10

MACHINE DESIGN

This week we worked on desinging any machine! Our group (EECS) decided to make a milling machine to help us work faster since our milling machines are usually always taken.

| Tools: | E V E R Y T H I N G |

| Date: | 11.21.2018 |

Ideas

This is a group project week. Please see our group page for a full run down of the process: milling machine

I knew I'd be out of town later in the week for an early Thanksgiving break so I got started right away as part of the design team.

The fist thing we did was take a look at all of the parts and materials we had to work with. It was like opening presents on Christmas day!

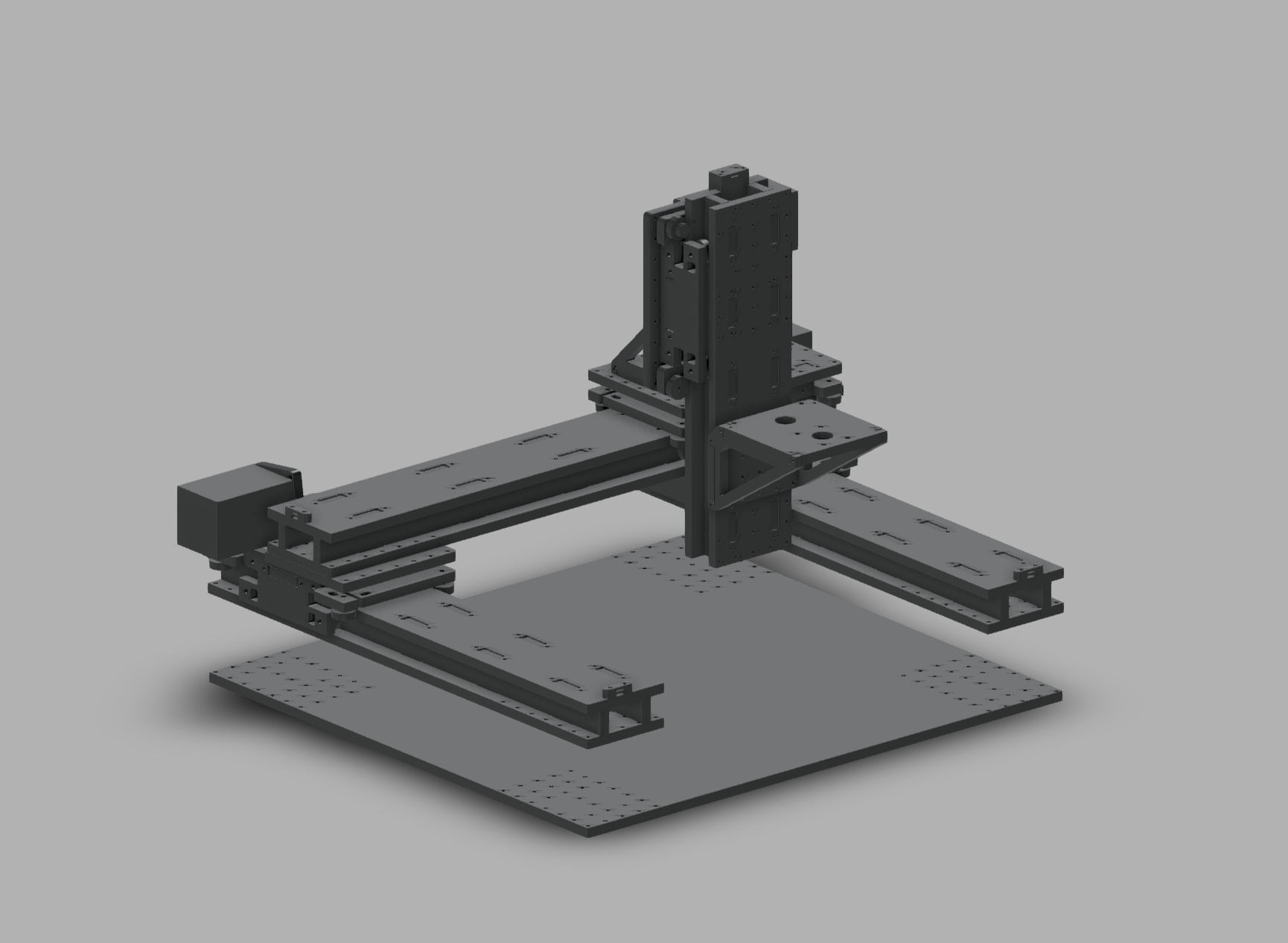

Designs

Next, we divded up into teams and figured out when we each would be able to meet. I was on the design team, but more specifically the part of the team designing the z-axis of the machine.

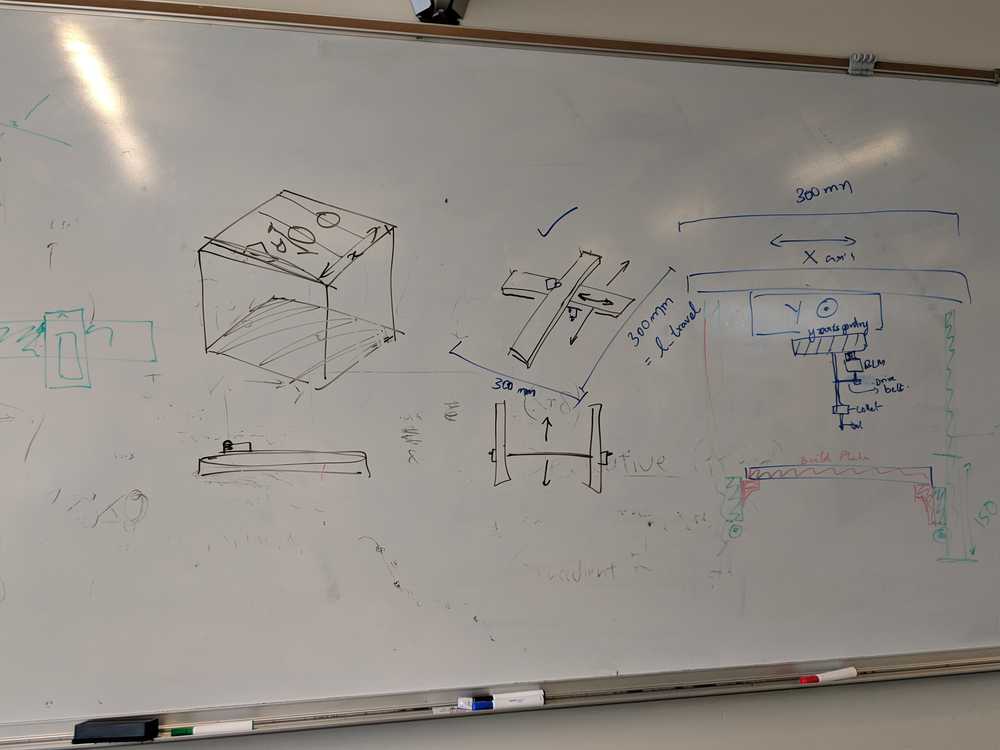

After drawing our designs on the whiteboard we "settled" on a design. I say settled in quotes because like with every assignment in the class, things ultimately need to be changed.

We wanted the spindle to be at a fixed height and then we'd move the bed up and down the z-axis as needed. This proved not to be the best idea since it required extra supports for the bed (thus using more material) and it would be harder to assemble. Additionally, it made the center of mass really high which made the design unstable. So instead, we went for a more traditional approach where the spindle itself is moved along the z-axis. Here is a rendering of the final design that we ended up fabricating.