In the past couple of years I've gained an interest in soft robotics, but I have never made soft robots myself. So this week was a perfect opportunity for me to try some techniques.

1. SOFT ROBOTICS TOOLKIT

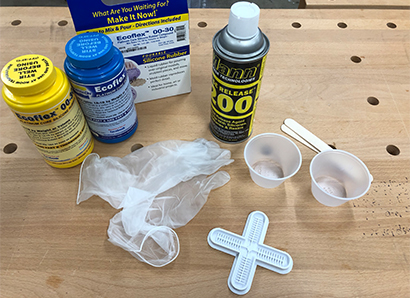

The Soft robotics toolkit is developed at the Harvard Biodesign Lab, and is a collection of shared resources to support the design, fabrication, modeling, characterization, and control of soft robotic devices. First, I gave their soft gripper tutorial a try.

2. SCIENCE BUDDIES

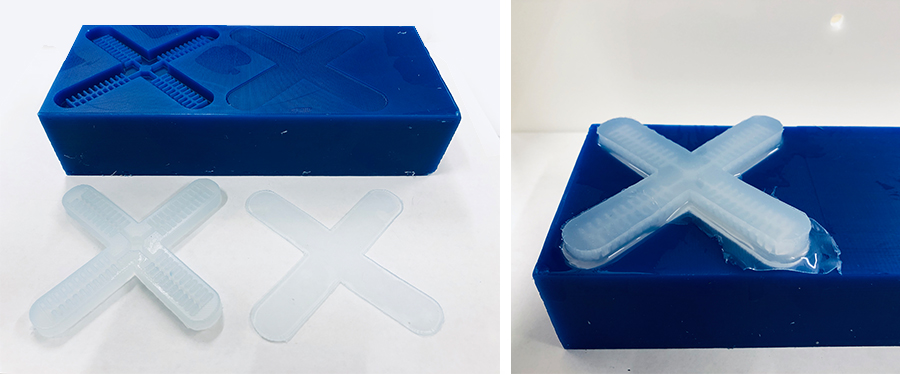

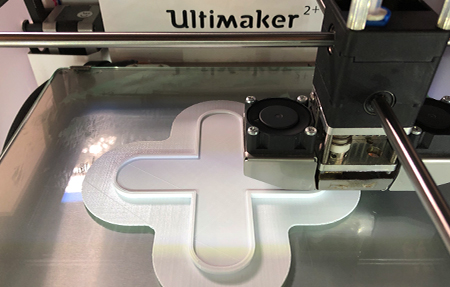

The Science Buddies website has a tutorial for a similar soft gripper, along with the necessary stl files for molds.

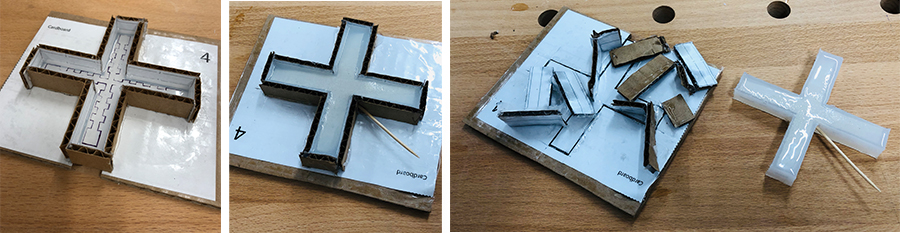

I printed the stl file they provided, and modeled one myself to serve as a "bath tub" to mold the other side of the gripper.

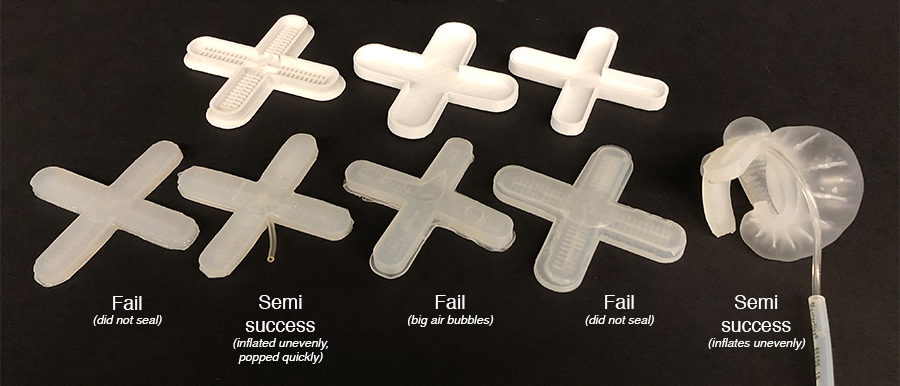

Last try before I give up! I made sure the oven was leveled before I did any curing. I tried both a smaller, tight "bath tub" and the previous larger one to mold the bottom layer and glue the bottom and top layer together. The smaller bathtub resulted in large air bubbles. The larger bathtub resulted in a well sealed soft robot. Still.. inflation is uneven, which can cause overinflation in one finger and result in leaks, but this one seemed more robust than the previous ones I made.

The stl for the top part of the soft gripper (from Science Buddies) and the "bath tub" I modeled for the bottom part.

Sticking the piece with the air channels together with a 2 mm base worked well: it gave the most even performance among all four fingers. The 1 mm base proved too thin.