Week 4. 3D Printing and Scanning

3D printing is a technology I am use to it! On the other hand, I’ve never done laser scanner. To make this week more interesting, Joao and I were printing filaments that I’ve never worked with. For this reason, we have modified a little bit the group assignment. Instead of characterizing any 3d printer, we characterized those filaments!

Group Assignment

Joao was interested in print conductive filament, and I was interested in printing flexible filament. We started with Proto-Pasta. The material itself seems pretty stiff, and it’s PLA base make that the print was straight forward. We designed different geometries to be able to measure different resistivities.

The surprise result was that a small piece of extruded filament (aprox 20mm x 1mm x 0,5 mm) had a resistance value of 2kOhms!

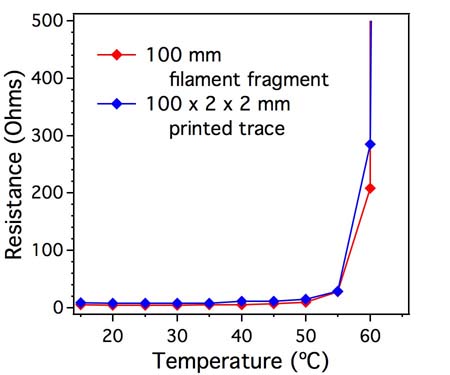

After this first disappointed result, Joao told me that some researcher in his lab has got a much more conductive filament called Multi3d Electrifi.

The recommended parameters provided by the brand were difficult to reproduce. As this filament was much more tender than any conventional PLA, the wheel that feed the extruder deform and broke the filament. Also, the recommended temperature of the extruder was 150 degrees. Without any external help, it was not possible to print at 150 degrees due to the filament was not being extruded. The limit temperature we found possible was at 172 degrees. To maintain the recommended temperature to ensure a desired conductivity was extremely important as it can be seen in this graph.

After several attempts trying to print it, we decided to change the nozzle to a 0.8mm diam. The same behavior was shown and we finally decided to focus our energies in other projects. The last material we tested was the TPE NinjaFlex. After the first complex results, the same behavior was shown because this filament is extremely tender, we trimmed perfectly the feed speed and changing the nozzle into a 0.8mm the results started to be good.

FOTO DEL FLEEEEEXXXAfter trim all the parameters, I decided to use this material to my personal project.

Personal Assignment

3D Printing

The personal assignment was to 3d print something not possible to be reproduced with other technology. I decided to do a flexible monolithic wing, with a morphing trailing edge!

