Work Progress

I decided to use this week to develop my final project. My goal is to make a smart curtain system, so I need at least one motor.

Neil gave us a lot of motor selection and introduction in the page,

including the DC motor,servo motor, brushless DC motor(what???), and unipolar and bipolar stepper motor. In order to better understand

which output device is more suitable for my project, I want to compare the difference and advantages/disadvantages of them.

Some take-aways from this site.

DC (Direct Current) motors are two wire (power and ground), continuous rotation motors. When these wires are connected to power supplies, a DC motor starts to spin until that power is removed. Most DC motors run at a high RPM (revolutions per minute). DC motors could be used for computer cooling fans, radio controlled cars or other automotive applications.

Comparing servo with standard DC motors, servos usually have three wires (power, ground and control). Power to servo motors is constantly applied. Servo controller regulates the current draw to drive the motor. These motors are designed for more specific tasks where position needs to be defined.

Although, we must mention that servo motors do not rotate freely like a standard DC motor unless it’s modified for continuous rotation. These type of motors do not have a limit on its range of motion and instead of having the input signal determine which position the servo should rotate to, the continuous rotation servo relates the input to the speed of the output and direction. However, for most of the servo motors the angle of rotation is limited to 180 degrees back and forth. Servo motor receives a control signal that represents an output position and applies power to the DC motor until the shaft turns to exact position, determined by the position sensor.

To control stepper motor, we need an external control circuit or micro controller (e.g. a Raspberry Pi or Arduino) to individually energize each electromagnet and make the motor shaft turn. When first “A” and second “B” electromagnets are powered, motor shaft aligns between them. When “A” is switch off, and “B” switched on, the gear rotates to align with magnet “B”. With each electromagnet around the gear we turn them ON and OFF in turn to create rotation. Each rotation from one electromagnet to the next is called a “step”, and thus the motor can be turned by precise predefined step angles through a full 360 Degree rotation.

Based on my understanding of those motor types, I think stepper motor with precise control and low speed is the best choice for a curtain system. (However, the shortcomings of the stepper motor are also obvious. We can see from Neil's video that the motor resonates easily at the turning.)

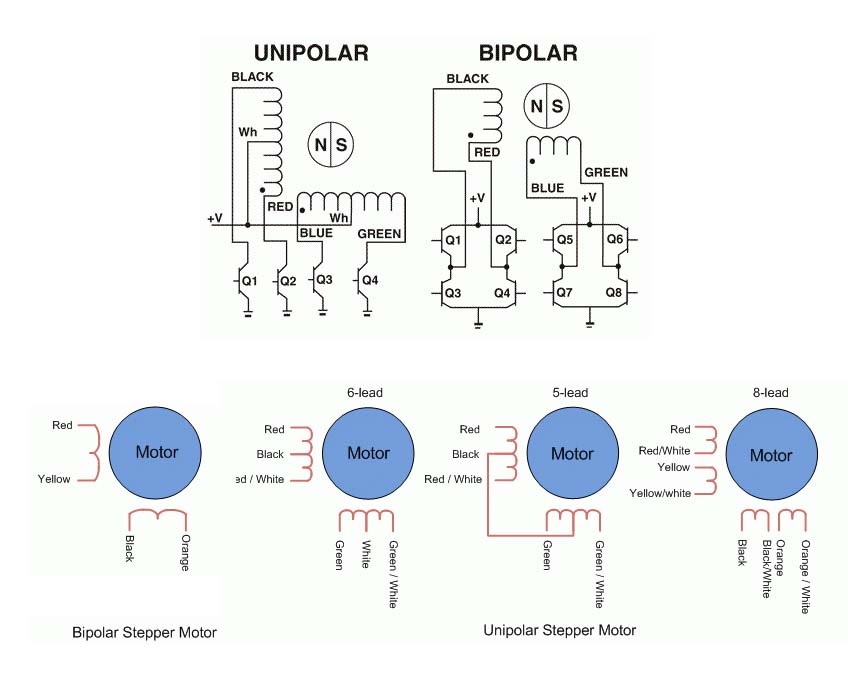

There are different types of two-phase stepper motor, unipolar and bipolar. This page explains their differences and basics behind the motors.

In conclusion,unipolar motor has a magnetic pole which can be reversed without switching the direction of the current, while bipolar motor needs to be more complicated to reverse the magnetic pole, this is done to reverse the bipolar stepper motor - circuit specialists blogcurrent in the winding.

Because bipolar motor winding is easier, I ended up choosing bipolar motor. I used H-Bridge A4953 and a four-wire bipolar motor.

