This session of the course is focused on computer-controlled machining and the main goal of the week is to build something big.

For this week, I decided to build a chest of drawers. My first final project idea was to build a faucet that could change design depending on water consumption, however, I decided to change the final project to a chest of drawers that can change the design depending on its content and the users personalization. So this is a good assigment to try and build a chest of drawers.

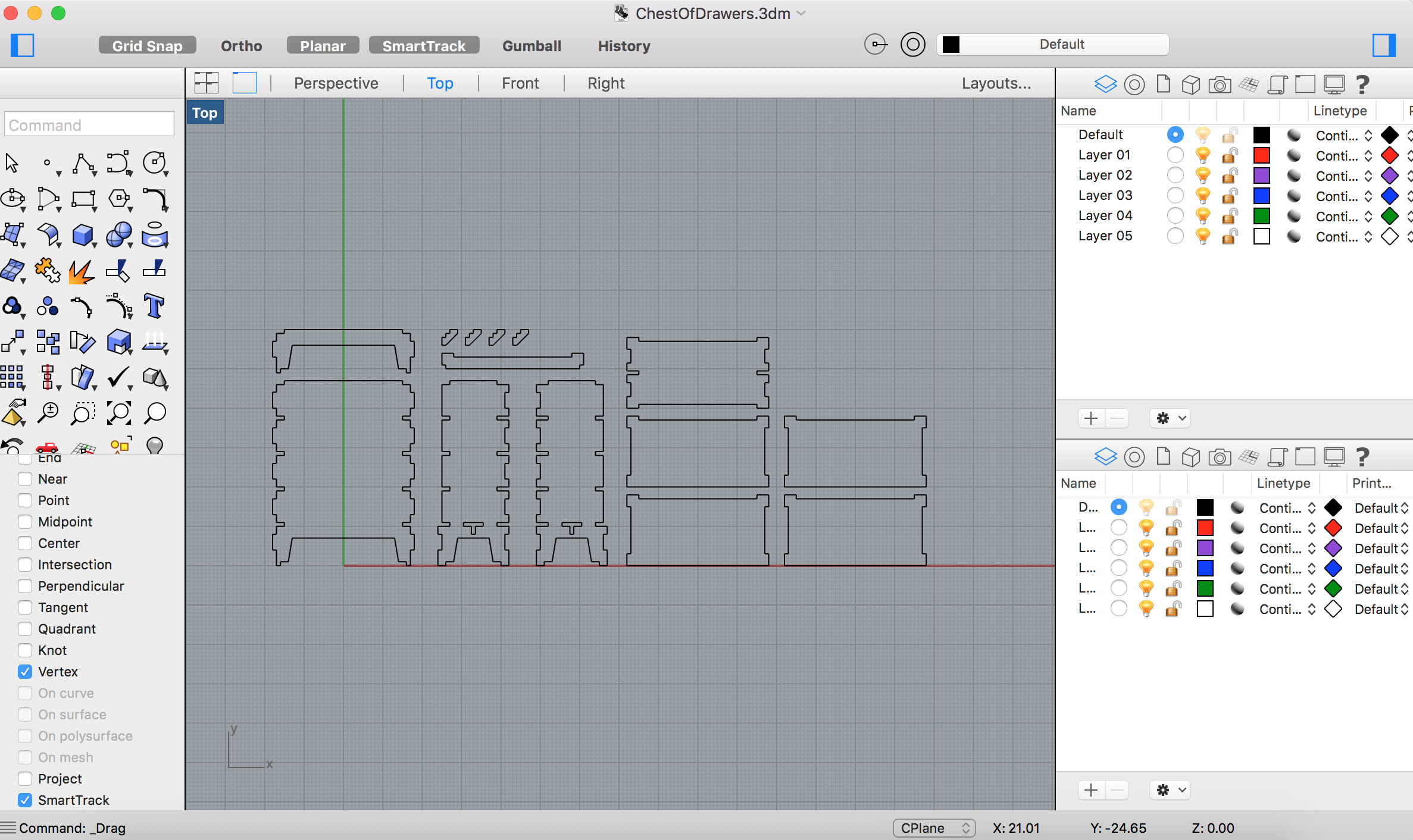

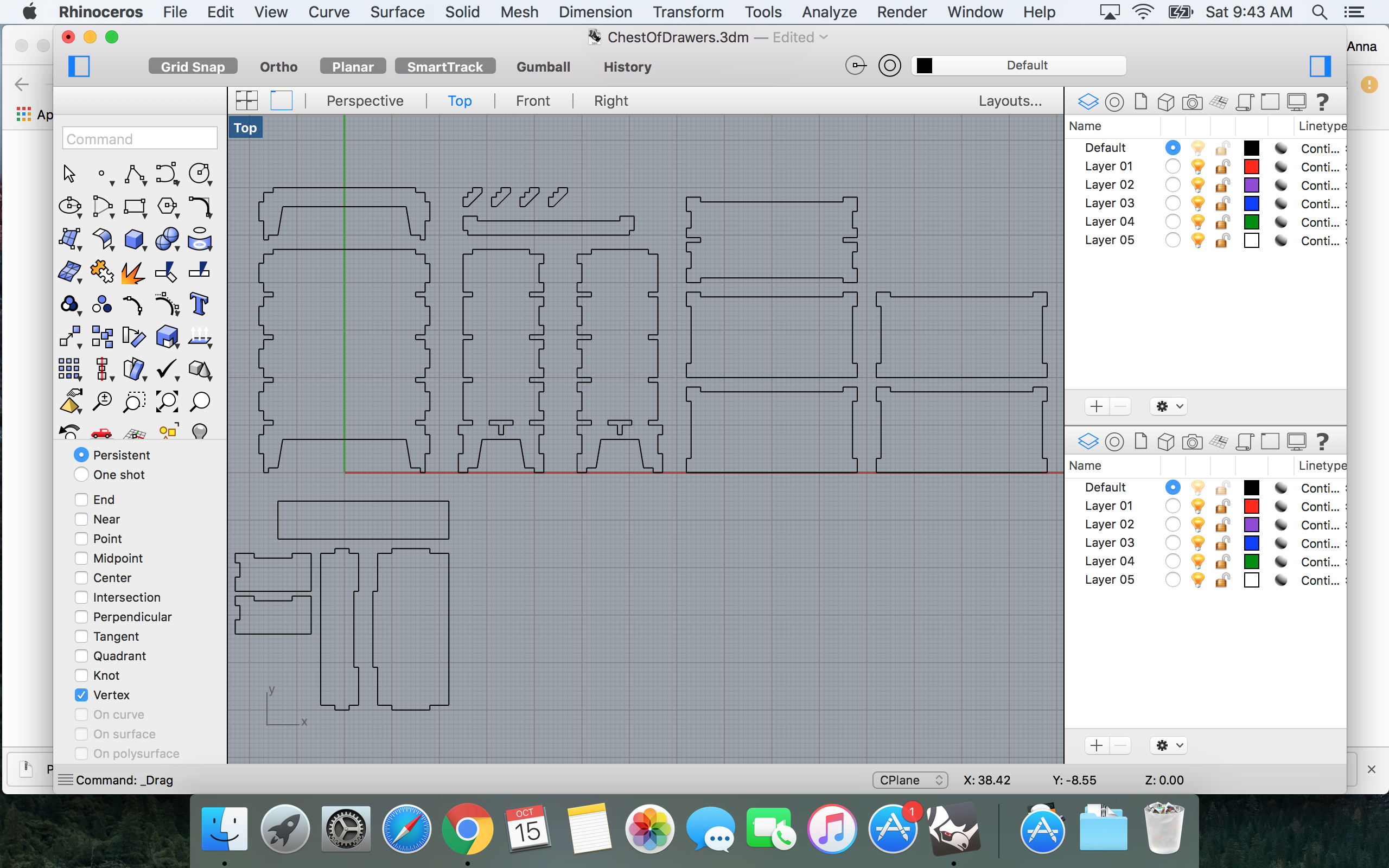

I got inspired by some design on the web and started designing my chest of drawers using Rhino. I exported my file in DXF format.

