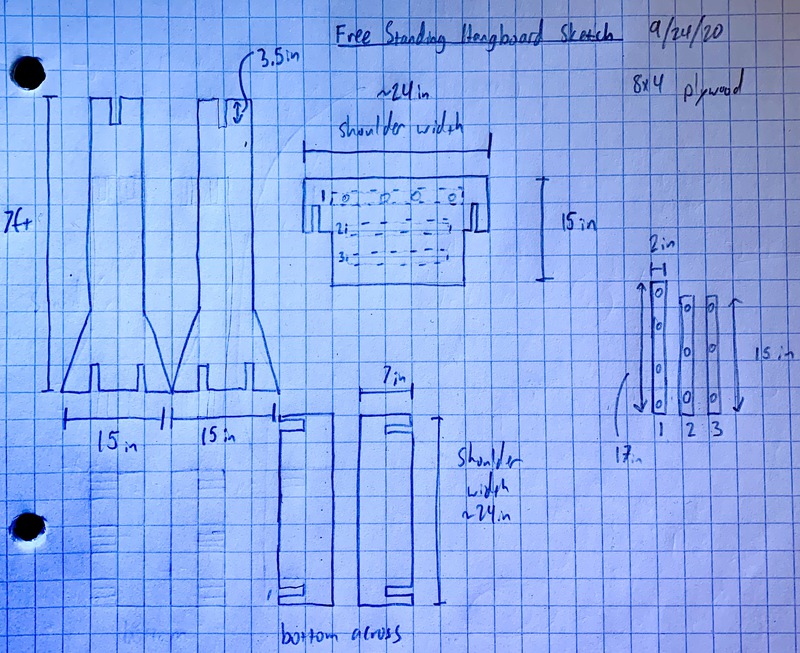

Well first things first, time to try to sketch up what I want to make.

