Week 7 - Molding and Casting

— weekly — 2 min read

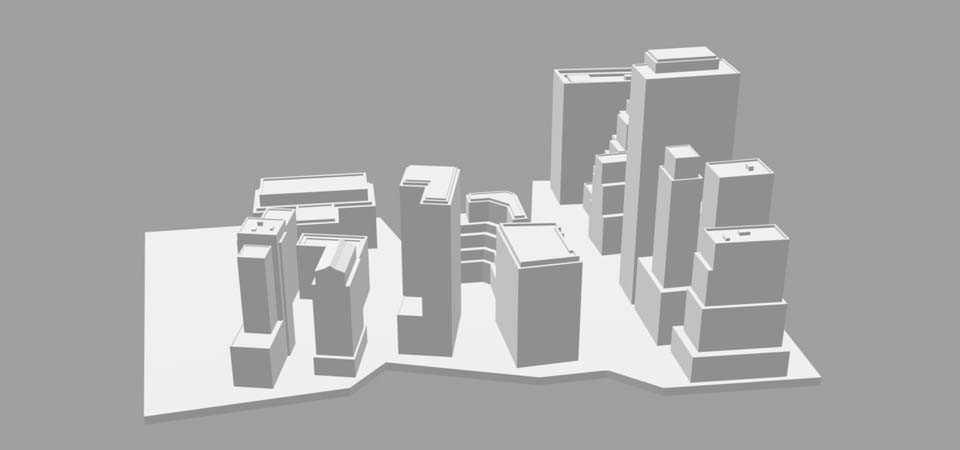

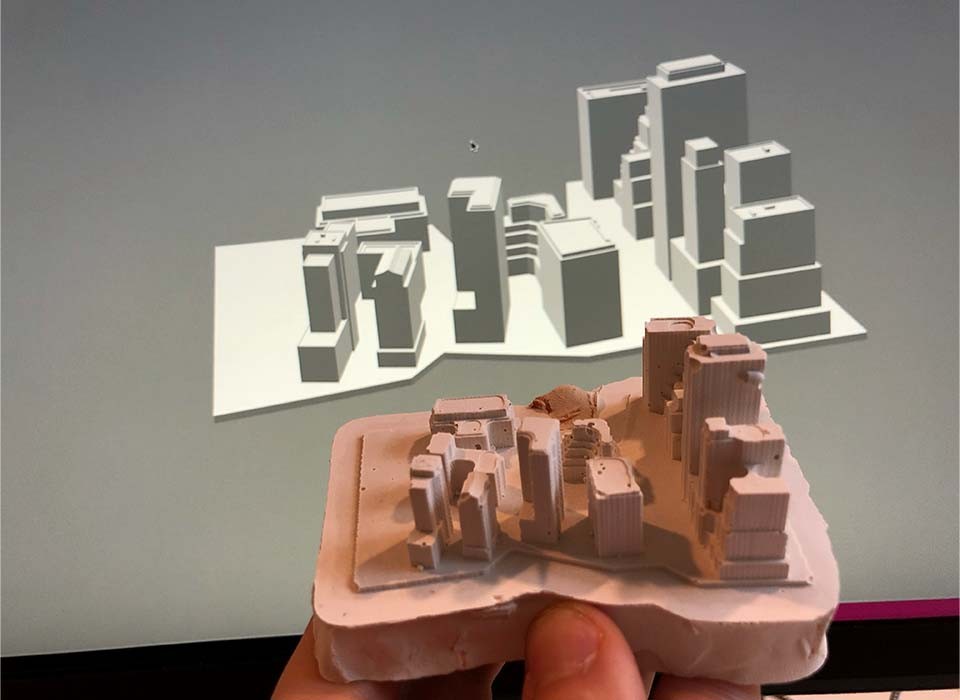

This week I decided to take a break from my final project efforts and try to do something cool instead. I really miss my hometown Tel Aviv so I wanted to make a topography model of my favorite parts in the city. I used CadMapper in order to get the CAD topography for my desired geolocation and translated it into an STL file which can be milled using ShopBot Desktop.

This model looked very good to me, but unfortunately after loading it in VCarve Pro it seemed too detailed for our 0.3 inch endmill. I figured out that in order to achieve a good milling, my topography has to be way simpler and less dense so that the endmill size would be able to fit in between buildiings.

