Week

three

electronics

production

PCB Milling/Cutting 🔌

highlights

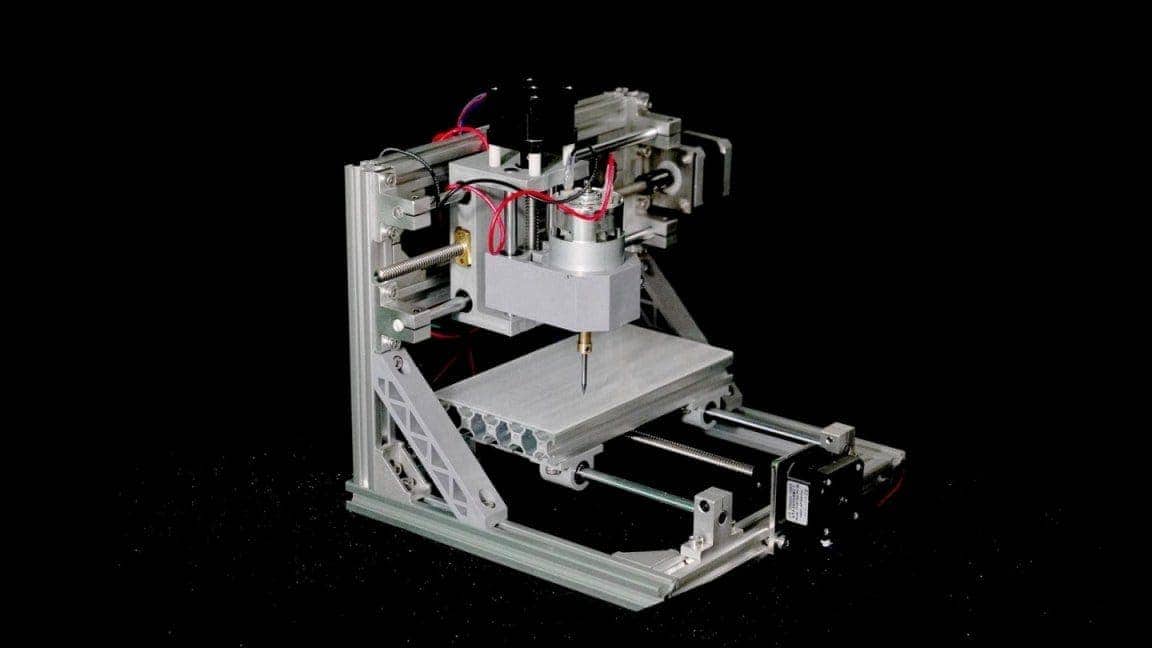

How does a $200 DIY desktop CNC do in milling PCB?

it is very loud...and it could bite, but it works!

