Press Fitting

This week we were tasked with generating a press-fit design kit using a laser cutter.

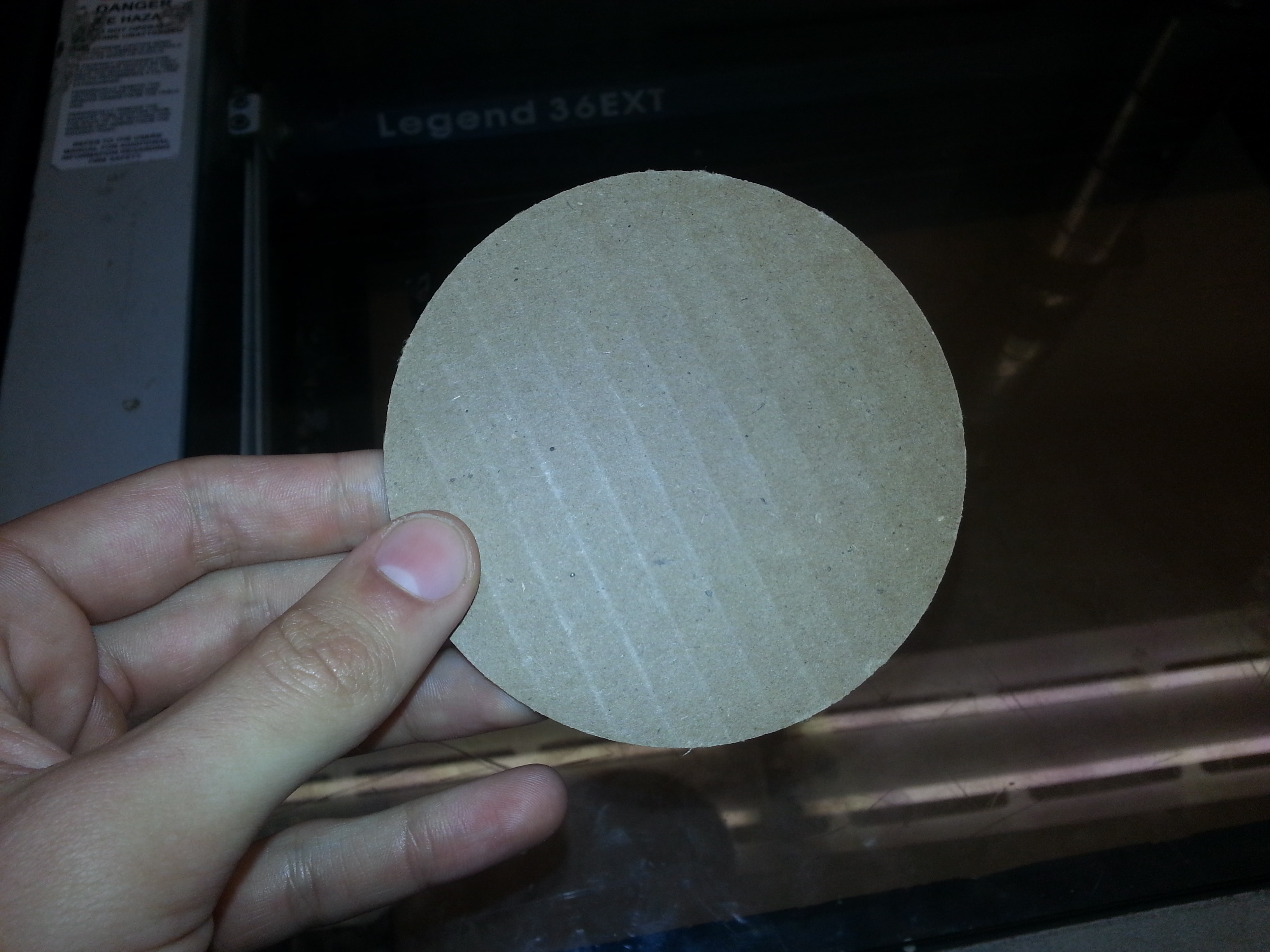

I had never used a laser cutter before, so to start I decided to cut out a circle. This took me almost 20 minutes.

I am truly a master of the craft.

