This week, I wanted to take advantage of the ability of silicone molds to make many copies of the same thing, and the excuse to make something much more organic (read as: modled in Maya, rather than a CAD tool).

After experimenting with flowers for a while, I realized that CNCs can't do any sort of geometry with complex overhangs without a really complex mold of more than 2 parts. Every variation on petals and flowers I could think of wouldn't work.

I settled on hexagon-shaped tiles with bees on them. The bees feature exactly the sort of geometry that the ShopBot can't do. The gaps under their legs and bodies are impossible for the mill to reach into. I was excited to see if Partworks 3D would be able to figure out a sensible solution to the problem.

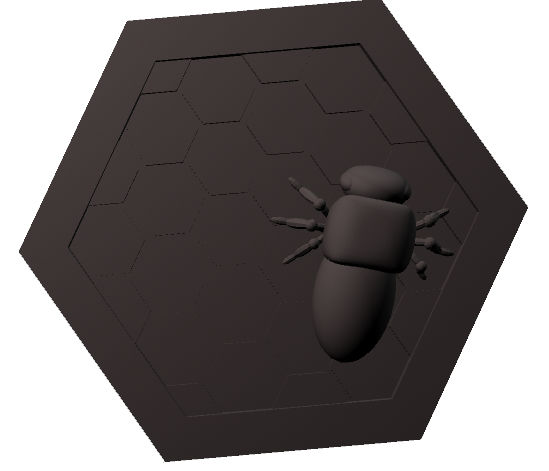

Maya render of one bee tile

Maya render of many bee tiles

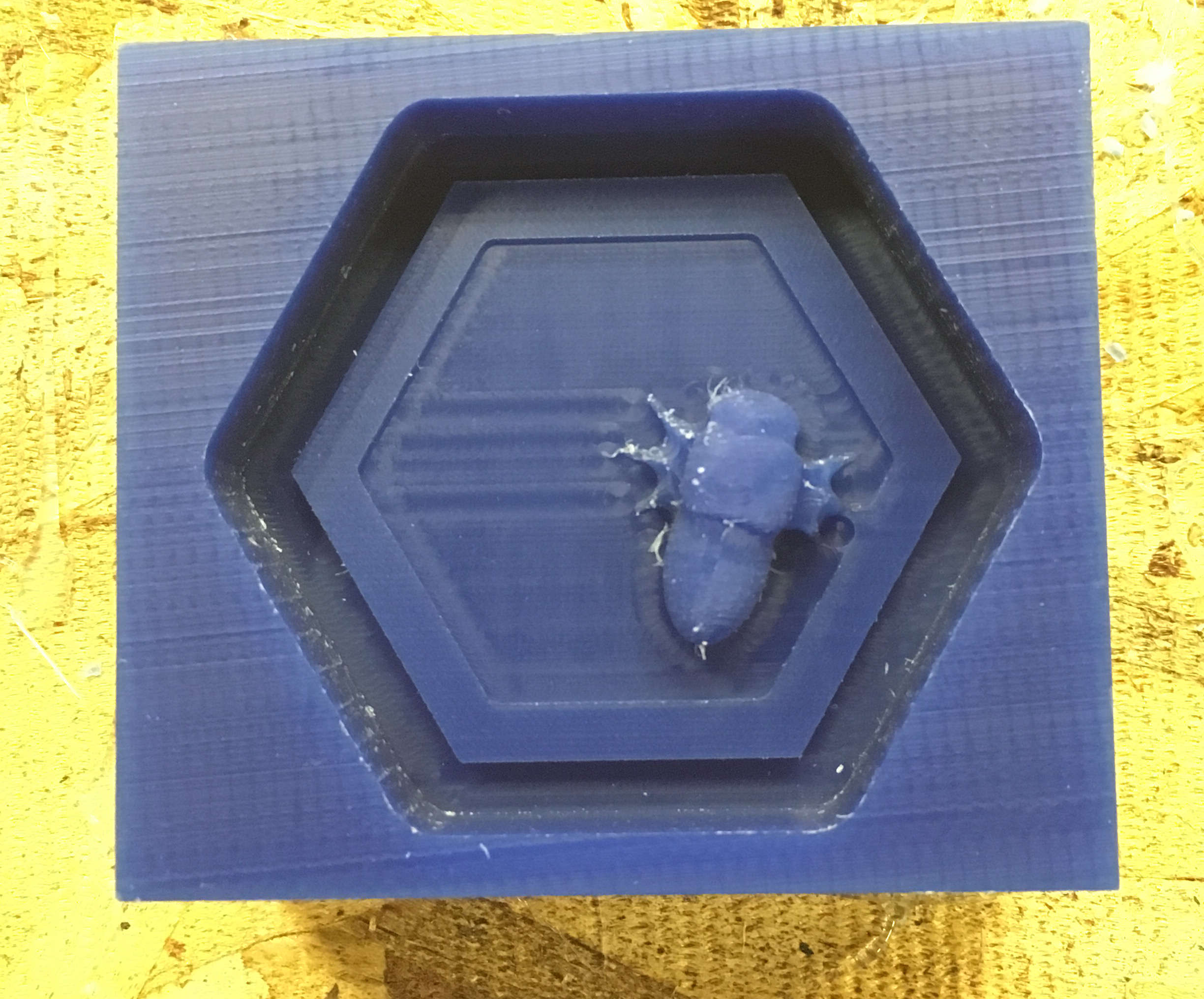

Partworks3d did a pretty solid job of understanding what it could and could not cut.

The Desktop ShopBot did a pretty good job of cutting out most of the part, but the smaller hexagon details were too small for it's 1/8" endmill.

I then added a few more details with a precision screwdriver. I carved out a little more space around each of the legs, and added a little fuzzy texture to the middle segement of the body.

