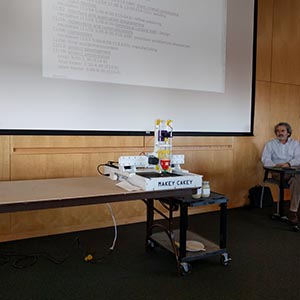

MAKEY CAKEY

Week 10: Machine Dessign

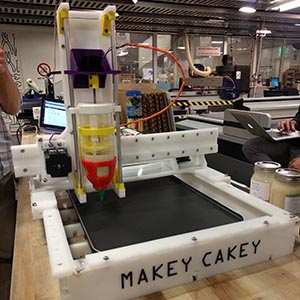

This week, as a CBA group, we designed and built a machine that can print a pancake! 🥞🥞

you can find the details as a whole system in this link as well. Here I will focus more on the work I contributed for this group project.

Idea Discussion

|

|

Extruder Design

|

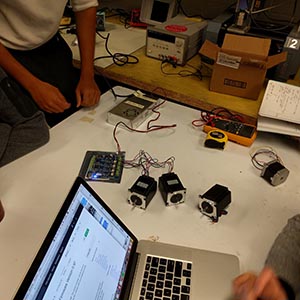

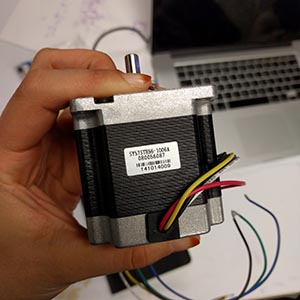

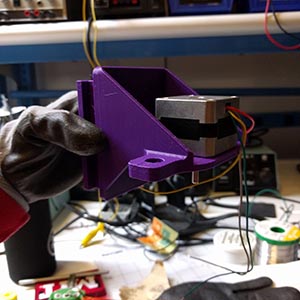

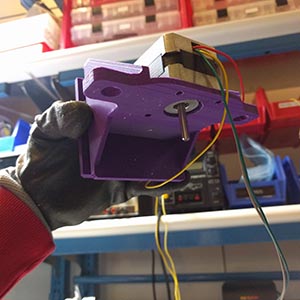

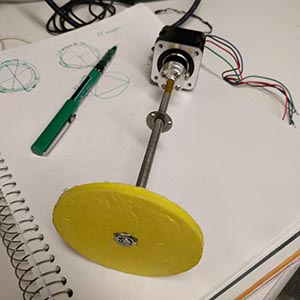

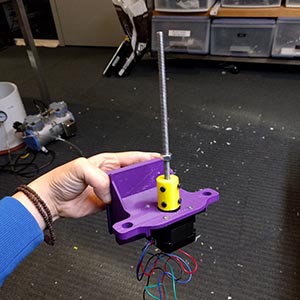

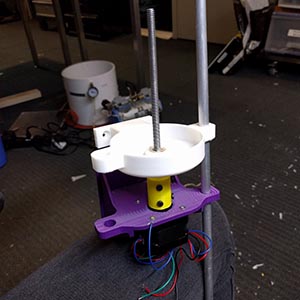

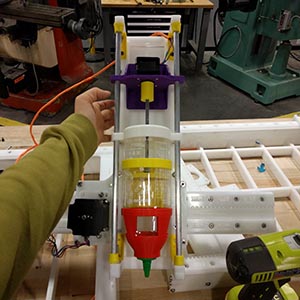

I suggested to replace the stepper motor for the z-axis motion with NEMA-23 which is smaller than the one we got. I thought that the size and the spec were kind of overloading and redundant for this pistion motion application. Based on this, I designed the extruder mechanism that has a linear motion by rotation of a stepper motor.

|

|

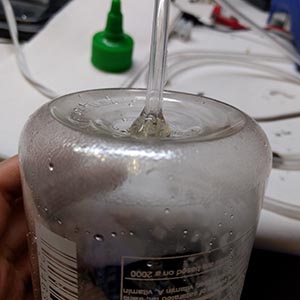

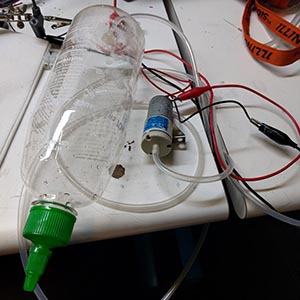

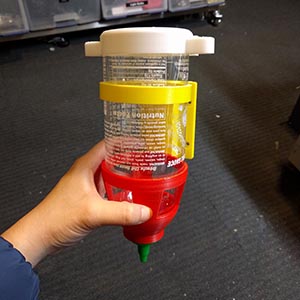

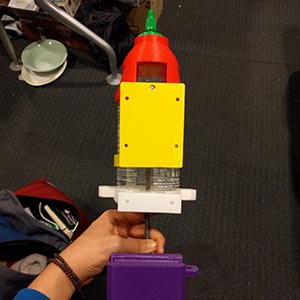

I found that the Sriracha bottle was pretty good for the container of pancake batter since it has a nozzle like botle cap and the extruding size is adjustable by rotating (opening) it.

|

|

First, I thought that using a pump would be great to extruding the batter out instead of designing any external mechanism to push it out. But we decided not to use it because of the compatibility with the TinyG board.

|

|

|

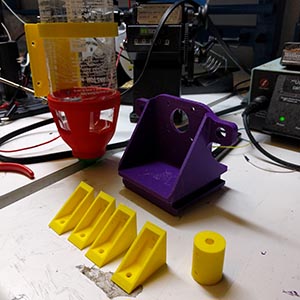

I 3D printed the all parts needed for mounting the bottle on the z-axis of the machine.

