Test runout, alignment, speeds, feeds, and toolpaths for your machine. [GROUP]

Make (design + mill + assemble) something BIG. [INDIVIDUALLY]

Given I have no space in my room to store something big, I decided to ask around and see who of my friends needed a piece of furniture. Turns out one of my friends needed a coffee table with the following dimentsion 48'' * 18'' * 15''. I was keen on doing a press fit (no screws assembly) so it the piece travels easily.

From the group assignment, we discovered that shaving 1mm off on each the joints would give for a good press fit.

I was initially considering doing a tight alignment of vertical boards but realized it would not fit on a 4'*8' foot OSB board. I decided to go for a simpler design that included some interesting shapes.

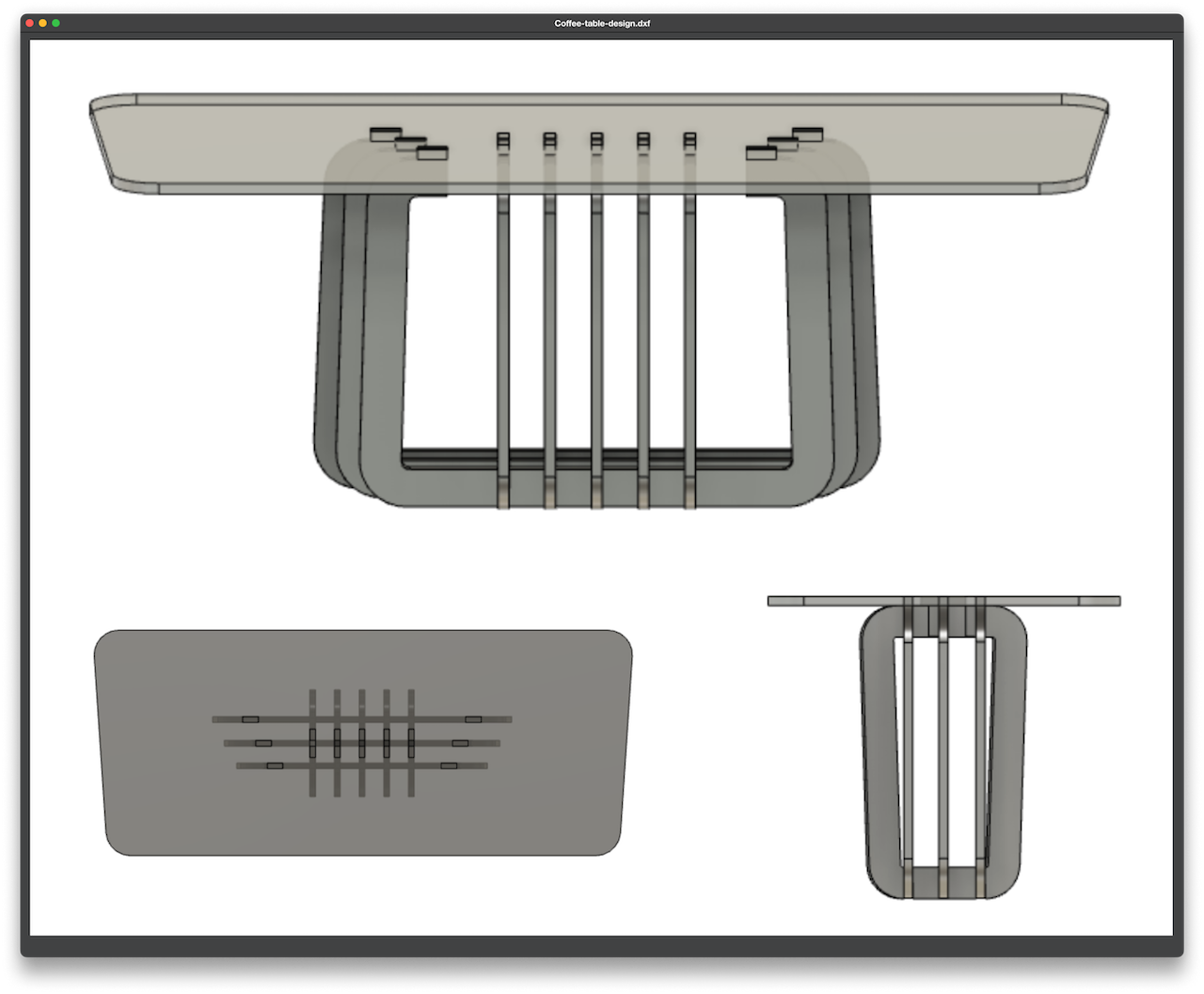

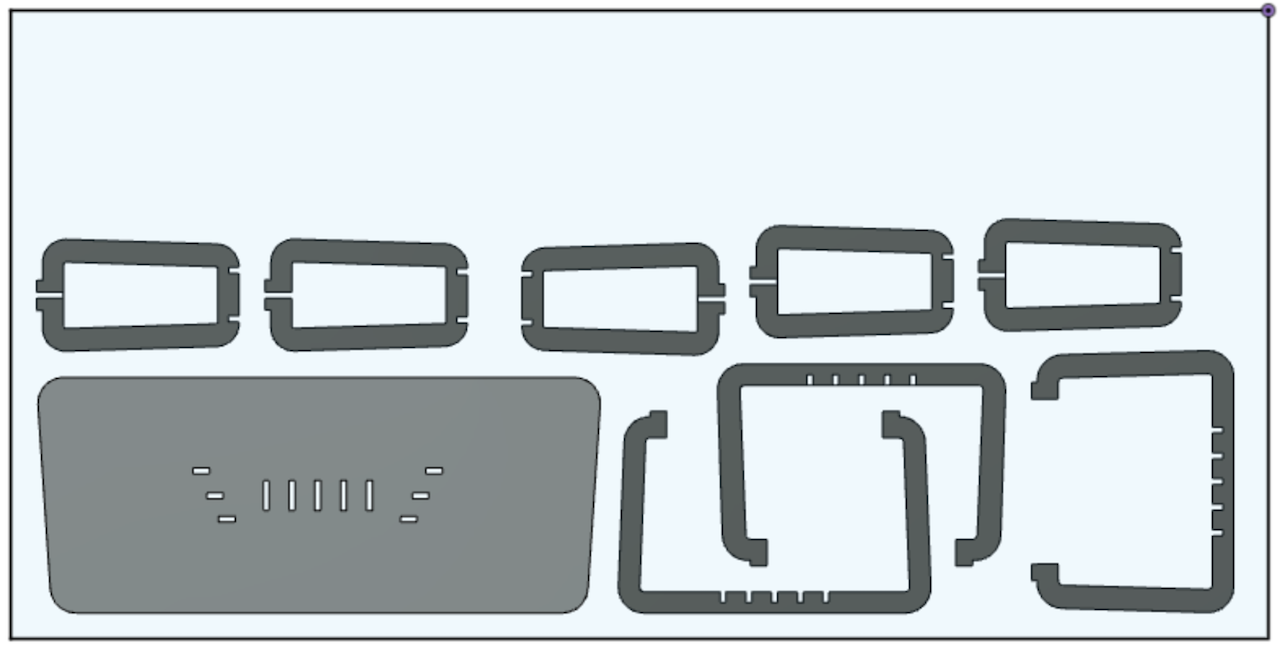

The table is made up of 9 pieces:

- A tabletop with a trapezoid shape and 8 holes to fit the leg joints.

- 3 long trapezoid-shaped feet

- 5 short trapezoid feet

With the help of our TA Zain, he helped work the CAM on the Mastercam software and added the dogtag holes on the sharp corners.

The design didn't fair too well during post-processing and became very brittle. This is partly due to the poor material properties of OSB but also to some design flaws.