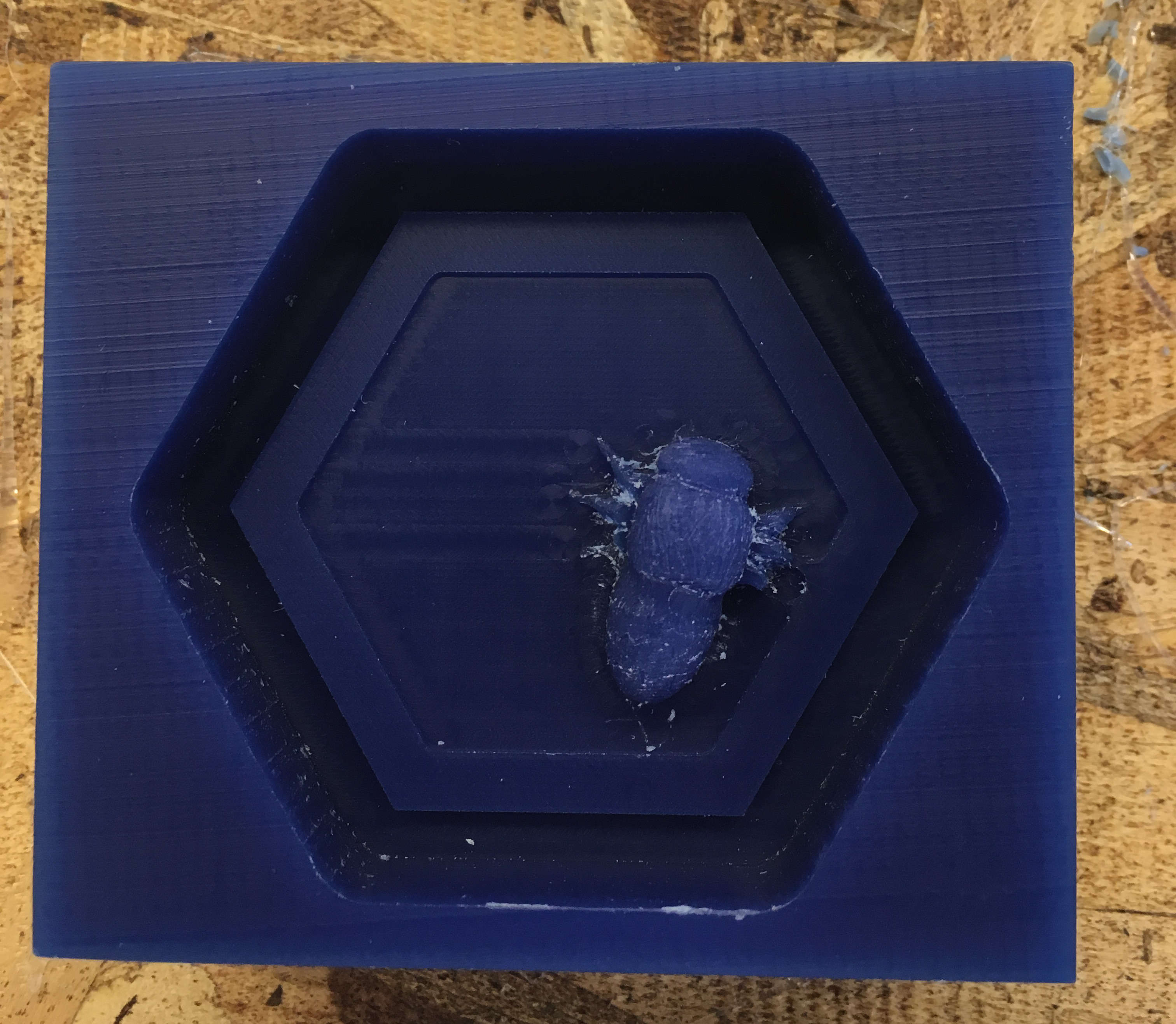

Oomoo in a wax mold.

Drystone cast from oomoo mold.

