Week08 - Input Devices

This week's intrepid adventure concerns the fabrication of Input Devices built on top of custom micro controller circuits. The assignment was to build and program a board that reacts in someway to the outside world. We were all to become intimately aware of the tiny45 or tiny45v data sheet, python-tk installation, how to determine exactly on which port our FTDI cables were running.

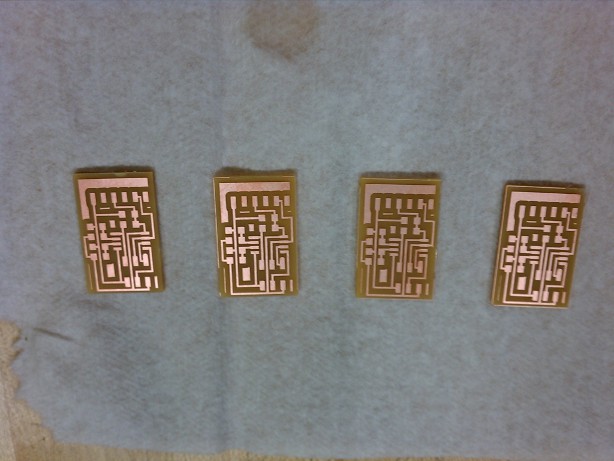

Measure twice, cut once. And then cut three more copies just in case I made any mistakes. I'm getting comfortable enough with the Roland Modela that I can now mill about four boards in the time it used to take me to cut one. I also had this crazy idea of maybe building more than one. I managed to get all four of these off a single sheet of F1.

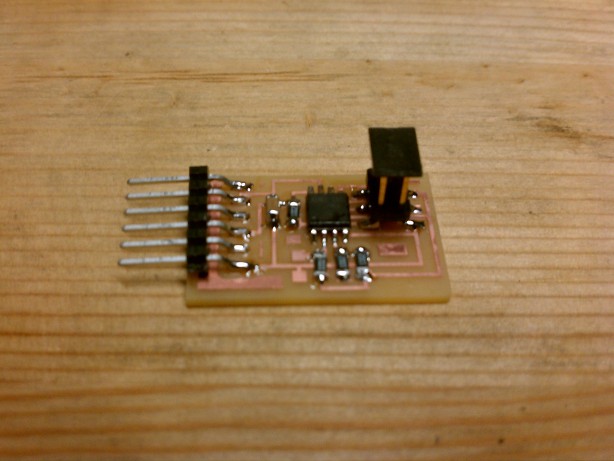

All stuffed and ready to go. Having a soldering bench in out groups area is extremely helpful. Notice the two empty pads coming off the Bridge. This is where the actual sensor leads would go. I had a specific sensor in mind but I would need to add a special new tool to my kit.

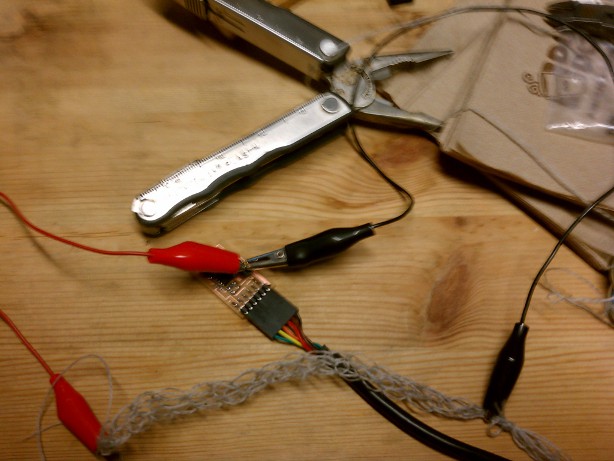

Yes, a Singer spool knitter. This handy device, courtesy of High Low Tech allowed me to quickly knit up a length of conductive yarn that was to interface with the board and act as a type of strain gauge.

Here you see the basic setup. To interface with the board I took a 2x2 header, clipped off one side, and soldered the remainder to the input pads. This allowed me to clip the sensor leads to the upright posts of the header. The strain gauge reads the change in resistance as the fibers of the conductive yarn bunch up and change the flow of electrons. This one just happens to be made from a stretchy fabric.

Success! With 10 bits of precision, I can map 0.0 -1023.0 units of strain to be visualized in a python-tk script. Now that it was working, what should we do with it? The obvious answer is of course Basketball.

The Basketball hoop of the future! We discovered that even a single thread of the conductive yarn would provide an reading and went about determining where to mount the sensor for consistent accurate reading. We also discovered this is where the "black art" of input devices lie. Having the greatest sensor in the world is useless if you can't find a location that allows it to work. Luckily by stringing a single thread through the middle of the net enough displacement occurs as the ball passes that a reading can be taken and the force of the "dunk" can be calculated. This proof of concept is enough that Turner Sports and Hasbro, both sponsors of the Media Lab, are interested and coming to take a look in future weeks. We'll continue work to make the system robust enough to handle endless slam dunks and add additional sensors like a photo diode circuit to measure the speed of the ball to help in the calculation of the force. F = ma is beautiful thing.

So, until next time then, Space Cadets! NovySan, OUT!