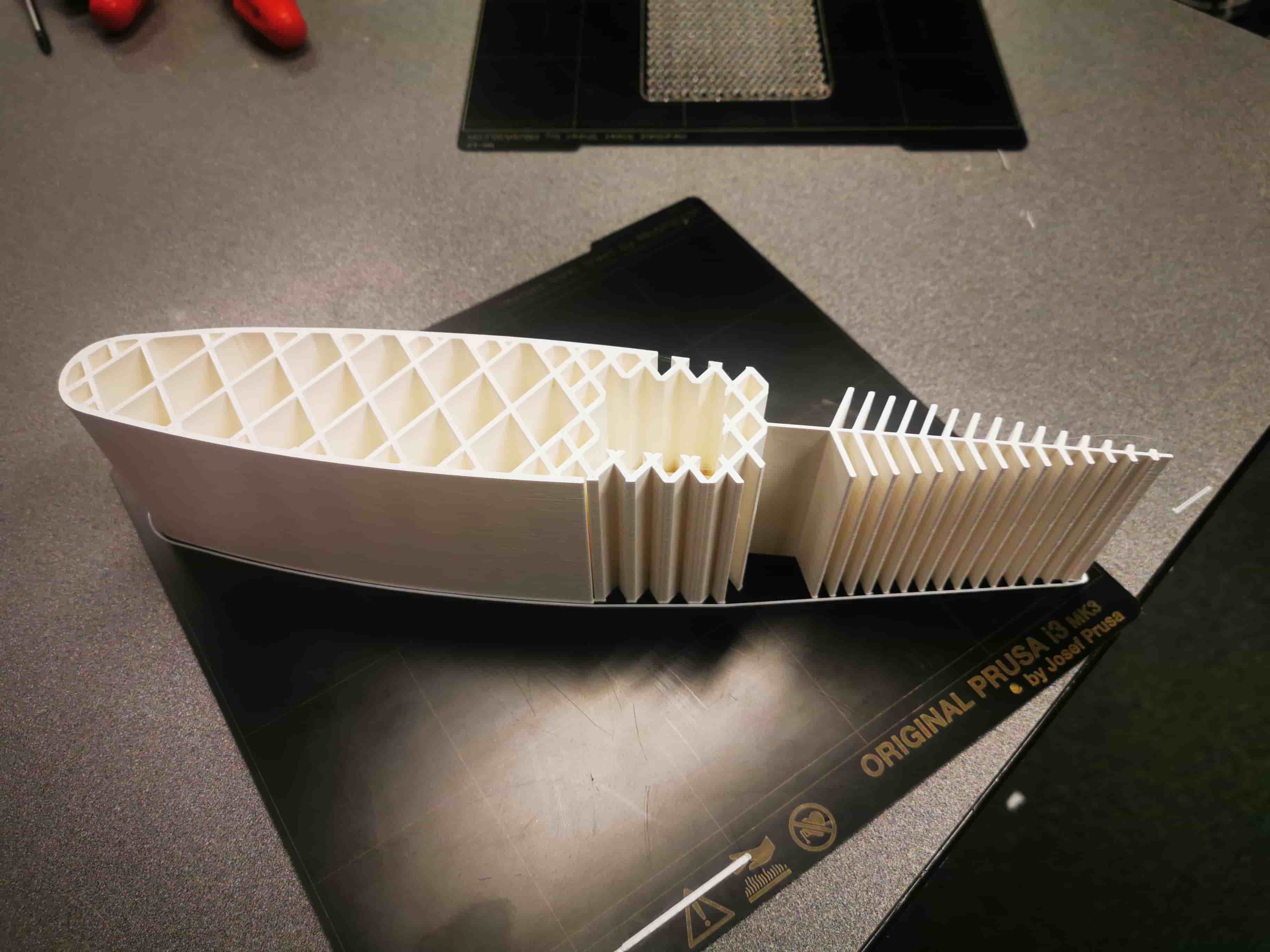

3D printing allows us to do complex geometries with complex aspect ratios that could be so difficult be milled. This is the reason why I used FDM to play with the thickness of the spines of the morphing tail and also to generate an optimized core inside the aeroprofile