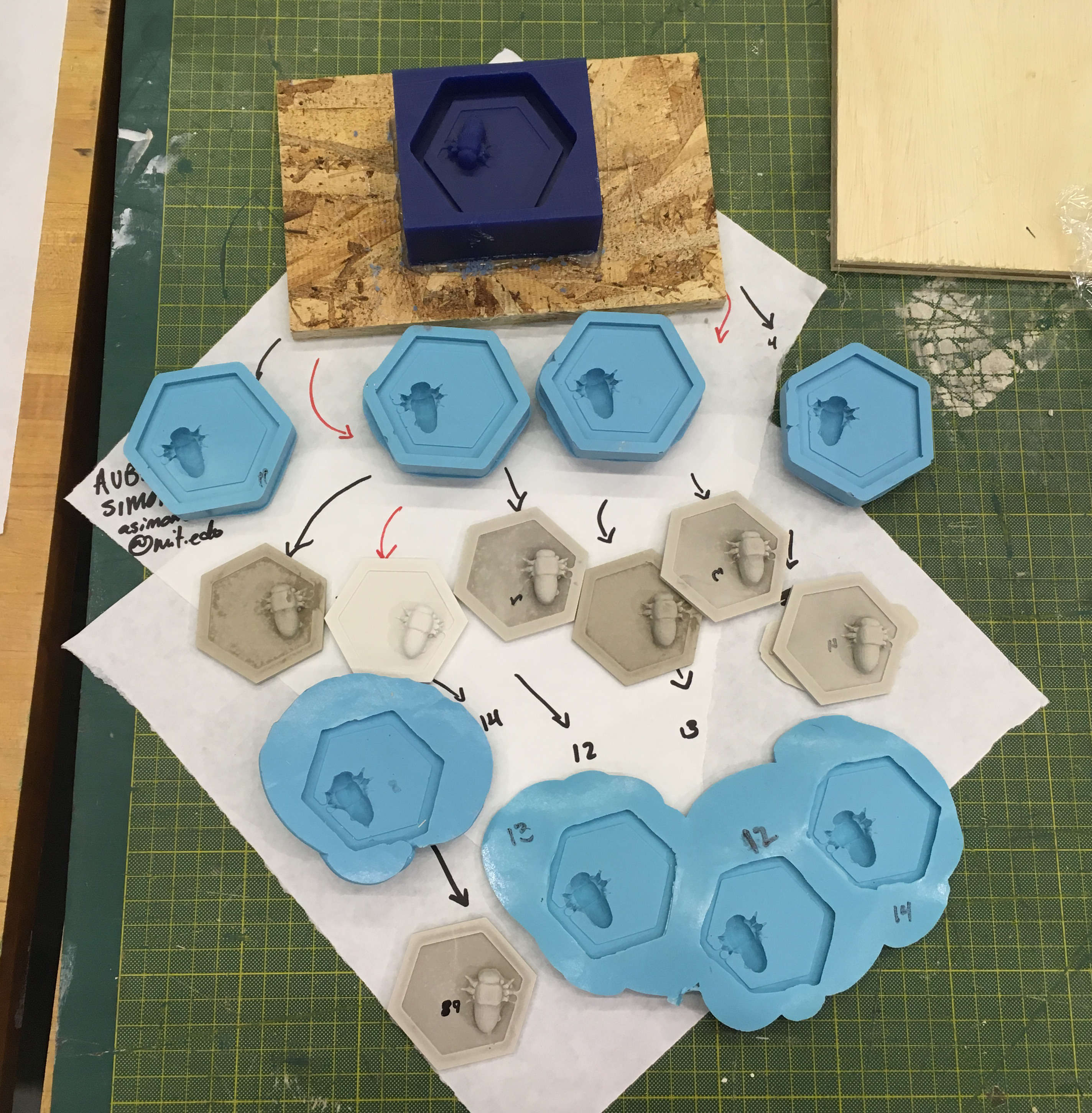

Then, I got excited about the idea of the propogation of errors in analog copying. Each individual mold is a relatively exact copy of the mold that it came from. However, there is always some small loss of detail, and some number of mistakes must make their way into the system. Graham actually metioned that people will do this on purpose to shrink a model, because each plaster cast is slightly smaller than the mold that made it. There's also something really cool about the fact that, once you have a mold, as long as you aren't using a particularly abrasive material, you