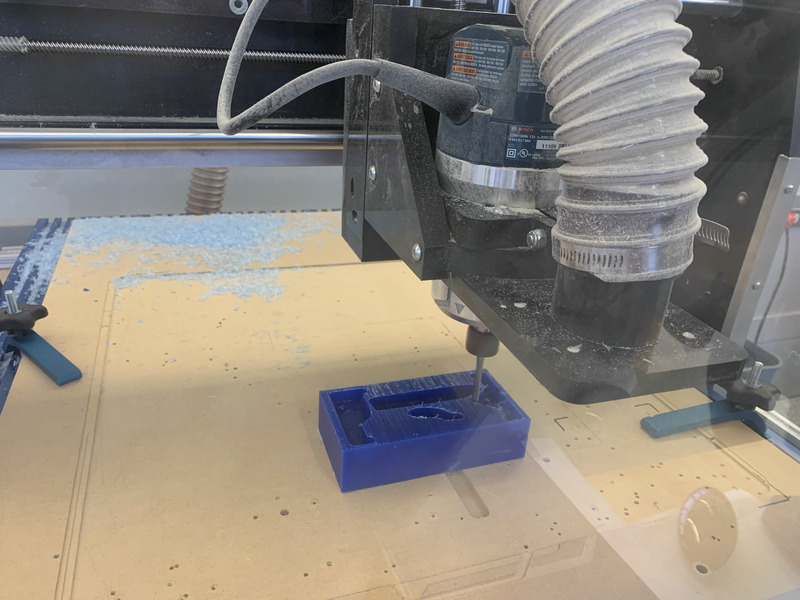

I just hopped on fusion and whipped up this bad boy. There were a couple things wrong with this including the fact I didn't leave enough spacing around my part so that a quarter inch drill bit could fit around everything. Thankfully Anthony helped me out to do it quickly and then cam it up on solidworks. Next is actually milling it out!

Went ahead and started milling my climbing hold out. It got a bit noisy when trying to cut out along the long wall, because I had to make it so thin (In the future I need to plan out better dimensions for my part).

