Toks Fifo

Student. Builder.

Motivation

The goal was to make something big with the large CNC machine. I decided that I needed a place to store my dirty laundry, and I figured that whatever that was could double as a coffee table, instead of taking up precious space in my room. Hence, I created a table that doubles as a hamper when you open the top.

Here is a picture of the table that is currently in my room.

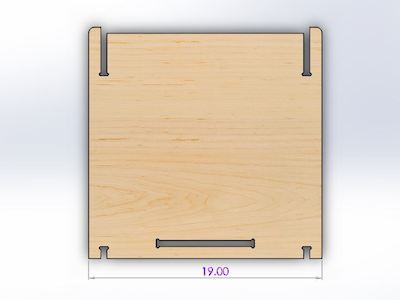

Parts: Side

I used SolidWorks to design all the parts of the table, envisioning 0.5" plywood. A key constraint for me was that I didn't want to use any fasteners on the table/hamper, such as nails or glue; I wanted to design it using only wooden joints.

Here is the one of the sides of the table, with cut-outs for the base.

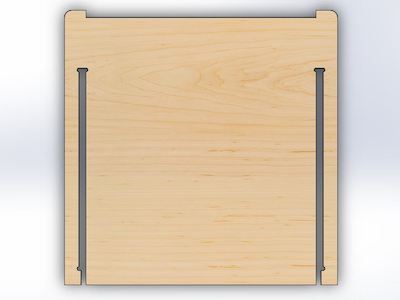

Parts: Other Side

And here is the other side of the table that connects to the 1st side, via halved joints.

I designed dog-ears into the part becasue the bit that will be milling has a radius associated with it that would otherwise result in curved edges on my part.

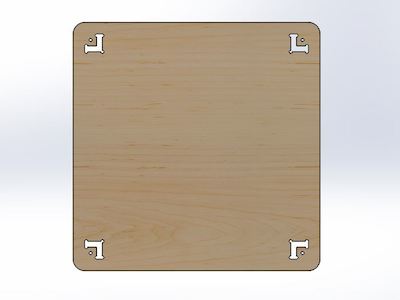

Parts: Base

This is the bottom part of the table, that will allow my clothes to sit on a surface rather than the floor. It will connect to the main side via the designed mortise and tennon joint.

Parts: Top

This is the wooden panel on top of the table. I will top everything off with acrylic (below), but wanted a surface that isn't see-through so that my clothes would remain invisible.

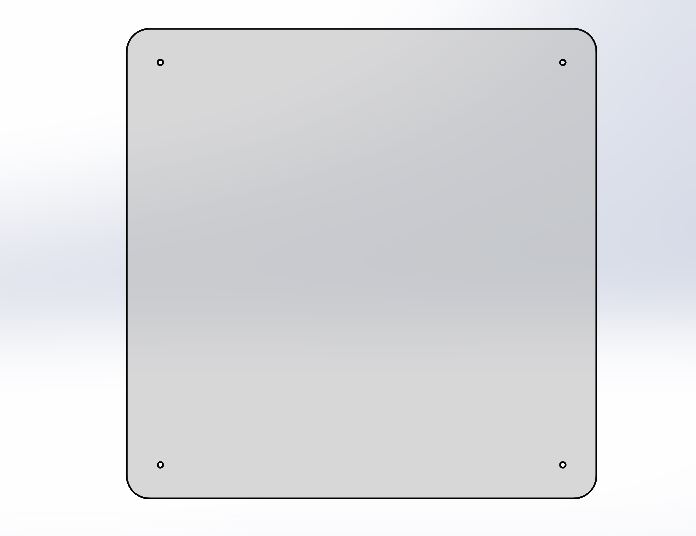

Parts: Acrylic

Acrylic top of the table. This is the usable surface.

Model

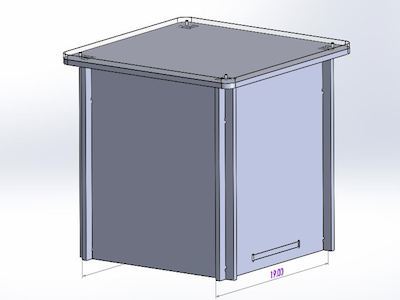

Full SolidWorks assembly!

Milling

Unfortunately, it was a really busy week in the IDC shop, so I never got a chance to mill my parts.

There were issues with people working alone, failure to honor the alloted time of others, shortage of materials, and (most importantly?) general shop cleanliness.