| Back to Index |

My net result for the week was not a network, but I did get some work done. Harvard classes ended last week, and a number of my projects for those courses culminated last and this week. As a result, I wasn't able to find a few hours to get into the shop and start working until Monday of this week.

I went in with the intention of laying out, milling, and stuffing the three boards to do Neil's serial network, modify the code a little bit, and get some ATTiny45s talking to each other. Of course, the lab was a flurry of activity, all our PCB milling machines (the Roland MDX-20 and the desktop ShopBot) were in use, so I set about my other task for the week: progress on my final project.

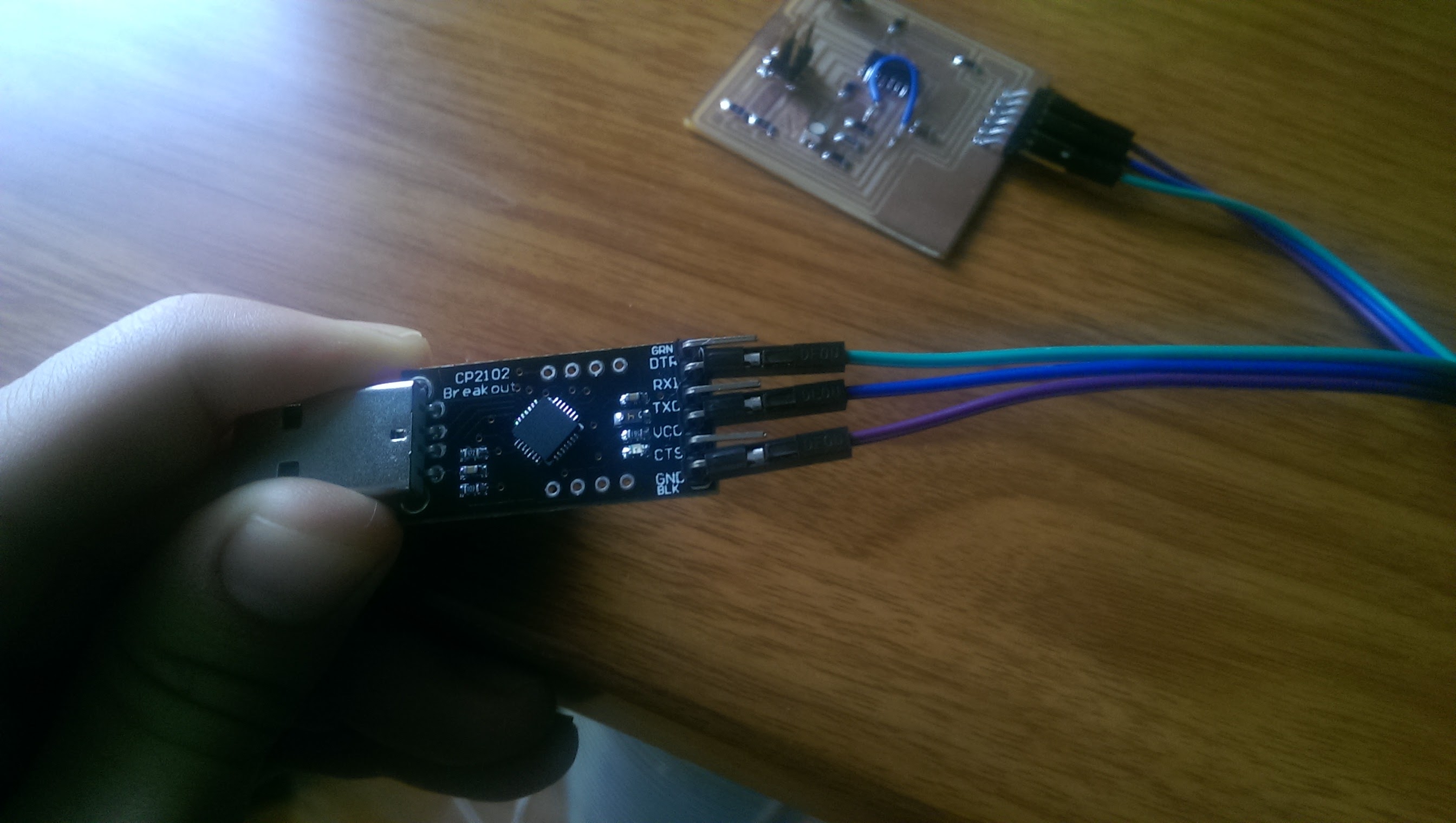

I had received my USB-FTDI converter from Amazon, but was unable to get my step-response board from Week 8 (Inputs) to talk to my computer, using CoolTerm as my serial display program, per Rob Hart's suggestion. I wasn't sure if the issue was with my board, the converter, the wires connecting my board to the converter, or my computer. In the lab, I worked to eliminate the variables. Using a new FTDI-USB cable, and one of the lab's Macs (with CoolTerm installed), I confirmed that my step-response board was still working. I next swapped in my cheaply acquired converter, and nothing showed up. The LED on my converter was glowing, so I knew it was getting power. I swapped out the cheap cables that came with my converter for some from the lab, and after re-scanning CoolTerm's serial ports (under "Options"), my step-response board started spewing data. Success!

