<-- HTMSTMAA

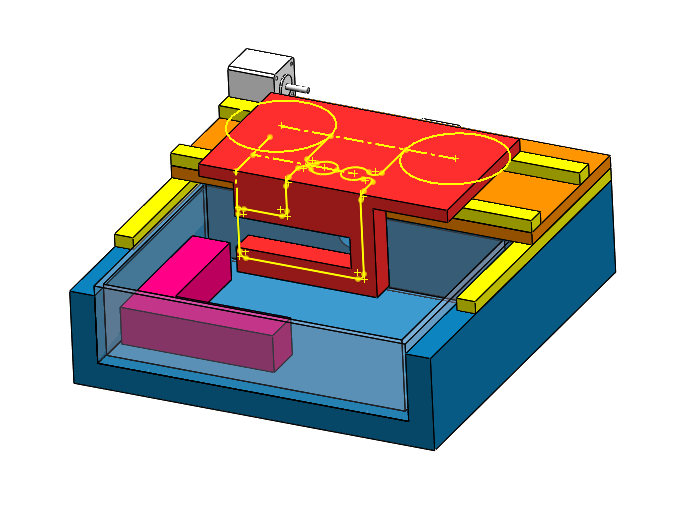

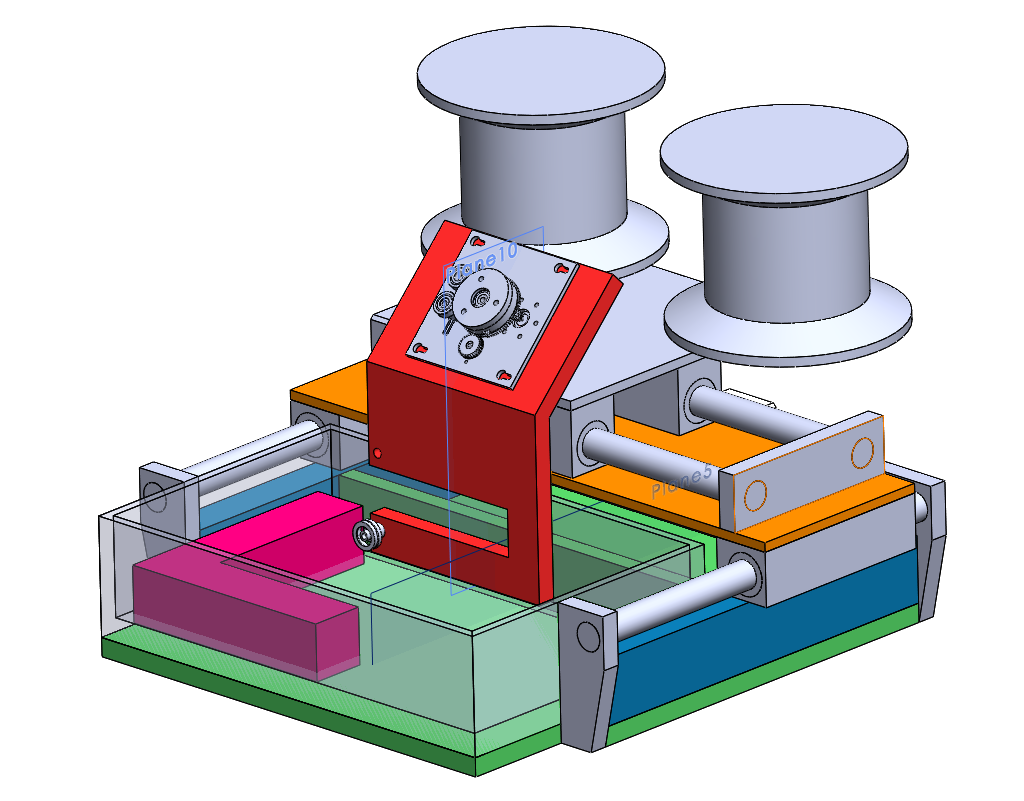

In the coming week I'll be making this machine...

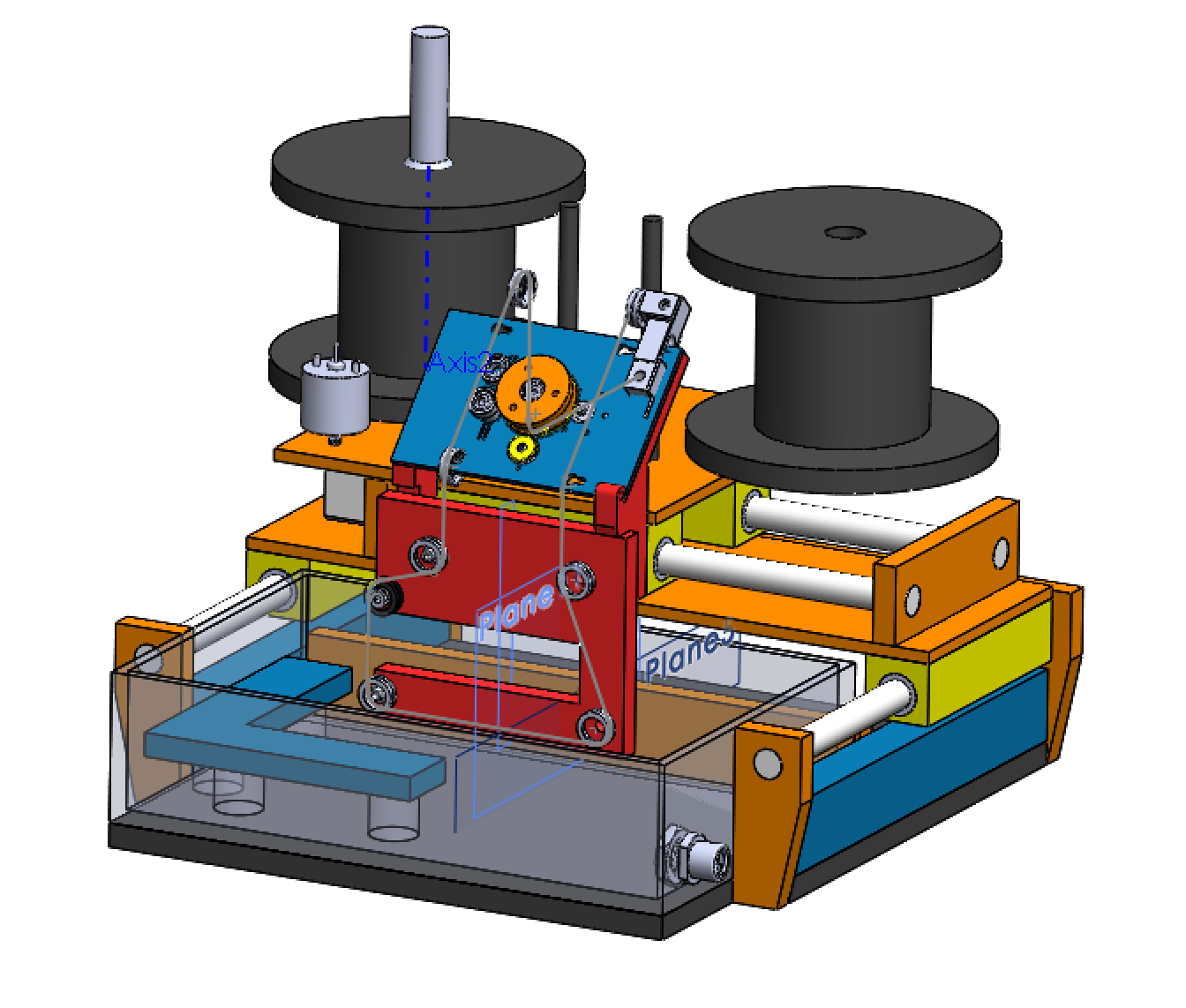

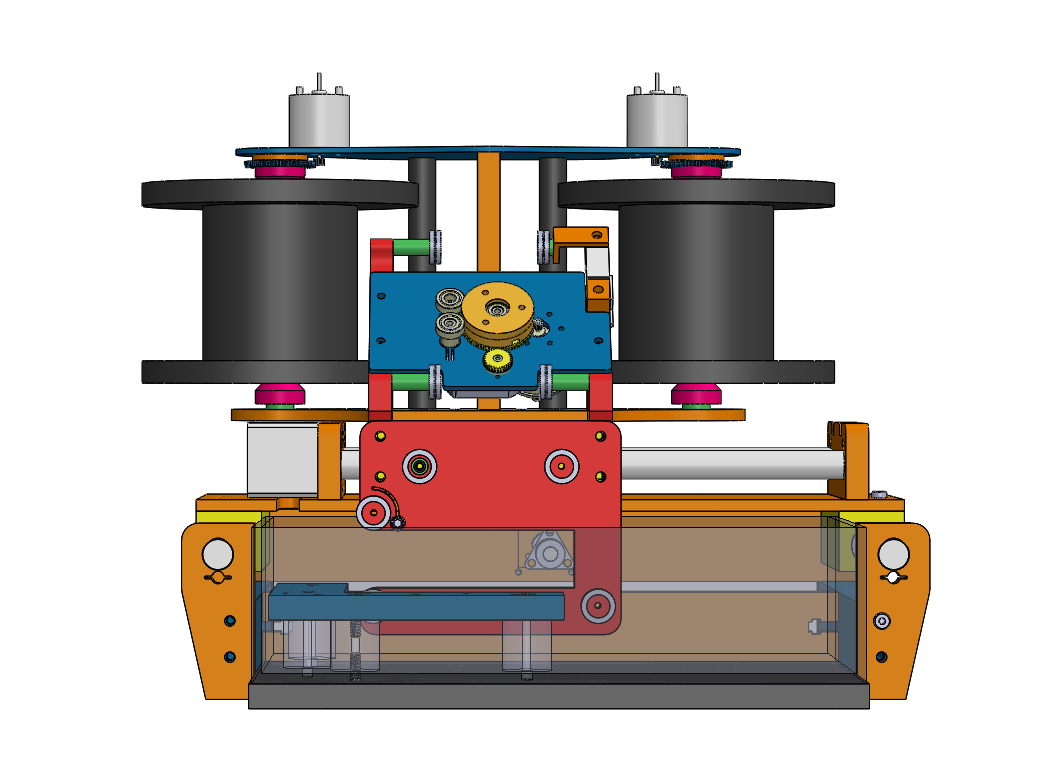

It'll have a work volume of 4.5"x4.5"x1.25" and a footprint of roughly 14"x15". Two stepper motors with integrated leadscrews will be used to move in X and Y. Wire feed will be controlled by the mechanism I built earlier which uses a closed loop DC motor. The wire tension will be sensed using the wire-tension gauge I made previously and controlled by simply pulse-width-modulating a DC motor on the take-up spool. A third DC motor on the feed spool will be used to make sure no part of the wire is slack.

I also started testing the power electronics that will be used to actually do the discharge machining.

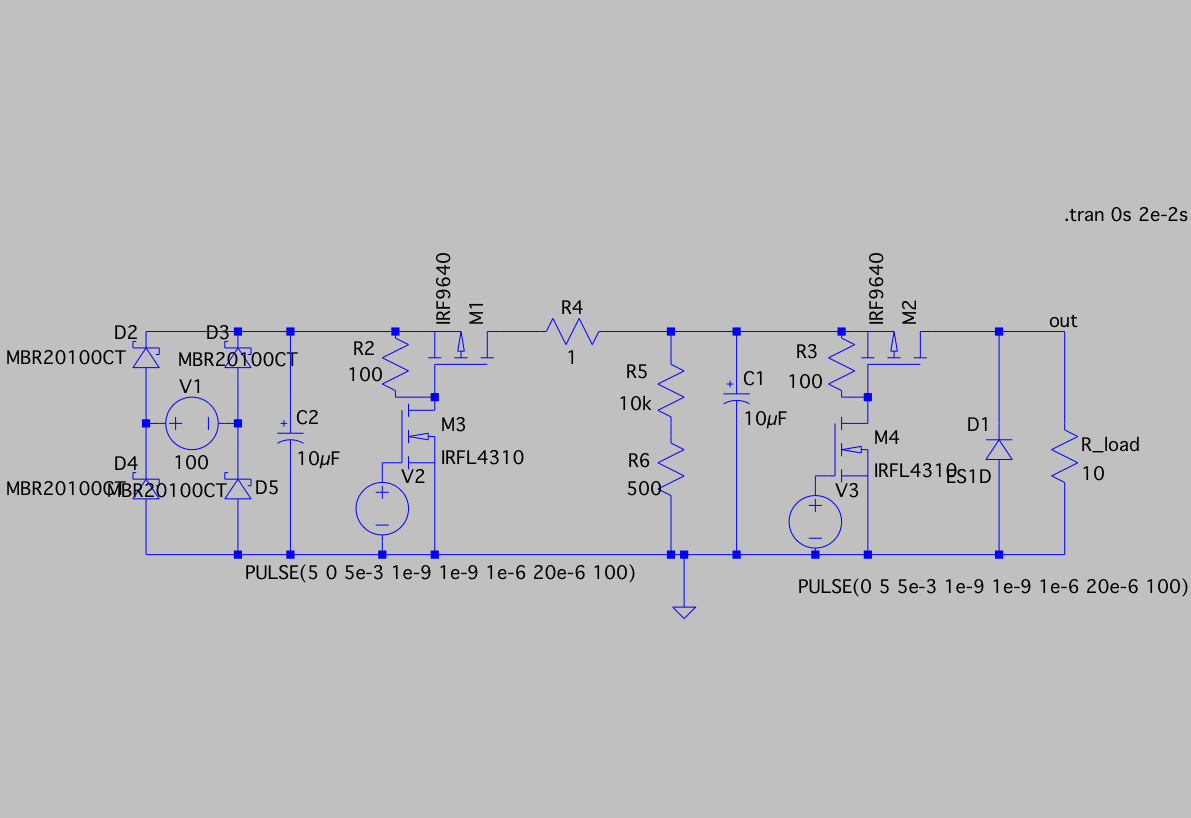

My circuit started like this:

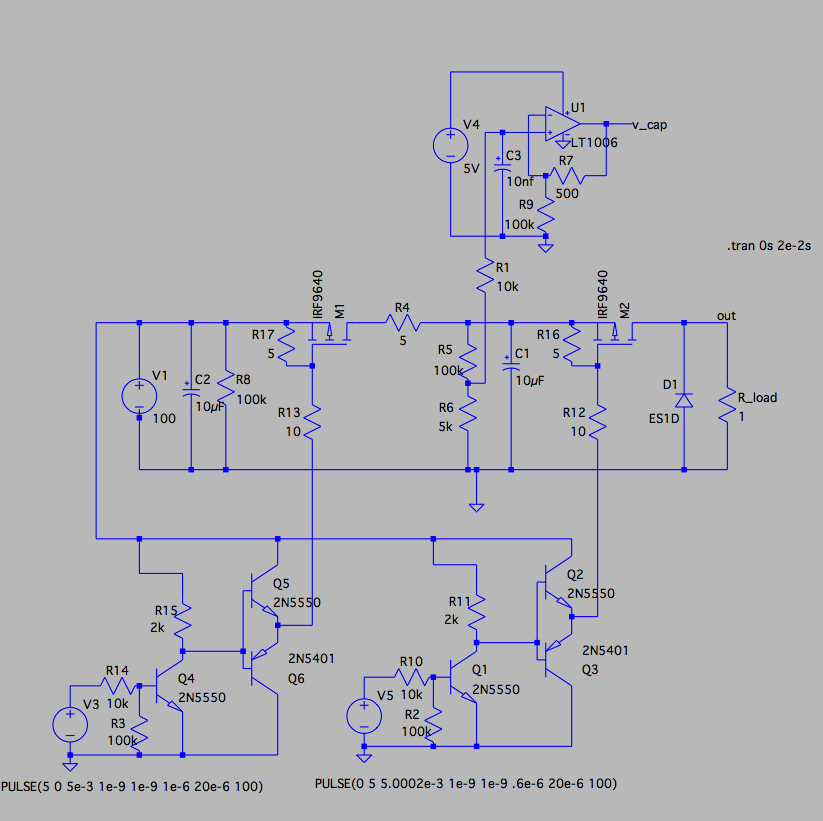

And then evolved to something like this:

And will further evolve one more step as I switch from P-MOSFET's to N-MOSFET's with gate drivers.

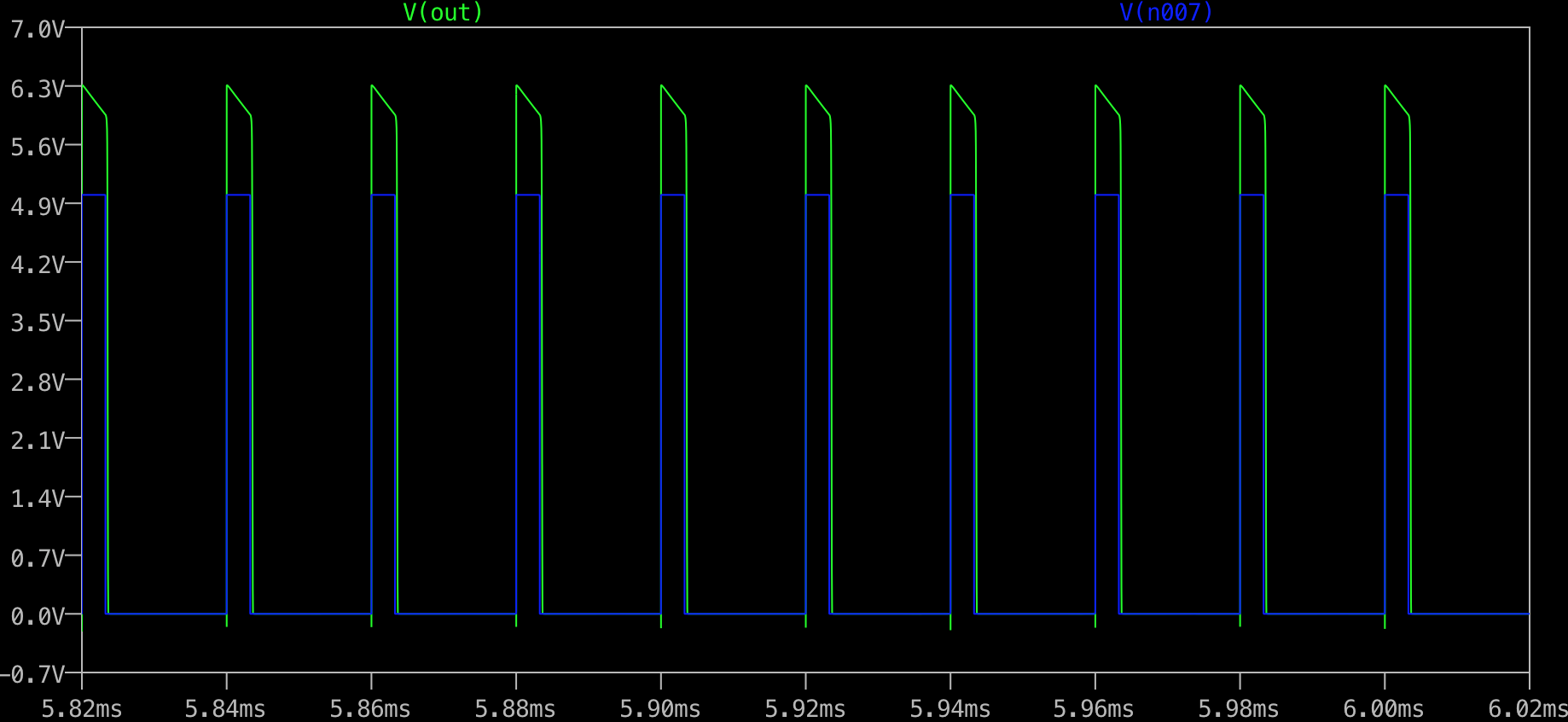

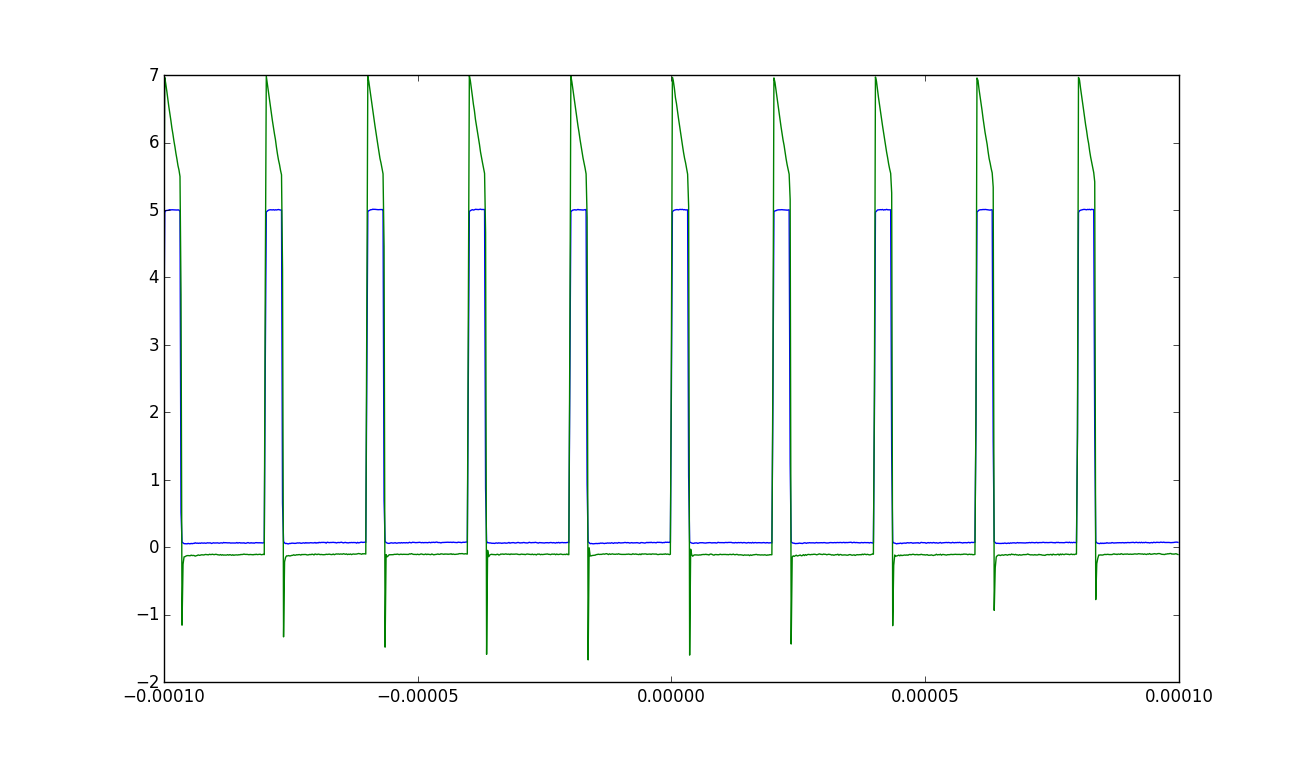

Along the way I tested a low voltage version of my first design. Simulation seemed to match reality...

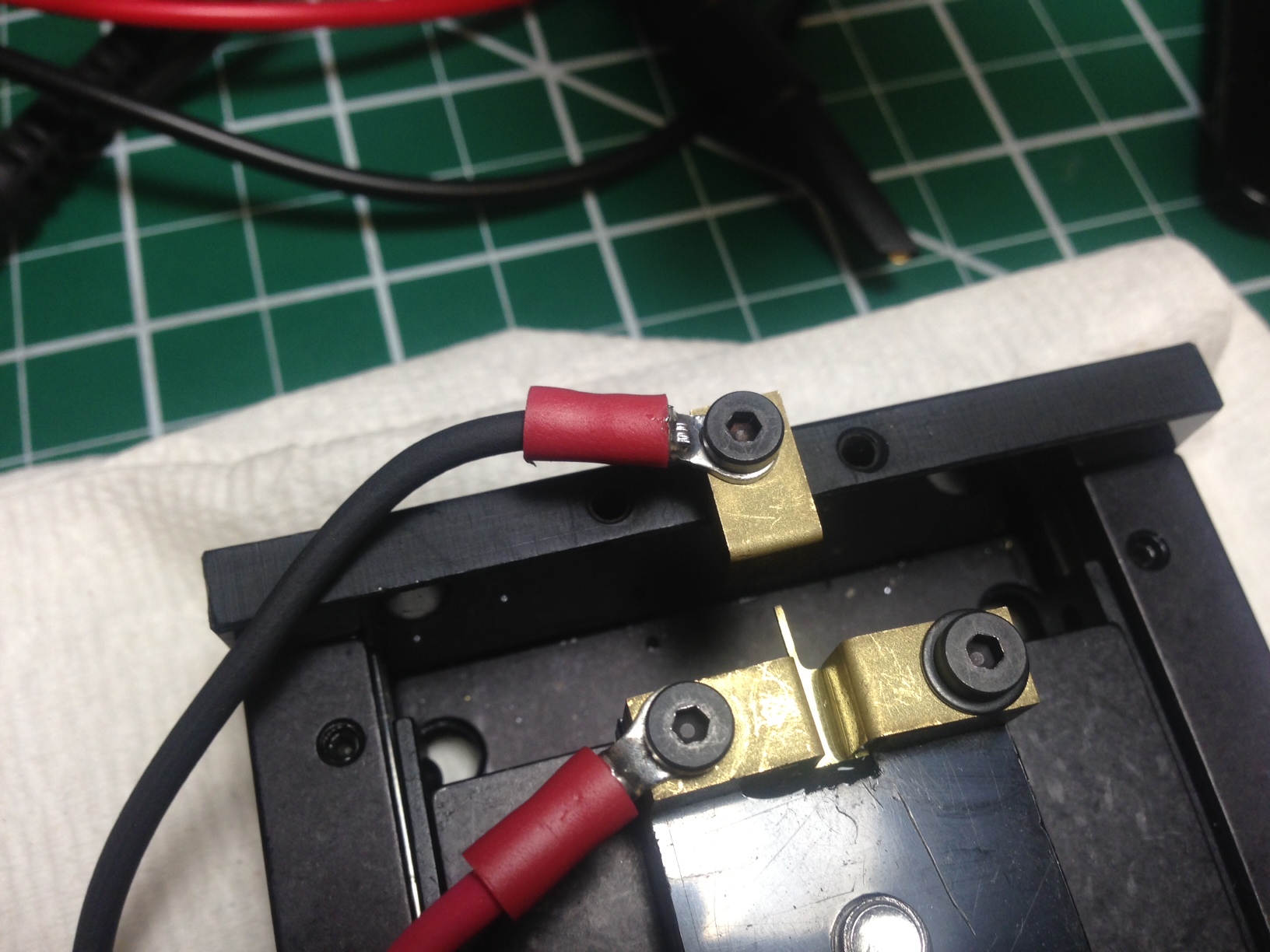

and then I saw sparking!

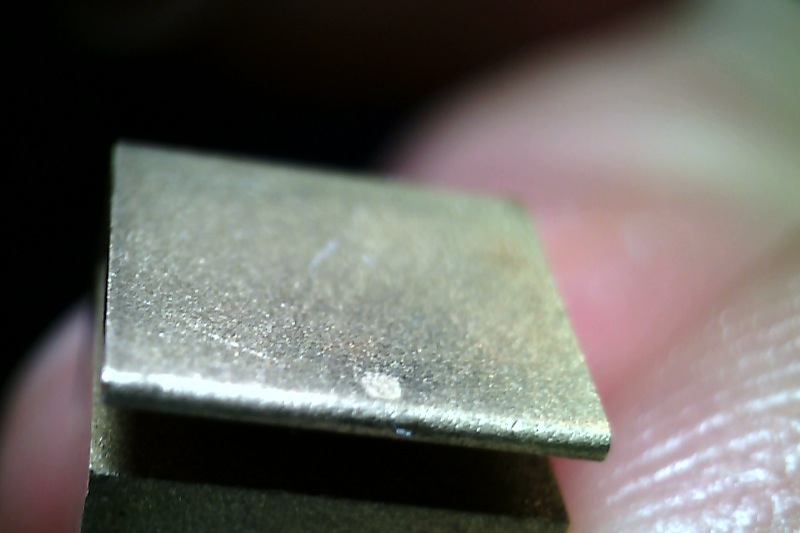

and eroded metal...