Week 3: 3D Scanning and Printing

Introduction

This week, I learned how to use the 3D printer as a way to transform a 3D digital file to a physical object, and I learned how to use a 3D scanner as a way to transform a physical object to a 3D digital file.

- Software used: Fusion 360, Sense

3D Printing

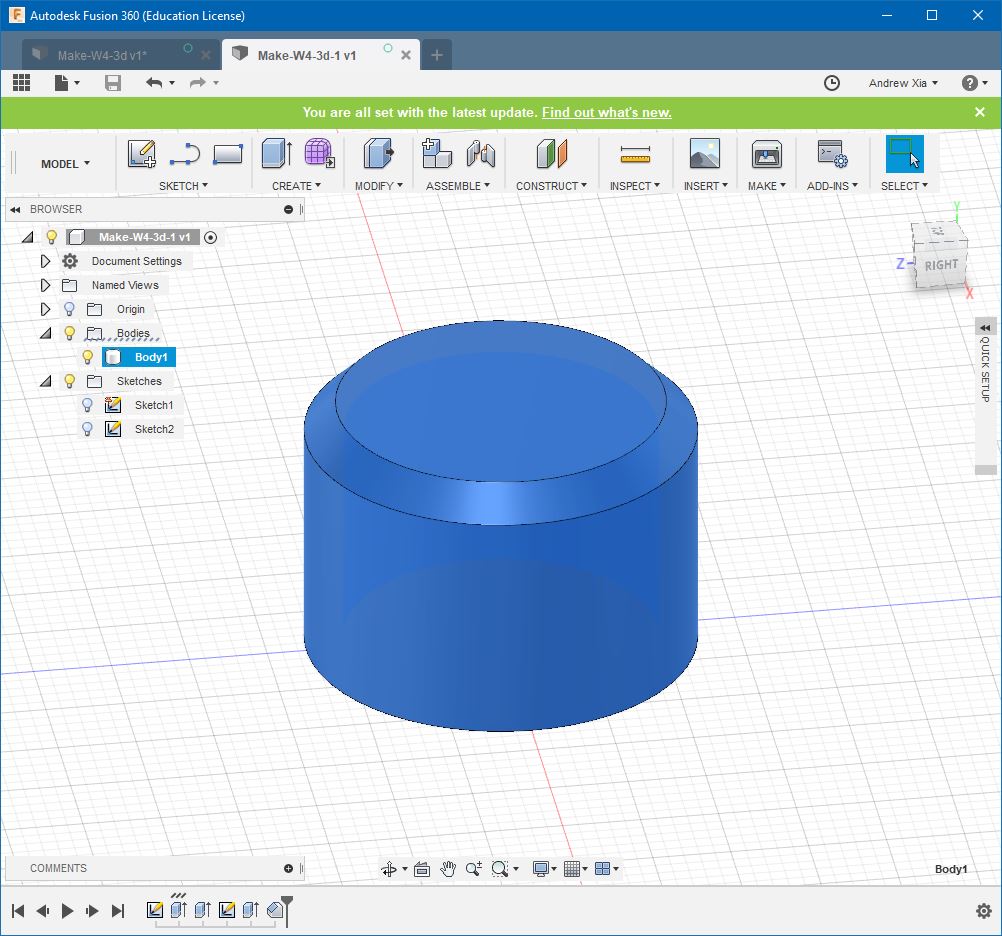

As someone unfamiliar with computer aided design, I spoke to some of my friends who majored in Mechanical Engineering, and I was recommended to use and learn Fusion 360.