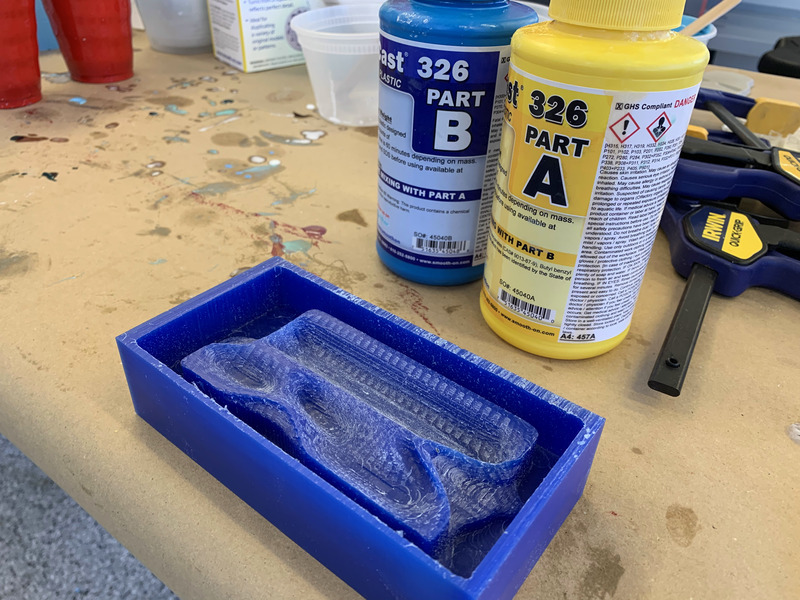

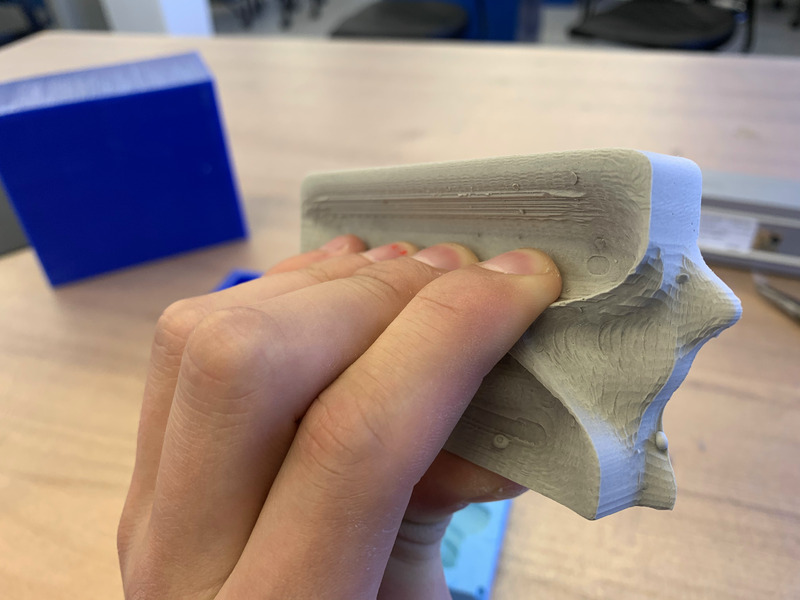

The piece came out well and the roughed up features were actually great because they add helpful texture.

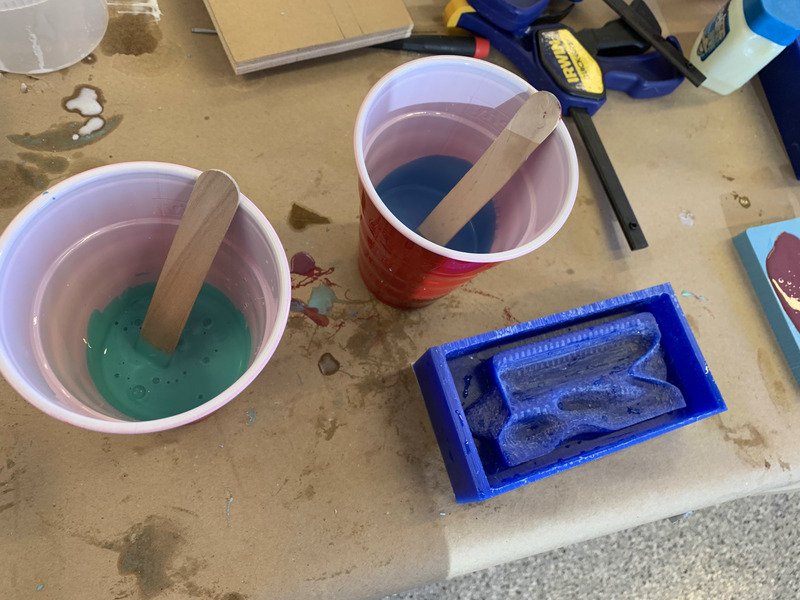

Next it was time to pour in the Oomoo and make the mold. 2 equal parts of oomoo mixed separately and then together and finally poured into the mold. Pretty straight forward. Then I sped off to my next thing.