Culling my urge to submit the circle as my project for the week, I decided to try something marginally more elaborate.

Construction Kit

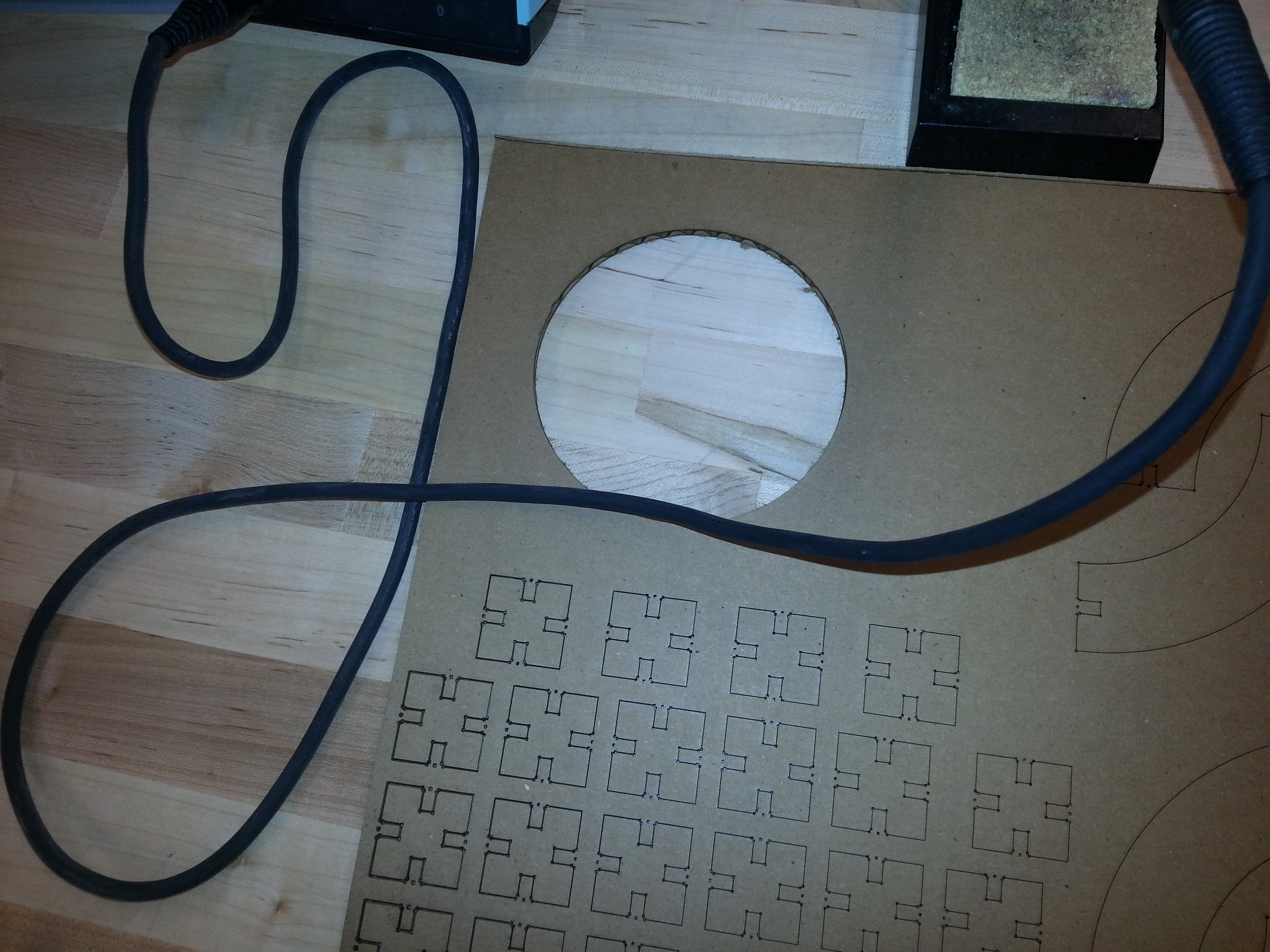

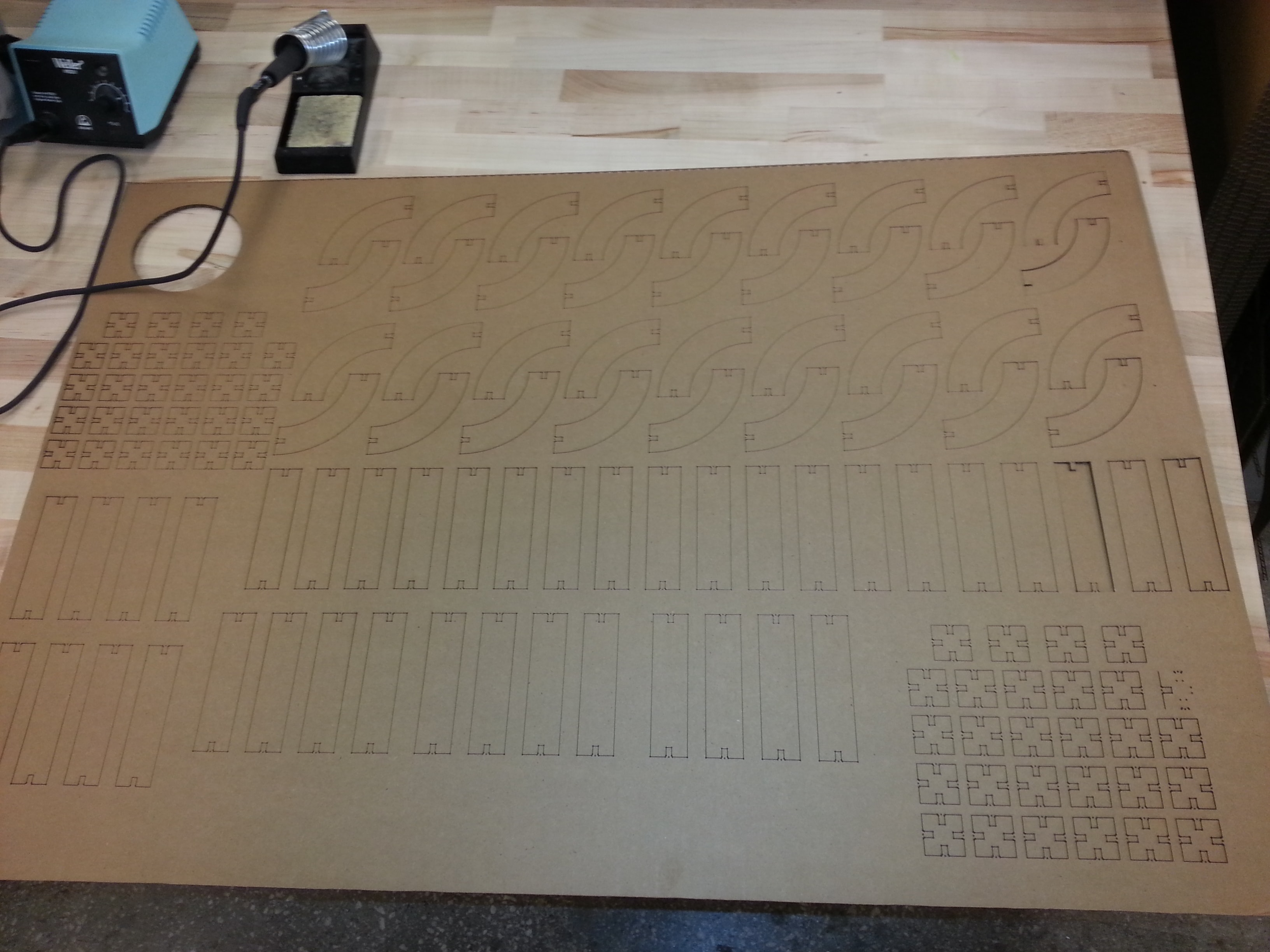

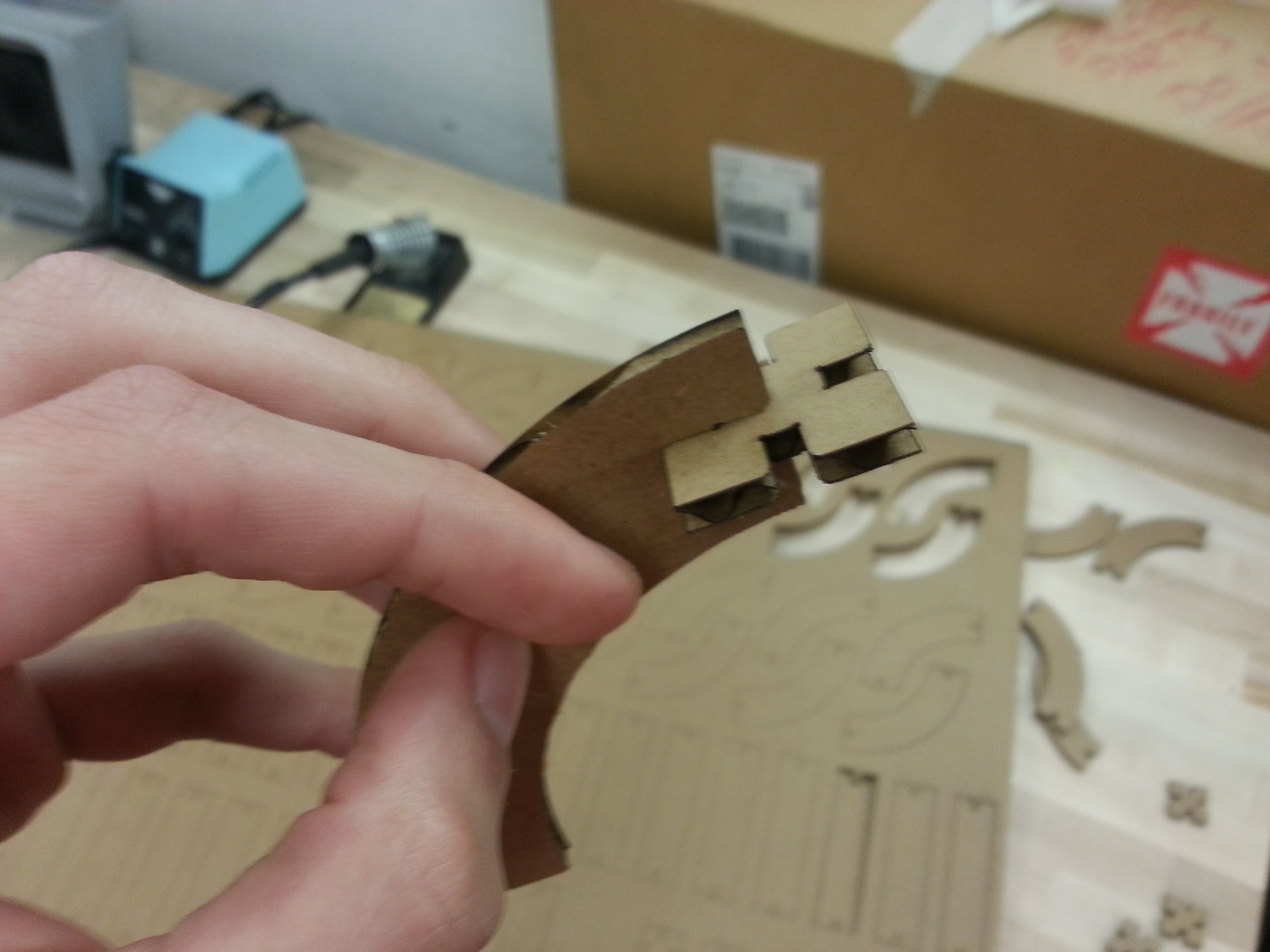

I decide to start by making a simple toy constructions kit, of vaguely the K'nex or Lego flavor. I settle on three simple pieces: a straight piece, a curved piece, and a connecting joint, as shown below.