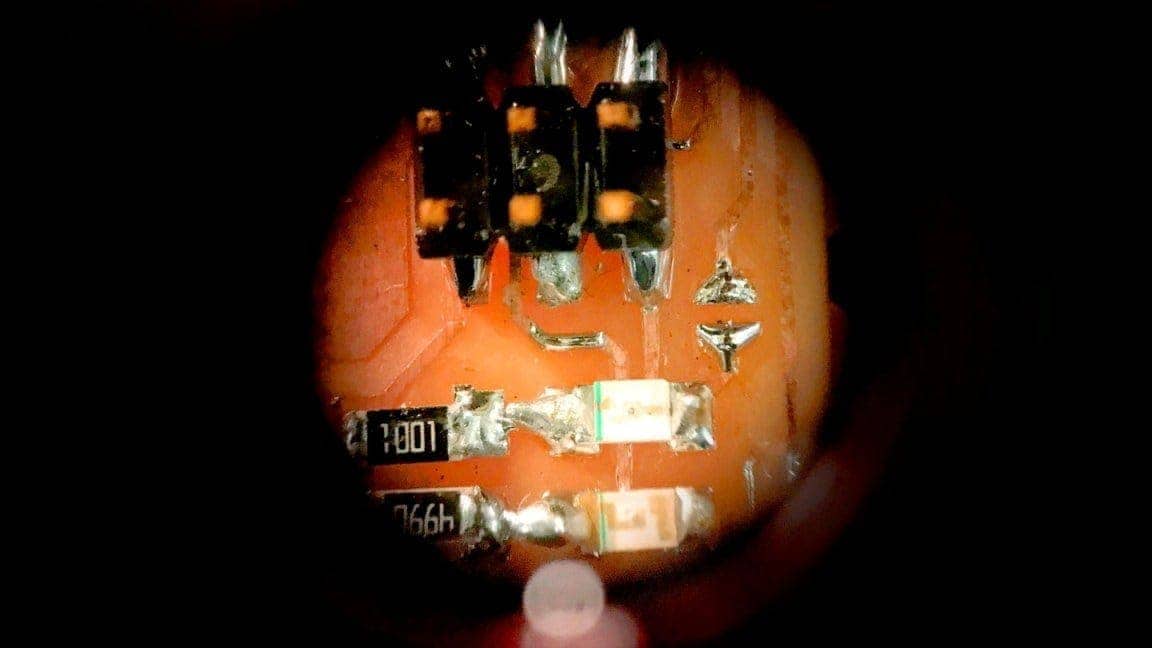

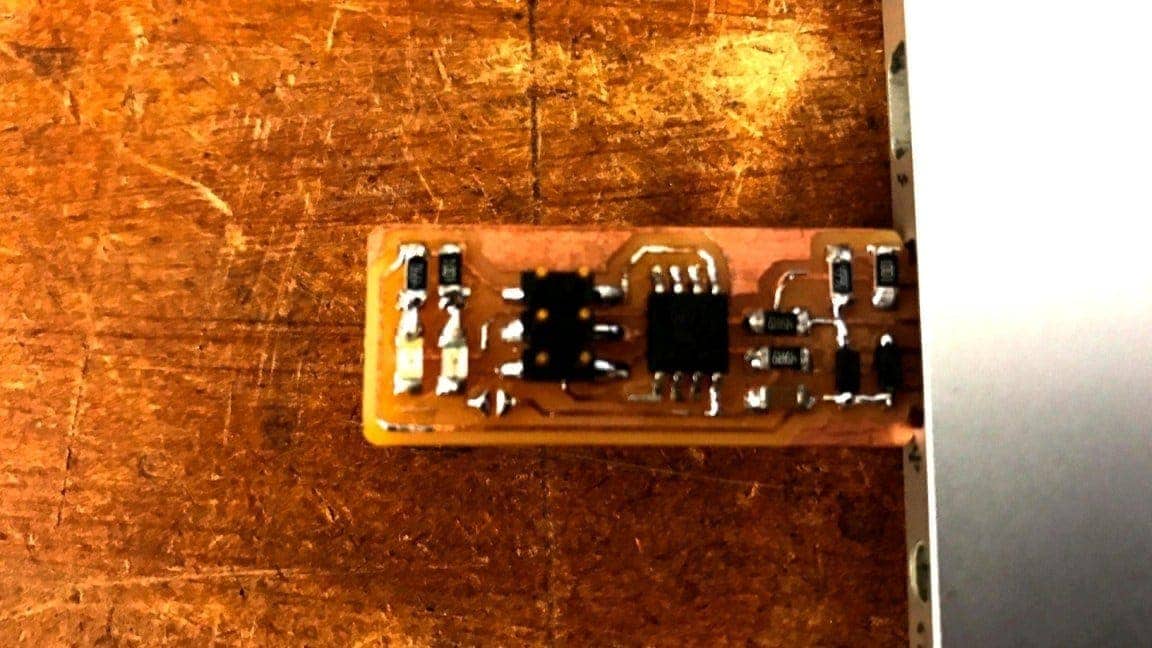

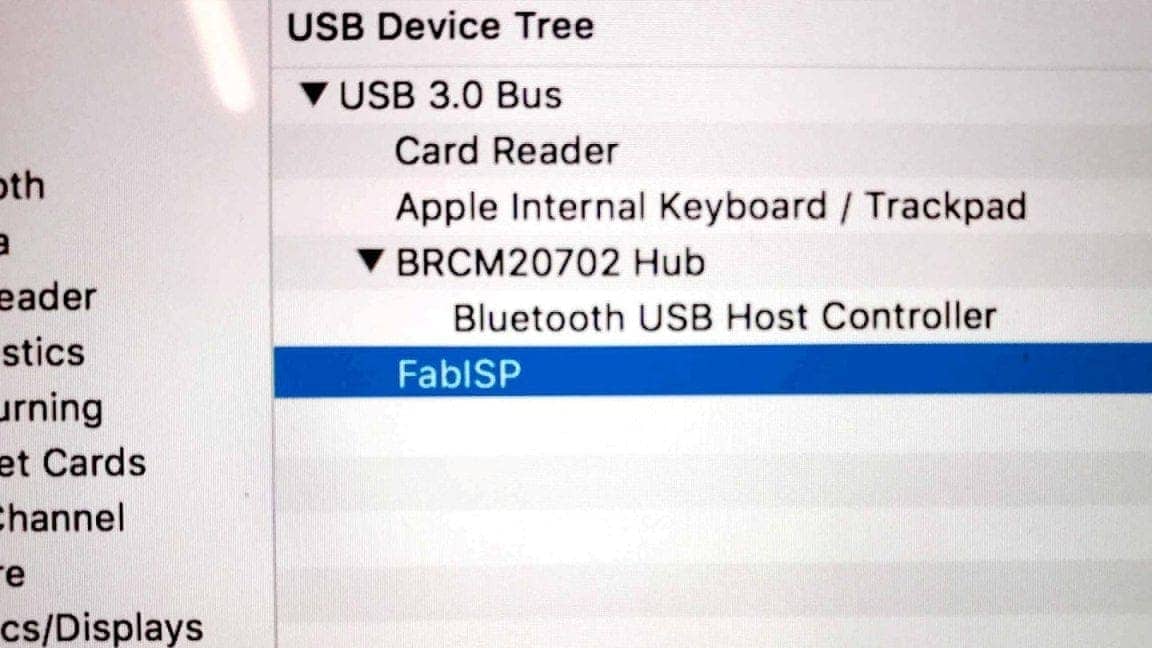

How to produce a programmer board with a ATtiny45

still don't understand why can't the computer be the programmer

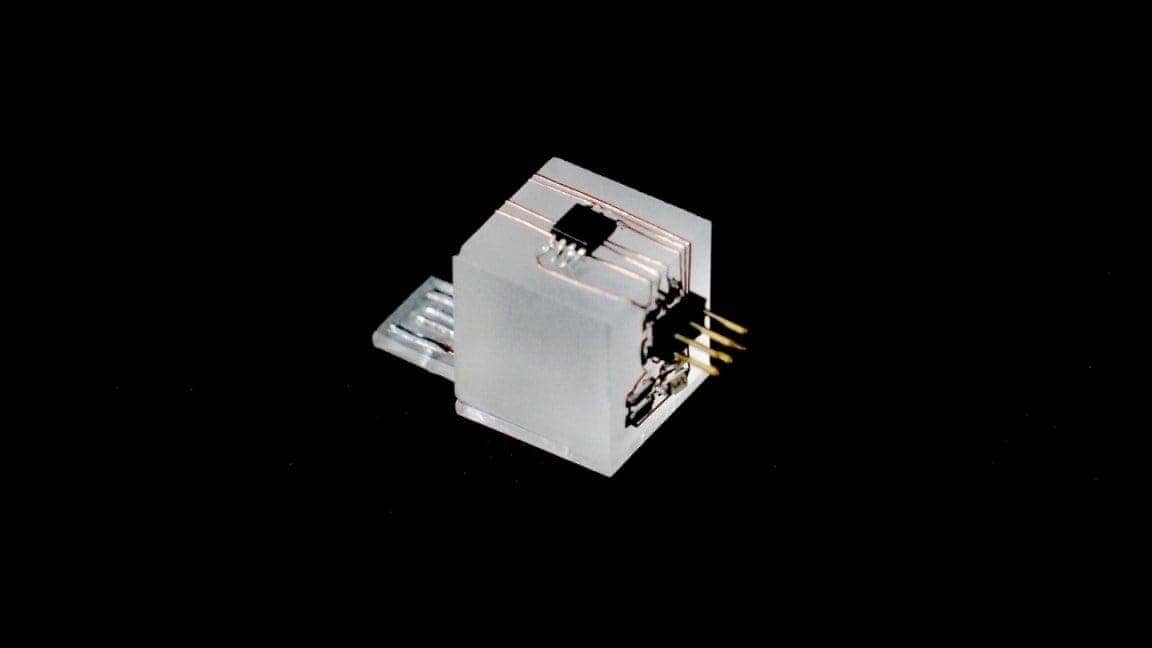

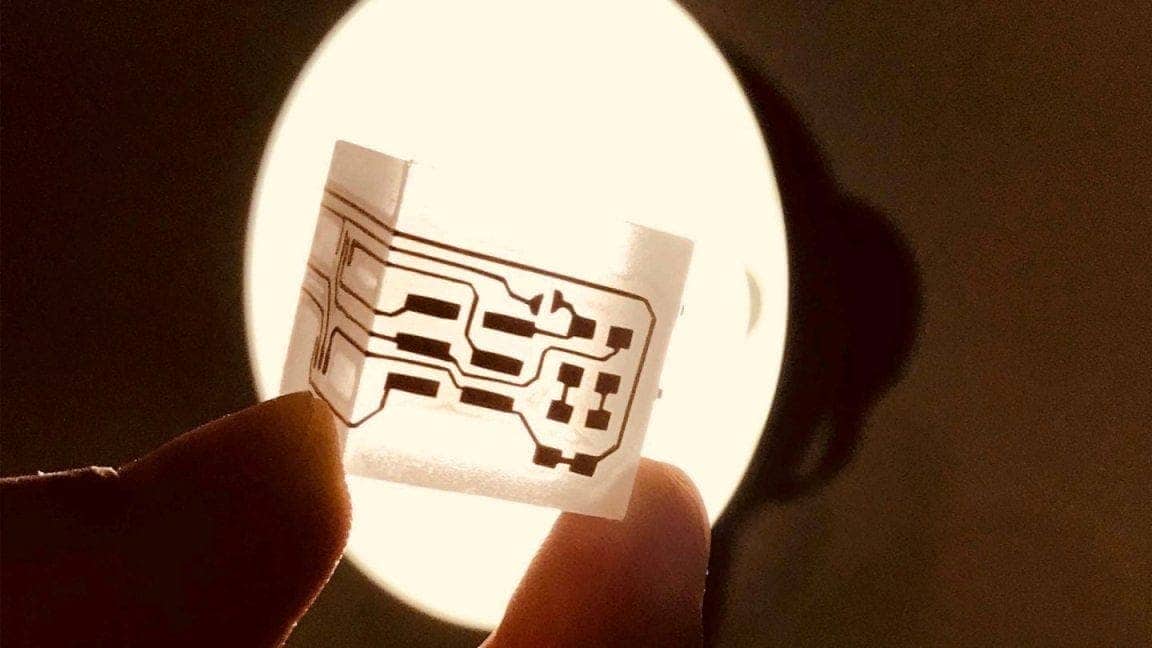