can make an enormous number of plaster copies of that mold. And, from each plaster copy, you can produce another mold. And if it takes somewhere in the neighborhood of an hour and a half for a plaster cast or a mold to solidify enough to be used to either make a mold from it or use it as a cast, then it seems like the total number of molds/casts should be able to double every 90 minutes...

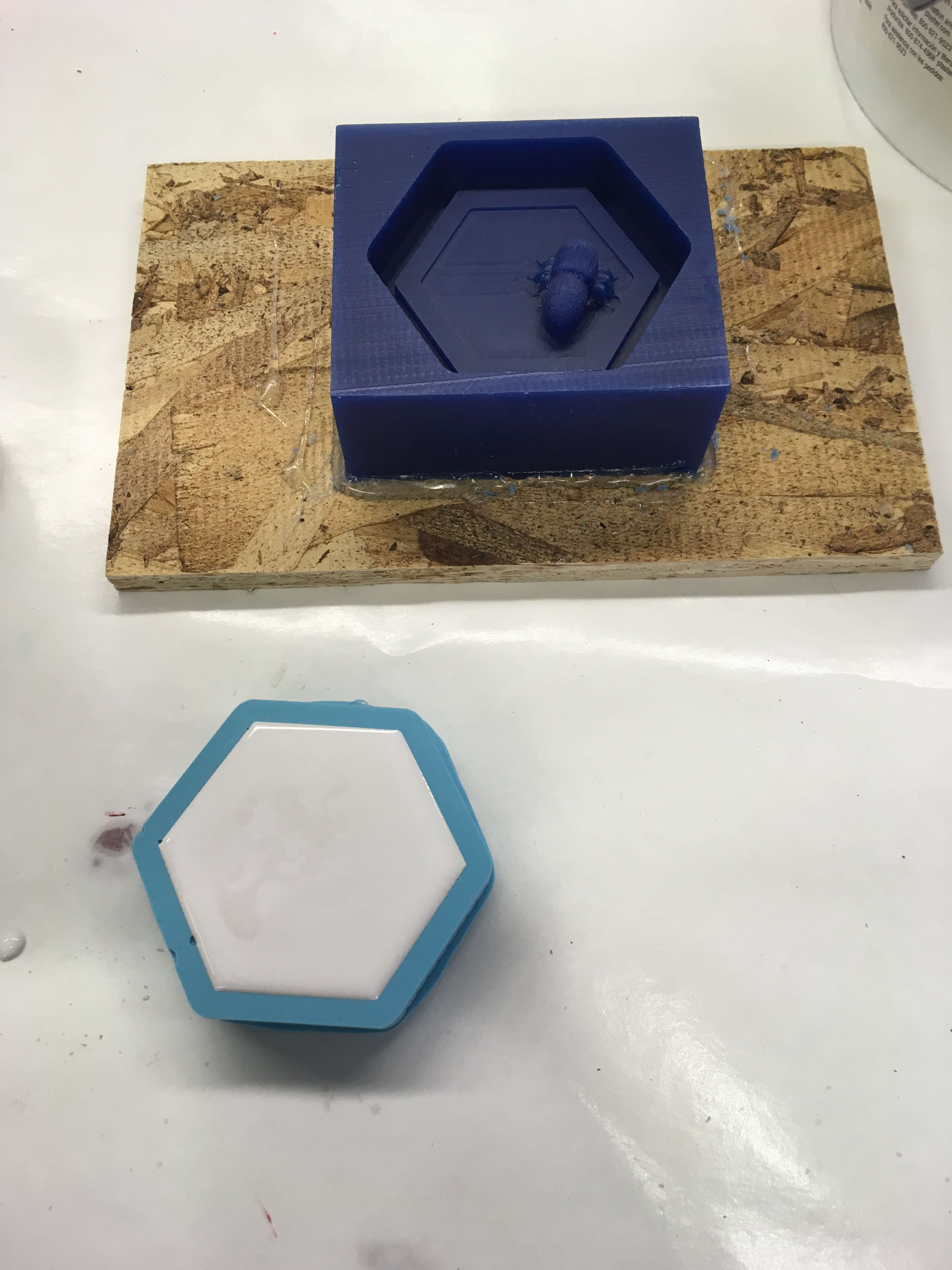

Another oomoo mold being made in the original wax mold, two drystone casts being made in oomoo molds made from the wax mold, and an oomoo mold being made from the first drystone cast.

