This week, I wanted to come up with something really creative for the "make something big" assignment, but with most of my energy directed toward getting ready for sponsor week, it just didn't happen. So instead, I made something with a relatively simple design: a press-fit table. It was still an effective way to learn how to use the ShopBot. For something a little bit more interesting and to learn how to use the waterjet cutter, I also made some not-so-big aluminum parts, described on a separate page.

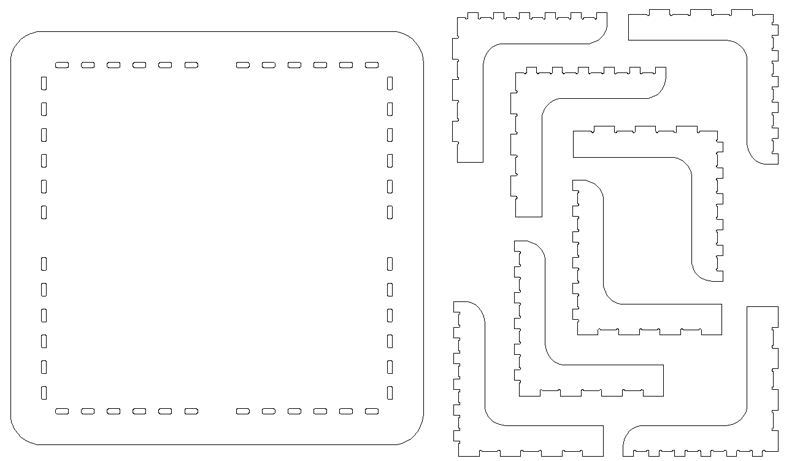

I designed the pieces for the table in SolidWorks, which enabled me to visualize how they fit together and make sure that all of the tabs and slots were in the right places. I then created 2D drawings from the parts, saved the drawing as a DXF file, and imported it into the ShopBot software.

Prior to coming in to the CBA shop, I prepared the files for the ShopBot software, which really sped up my time in the shop. All I had to do was load the material, screw it down to the bed, and run the job.

I cut with a 1/4" endmill, with a spindle speed of 11 kRPM and a feedrate of 200 inches/minute, which worked pretty well. The cut went smoothly without any problems.

After cutting, the pieces had a little bit of a rough edge along the bottom (the endmill I used was down-cutting.) I removed most of the rough edges with coarse-grit sandpaper and finished cleaning up the parts with some medium-grit sandpaper.

I dragged the finished pieces back to my apartment on the T and assembled them there. Everything fit together okay. The two pieces of the legs fit together with a little bit of friction, where I was mating cut edges on both sides. The slots in the tabletop required a friction fit between cut slots and the thickness of the material, and the material was a bit thinner than I designed for. As a result, there isn't very much friction between the tabs on the legs and the tabletop, so if you lift up the table to move it the legs have a tendency to fall out. If I were to cut the parts again, I would make the legs fit together just a little bit more snugly, and make the fit between the legs and the tabletop considerably more snug.

Once assembled and when not being moved, however, the table is robust; it's possible to stand on top of it.