Design a parametricly modeled mold that incorperates much of the necessities for injection molding or composite molding and curing into one peice that can be cheaply manufactured. I invision this being machines out of Al and can just be sent to a machine shop or MFG.com. By modularizing an injection molding machine I hope to make the process possible with less capitol costs.

A big benefit of heating elements within the mold is that it can double as a curing chamber for composites. Not sure how that will scale for LRP though...

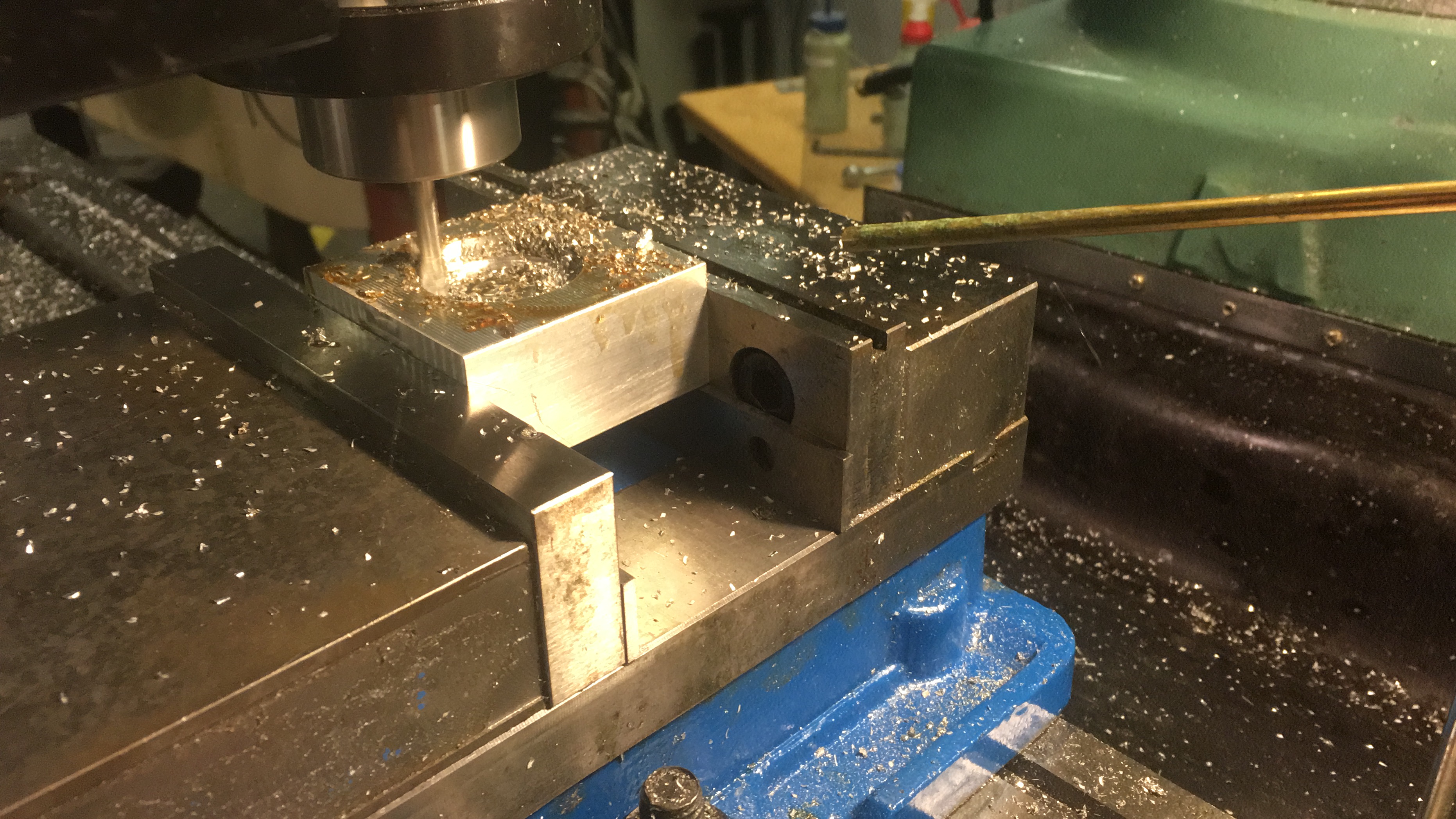

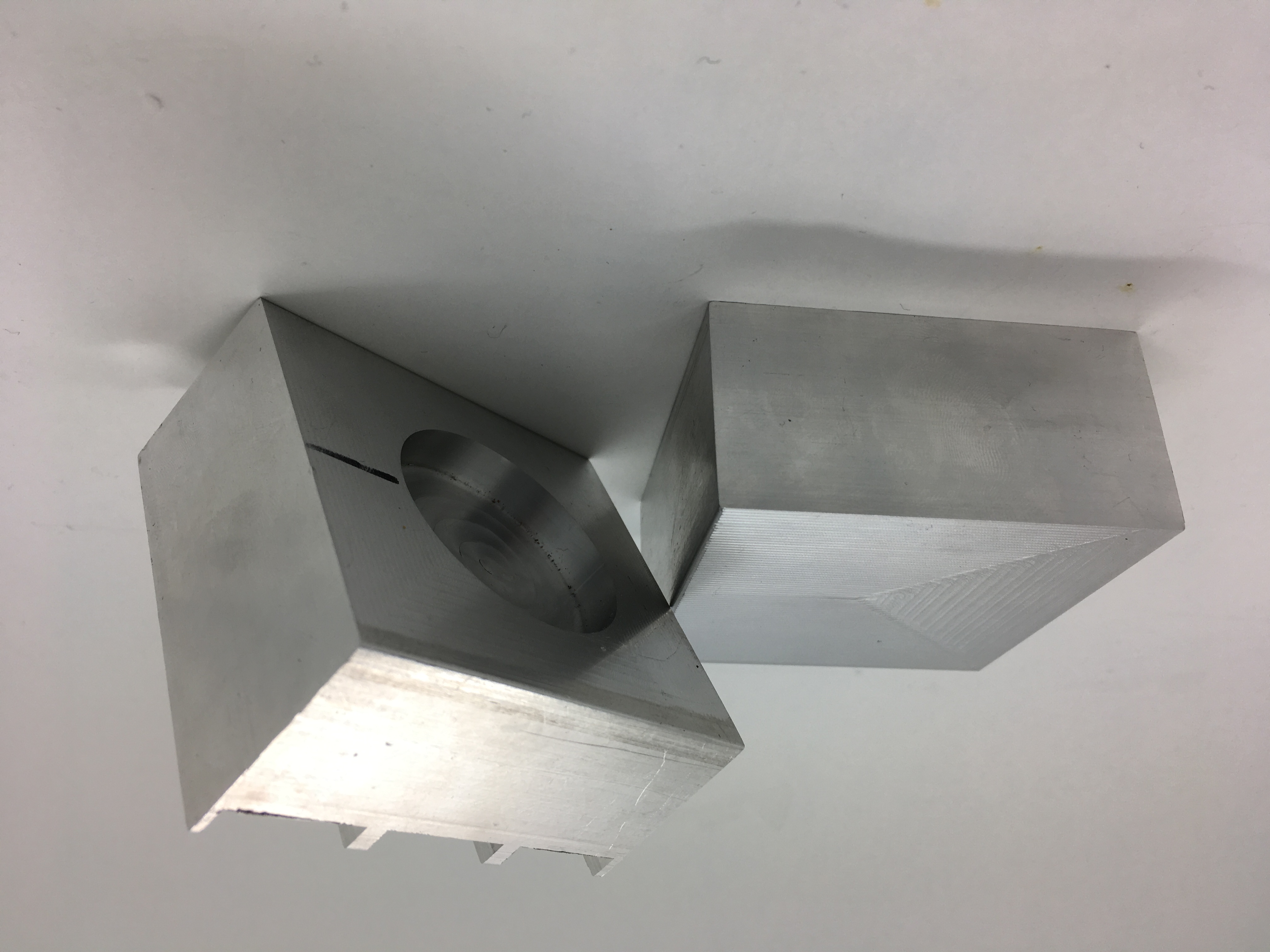

Quick and dirty prototype of a disk to test heating elements and molding process with the Extruder prototype #1. A crucial element to these molds is facing them so the surfaces come together without causing flashing when molding. I milled slots into the back to fit heating coils as well...

I don't know why this picture is updide down....?