Here's what I want to test/attempt with this development board:

- What do these LEDs look like on 3.3v?

- What do these LEDs look like on 5v?

- What's the power/current draw of one LED?

- Use a microcontroller to talk to the LEDs

- Use a microcontroller to talk to the GPS module

- Parsing sentences

- Reading the time

- Using the GPS's Pulse Per Second (PPS) output signal

- Attempt to recreate David's TinyNav Simple GPS Navigator using the DotStar LEDs

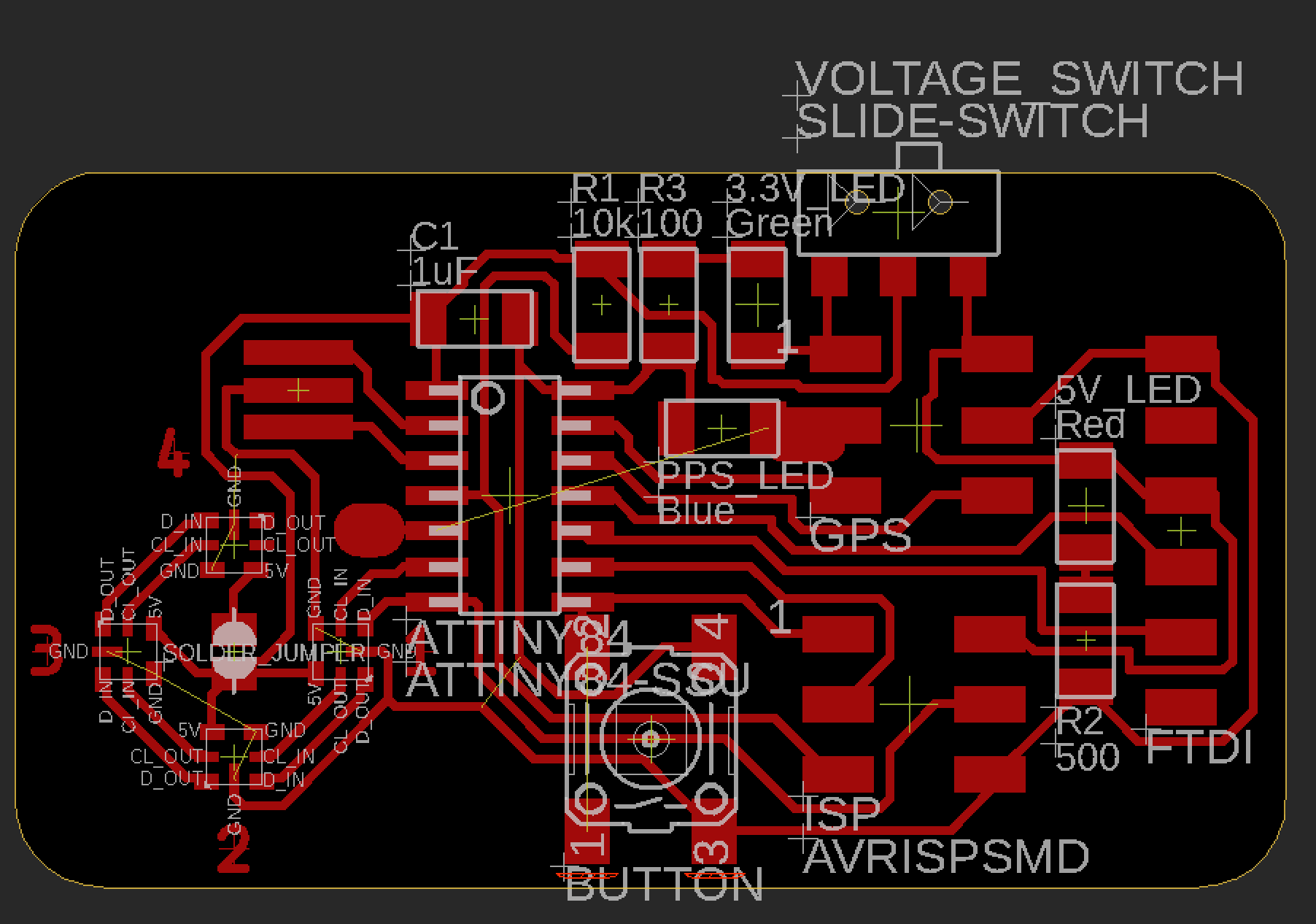

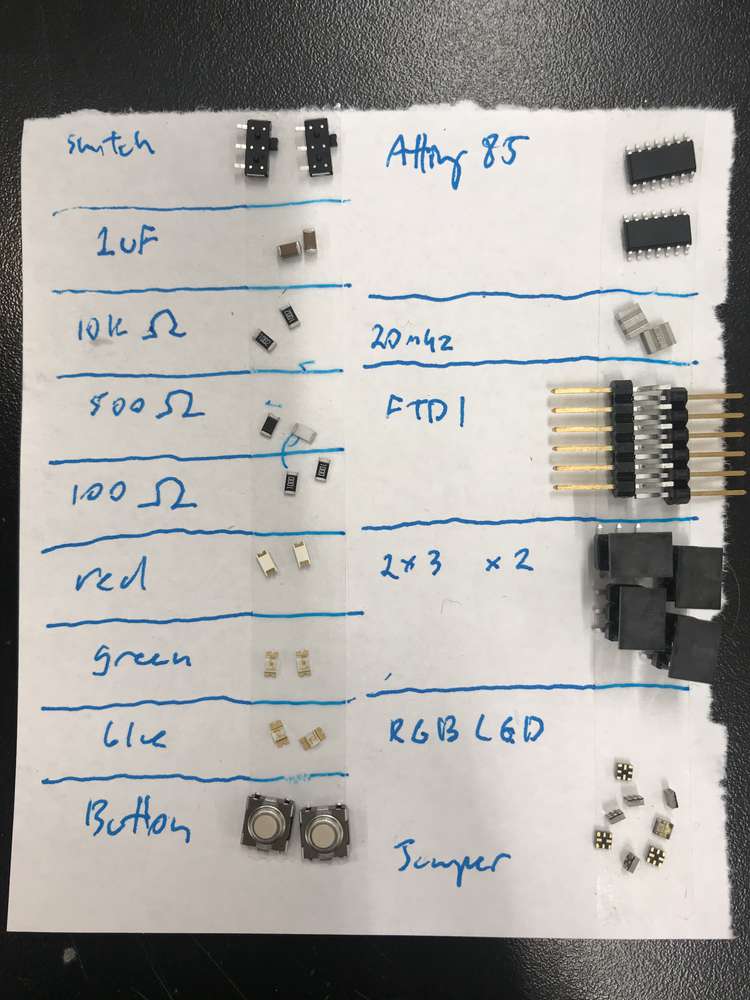

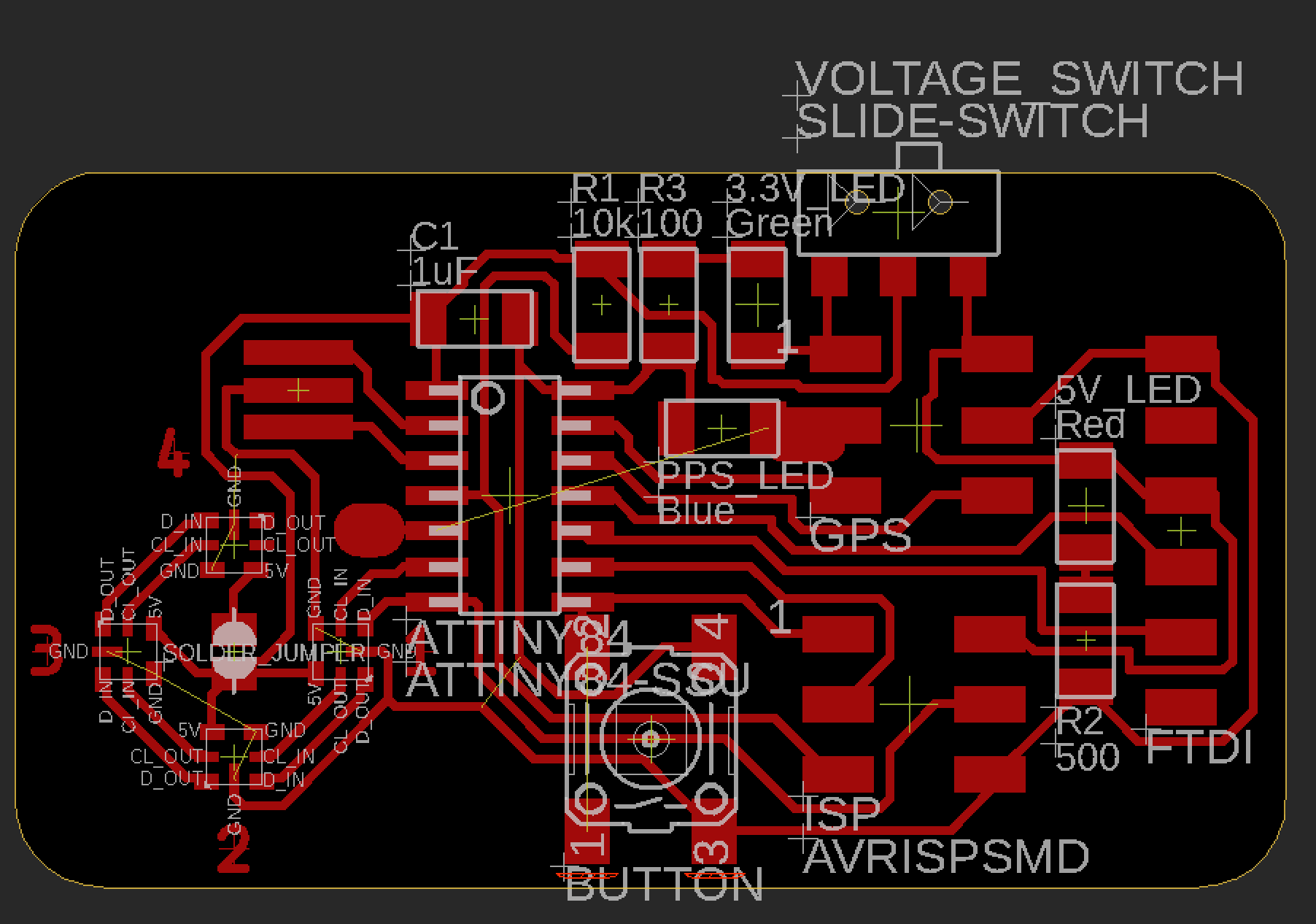

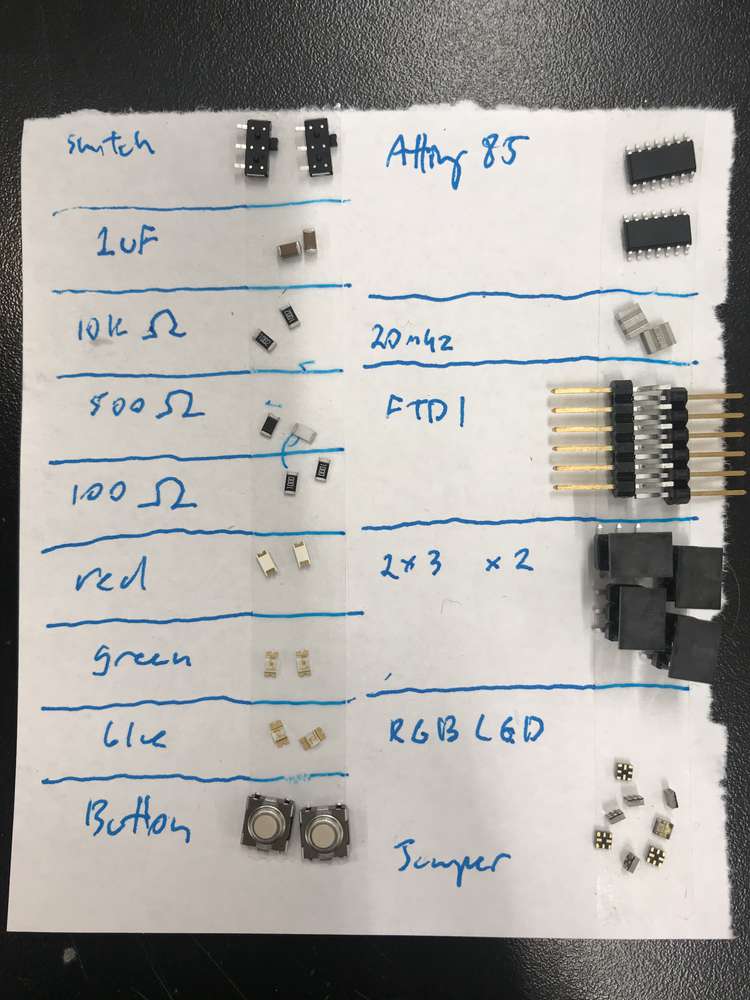

For simplicity's sake (and because these GPS modules are expensive) I plan to use the GPS breakout board and connect to it via jumper wires. This will also give me ready access to a 3.3v power source, using the breakout board's onboard voltage regulator. I intend to use the individual, surface-mount GPS component in my final, and Adafruit provides a reference schematic for the breakout board which I can selectively recreate when needed. The GPS module datasheet also has recommended component configurations.

