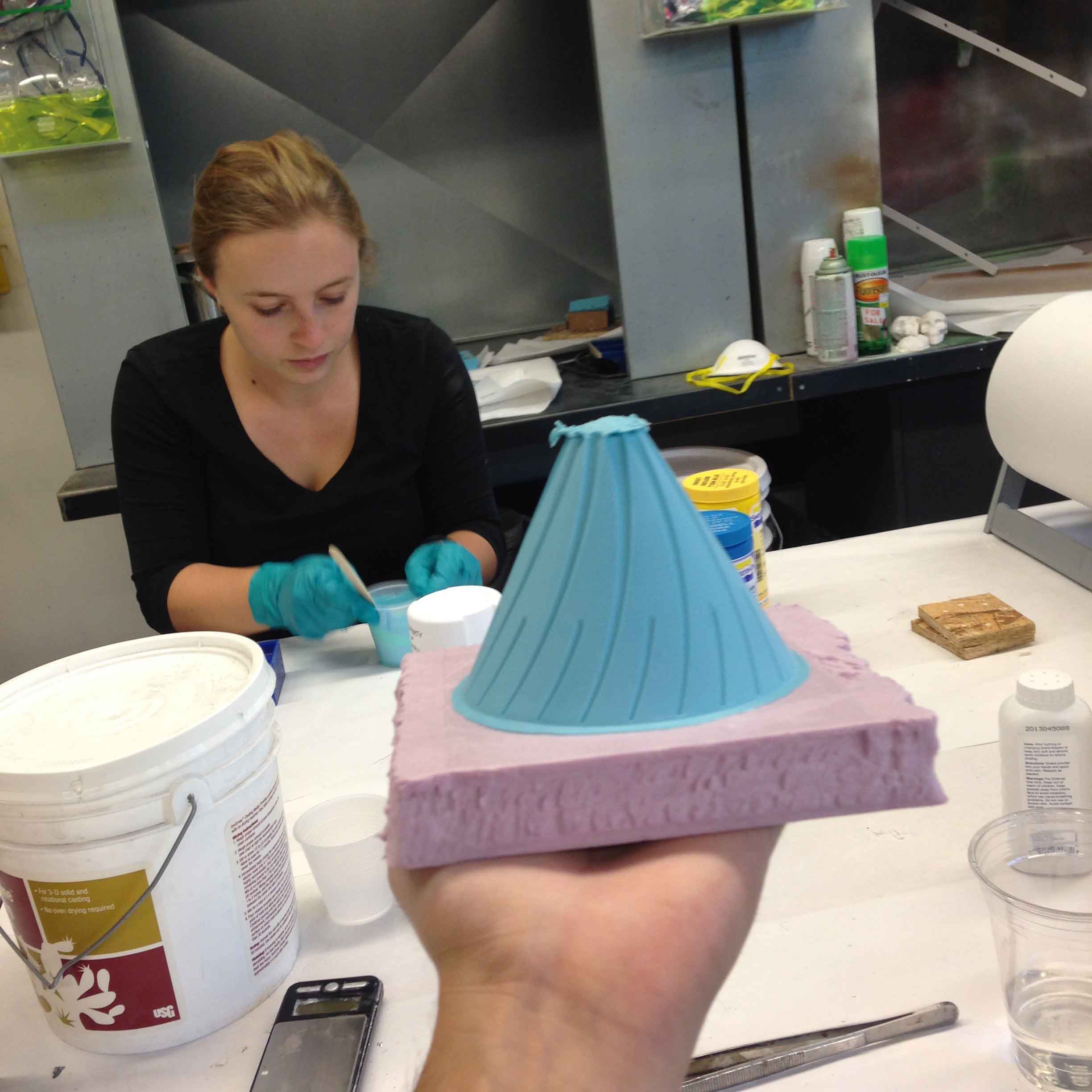

Ready to pour in some OOMMOOOOO!

