Week 3 - 3D Printing and Scanning

— weekly — 1 min read

In this week I wanted to make some progress with my Pong table final projects. I thought a good use of my time would be 3D printing the actual pong handle I would like to use for the final. So I designed a 3D model using Fusion 360 of a basic circular base with a cylinder on top. With Cedric's advice, since the job is very long, I went on and printed a sample with 25% the size. That reduced the time from 8 hours to 20 minutes!

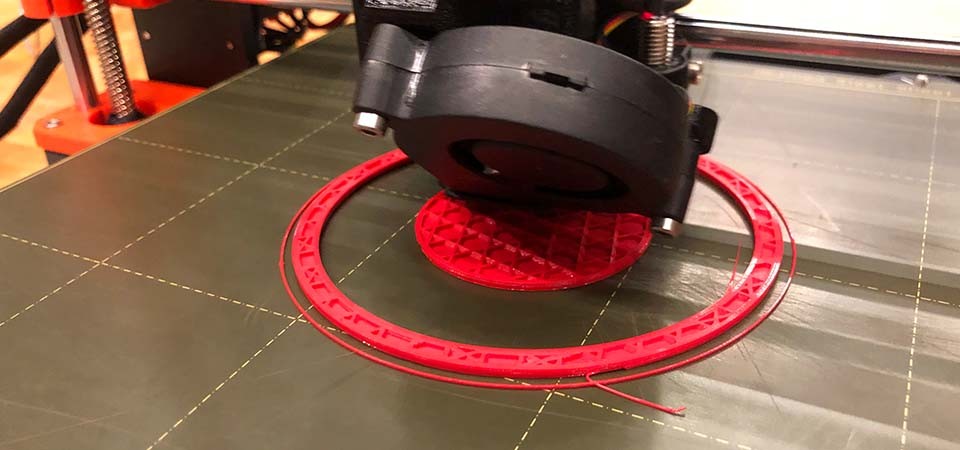

Baby handle! so far so good. I noticed that the Prusa machine decided to print a test base before printing the actual handle, but it didn't look like a problem so I assumed we are all good. Let's move on with the 8 hours job!

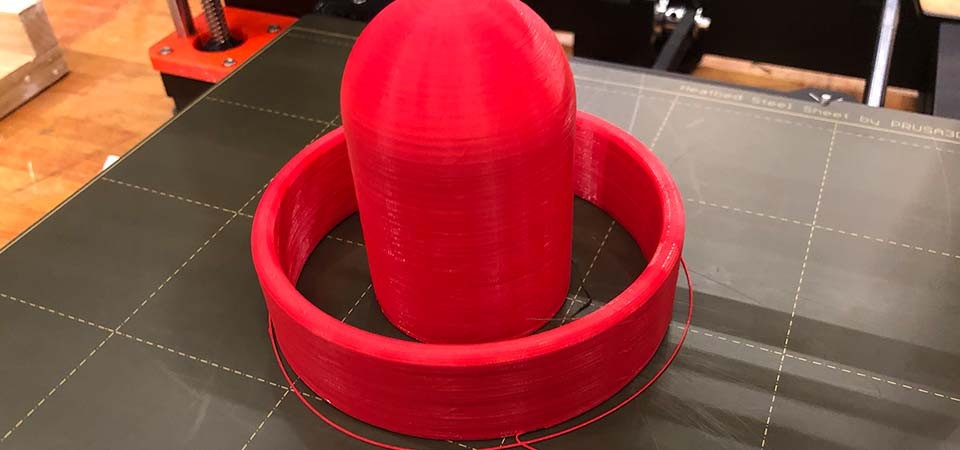

Looks OK... I guess?

Looks OK... I guess?

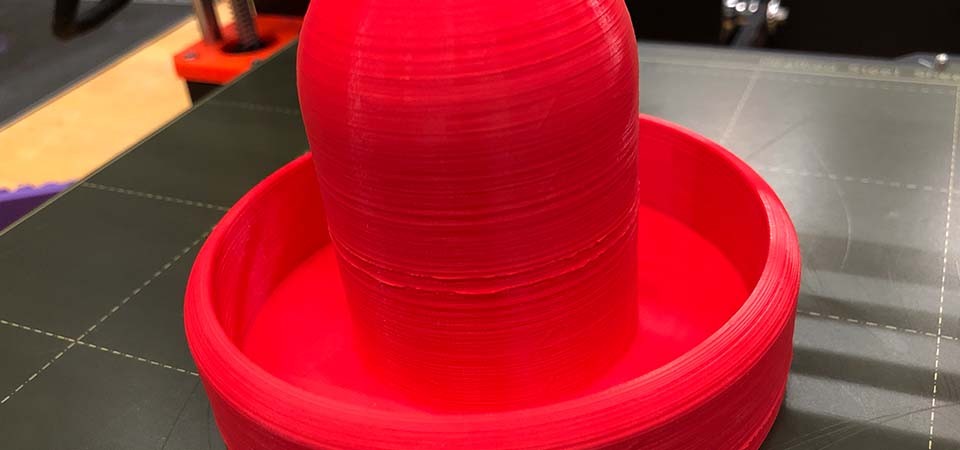

Oh no! after an overnight job, it looks like my base separated from my handle. The reason for that is I swapped the 3d model last second due to some advice from a friend. Two key conclusions: don't always listen to advices, and never make a last minute change if the sample worked as expected! Now, to save time I printed the same model as the sample, but with 100% scale. Let's see how it worked:

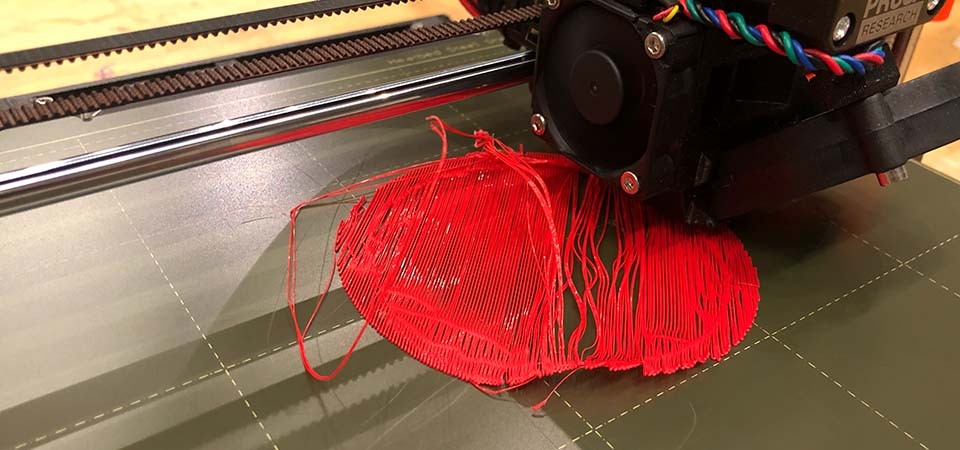

What the hell is this spaghetti? well, after 3 tries, it seems like one of the Prusa machines was not calibrated. So it's not always my fault if stuff don't work out! Let's retry on another machine:

Yep. we got it! Moving on to scanning with Leo, I thought it will be fun to scan (and print!) my dear labmate - Kevin!

So now loading it to the Leo software:

All seems pretty smooth! The Leo machine is quite amazing and detailed. We sent this model to the J55 and hopefully by the night we are going to have a mini-Kevin for our office! One small comment regarding Leo - we had some troubles when overlapping the same angles, so a key takeaway is to scan exactly once from each angle of the object.