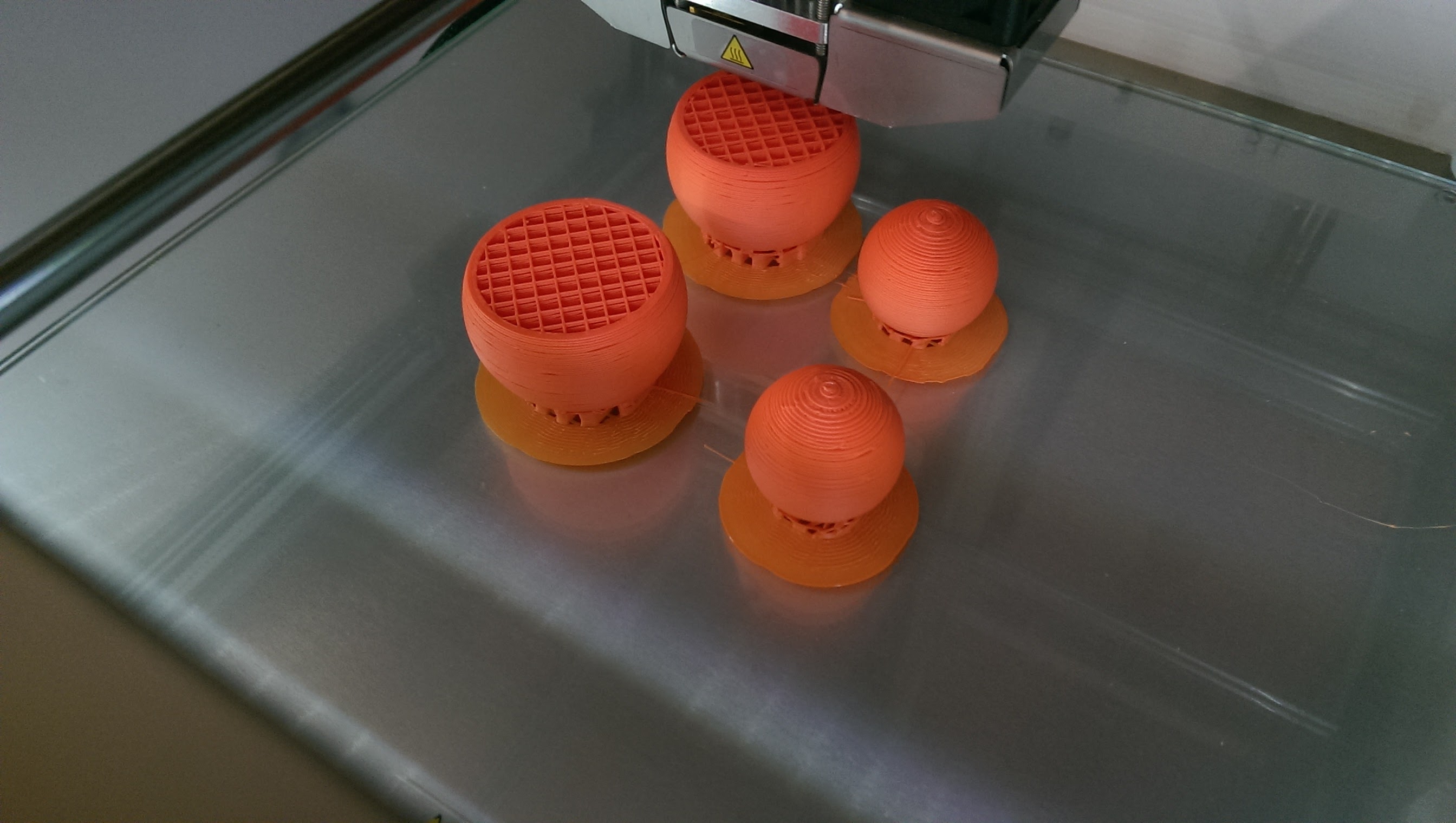

At this point, milling machines were still occupied, so I moved on to the next step for my final project: replacing my step-response pads with spherical electrodes stuffed inside some foam balls. I quickly threw together two different-sized electrode core spheres in Fusion360, and got them printing on our Ultimaker.