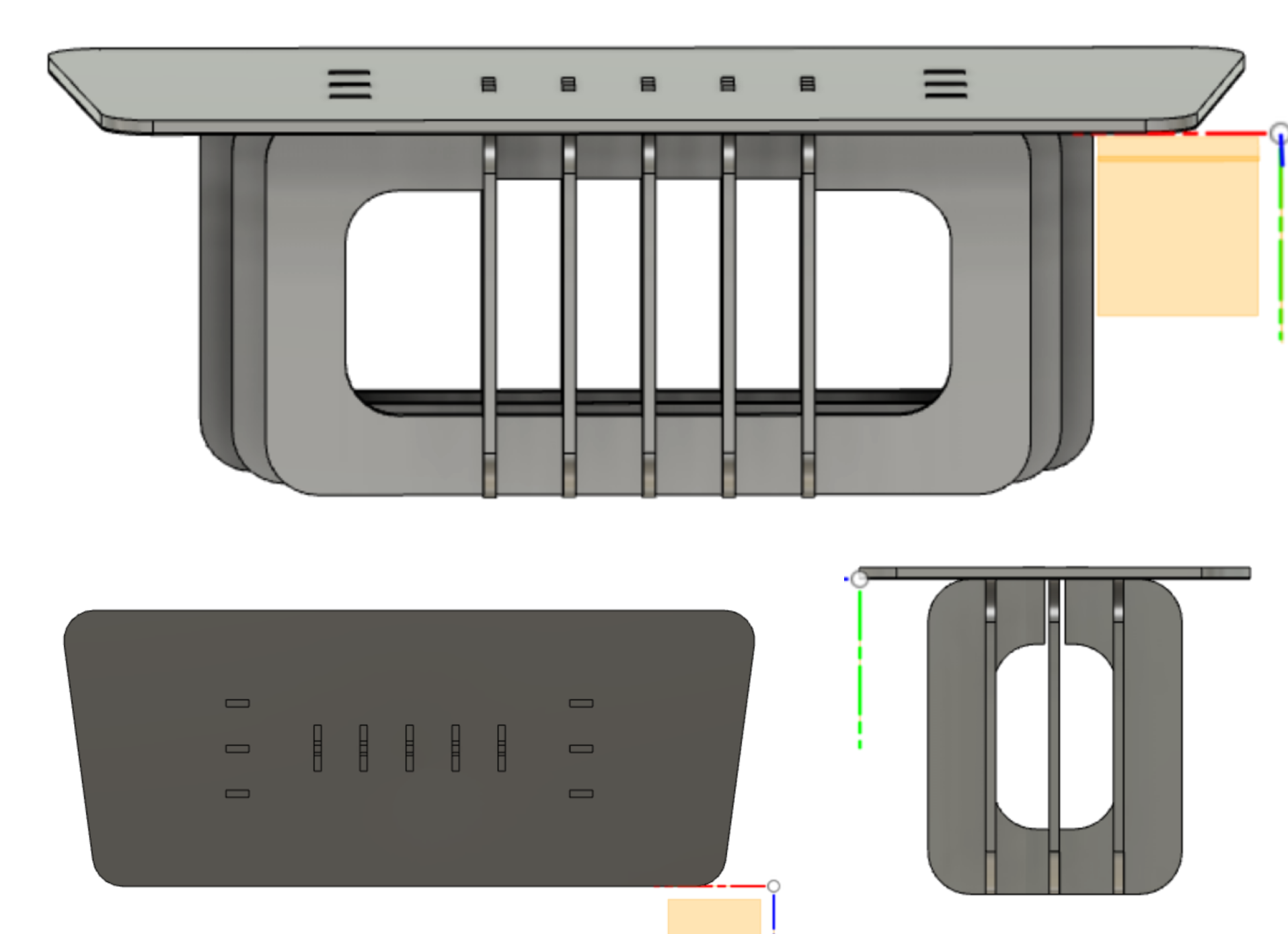

I tweaked my original design to adress the flaws. I made the feet wider and added rounded inner corners withh a bigger radius. I also increased the tabletop areas contact area with the feet.

I was hoping to mill this updated design on some sturdier wood, but unfortunately there was enough capacity at the wood shop last week.