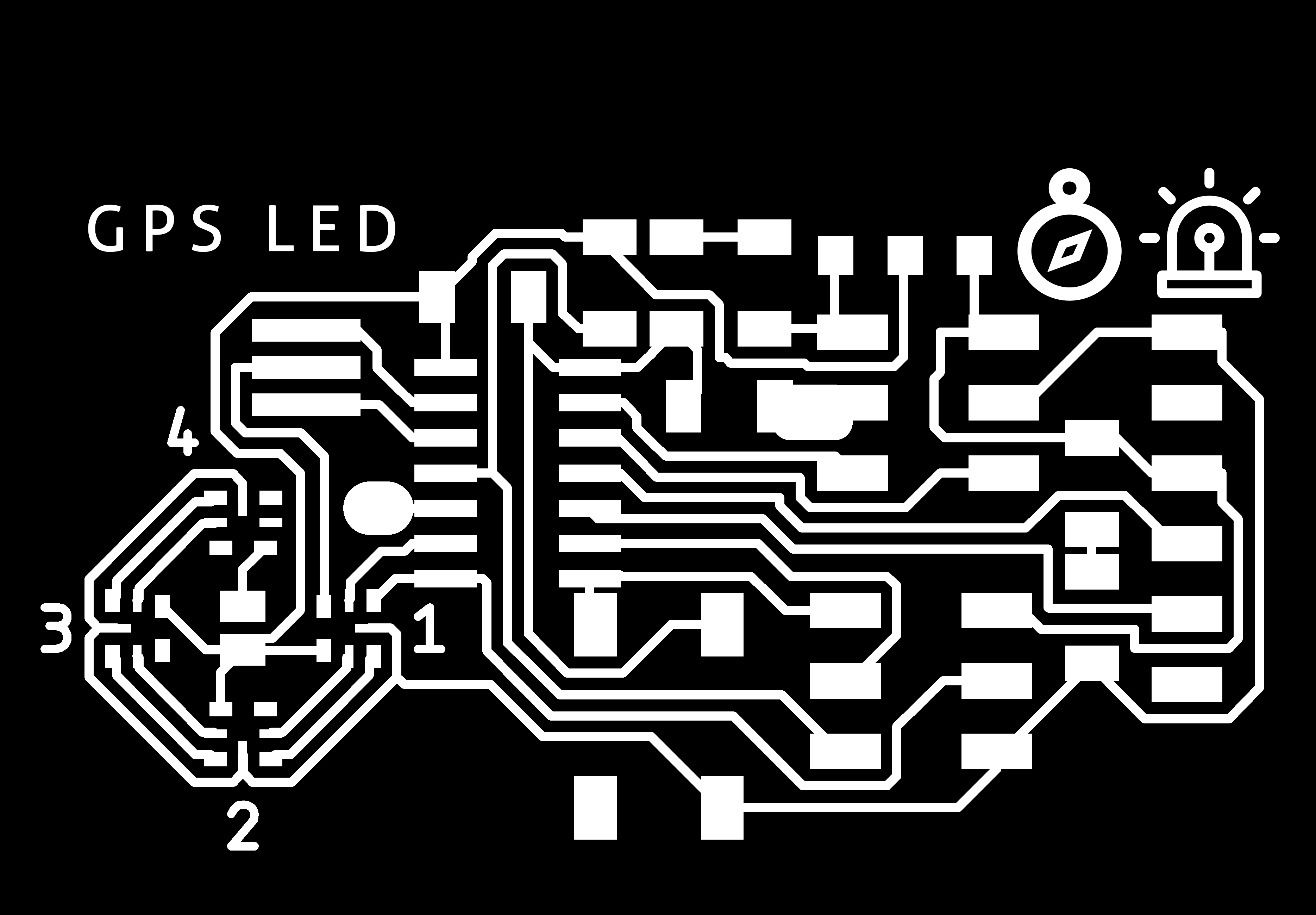

I'll plan to use four DotStar LEDs for this board, just enough to test with something akin to a compass rose. I'll put a solder jumper between the power connection for one of them, which I can use to sample current draw for that LED with a multimeter.

I'll use an onboard switch to toggle between 5v supply and 3.3v supply (the latter taken from the GPS breakout board). This will let me test how the entire system operates on 5v vs. 3.3v.