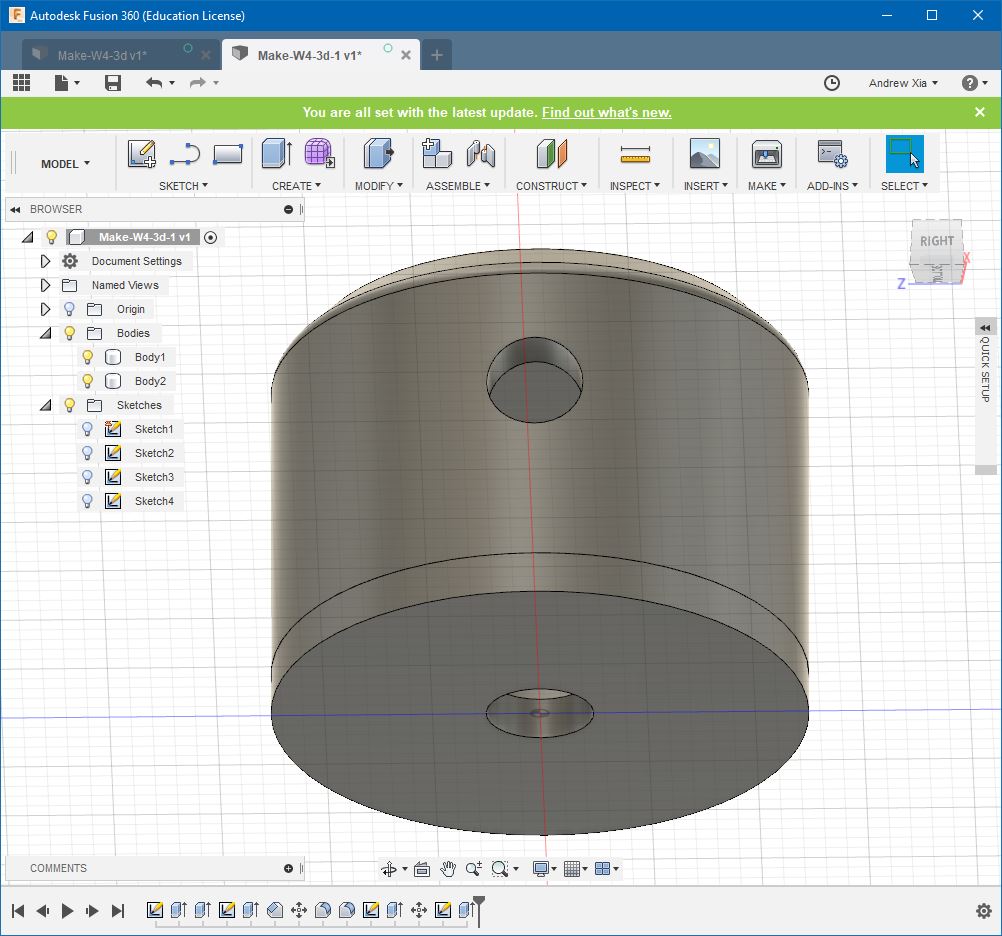

Later, Zach noted that my design of simply having a cup with a cap, could be constructed subtractively -in other words, another maching simply removing material could have created this too. A 3D printer is an additive construction technique, so having complicated extrusions within a cylinder would prove to be a design incapable of being created by a subtractive method. To do so, I added a top to my cylinder, along with a hole on the side (which also proved to test my Fusion 360 skills).

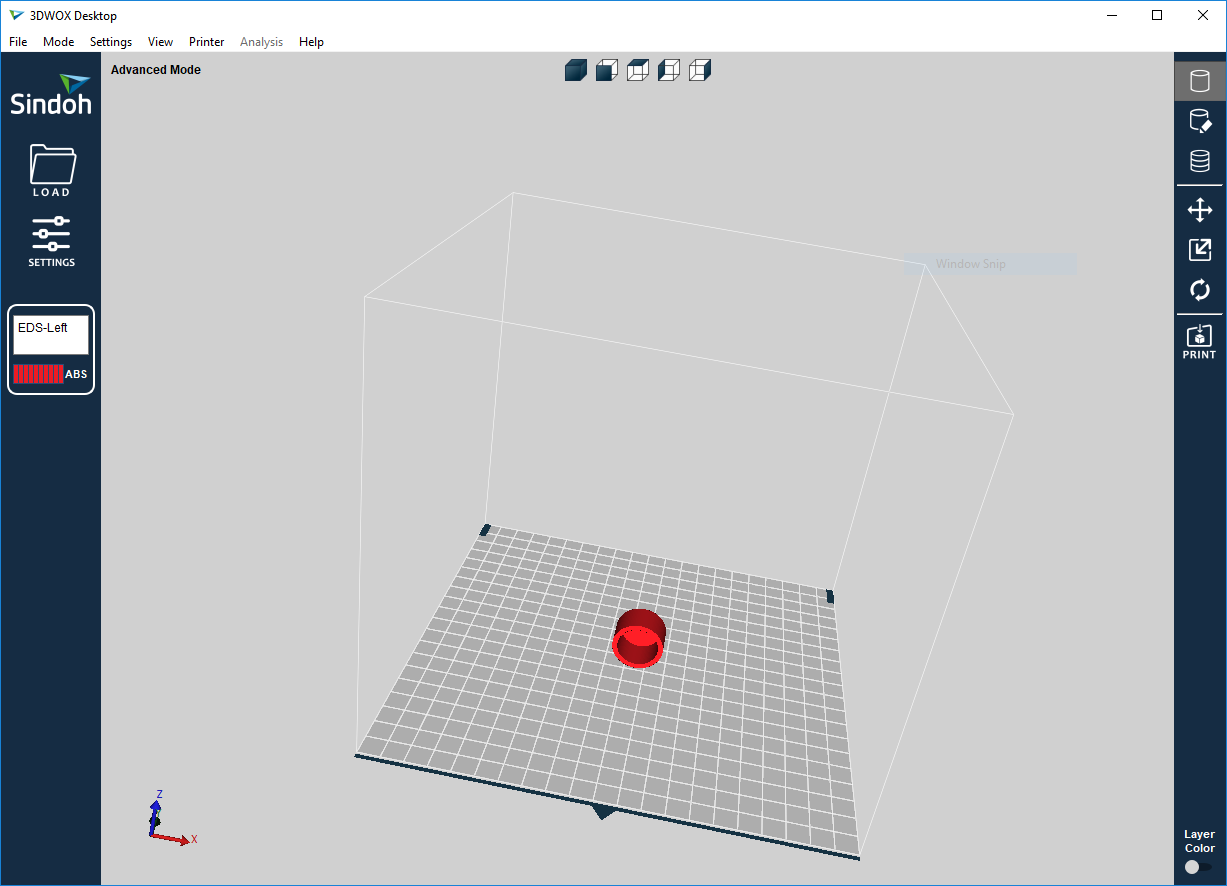

Next, I sent the file as a .stl extension and used the 3D-Wox software to orient my object before sending it to the 3D printer

