here is my starting workspace on rhino:

i took an image from the internet to use as a bitmap background guide. the first problem i encountered in rhino is that i couldn't find a way to loft the curves continuously, which seems to be the only way to build a smooth paneling. so i broke up the lofting which left me with a slightly awkward bottle shape. the paneling was also divided up into several surfaces, which was a pain when working with so many points:

another problem was that rhino divided the neck area of the bottle into four non-continguous surfaces. i tried to patch up the slivers of surface in between, but there was one (the inner loop of the neck) i could just not reach. it was unclickable no matter the perspective or orientation of my 3d model. so i gave up trying to patch it and hoped that my finished piece would stay together. panels across different surfaces also were not smooth due to the piecewise lofting.

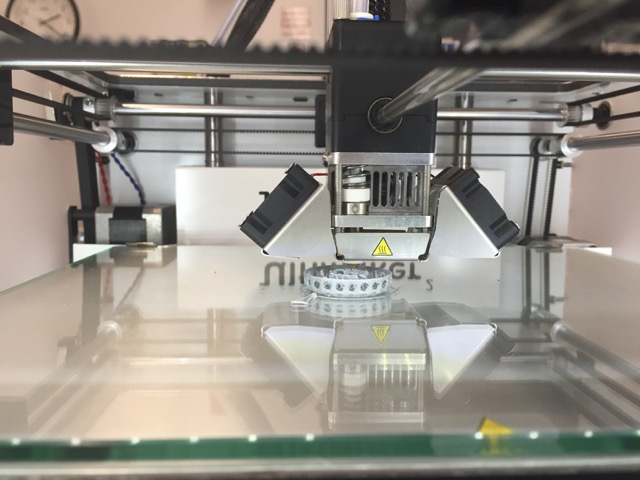

nonetheless it held together. it took about one hour to print at 50 percent density and .3mm shell (i was worried about the missing sliver of paneling and the overall fragility of the object).

during printing, however, i realized that although my pre-paneled model was a real klein bottle (the interior of which could be reached through the tube neck opening from the bottle), the post-paneling had actually closed the intersection between the body and the neck! i had not anticipated this because the paneling surfaces seemed to so clearly bypass the hole... i guess a simple follow-up project i could do is to just print the unpaneled klein bottle (show above) with translucent filament. then it could be a real klein bottle that also reveals its klein bottle quality! maybe next time.

for the next part of the week's assignment, i scanned my favorite little derpy bear using a sense scanner. (his name is TO, for transitional object, and he's a little messed up from poor laundry decisions but i love him anyway.)

LOL!

thanks to Ye for helping me with the 360 scan! TO ended up like this, derpy as ever:

after solidifying him and fixing up a few stray bumps on the software (i knew his hairs would be problematic), i exported him as an stl file and opened him up as a mesh in rhino:

uh ok.