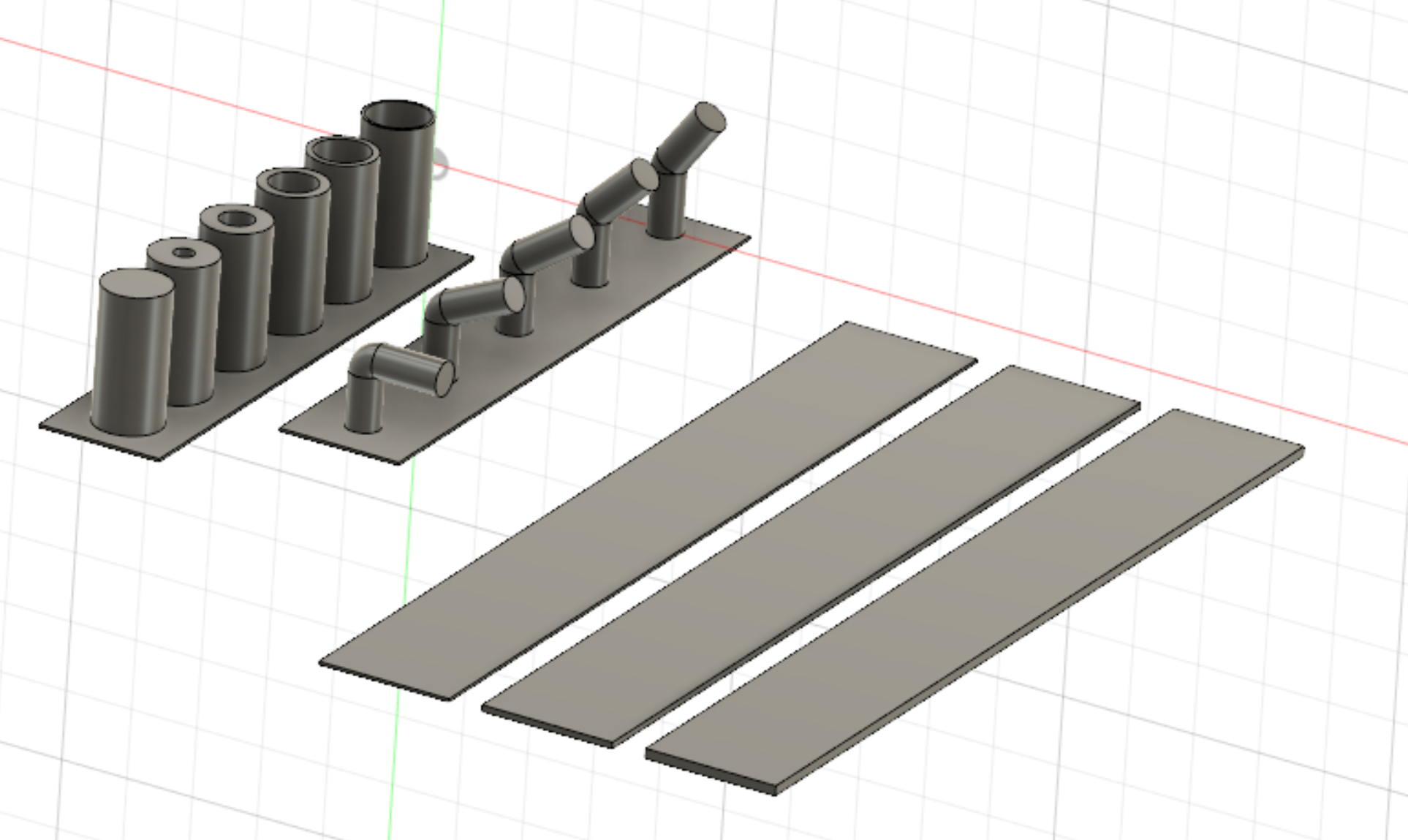

The design in Fusion360 looks like this:

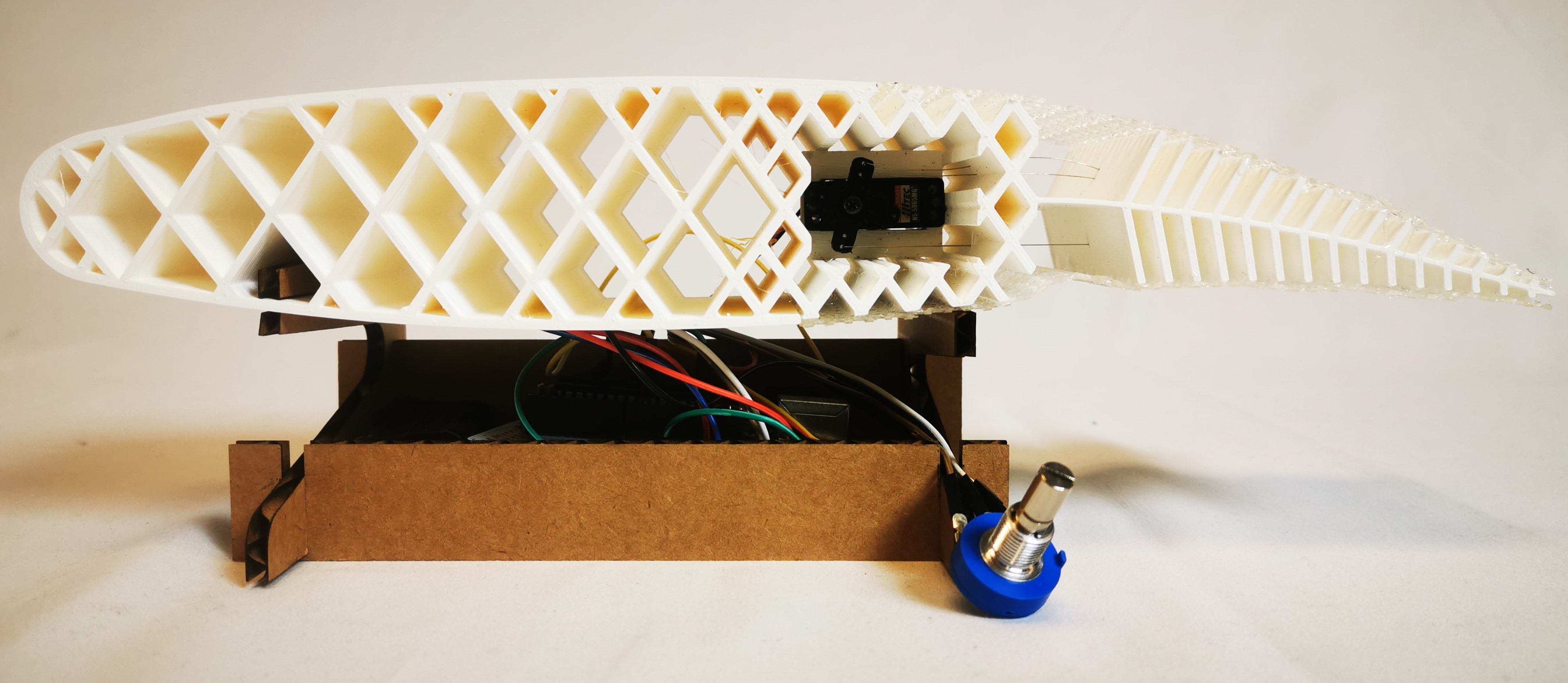

I decided to install a servo motor in the internal hole that will control the angle of deflection of the tail. I designed the central spine with the half of inertia than the vertical ribs (1mm vs. 2m). This design parameter will allow us to deflect the tail with a bigger tangent tension.