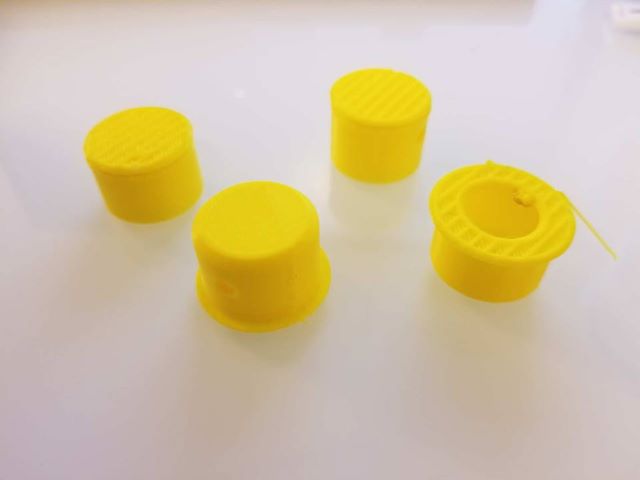

After running the machine (which takes a while), here is the finished product! I also experimented with orientation of printing the material

3D Scanning

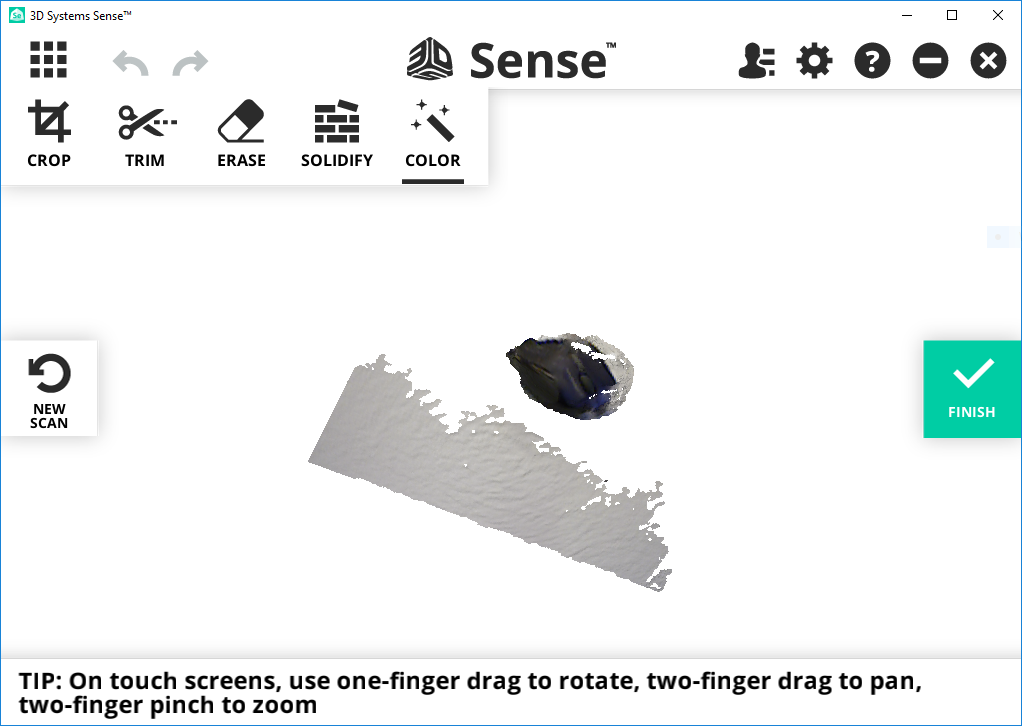

In the Cypress EDS we have a Sense 3D Scanner. I attempted to scan my mouse through this setup:

At first, I removed the black Vinyl material from the white spinning board (we would rotate the board for the scanner to capture all angles of the mouse), but I later realized that this was a really bad idea as the reflective white material confused the 3D scanner.

Above is an example of a bad scan. Eventually I was able to scan my mouse, as below:

Tips for the future

- Go through tutorials for how to CAD

- The 3D printer’s precision is not very high. Thus, printing very small objects will not yield the exact design you have in mind. Also, orienting an object up or down will affect the smoothness of the bottom side, as the 3D printer will print extra material to maintain contact with the bottom board.

- The 3D scanner was extremely frustrating to use. Definitely use a black material under the object you are scanning, as a white base confused the scanner for the longest time.

Assignments

- 3D print an object that must be constructed additively.

- Scan a 3D object