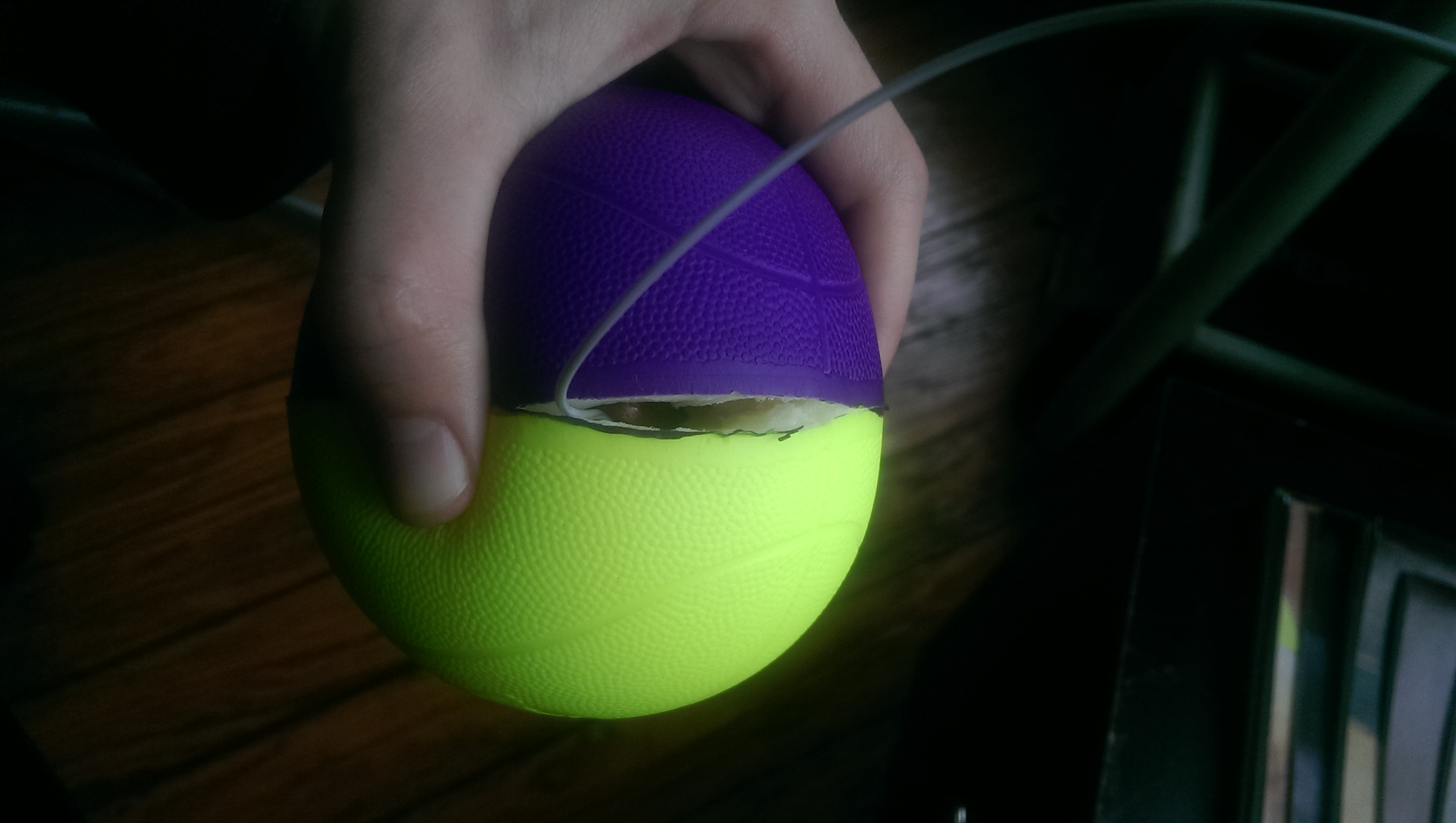

Next, I wrapped the balls in copper. I could've vinyl-cut a nice pattern that wrapped perfectly and cleanly over the spheres, but it seemed unnecessary, as hand-wrapping would work just as well, and no one was ever going to see them.

Next, I soldered some wires to the copper-coated spheres. I wanted them to have a harness on the end, so they could easily plug / unplug from my board. (I had initially wrapped the spheres in aluminum foil, but was having difficulty getting enough heat into them to get the sodler to flow, without melting the plastic sphere under the aluminum.)

Finally, I took my foam spheres, and sliced deep into them with an X-Acto knife. I used a sawing stabbing motion, as I knew simply dragging the (likely not brand new) blade through the foam would just pull and tear. With a 4" foam ball and a 1" core, I knew I needed to stab down 2.5" to ensure the core sat in the center of the foam. I considered hollowing out the center, but A) it would've taken a non-trivial amount of work, and B) it turns out it wasn't necessary. The cores sat happily inside the sphere, displacing foam, and not altering the shape or feel of the larger foam spheres.