Also, I decided to put an auxetic skin in the deflection area in order to be able to deform without much tension forces. The skin is going to be manufactured with the TPE NinjaFlex.

The designing of the auxetic 3d printed skin was so iterative. After some iterations, the result was favorable.

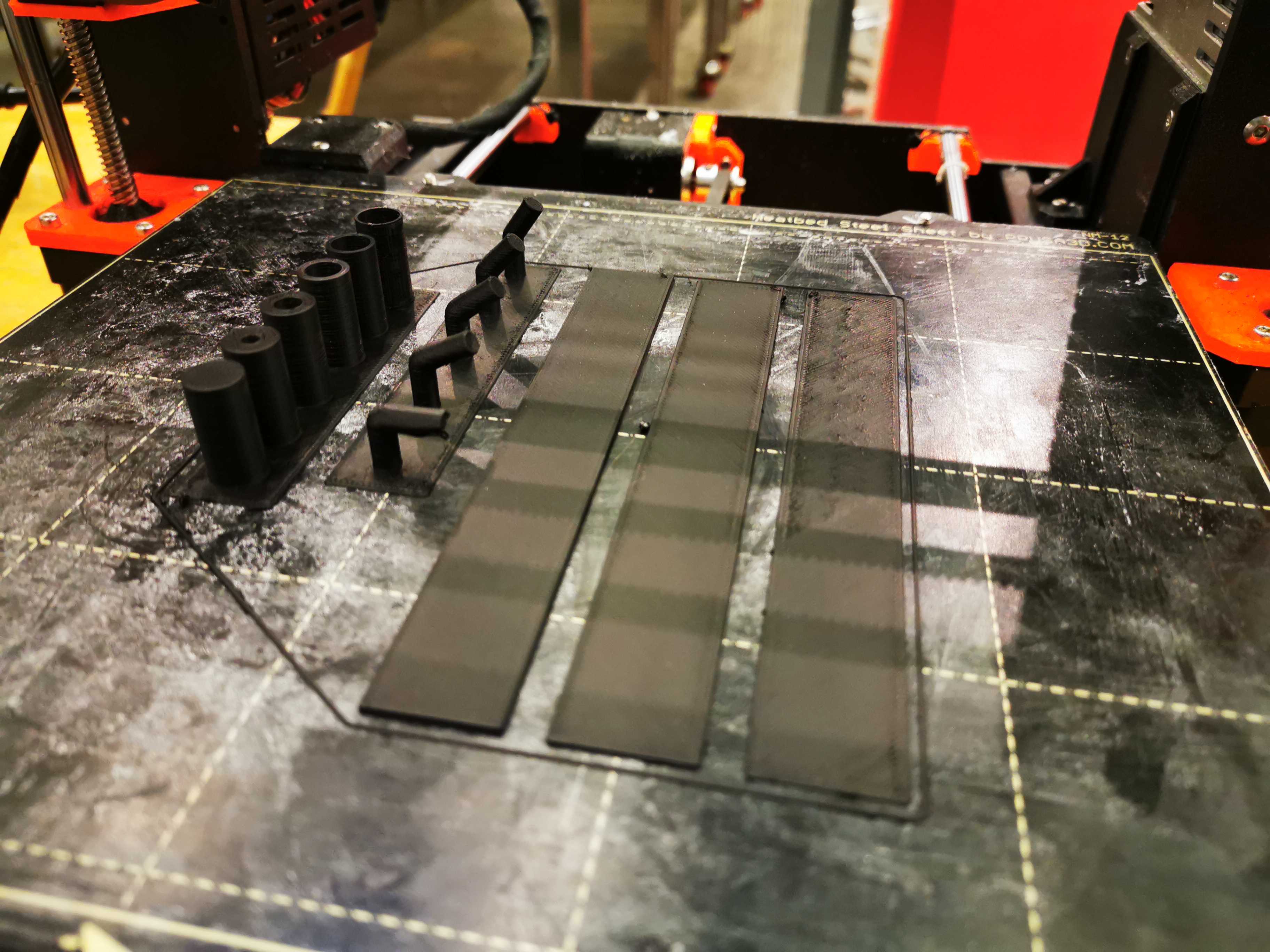

Both printings were committed in a parallel way. The first element done was the core structure.