uh

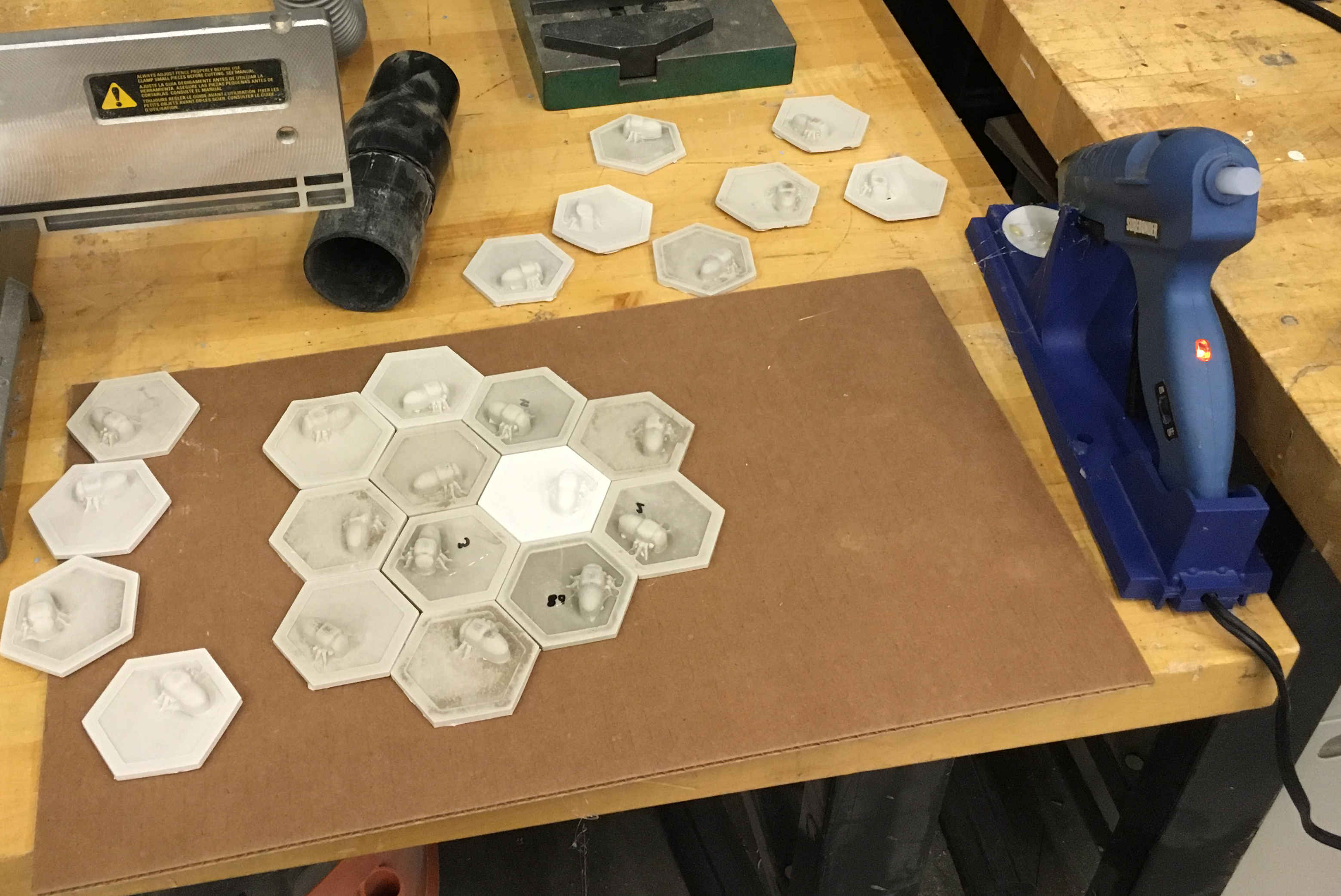

mounting our tiling bees on a piece of cardboard

all of our tiles, organized as a hive