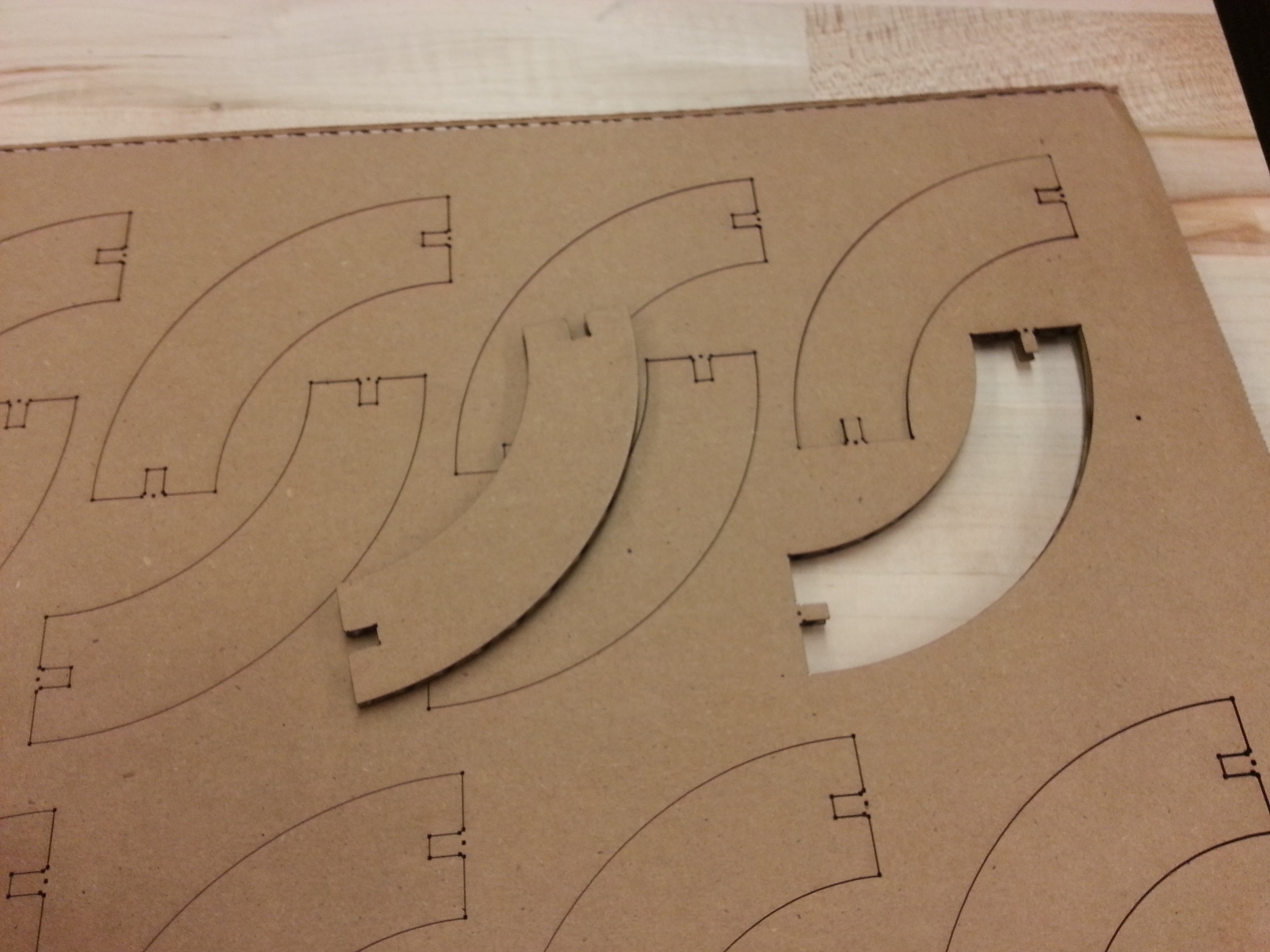

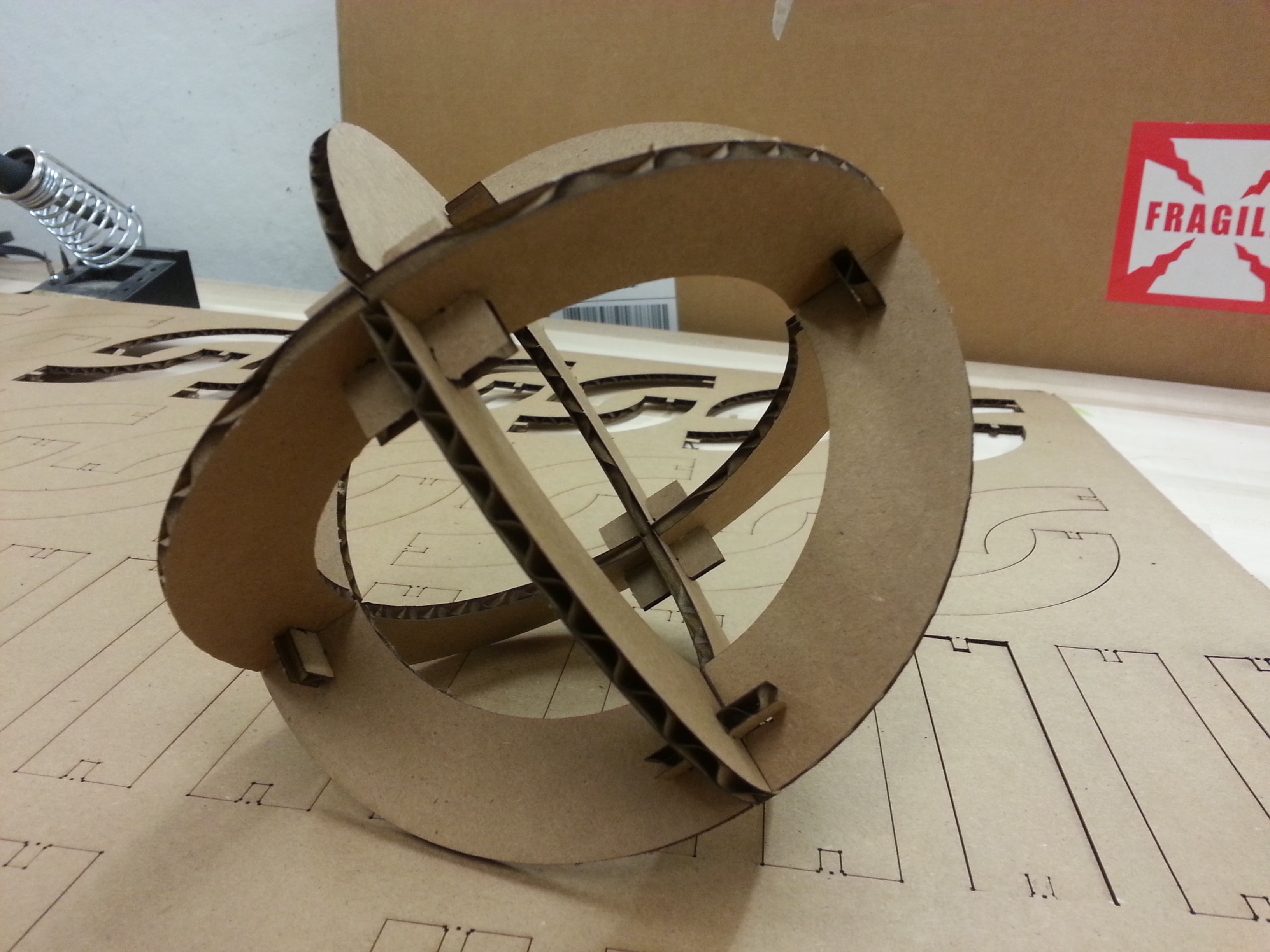

After popping out the pieces from the cardboard (with a little difficulty, in the future I intend to set the Laser's power to a higher setting), I was able to construct a simple sphere using the corner and joint pieces:

I then decided to produce a piece a bit more "organically,"

by which I mean I spent twenty minutes adding random joints

and edges together until I ended up with an octopus(?):

Unfortunately, a flaw in my joint design would proved to be the octopus's undoing; The width and design of the notches were largely without issue (if only the slightest bit too wide). Instead, the total size of the joint proved troublesome. The joints were only an inch wide, whereas the notches were a quarter-inch deep. In situations where only two pieces connected to a given joint, this was just enough space for both to fit snuggly. However, the two inserted pieces occupied some of the area the third and forth pieces were intended to slide into, effectively limiting their depth. This negatively impacted the structural integrity of my design, and made more complicated or precarious constructions impossible. Most tragically of all, the octopus disintegrated in my hands when I tried to move it.