|

|

|

|

|

|

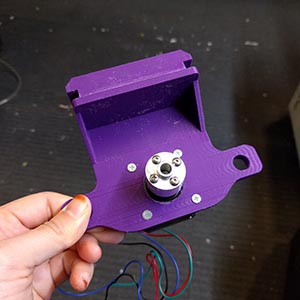

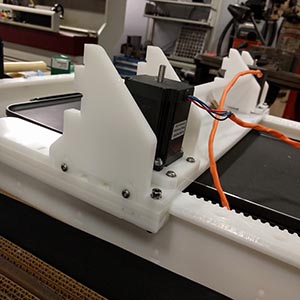

mount for the stepper motor.

|

|

|

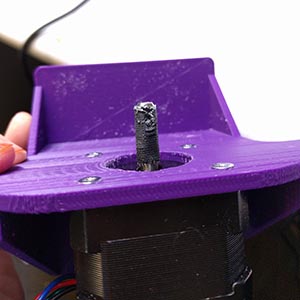

The coupler we had has a problem that it does not have a extact same diameter of the motor shaft which caused the misalignment with the thread rod we used for translating the rotation into linear motion.

|

|

|

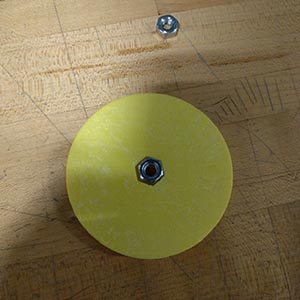

So, I replaced the steel coupler with a 3D printed one and it fit well.

|

|

|

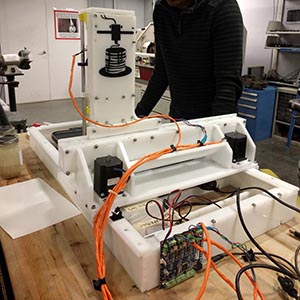

Fabrication and Assembly

|

|

|

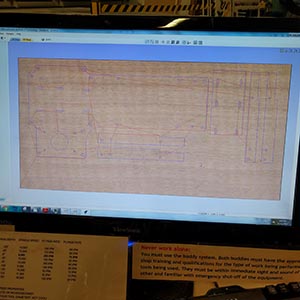

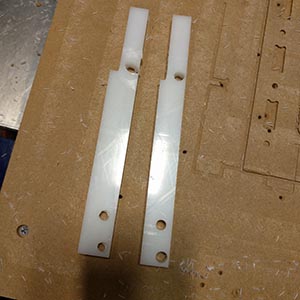

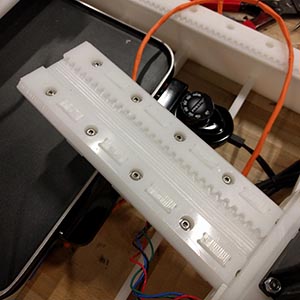

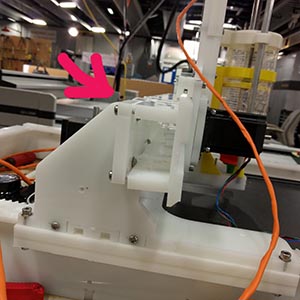

The overall structure for the machine does not need to be modified except for the z-axis part. To fix the extruder on the z-axis panel, I had to modify the Jake's cad.

|

|

|

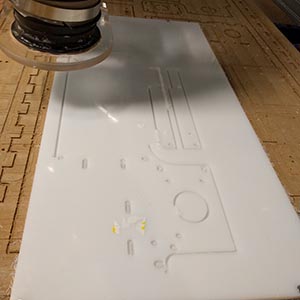

Cut the HDPE sheet using the ShopBot.

|

|

|

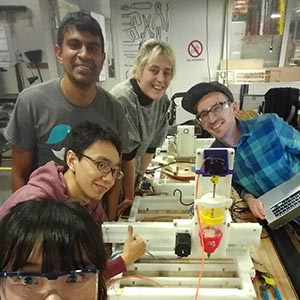

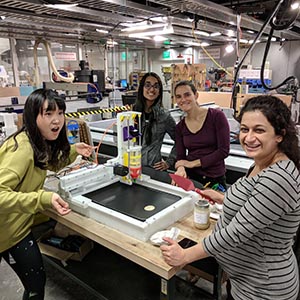

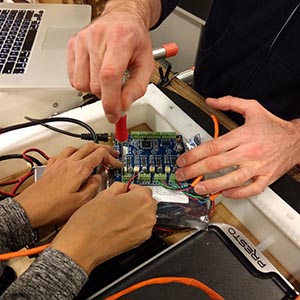

Had a lot of fun for assembling the machine with awesome friends!

|

|

|

|

|

|

|

|

|

|

|

|

We got bored and just wanted to test the griddle with the homemdae gluten-free pancake batter ;-p

|

|

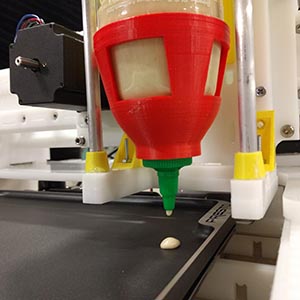

Close up on the extruder and the extrusion was working well.

|

|

|

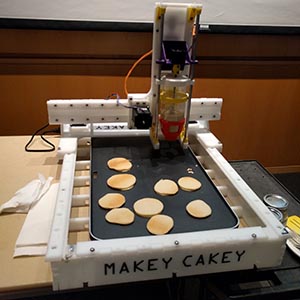

Test and Print 🥞

Extruder is pushing down the pancake batter!

put the logo on it! MAKEY CAKEY

|

|

|

Had a lot of fun for assembling the machine with awesome friends!