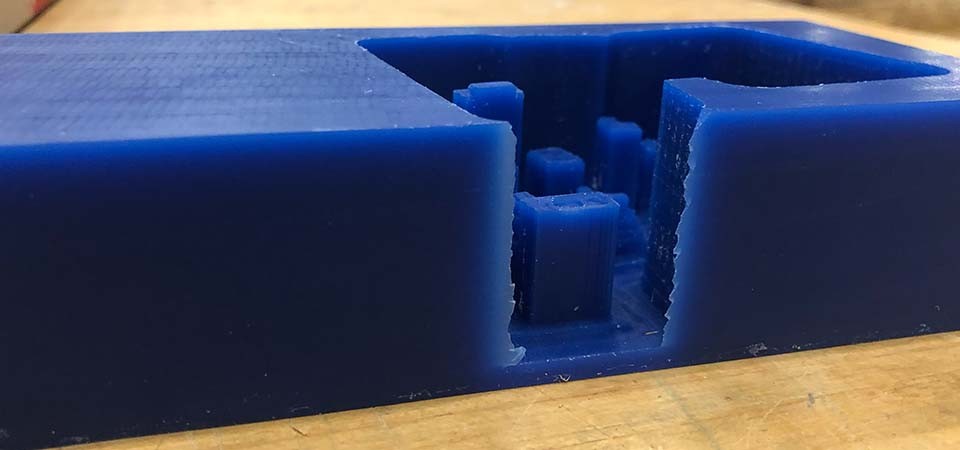

This model seems reasonalbe (I hoped!) so I loaded it and made it fit in dimensions to our 7x3x1.5 wax cube. One mistake I could have avoided in this process is: for some reason the X,Y axes speed went down to 0.05 before the milling process began. So I waited ~1 hour for essentially nothing. The ShopBot software sometimes randomly changes values in configuration so that has to be taken into consideration next time I'm milling.

This came out pretty well! One thing to notice is since I didn't zero the X,Y axes percisely on the bottom left corner, and since the model fit very closely to the edges, I had a gap on one of the wax faces:

However, this is not a serious problem because I can simply glue some cardboard and my OOMOO should flow in nicely.

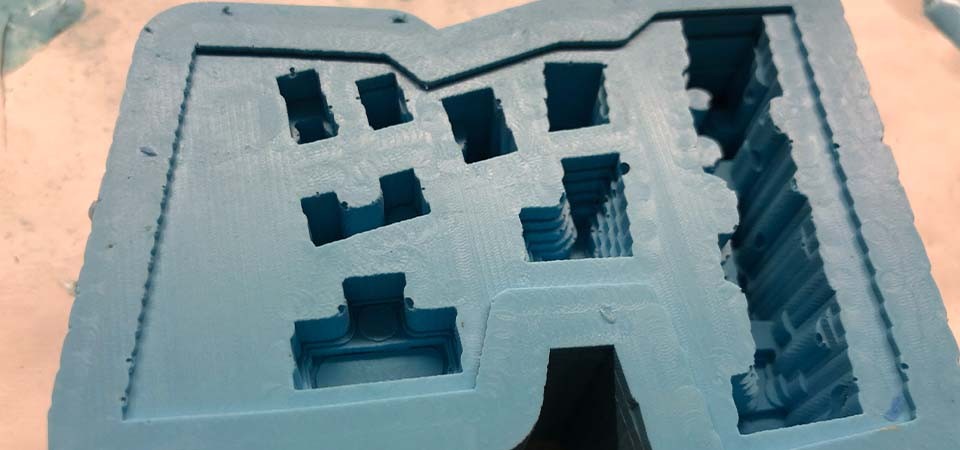

I mixed the two OOMOO parts and waited for about 2 hours, time to lift my silicon and see what it looks like:

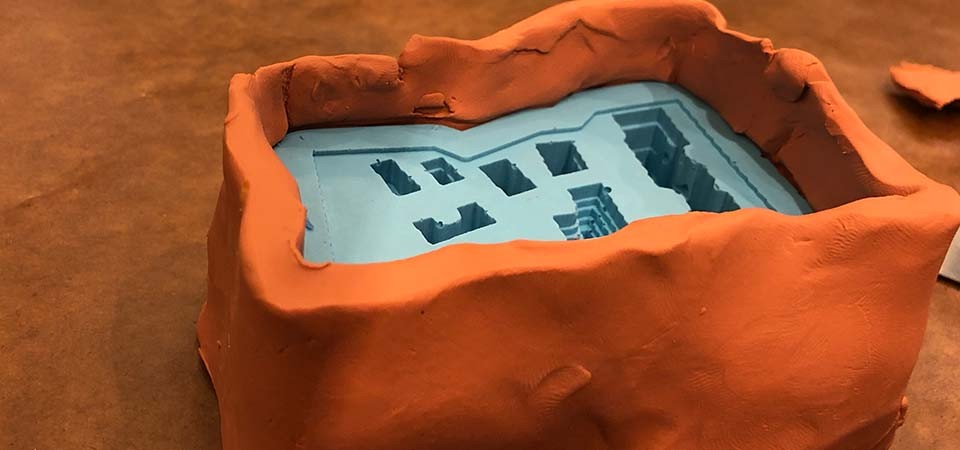

That came out very detailed! I was quite surprised, I expected my mold to not catch so many of the fine milled details! So now we are ready to cast, I chose Drystone as my material. I had to tweak my mold a little bit because the floor was too narrow to hold the Drystone and I was afraid my model will collapse. So I used oil-based clay to crate a "fence" surrounding my mold. I hoped that it could hold together that bottom of the model and maybe even add some artistic features to my model.

Now I followed a procedure similar to the OOMOO but with Drystone powder and water, mixed together and poured into my mold.

Normally Drystone takes 20-30 minutes to cure, but since my model had so many fine details, I thought the material would benefit resting in the mold overnight. So I left it for the night and came back to check on it the morning after:

Overall I am very happy and surprised by the details I was able to achieve with the OOMOO silicon and Drystone, the process was very satisfying and even though I can not use this for my final project, that has been a wonderful experience!