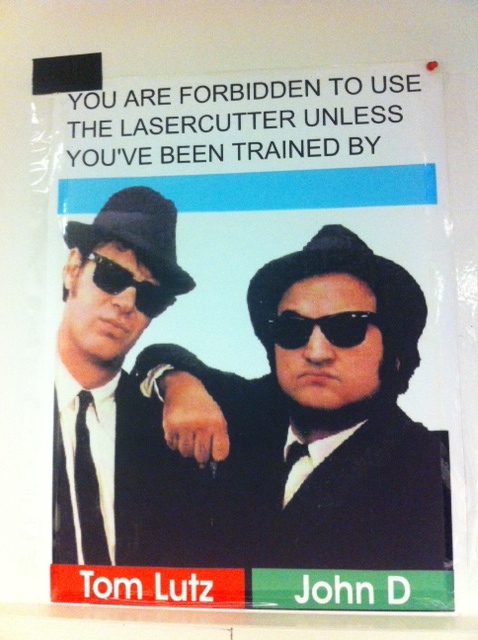

Of course, you should not use this machine without training and explicit permission of the shop managers.

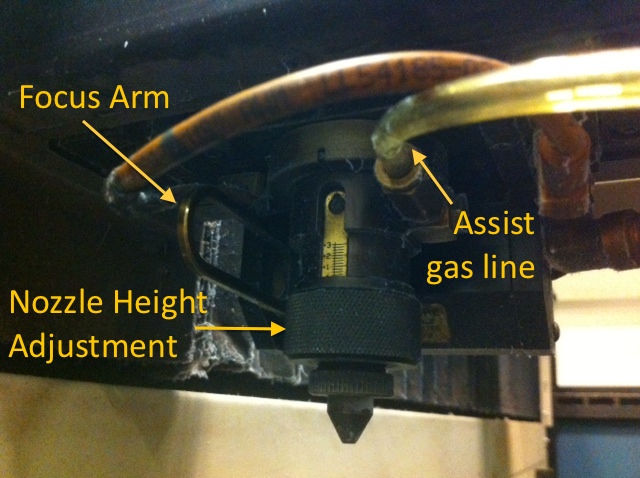

The head has a magnetic coupling for easy lens cleaning. You should clean the final optics every time you come to the machine.

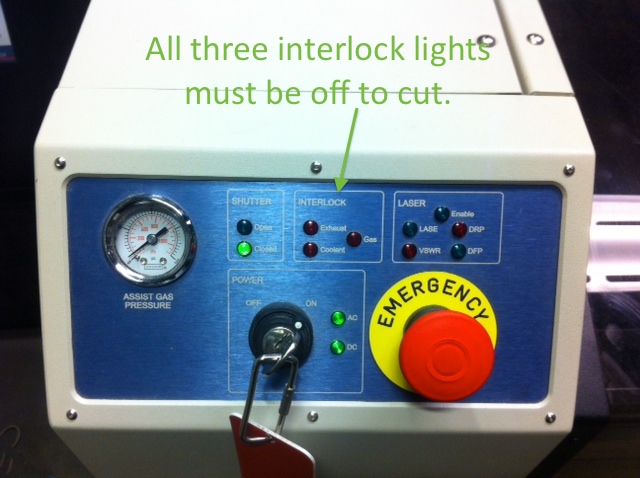

This breaker must be turned on to power the machine, as well as connect the Beam computer to the network.

The machine has interlocks for the chiller power, exhaust pressure, and assist gas pressure. Without all three lights turned out, the machine will not cut. To establish communication with the computer, 1) turn on breaker, 2) deactivate all e-stops, 3) start BeamHMI program, 4) when the progam launching icon appears, turn on the key.

The chiller is located to the left when facing the machine. Turn on before cutting, and turn off during breaks to cut down on noise.

Shop (compressed) air is used for almost all cutting. In some cases, an inert cutting environment is helpful and an argon gas mix is used. Oxygen can increase the effective cutting power, but it should be used with extreme caution.