Week one: final project idea

Where it all began...

In case you didn't read my "About Me" section, Big Hero 6 is the reason why I am taking this class. It is my absolute favorite movie. Just look at the robots in that movie! They're soft, intelligent, helpful, they swarm, who doesn't think those are cool?

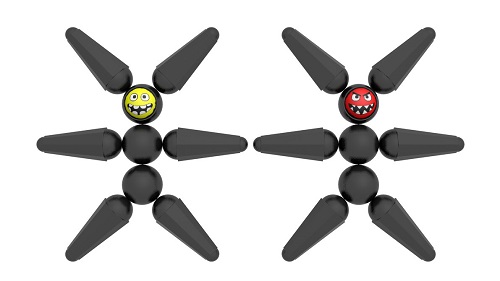

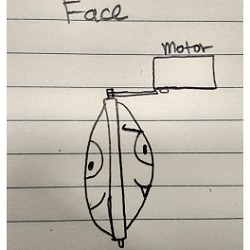

The robot in the first few moments of the movie, Megabot, is a particularly interesting one. Megabot has a modular design, it can reshape itself, it can communicate with each of its individual parts, it's bipedal (somehow), and it has emotions. My take on this robot will be to design just one of the modules: two arms and a body. The arms will roll around on the body controlled by remote control. My reach goal is to implement the switching face and incorporate some sensors to control it. Perhaps a pressure sensor on the remote?

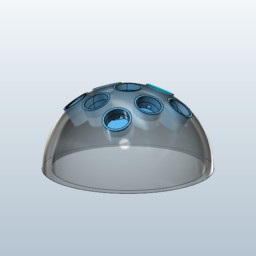

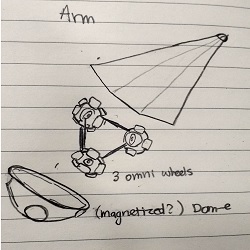

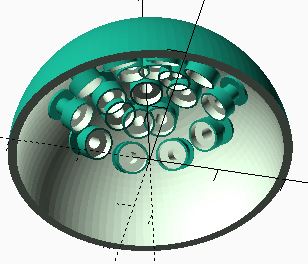

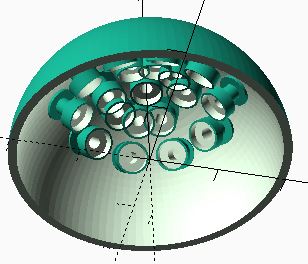

This week, I dusted off my old graphic design skills and learned some new ones. My sketches show what I imagine for the body and arms. The body consists of a sphere with a magnetic coating. A portion of the body is on a swivel to represent the two faces. The 3D design was made in OpenSCAD. The drawings are yours truly.

In class, Neil presented me with the idea of using electropermanent magnets to control the movement of the arms. I liked this idea and looked at Ara Knaian's thesis that describes electropermanent magnets and a motor he designed around them. However, I felt that I was not quite prepared to go down this road, so I decided to adjust and use electromagnets as the basis of my motor.

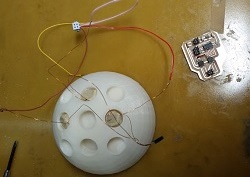

In input devices week I designed a simple joystick to use to control the arms and the face of the robot. In composite week I 3D printed the electromagnetic harness to test if it was actually a feasible idea. My backup plan would be to use motors to control the arms, and that will certainly prove to be more difficult.

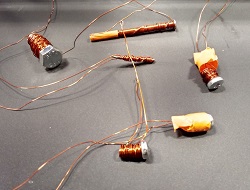

In output devices week I used a board with two H-bridges to attempt to control four electromagnets. Unfortuantely, my electromagnets overheated and burned out the H-bridges. Perhaps this was because the electromagnets had a magnetic core? When powered, the magnets made a ringing sound like speakers. My solution is to find some way to use an iron core for the electromagnets.

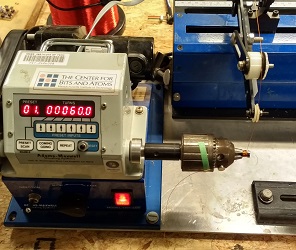

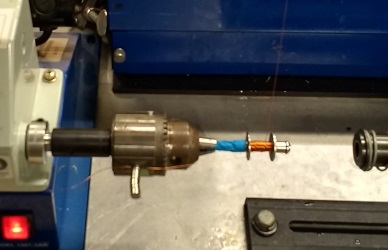

I made some new electromagnets since the first ones did not work. I used the coil winder because I had very small nails to wrap. Eric VanWyk has a great tutorial on how to use it. I tested my new electromagnets with a 5V source and found that they could barely hold on to a needle. So I need larger electromagnets.

These new electromagents were made with M5 1/2 inch screws. At this point I was getting VERY good with the coil winder. I liked these electromagnets more than the last batch but they have two big flaws: they aren't strong and they get hot. So I decided it was time to get really serious.

I planned out my electromagnets much more carefully this time. I want them to be as close as possible and as strong as possible. Since I still have not printed a new harness, I am starting with the harness that I already have. I used M5 1 inch screws with nuts and used a drill to put them through the harness and secure them. I then made 600-loop coils on a length of heatshrink. These were easy to slip on the metal cores to make some seriously strong electromagnets. Now I need a 3-inch radius hemisphere to go over this mostrosity.

The idea of making 3-inch diameter ears to match this thing isn't very appealing so I also designed a 4-inch model of the the electromagnet harness in CAD. While I'm testing out my current harness, I'll be printing the new harness and getting ready to make more coils.

And what about the electronics? Well I have my Fabduino and bluetooth ready to go. In output week I designed a board for controlling up to four electromagnets at a time, I just need to up that number to 9 electromagnets. My new design uses up to 22 electromagnets, but that seems like too much for the next few days. So I'll stick with up to 9.

Left to do after week 14:

- Design and stuff motor control boards

- Test motor control boards with electromagnets

- Print hemisphere to go over harness

- Test magnets on harness

- Print appropriate sized arms

- Buy batteries

- Make it prettier