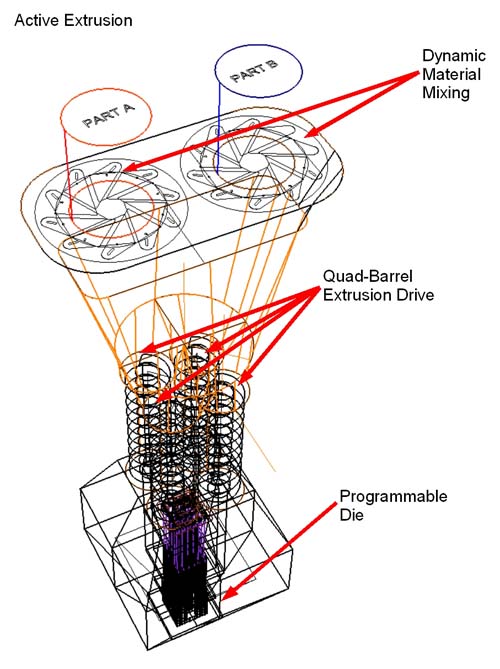

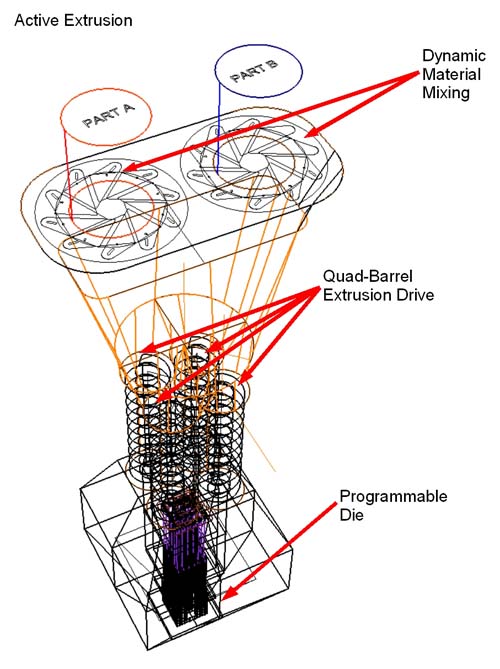

The active extrusion machine is a programmable system to control shape, size, direction, as well as variable hardness of an extruded part.

Active Extrusion Machine Details (PDF)

----------------------------------

- what process(es) will it use?

material mixing and extruding processes

- what will (and won't) it be able to do?

extrude custom sections and vary the section, direction, and hardness within a single part.

it won't be able to make extremely precise parts.

- what are the benefits (and disadvantages) over current practice?

advantages:

flexible way to produce custom parts without using several machines and making new dies for each custom part

disadvantages:

slower, not as precise, more complicated than typical extrusion process. will require more parts and more moving parts than typical extrusion process.

- what are the system components?

1) dynamic material mixer

2) quad-barrel extrusion drive

3) programmable extrusion die

- which parts exist, and which will require development?

mechanical/software will need quite a bit of development. we will not develop motors and the extrusion material.

- what will the workflow be from design to output?

- how much will it cost?

aluminum stock

stepper motors

leadscrews

rotary bearings

linear bearings

fasteners

misc hardware

- how fast will it be?

depends on the material, but probably not quite as fast as a industrial extrusion process

- what consumables will it need?

lubricants