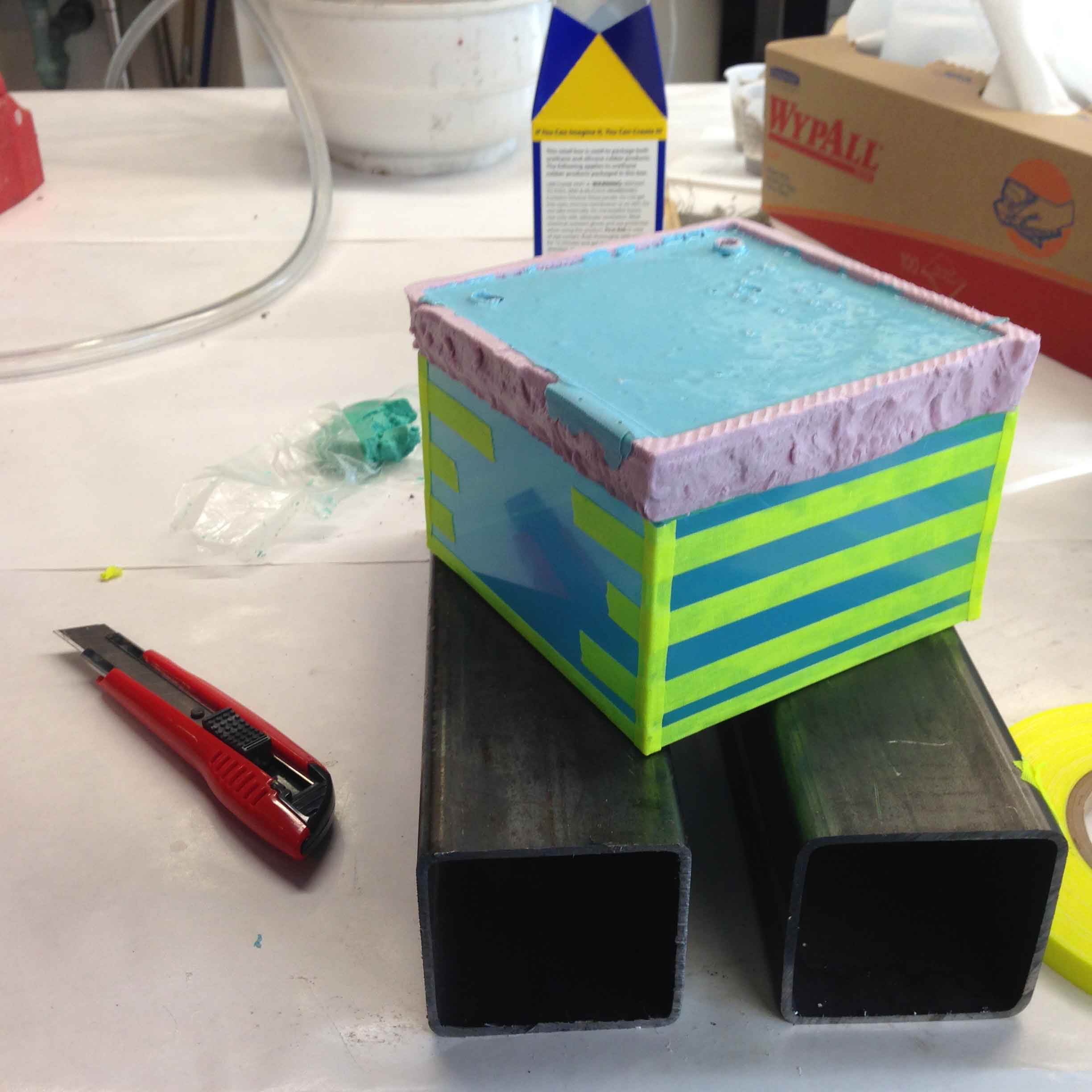

The negative came out really nice. The next step is to cut a box that would fit the negative and allow me to pour in hydrostone

Because hydrostone dries rather quick, I needed to make a large back quickly, so I made myself a tool from steel rod to mix large batches quickly by attaching a power drill onto it.