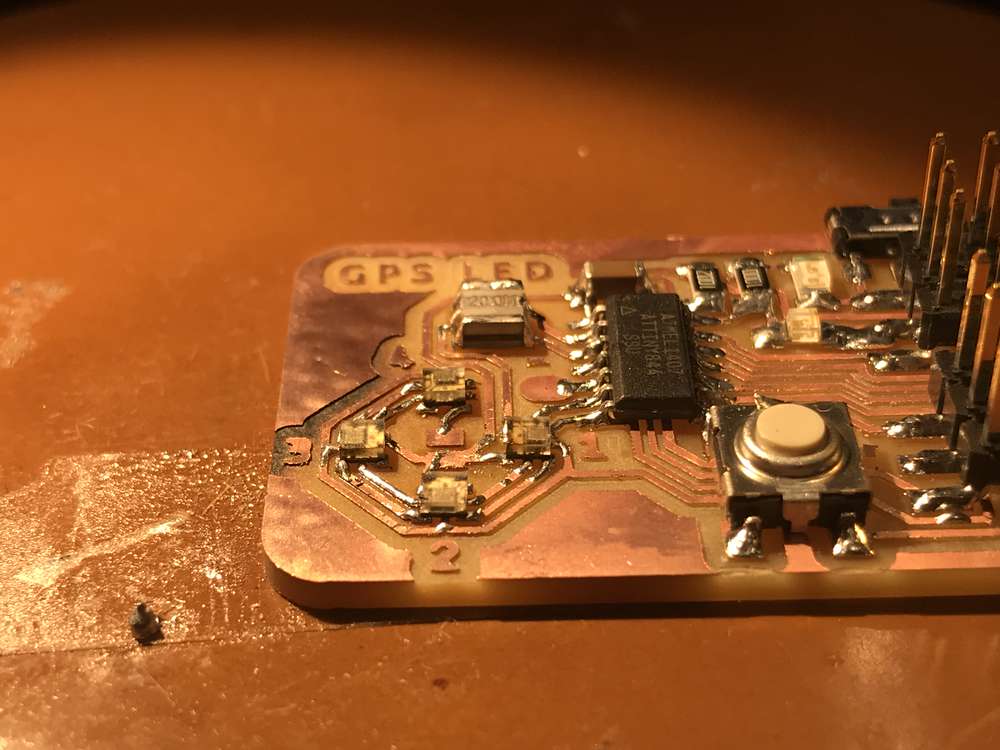

Lastly, I'll include an LED to indicate the PPS signal, and a button for some simple interaction.

I wanted to include power indicators which toggled depending on which power source was being used - that is, a red LED would be on when 5v were supplied to the components, and a green LED would light when 3.3v were displayed. However, I couldn't figure out how to do this, and resulted to two power indicators which would simply show whether or not each voltage supply were available.

