I teamed up with Elina and

Anna for this week's project.

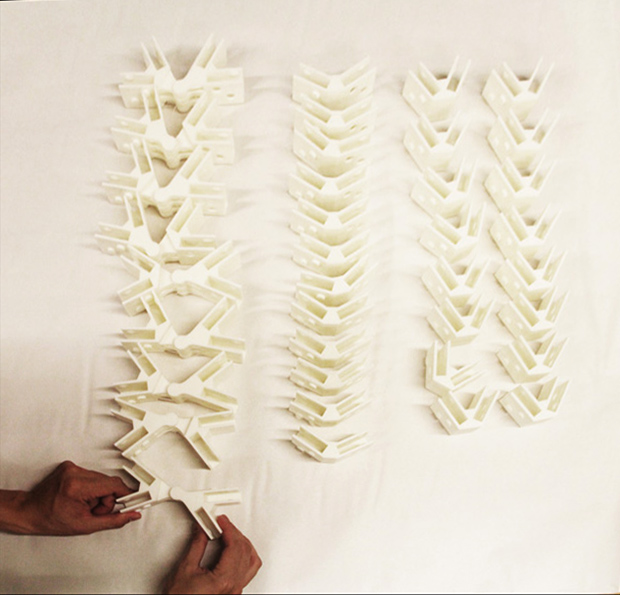

We wanted to make a structure that is flexible and transformable.

We came up with a system that consists of trapezoidal and triangular shapes, which can be assembled and disassembled easily.

The height of the trapezoid is around 16", which is an optimal height for a stool to sit on.

Size of each piece were conditioned by the height.

We used Onsrud machine at architecture woodshop.

After milling, we used a treadmill sander to remove splinters.

There are three types of joints in the system:

60 degrees rotatable, 60 degrees static, 120 degrees static.

We went through a lot of trial and error to find a right

thickness of the joint in relation to the plywood. The thickness of the OSB plywood was

not uniform in every part. The thickest part was up to 0.455"(11.56mm), while the thinnest was

down to 0.441"(11.20mm).

These are the final joints with adjusted parameters.

60 Degrees Rotatable

60 Degrees Static

120 Degrees Static

Our very first unit!

Roles

Kii: Joinery Design&Modeling

Anna: Milling Toolpath Design&Exectution

Elina: System Design&Documentation