How to wire your bus network

I am terribly fond of not blowing things up when I plug them in. To assist in achieving this as often as possible, I use keyed connectors. The lovely RJ9 jack most often, but at times also RJ45. This is the jack I like. To make cables, I have a crimper that cost me almost $50, but it is so worth it compared to blowing things up.

For wire I cannabilize cat5. There is aways cat5.

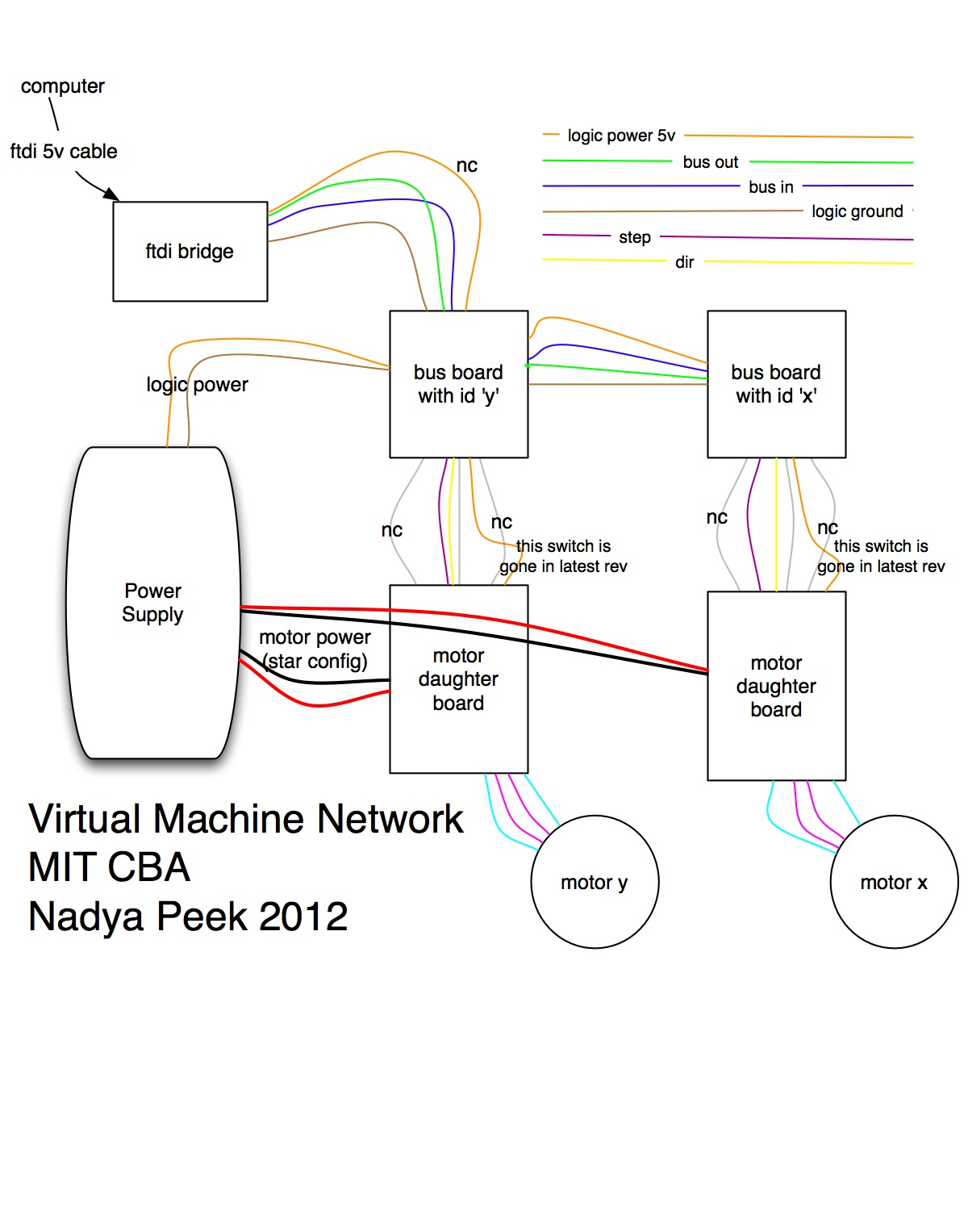

Here's a picture for context.

And here's how to control it woo.

Some details on the bus implementation

The bus network consists of a bus board (pictured left) and a bridge node. Cables between the bus network are straight through, cables between a bus node and the bus bridge need to have i and o crossed. Then the ftdi cable from the bridge to the computer is a 5v cable. I'm using 26 AWG wire and RJ9 connectors, also for the motors.

For the motors, I'm wiring each motor driver board, in star configuration, back to the 24V/8A power supply. Even though the connector suggests otherwise, I'm only connecting the 5v power line to the motor controller board, NOT gnd or 24v.

Virtual Machine Control

CNC machines currently mostly work with some kind of machine control language that you generate and stream (with some buffer) to a machine. Instead, we're working on having a computer directly control a machine, abandoning the machine state. Instead of streaming things like g-code, there is a representation of the motors directly in the virutal machine.

See the circuits and the pngs for milling here.

Download the zip with everything.