After some iterations, I mastered the TPE printing!

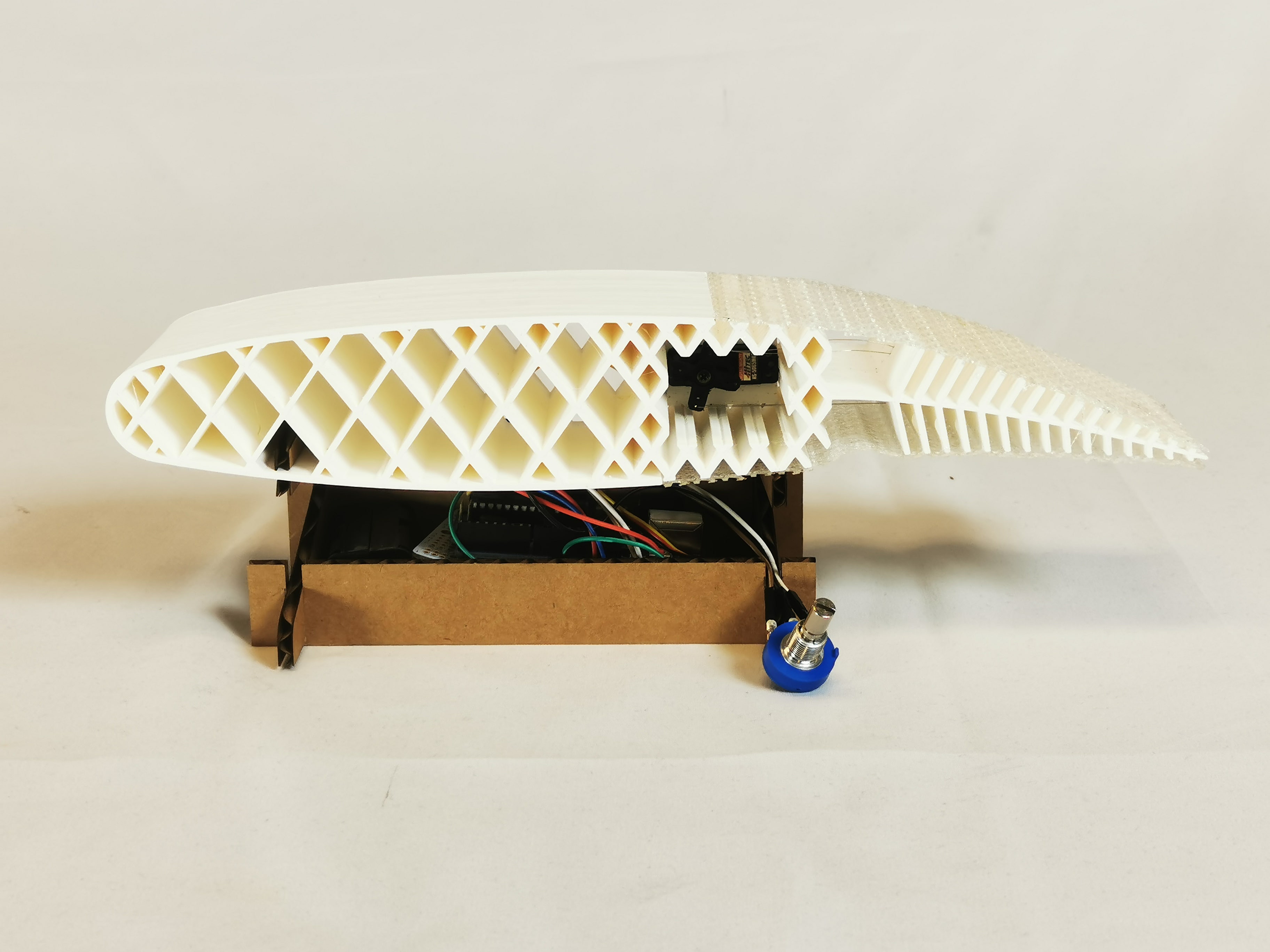

Once all elements were printed, the assembly started. I attached the servo motor and with some metallic wiring I assembled the control system of the trailing edge. After that, I glued the skins to the structure and I programmed an arduino one with a potentiometer to control the deflection.

Looking good!

Scanner

It has been my first experience with a 3d scanner. And to be fair, It’s been awesome. Patricia and I worked together to scan ourselves just for fun. Once trimmed the distance to focus the scanner, the process was pretty straight forward. The texturized STL was AWESOME. I felt ready to be inside any videogame.

Meta Alfonsos. 3 in 1.

As the stl generated was so clean, I decided to 3d print it.

Is this considered a selfie?

back to menu>