Week 5 - Make Something BIG

— weekly — 2 min read

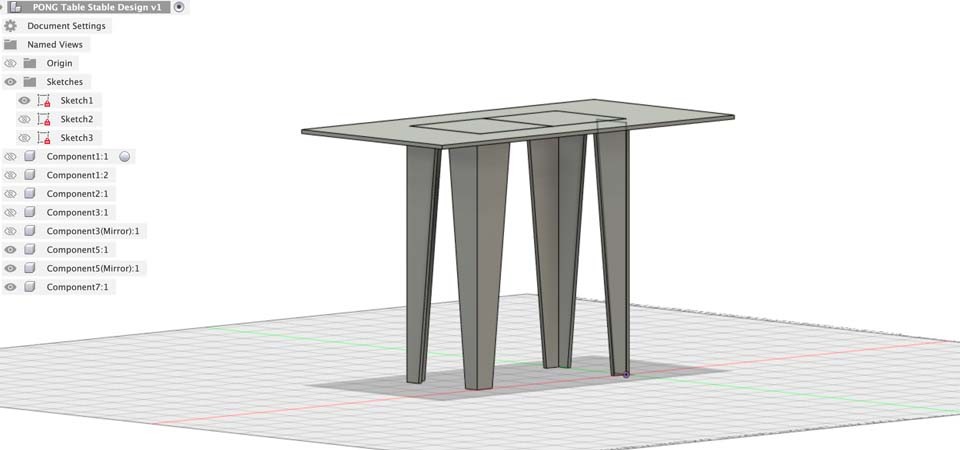

In this week I am going to make another step forward with my final project. Since we need to make something big, I thought the actual table my game is going to be designed on can be a nice project. So I started off by designing a simple table:

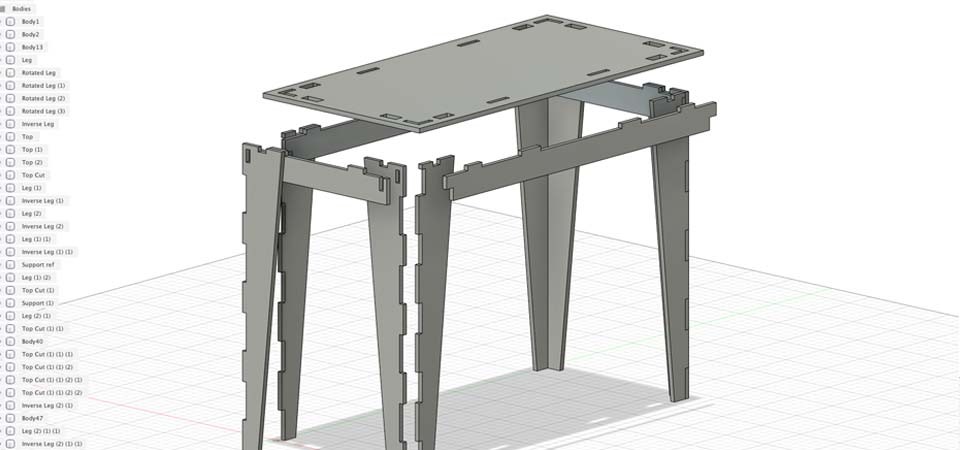

So now that I have the complete model in mind, let's go ahead and design the joints. The first step is to define how the two parts of the leg are going to connect:

After some trial and error with this joint, it didn't feel stable enough to hold the two pieces together so I had to make a dovetail-like joints across the entire leg. So I fixed that and got an idea on how to join the top of the table to the two parts of the legs:

The problem with my initial model is that the legs are too far from the tips of the top, so especially with the material we are about to use, this is not going to hold. With my current design, the legs and top hold up really nicely:

With a tip from the Maestro himself Alfonso I added another layer to add more stiffness to my design. This component basically holds the legs to its corresponding quarter of the top:

Finally, let's make sure that all the parts make sense together and that it's going to be assembled correctly:

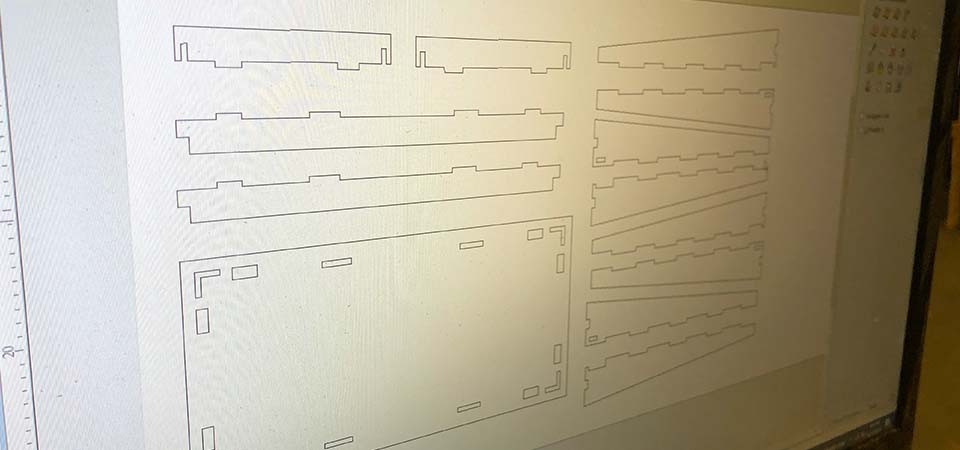

Looks good, now I export my DXF files so that it can be milled using the VCarve software. This is also a good time to ascertain that my parts actually fit together nicely to the 4''x8'' plywood sheet.

Perfect. it fits. I had to do some clicking to get the endmill cut sharp corners nicely, but after that we are underway:

We are ready to assemble. First try failed because I tried to assemble the legs first and then the table. However, it is very hard to hold together all the parts and insert the top into it's respective slots. So instead I flipped over the entire table and started from the top down:

Nice! looks like all the joints work well together. However, it is not 100% stable because the holes for the joints were calculated with a constant material thickness. An intrinsic disadvantage we have using this material is that it's not evenly thick across the entire sheet, so some holes were wider than expected, and the design could not hold strongly without glueing. Well, so let's glue:

One thing I would want to do for my actual table is to rethink the assembly while 3D designing my model. This was relatively hard to put together due to the support component complex joints. The next time I will design it I will try to simulatenously realize how the all the pieces should be joined in assembly time. Final result: