Olga Geletina

This is my Rapid-Prototyping of Rapid-Prototyping Machines:

How to Make Something that Makes (almost) Anything class page.

Areas of interest /

art

mutliaxial textiles

craft

looms

"smart" textiles

weaving, knitting, felting, braiding

Menu /

weaving vs. knitting vs. felting...

how does a loom work?

thoughts on Brother electric knitting machines

how clothing is made

etcetera

weaving vs. knitting vs. felting...

This section evaluates different ways of making textiles given a somewhat abritrary criteria.

weaving a process in which two types of thread or yarn are interlaced together the two types of threads run in different directions, with the warp threads running length-wise as the weft threads get inserted horizontally. In weaving threads are always straight and perpendicular to each other. The most common means of producing woven textiles is on a machine called the loom, which can be configured to produce both flat sheets as well as circular structures of fabric.

open source options: OSloom : an open source Jaquard loom that never posted it's models, files, etc.

Pamela Liou's loom is also undocumented.

clothing / final product: because woven fabrics are typically made in sheets or tubes, they are less suitable for "printing" a garment and would require tailoring. Read more on how clothing is made here.

etcetera: there have been a number of studies comparing different kinds of woven fabrics as well as their mechanical properties here are two papers on the subject matter:

Development of the Weaving Machine and 3D Woven Spacer

Fabric Structures for Lightweight Composites Materials thesis by Said Sobhey Badawi

3D Woven Fabrics

knitting unlike weaving knitting typically uses a single source of yarn that loops onto itself, over and under the established path. This gives knitted fabrics greater flexibility. It also allows for a greater contour control.

open source options: Open-Knit is a great project with both a github repository and instructables tutorial available. Open-Knit's github repository even features a 3D model of it's machines – e.g. here's a model of Wally 120. The initiative "spun" itself off into a start-up called Kniterate, priced at ~$6,500.

Circular Knitic is another well-documented project with both a github repository and instructables tutorial available. Mar Canet, a collaborator on the Knitic project has also written processing sketches for the Brother KH930 and KH940 electronic knitting machines to replace the machines' existing electronics with an arduino.

clothing / final product: since knit fabrics are typically stretchy there is less tailoring that needs to take place and thus making a garment from a knit requieres less seams – think of a dress shirt relative to a T-shirt for example.

The Singer 560 electronic knitting machine manual (pages 56-70) gives a resonable explanation of how to create a range of knitwear.

Here's a cool research project (thanks Jake!) on converting 3D meshes into instructions for a computer-controlled knitting machine.

etcetera: a paper with a comparison of mechanical properties of woven and knit fabric for composites.

Interestingly, knitting offers a multiaxial option as well called inlay knitting – a method that introduces stuffer threads into the knit. Here's a course with more information on the subject matter.

For aesthetic purposes it is possible to create elaborate patterns with knitting by varying the colors of threads a common technique called short row knitting is tyically used to achieve this.

crochet chrochet is a method, similar to knitting, that manipulates loops of yarn with typically one active loop the chrochet doesn't lend itself to unraveling during the production process. There do not seem to be active DIY chrochet projects, it's a method that remains confined to a craft domain with very little automation. Mainly because unlike knitting the process entails multiple loops on one needle rather than multiple stitches on multiple needles as seen in the knitting machines.

felting is produced by matting, condensing and pressing fibers together – there is no stitching or looping involved. Needle felting does not require water to form fibers into place – this is the type of felting that has seen greatest automation. Currently the Textile Academy is working on a felting machine.

braiding / plaiting is produced by interlacing three or more strands of flexible material.

open source options: Stig Anton Nielsen's open source modular machine.

a loom... what's that?

A loom is a device that is used to weave clothing and tapestry.

Here's a basic schematic of shuttle loom courtesy of Wikimedia.

The process beging by threading the warp 1(vertical component of a woven textile), the warp threads get assigned to harnesses 3 that are associated with pedals, also known as treadles 6 As the loom is thread the weaver must assign the treadles to warp threads and specific harnesses. The pattern of the textile is determined by the sequence of treadles that are raised, treadles must be alternated and never raised all at once. The alternating treadles establish periodic openings for the insertion of the weft thread 2using a shuttle 4the warp and weft threads are then compressed using a reed 5thus forming a tightly bound textile.

More looms

A few examples of historical and contemporary loom types.

To the right is the £1.5 million Van De Wiele axminster loom commissioned by Wilton Carpets in Wilton, UK.

Textile close-up

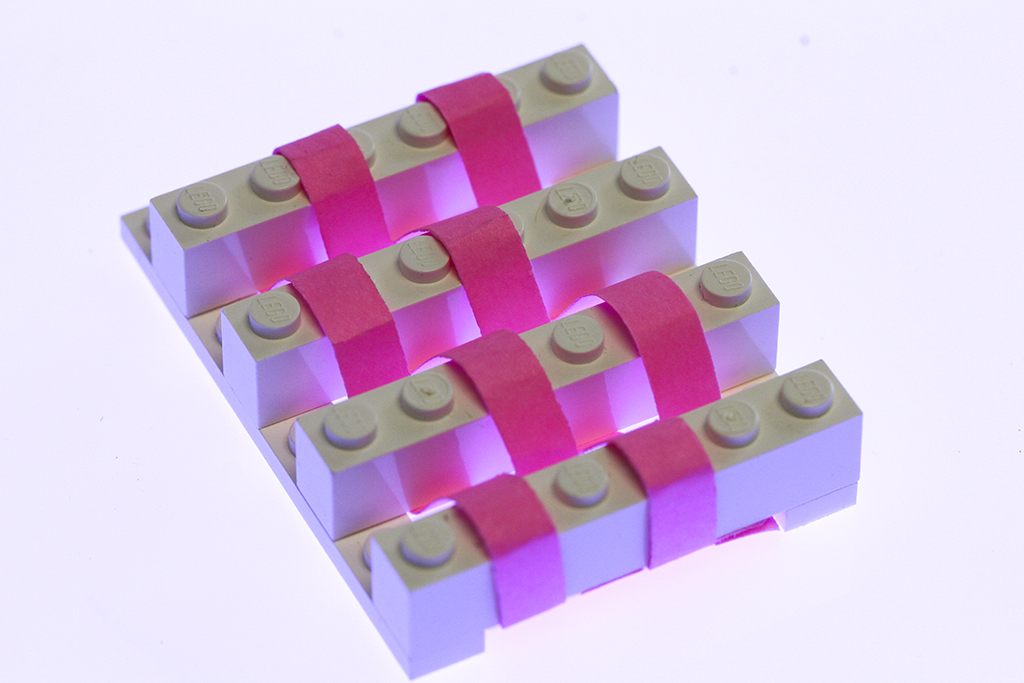

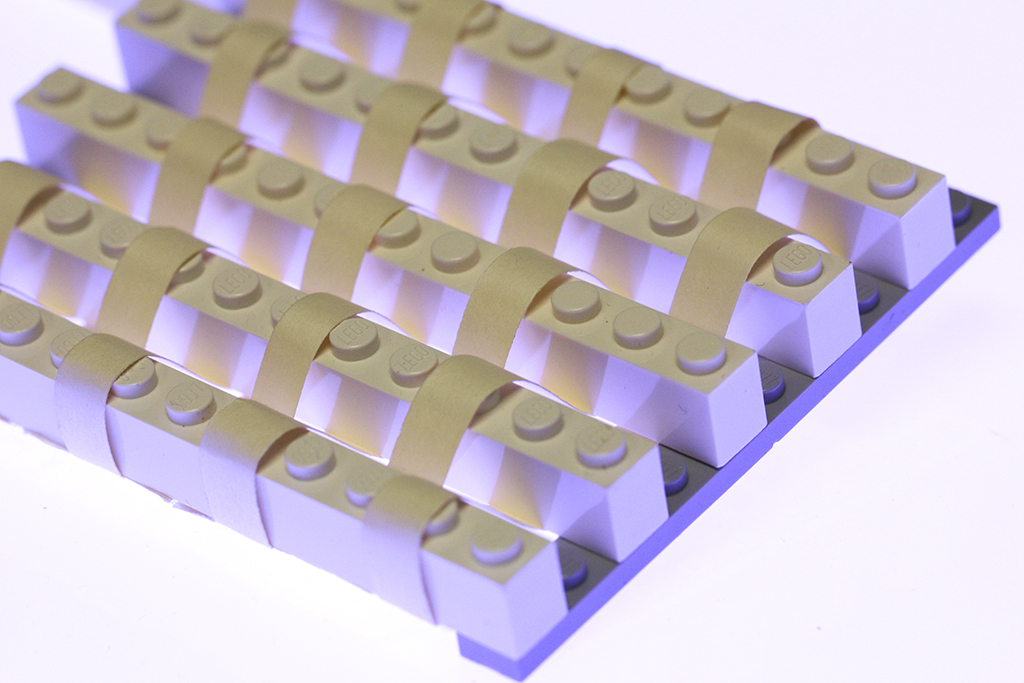

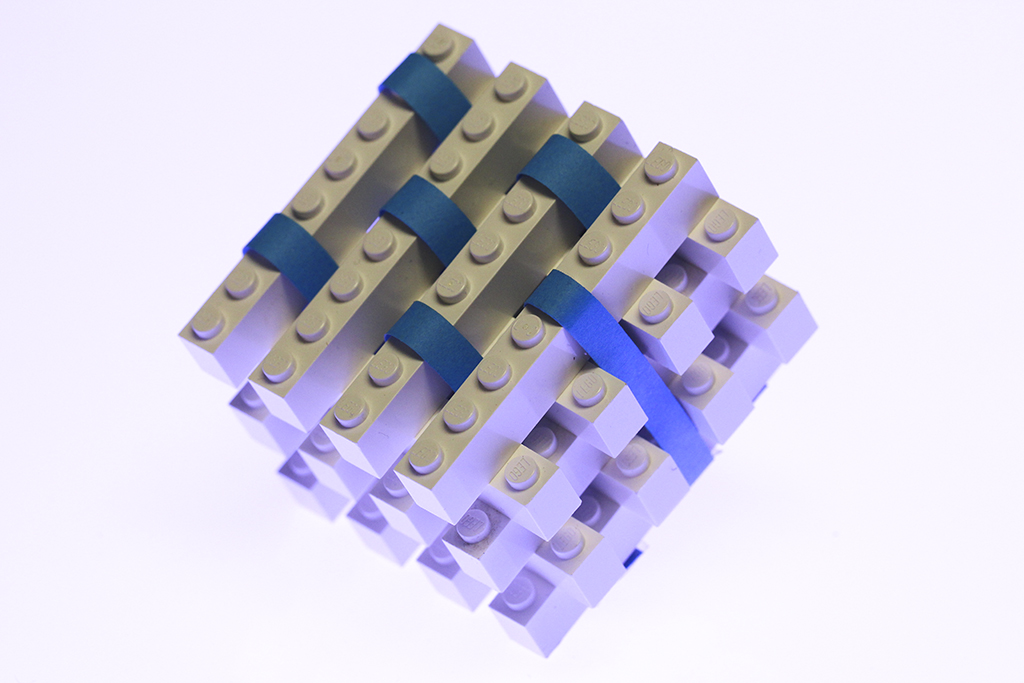

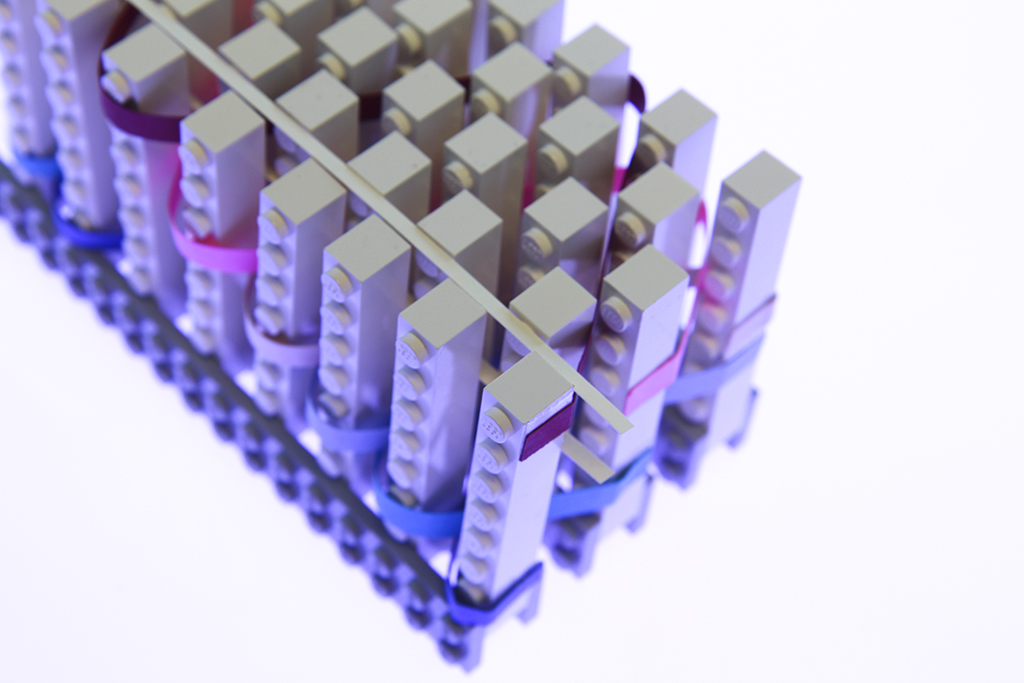

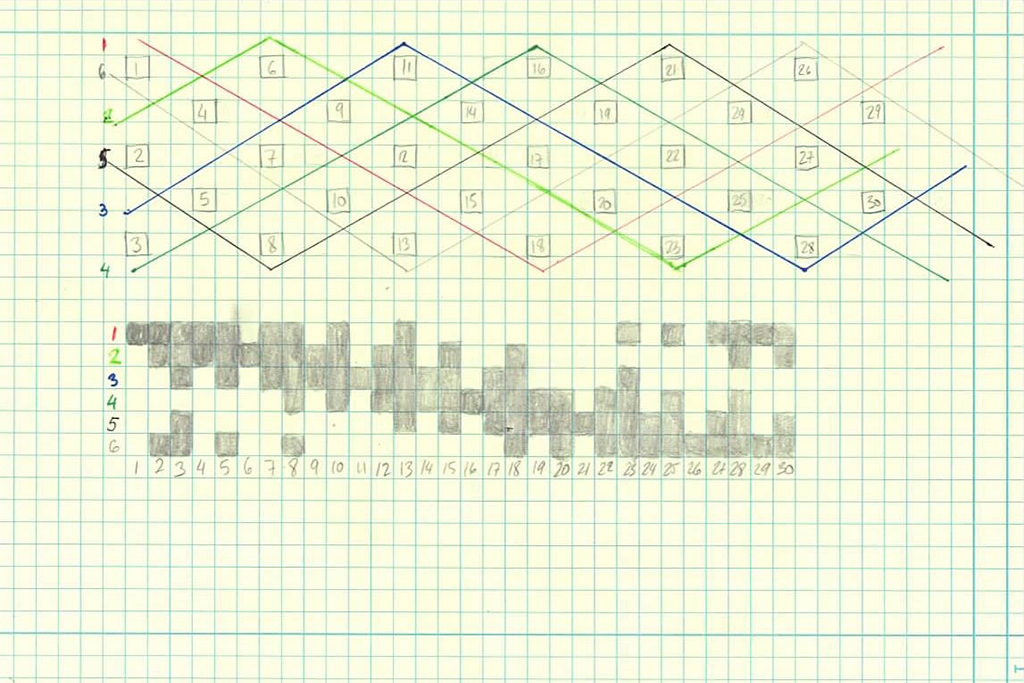

From fabric density to color and pattern to material and scale, many technical and creative factors come into play when planning a weave. All woven fabric comes form a combination of warp (vertical threads 1from the loom diagram above) and weft (horizontal threads 2from the loom diagram above). Given a spool of thread an a loom how does one accomplish a precise control over the textile properties? Draft / lifting plans are used by weavers to plan and trouble shoot a textile. Here is a few models of different textile patterns, in the models below LEGOs represent warp threads and paper represents weft:

-

Plain weave

-

3-1 twill (used in denim)

-

3D orthogonal weave

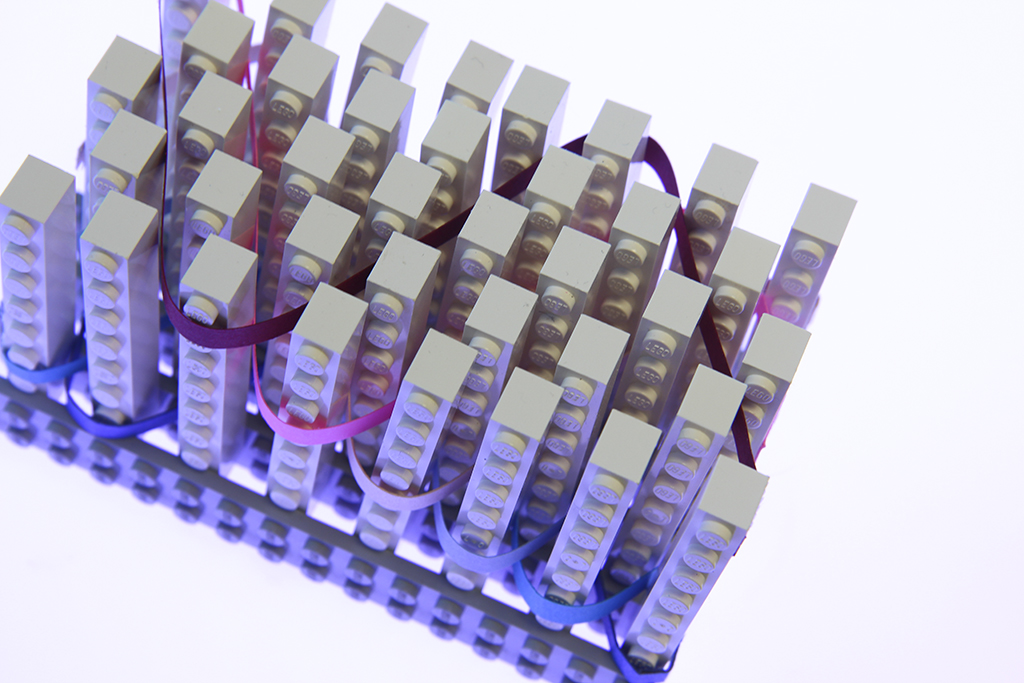

Textiles that interlock more than one layer of warp and weft are called multiaxial or 3D textiles. Unlike the orthogonal weave shown above, angle interlock multiaxial weaves can be made using a regular loom. Here's a good tutorial explaining the technique for a 5 layer angle interlock textile, something I wasn't able to understand until making a model of my own:

-

5 layer angle interlock

-

5 layer angle interlock with warp

-

draftting plan

The leftmost image shows the draft plan for the fabric, which becomes even hairier if wadded warps are added to the textile (center image). The draft plans lend themselves to the fundamentals of digital systems – this is why the Jacquard loom is frequently credited as the mother of modern computing. For my final project, I aim to abstract these processes by creating a tablet loom as the first iteration of the machine.

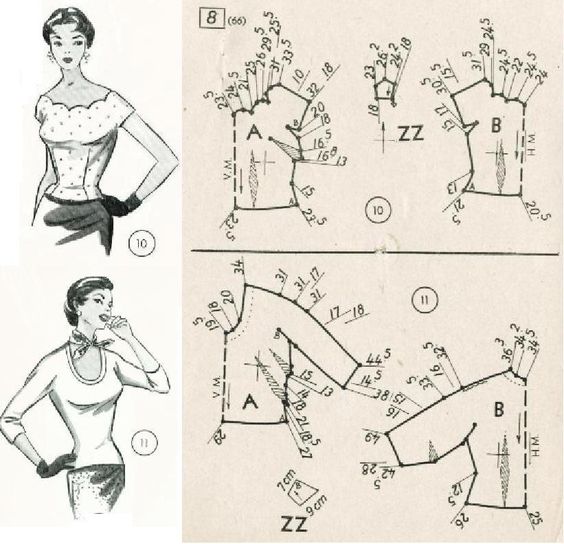

How clothing is made

In order to get from a piece of woven textile to a garment, a pattern is needed. A pattern serves as template for seams that need to take place in order to realize a garment. Typically, knit garments require less seams, commerical clothing production is equally intricate for both wovens and knits. Garments are conceived of, modeled in software, and block patterns are created to account for different sizes. The specs are then sent to factories who over the course of several months produce samples that are optimized for fit and aesthetics.

Read more on pattern making here.

Open source pattern making software: OpenFit.

Notes on Brother knitting machines

The Brother knitting machines was a Japanese-made home knitting machine produced in the late 1980's. While no longer in production the device has developed a cult following. Hanna Napier has a few fantastic write-ups on the machine, herself an owner of the 950i model. supercub33 also has an online guide, however supercub33 both sells the machines and somewhat annoyingly ends a few reviews with this is a nice machine. Due to the posthumous popularity of the machines there is a substatial amount of information available online. Here are some potentially useful tidbits by model group type:

KH230 KH260 KH270 aka chunky needle machines, manual operation (except the KH270 model), 1980 - 1990, 9mm gauge. Currently (2018) priced on eBay for ~$700 - 1,000.

KH930 KH940 KH950 KH950i computerized operation 4.5 mm gauge, 1986 - 1988, these machines have been quite popular with the maker community: Knitic project being the prime example. Currently (2018) priced on eBay for ~$700 - 1,000. Manuals: KH930, KH940, KH950, KH950i.

KH910 computerized operation 4.5 mm gauge, 1980, these machines are the oldest of the brother computerized knit seriee and therefor the cheapest reatiling at ~$350 - 600. A notable project for this model is described here with hardware and software specs availble for download AYAB.

general notes

Relation of gauage size to knitting dimensions explained here. In general larger gauge = thicker yarn and needles = faster garment production.

As an alternative to eBay (it's also worth taking a peek at etsy) China Creation Group and Hong Kong Knitting Machine seem to be making replicas but I am not sure what the quality of these options is – their websites are pretty crummy.

Brother knitting machines have different carriages manual and electronic – covering different knit patterns ranging from lace, garter, and ribbed patterns

Manuals are available for [free] here.

Other options

Singer also made electronic knitting machines, albeit not as popular at the Brother series the 560 model seems to be coveted and pretty well documented. Here is the machine operating manual and knitting manual.

And thus

Retrofitting a old Brother machine is economically advantageous and a viable solution to building a reliable eletronic knitting machine – Hanna Napier's photos indicate lots of flip flops and ceramic disc capacitors maybe be required.