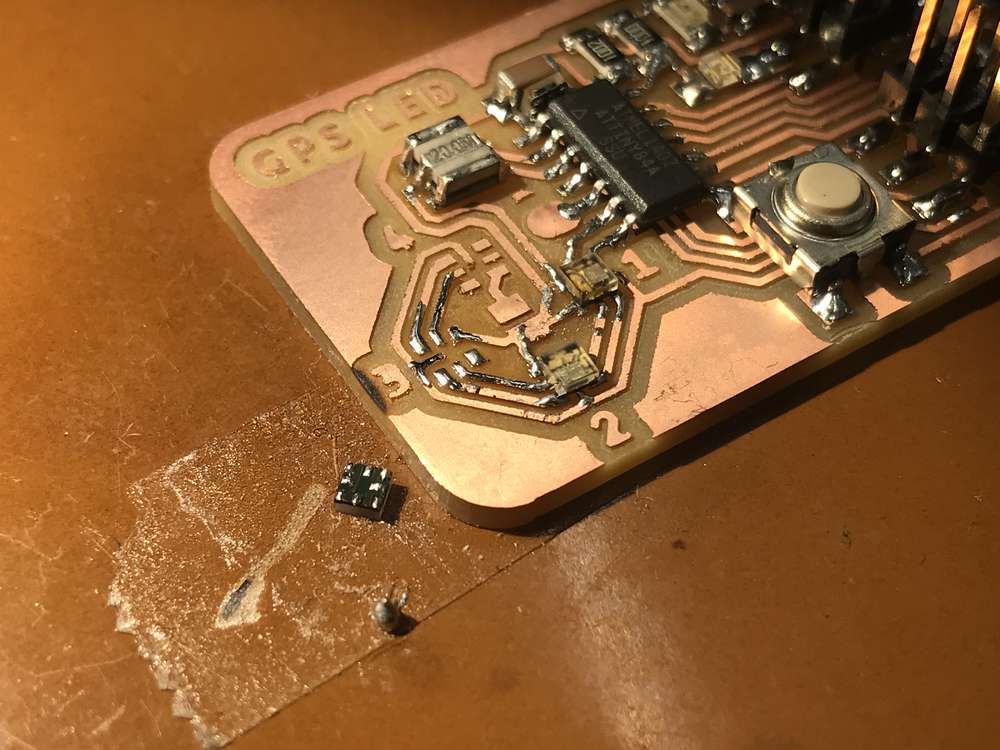

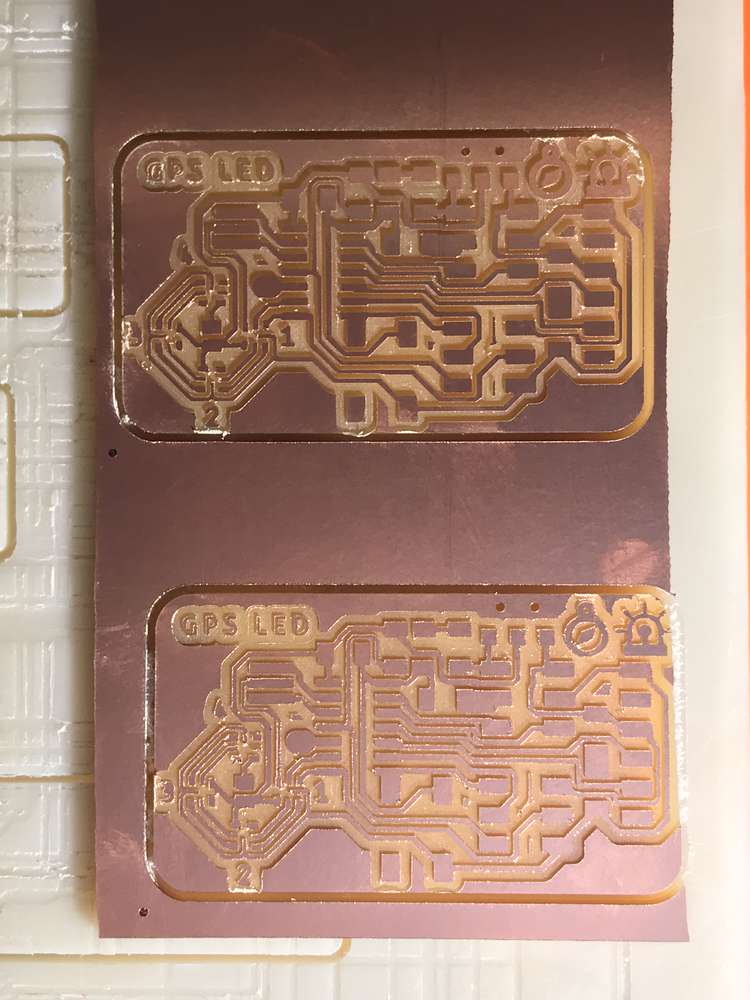

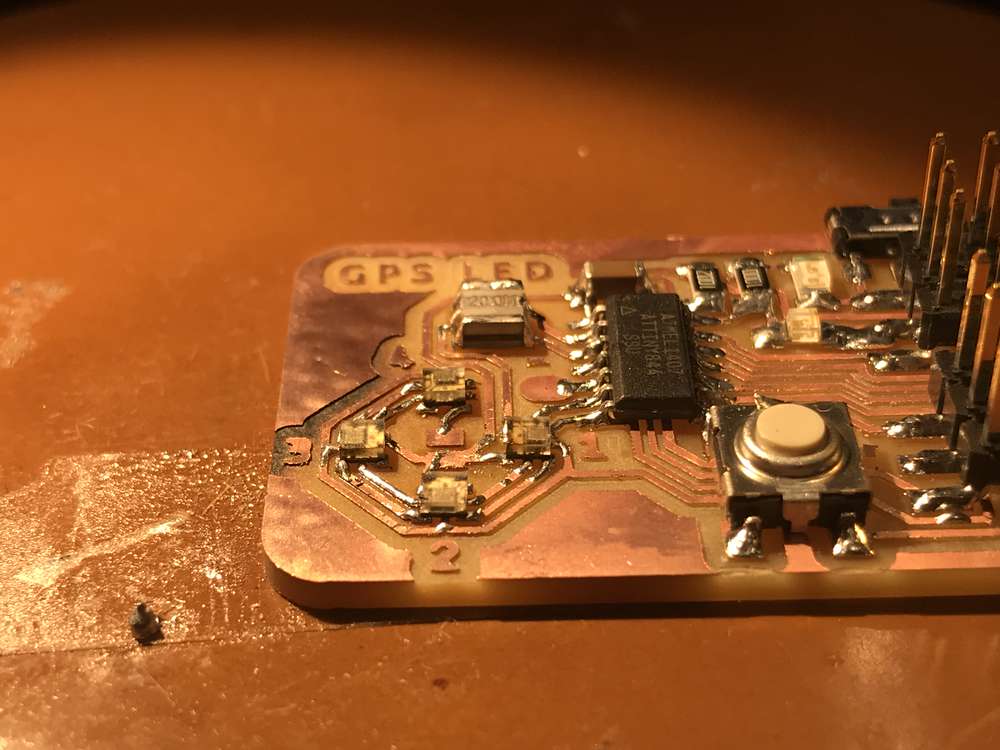

Routing this was super challenging. After several attempts, I was able to get almost everything onto a single-sided board, but needed one jumper wire for the PPS signal. You can view the schematic here.

I was able to find a library for Eagle which included the APA102-2020 footprint, though the pads are so small and so close together that I needed to modify it in order to mill it using our standard end mills. It also lacked connections to the center pads, so I added one of those as well.