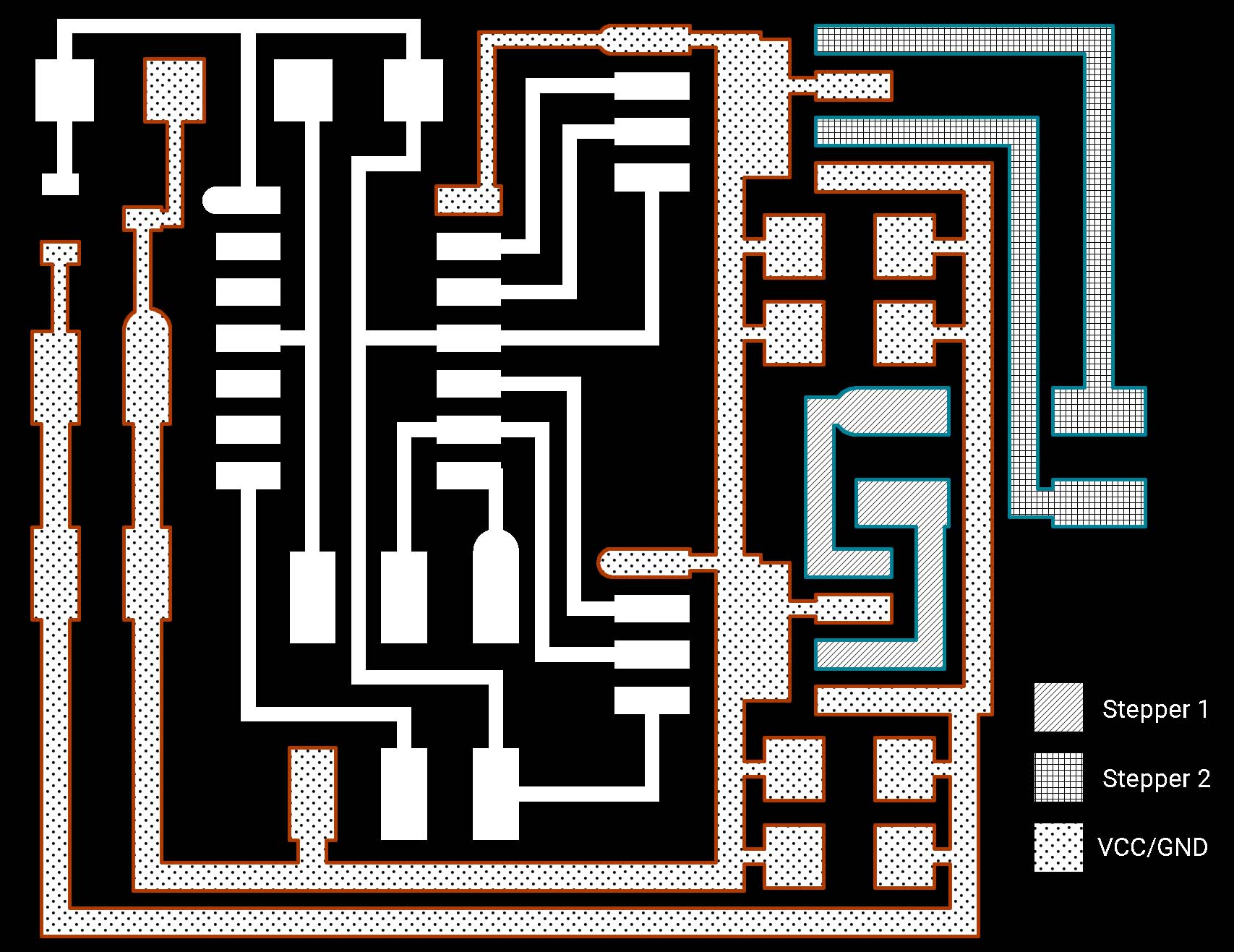

The rotation of the current needs to be realized through the combination of two h-bridges. In Neil's board, we can see how these two h-bridges control the motor. This is an analysis of Neil's example board.

My board

I used power supply machine to supply power to the board this week. Please pay attention to setting a voltage of around 8v before connecting power (since we use a regulator of 5V, just to ensure that the voltage value of supply is higher than 5V). If you see a current passing through, your motor has been powered.

The process of the Program was very smooth. The only factor that led to my failure in the Program was that I did not keep the board in the state of powered (no power to motor), so arduino kept reporting errors to me.

Arduino Code edited.

An important syntax——Stepper(steps, pin1, pin2, pin3, pin4)