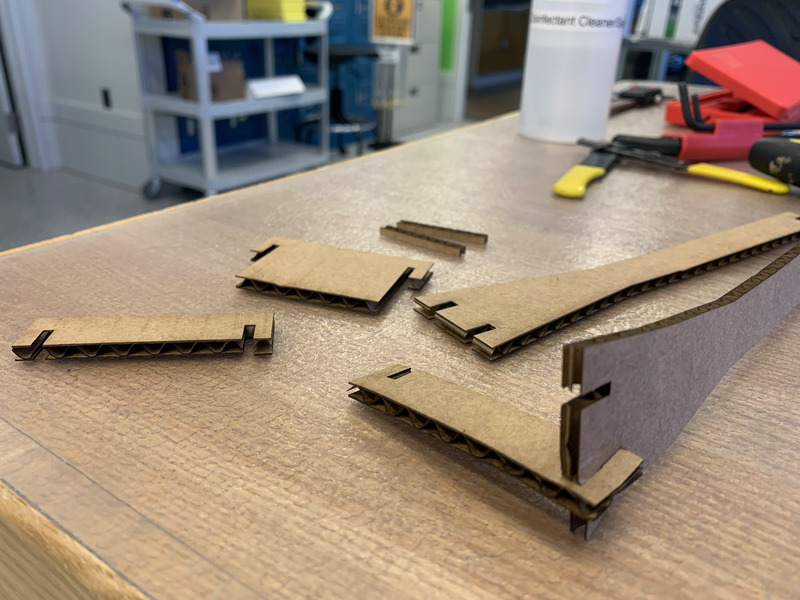

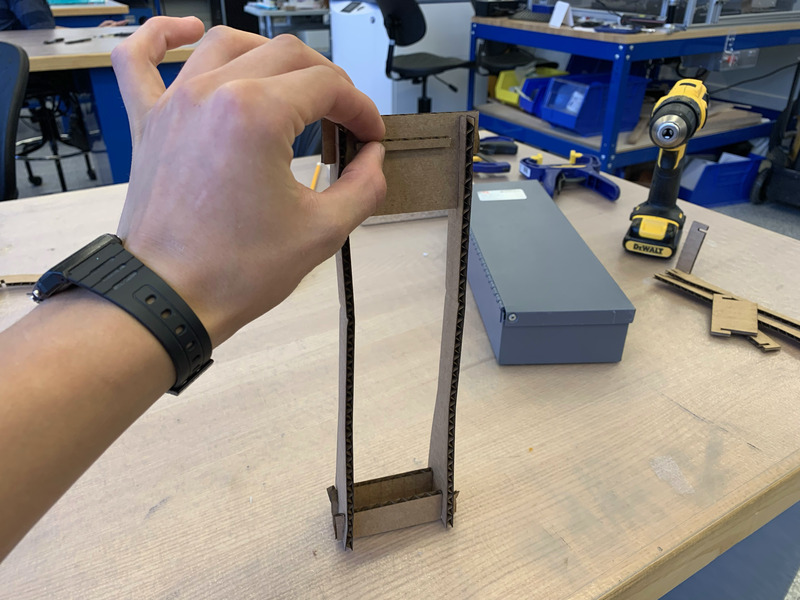

I got to work making a small model and lasercutting it. I forgot about thickness of the cardboard and it only fit together with much pushing and shoving.

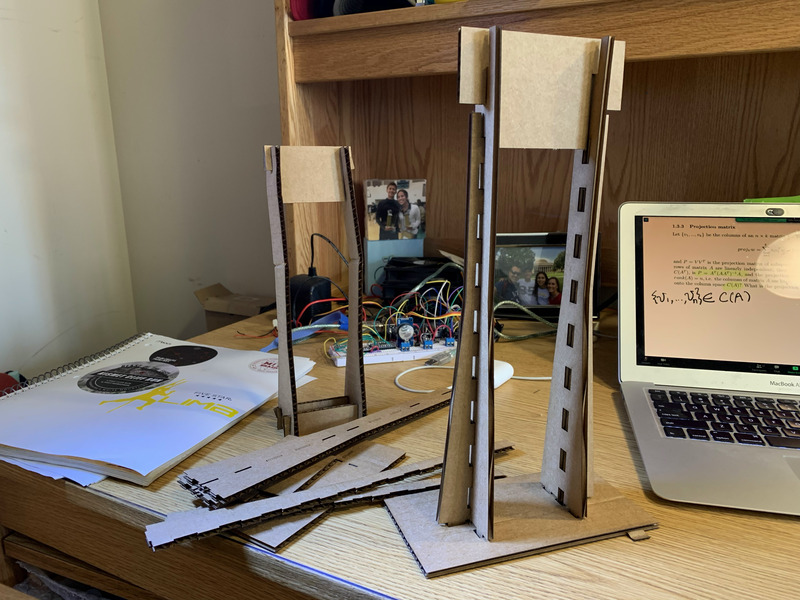

Then I got roasted by Anthony about my design. Anthony was actually super helpful though, thank you so much. So I added diagonal supports on the sides and made a baseplate instead of whatever I was doing before. It resulted in a much cleaner look. Also added a bunch of finger joints all over to reinforce my connections.

Now it was time to go to the machine shop. I had an online session with Anthony and made the emcam files.

I used two sheets... sorry. For some reason it didn't cut the base plate holes out so we had to redo that. I'm still not sure what happened there.

Anyways I got it loaded up on the cart and took it to the EDS/Cypress shop. Funny story I was walking in the biking lane and right as someone went by one of my pieces fell off and nearly made him eat it. Thankfully that didn't happen. Thanks random biker for the words of advice: "Don't do that again!"

I got everything up to lab and started filing the heck out of it.

Also I had to saw off the ends of the side pieces, because they interfered with the piece that goes on top.

Honestly it was way too hard to fit the joints together. I need to add way more spacing next time so that they fit together nicely. Buttttt anyways I was able to hang off of it so I'd call it a success.

I loaded it up in the elevator (had to take the big pieces off the cart because they don't fit in horizontally). Then I took them home to finish up the glueing.

In the first stages of glueing the pieces together and realizing that with glue it's even harder to press the pieces together. Also it was 11pm and I was banging hard with the rubber mallet to make them fit. It was bad. Someone thought our floor was working out in the lounge. Thankfully no one came to tell me to shut up.

Unfortunately I couldn't hammer the bottom of the stand into the baseplate well because there was nothing down there to hit as an edge. The holes for the jointes were just too tight. So unfortunately it stands, but isn't quite as sturdy as it could be.