Once I had my design, I went to the machine shop to cut the wood. Important things to consider for this assignment:

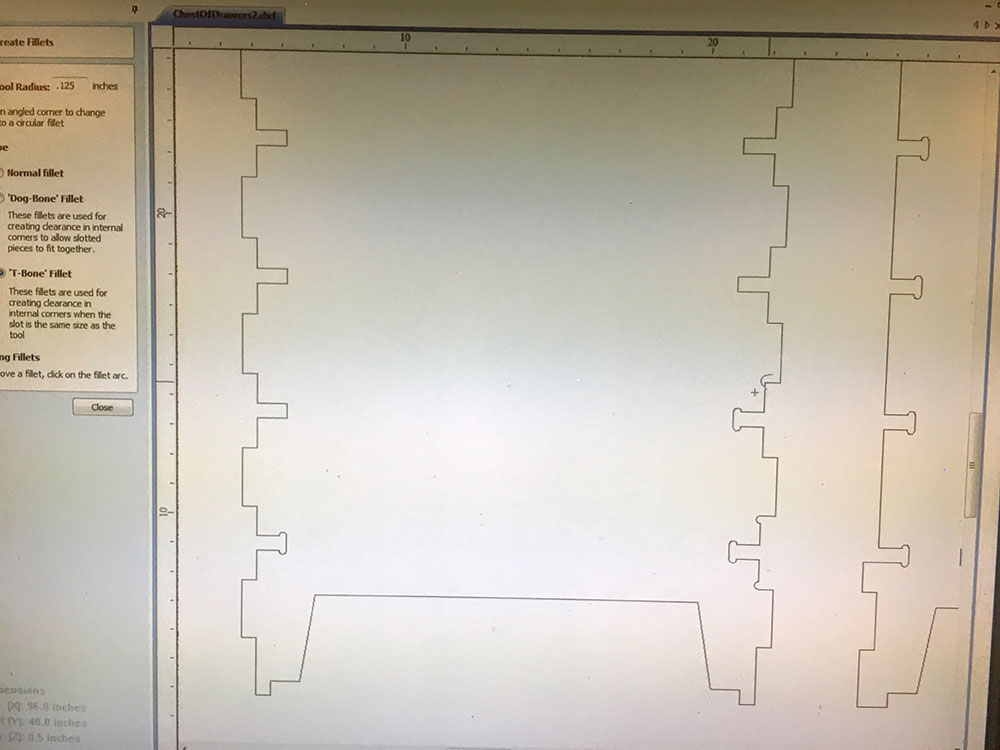

Once in the machining shop, I uploaded my dxf file to the software. I then realized I hadn't add fillets to my corners and this is BAD! The machine cannot cut perfect corners, it always leaves a radius. Then, when you try to mount your pieces, the wood cannot go all the way through.

Another important problem I had was that I designed the pieces with the wrong size. I wanted to make a big chest of drawers but I considered the wood to be thicker and I didn't have time to parametrize my design so, when I got there I had to shrink the whole design down and the chest of drawers ended up being half the size it should have been.