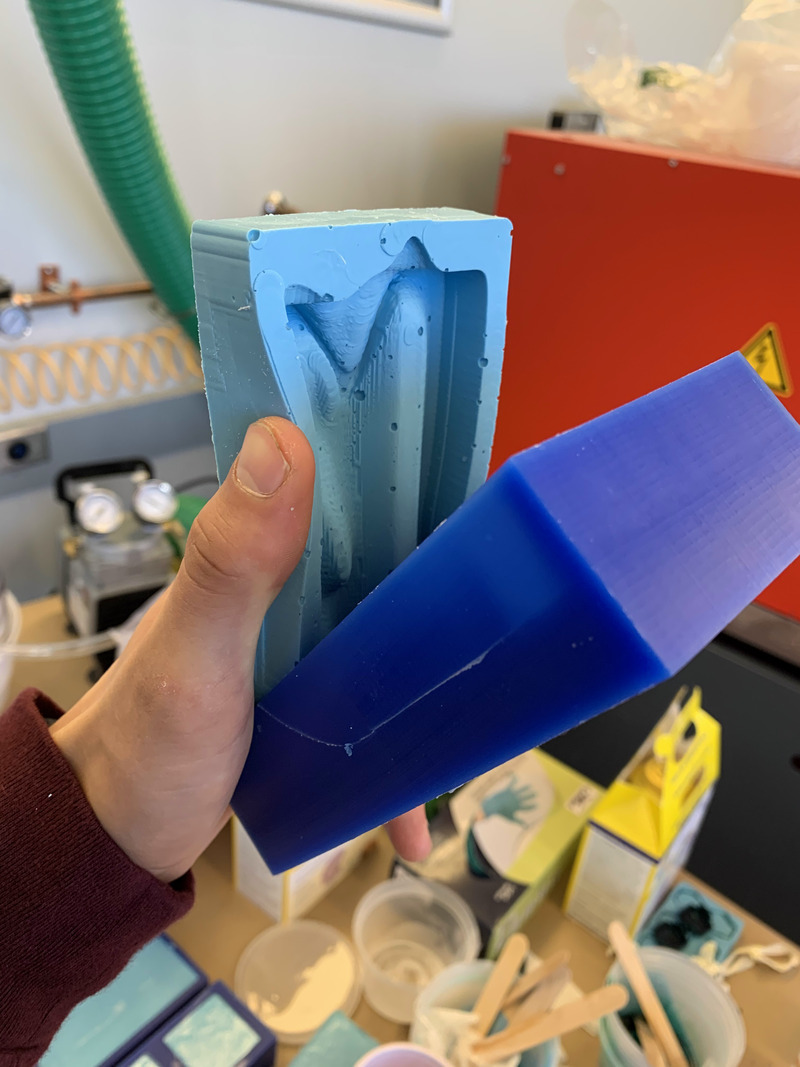

The only problem was the bubbles that came out in the oomoo, I should have been more careful pouring the oomoo in and tapping out the bubbles. This is just an aesthetic thing and the mold was still perfectly functinal so I am still very happy with the result.

Unfortunately as I was taking it out though I broke the side of the wax mold. Just a reminder to make thicker walls next time, smh.

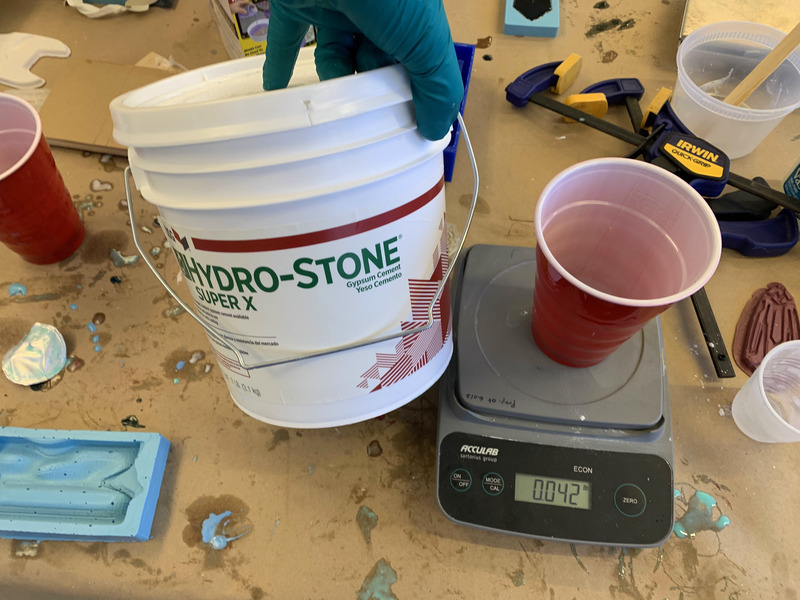

With the Oomoo having worked out so well, it was time to fill the mold and cast my hold. I decided to go with hydrostone and found out much to my suprise that it's 100 parts powder mix to 22 parts water. Not the other way around. so yeah I messed that up. So then I just added powder until I thought the consistency was right.

Thankfully it worked out great. The piece came out very nicely. Now I just need to add a 3/8in diam hole and a small recess to be able to bolt it into a wall. I can probbaly just use the drill press to add that to the wax cast. The hold works out to be a nice pinch and totally looks like holds I've seen, which is really cool.

Take a look at the final page for this same hold, but with holes/recesses in it for bolts! Also I made a second oomoo mold of this that had way fewer air bubbles:)