Week 2: Electronics Production

Introduction

This week, I learned how to work on electronics production. Specifically, there were three parts to this assignment: first, milling a PCB; second, soldering the circuit and ICs onto the PCB; and lastly, installing software onto the PCB.

- Software used: Avrdude

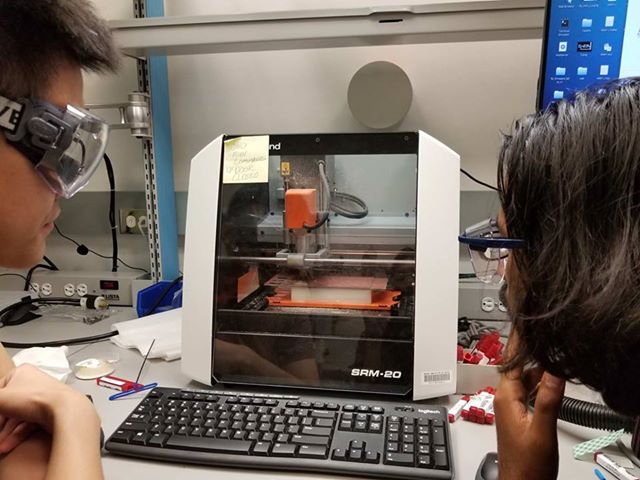

PCB Milling

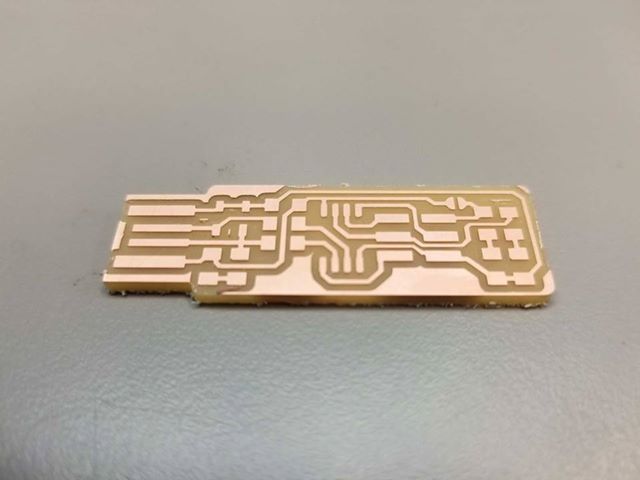

Given that we had a already made image for the PCB design, we had to run two cuts for the PCB in the Roland, the first using a 1⁄64 pointer for tracing, and the second using the 1⁄32 pointer for the outline and cut.

After running the machine (which takes a while), here is the finished product!

Soldering & Programming

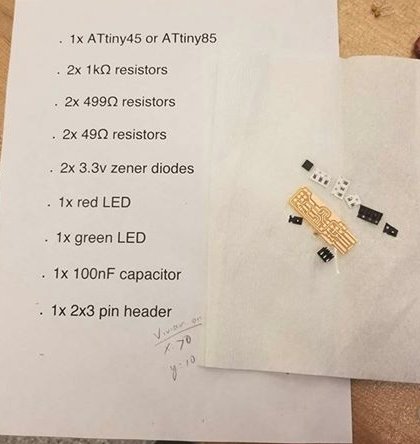

Next, I had to solder the components for the PCB onto the board. First, I gathered the equipment:

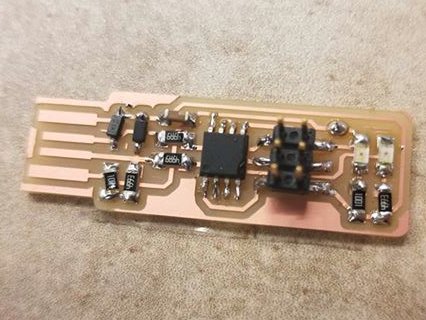

The soldering process took a while as our components were quite small. After half an hour or so, I finally finished!

Finally, in order to program the board, I used a programmer board to connect to the 6 pins of the board, while using another USB port to connect to the board for power. Fortunately for me, the programming part went very smooth, as I didn’t need to debug my software or hardware. Overall, it was a fun experience!

Tips for the future

- Use double sided tape to keep track of where your small components are.

- Check which resistor you are using by actually looking on the resistor itself. I had to un-solder two resistors as I ended up choosing the wrong ones.

- A lot of soldering techniques that I’ve learned in person

- When running

make flashandmake fuses, at first my compilation failed. Addingsudosolved the problem for me.

Assignments

- Make an in-circuit programmer by milling the PCB

- Solder components onto the PCB

- check if the PCB can be programmable, and do so

- refer to Ben’s documentation of the assignment link