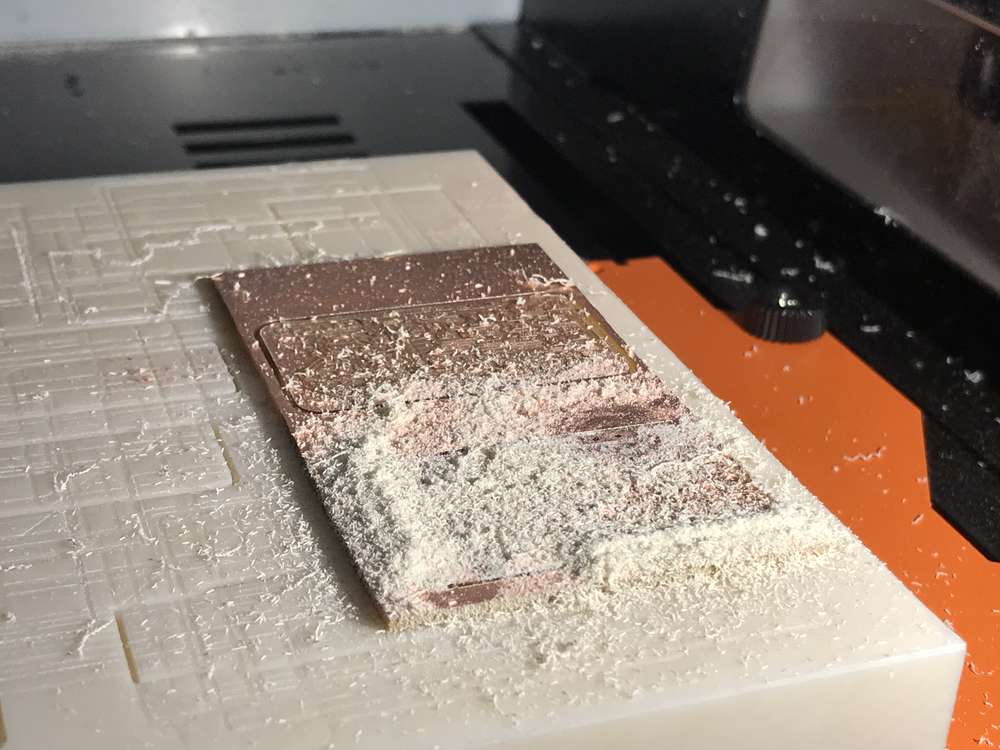

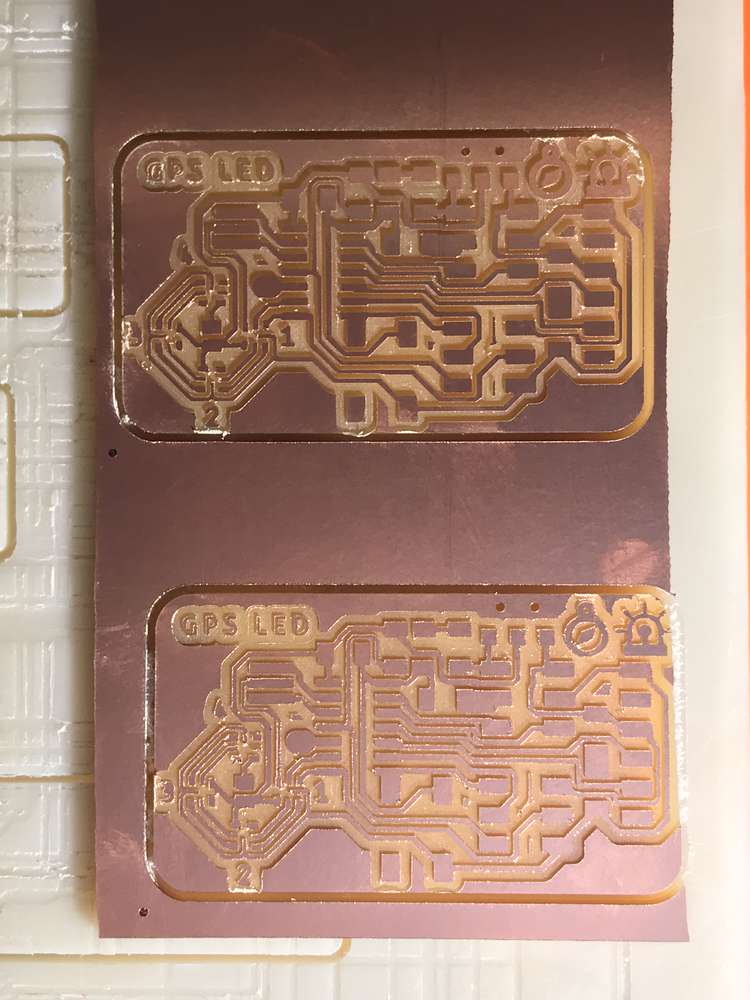

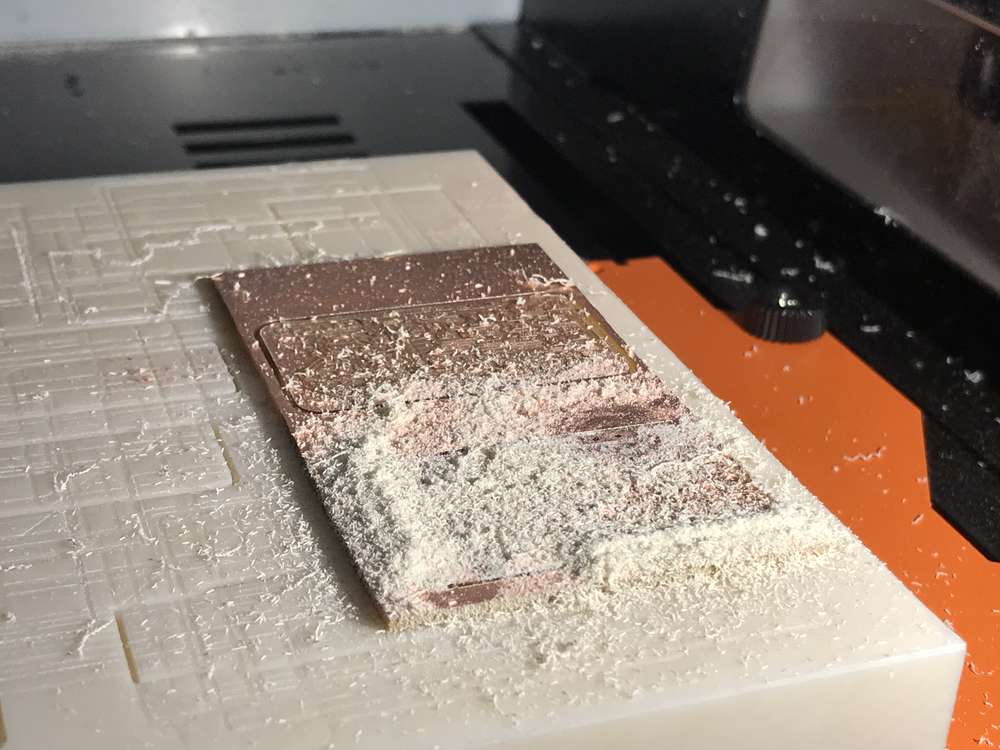

Fortunately, milling the board went smoothly (aside from a slighly clipped edge on one of the copies).

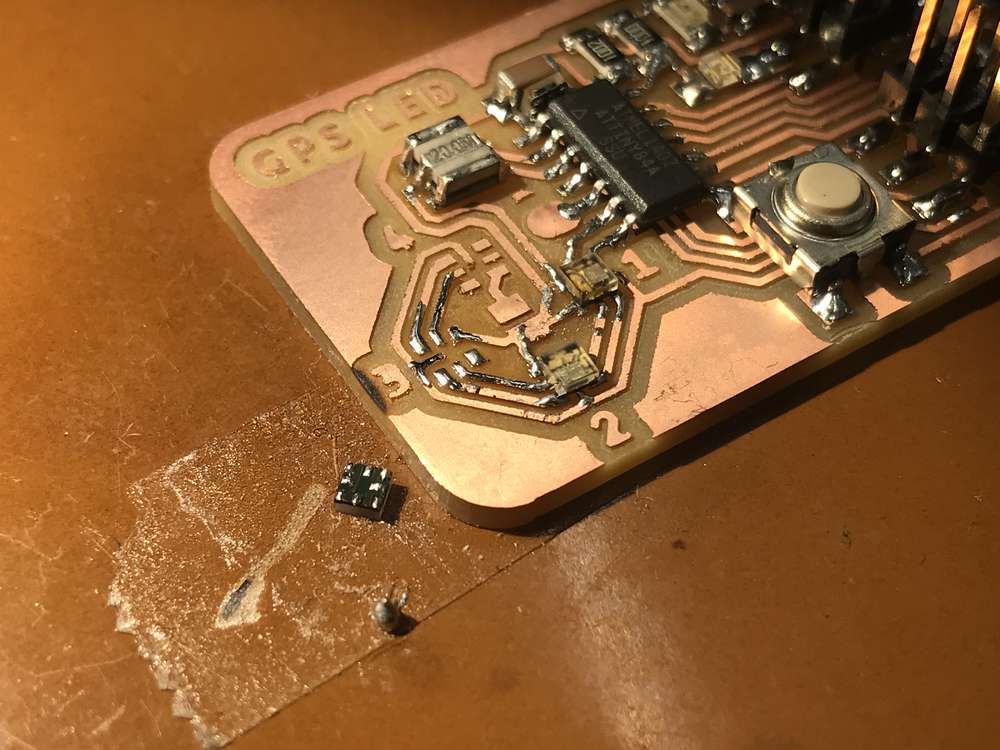

Stuffing the board was another story, mainly due to the super tiny DotStar LEDs. Tinning the LEDs was kind of fun, though super delicate and tedious. I applied a tiny bead of solder to the tip of the iron, and kind of rolled it around the back of each LED. The solder would stick to the pads and the surface tension caused it to hug each pad rather than cover the entire surface. I tinned the pads of the LEDs, tinned the pads on the board, placed the LED on top (surprisingly challenging to align even with tweezers), and used the heat gun to melt it into place. Sometimes the air from the heat gun would cause the LEDs to blow away before the solder melted. When it worked, the LED would slide into place like it was meant to be. When it didn't, the clear casing on the top of the LED got burnt to a crisp. As it was, the heat from the gun burnt the tops of my boards. Nevertheless, it seems like everything is now connected in place.

You can continue to Part II, here.