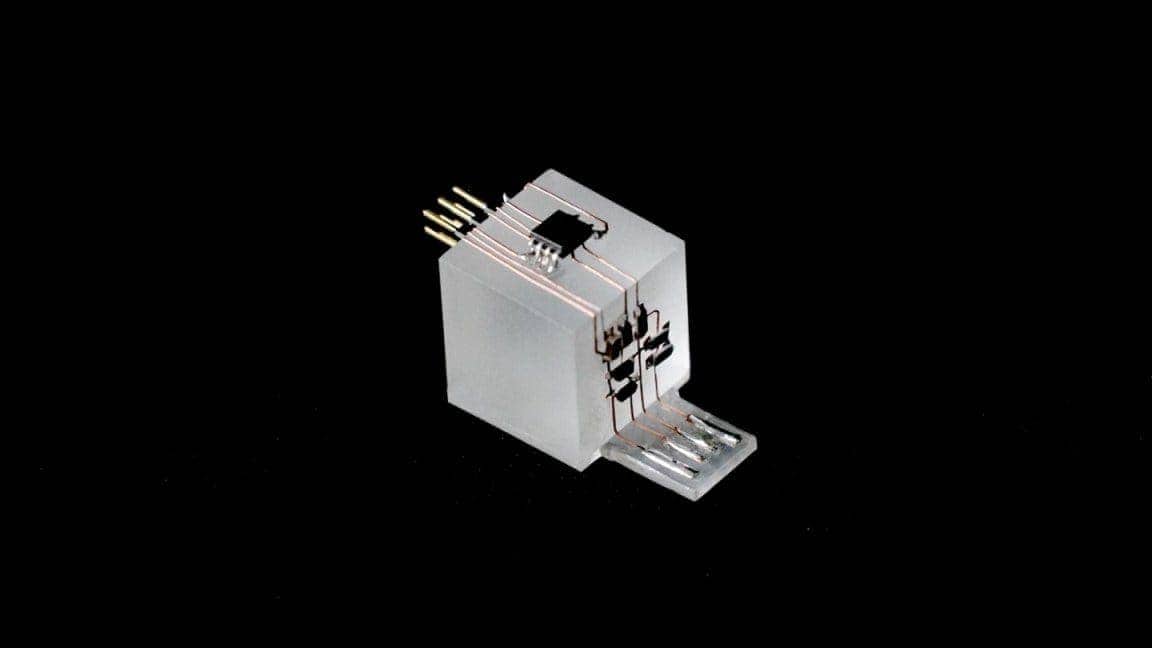

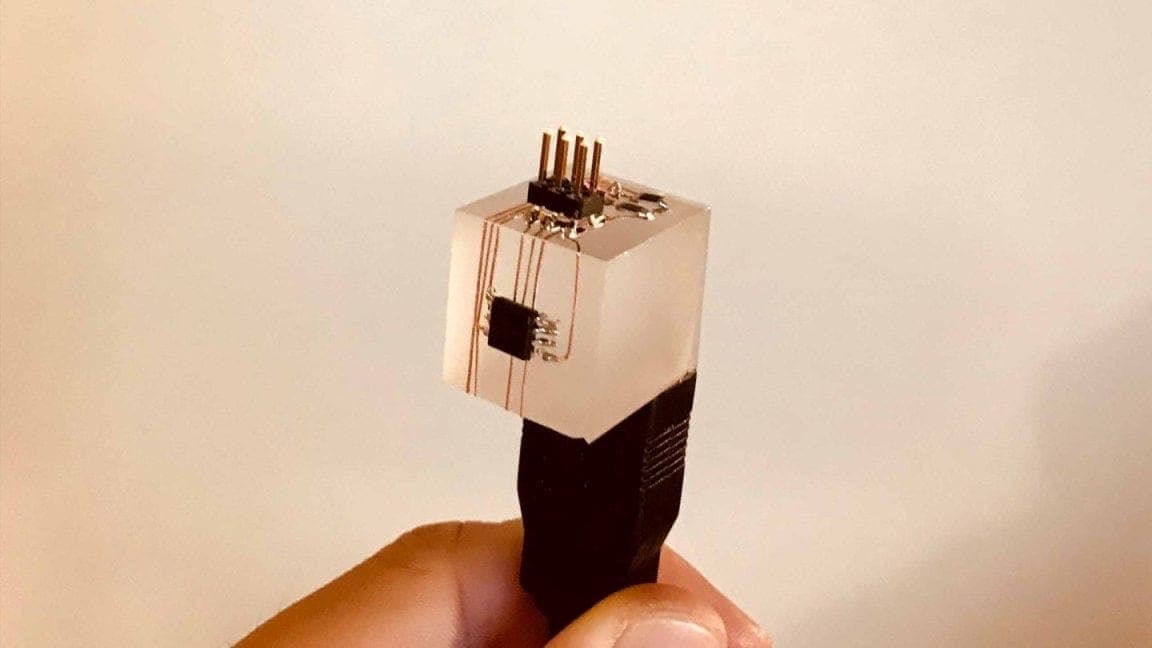

How to vinyle cut a 3d circuit

very very very fragile, don't leave the transfer film on when soldering

-

"home brew" pcb mill

-

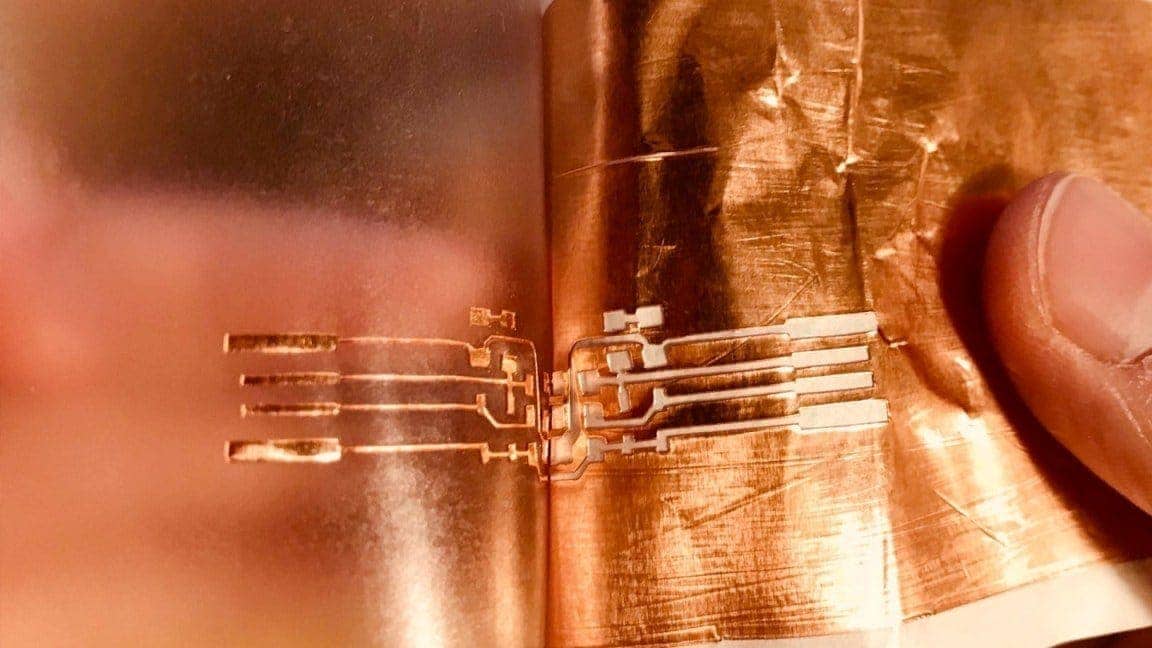

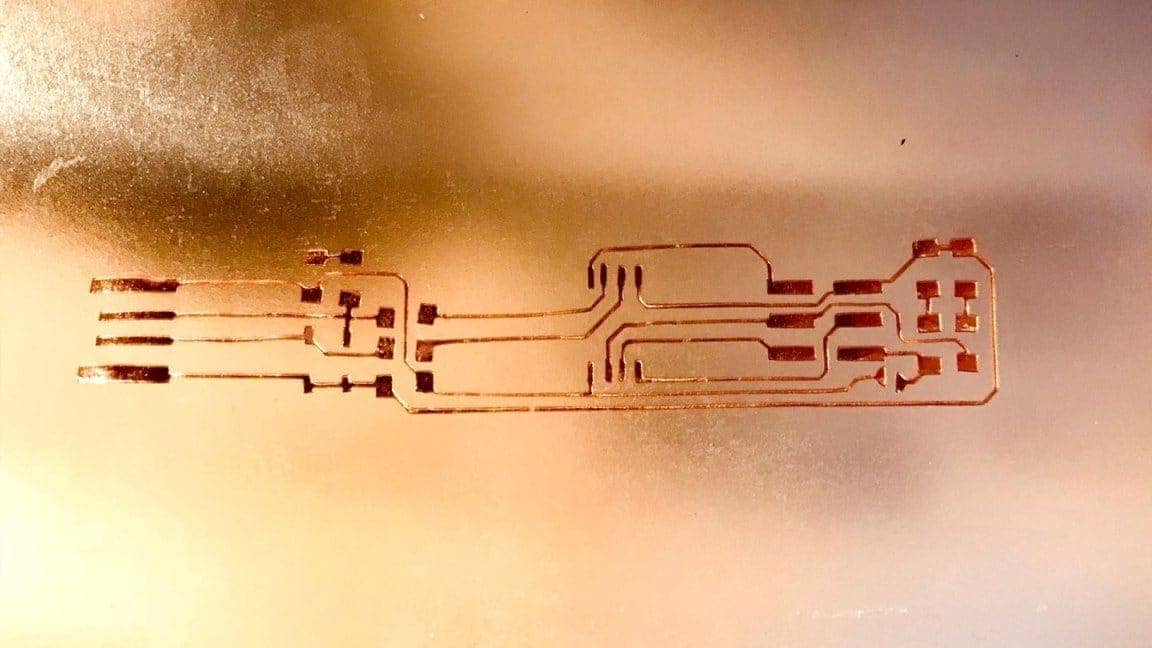

How far can a $200 DIY PCB mill go?

"home-brew" pcb mill

It works, but besides accuracy you also trade in your health, safety and time. Here is how the test mill came out after a few hours of fine tuning. It works. Few things worth point out, here are the reasons for why one should spend more money on a Roland: 1. no cover, no noise/dust protection. Very bad for both yourself and your neighbors. (never start it 2 am) I don't understand why they have to build the machine with aluminum at a price $200. A machine at this size, I think it should come as plug and play with plastic cover and plastic structure. Why there aren't someone doing it. 2.Mill platform and x,y moving plane is not perfectly paralled. That comes from hand measured hinge positions on the 80/20. Very poor design. 3. No feedback, the motor is x, y, z motor is blind controlled by the Grblcontrol software without knowing it's physical boundry.