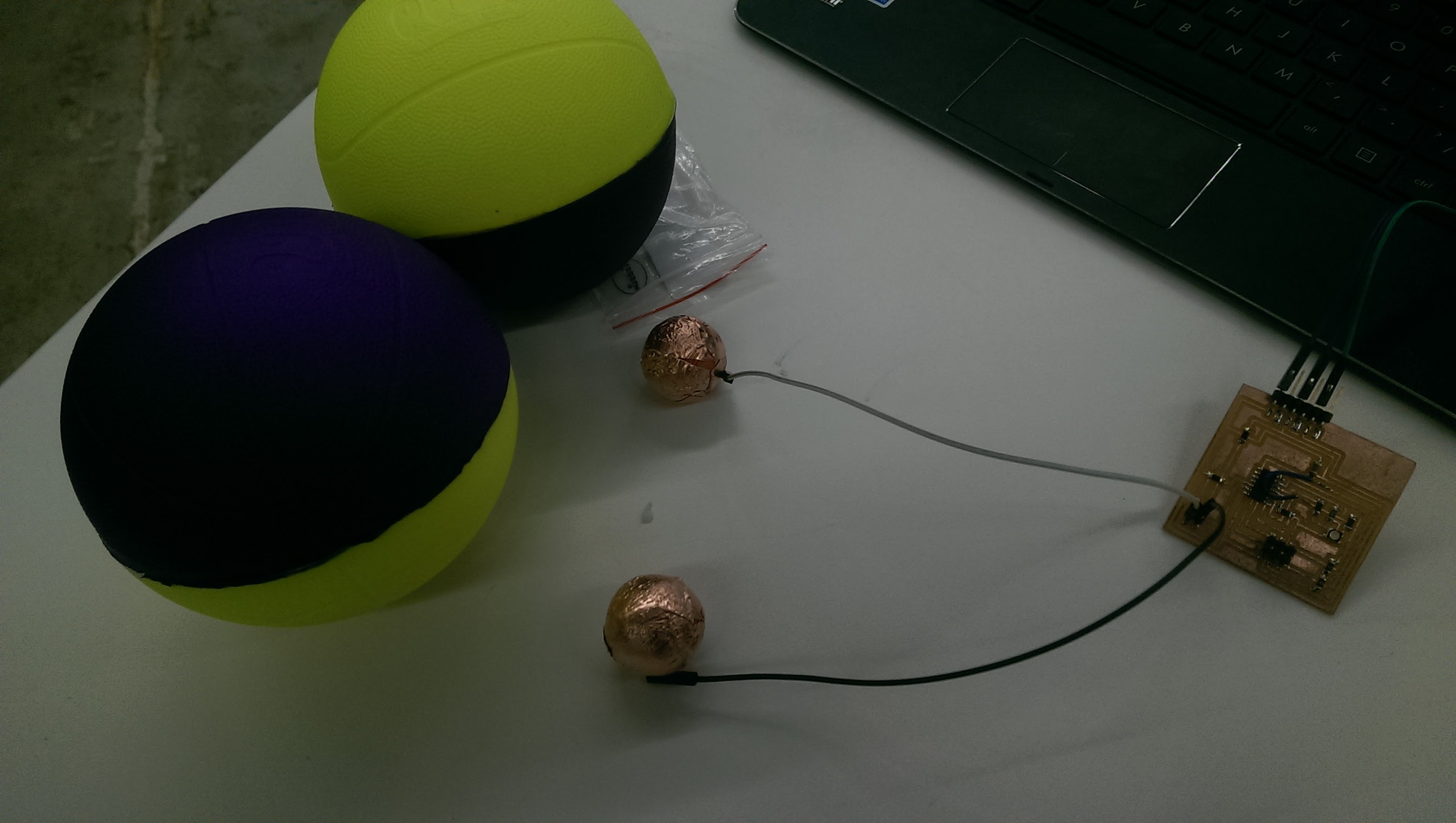

With copper-coated cores stuffed inside my foam balls, and plugged in to the Tx / Rx header on my board, I opened CoolTerm and prayed data was being sent, and that that data changed as I squished the cores together. Success!

My next hurdle, and the hurdle without which my project will not work, is figuring out how to take that step-response data and control the RGB LED with it. Once I get some basic control (#spiraldevelopment), I'll figure out how to map the LED PWM to the step-response values, ensuring a smooth transition from color to color.

With that hurdle cleared, it was back to networking! I needed to head home, but still had all of Tuesday and Wednesday morning to spend in the lab, getting some microcontrollers talking. Unfortunately, on the bike ride home, I hit some ice, and went down hard on my hip. Instead of spending Tuesday in the lab getting ATTiny45s to talk to each other, I spent it in an Urgent Care facility. Nothing is broken, probably, and hopefully no tendons or ligaments are damaged, but long story short (too late), I'm now on crutches for the next week or two, and I didn't have time to get the week's assignment done. Hopefully I'll be able to do so while working on my final project by Dec. 20.