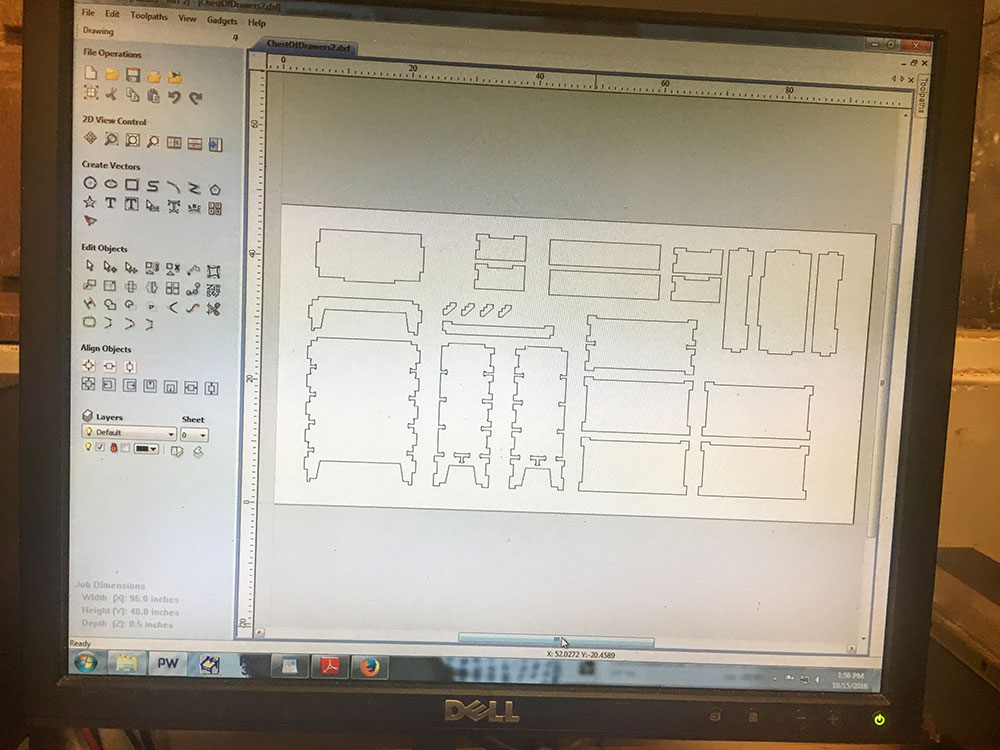

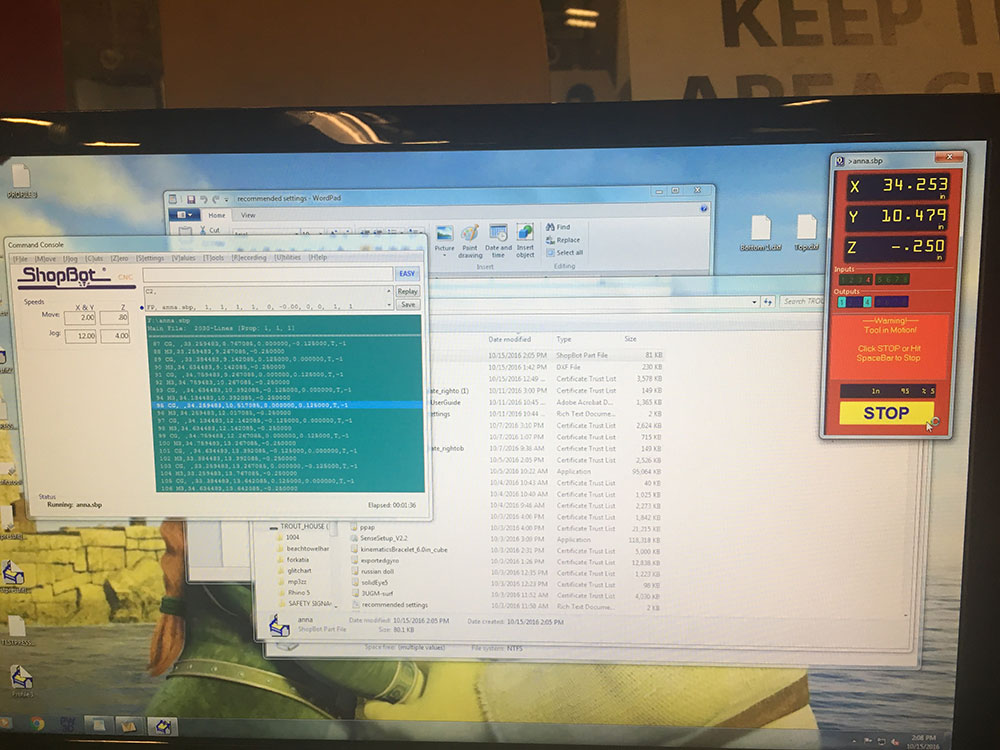

After adjusting my design I setup the tool to cut the wood in the program in order to calculate the traces. Once I had the traces done, I imported my traces into the ShopBot software.

I placed a piece of OSB wood in the machine and screwed it to the sacrificial layer. I then put the tool in the machine and adjusted the power and speed.

The wood was cut properly and I got all my pieces. There was only one piece that didn't fit so I had to cut it a little bit with a saw.

Unfortunately, the chest of drawers ended up being super tiny. But it was enough to keep some of my stuff.

And here is the result!