Additives

- Solid Colour

- Thermochromic

- Photochromic

- Glow Powder

- Stretchy

- Conductive? Is alginate an appropriate matrix for this?

I was thinking about what additives you might want in your biopolymer. An obvious one is colour, but you might also be interested in more active dyes like a thermochromic dye (I've only recently discovered that you can get these off the shelf. There are probably other non-aesthetic properties that might be interesting like conductivity or stretch but I haven't thought of many and am not sure how to make them happen!

The Parameters

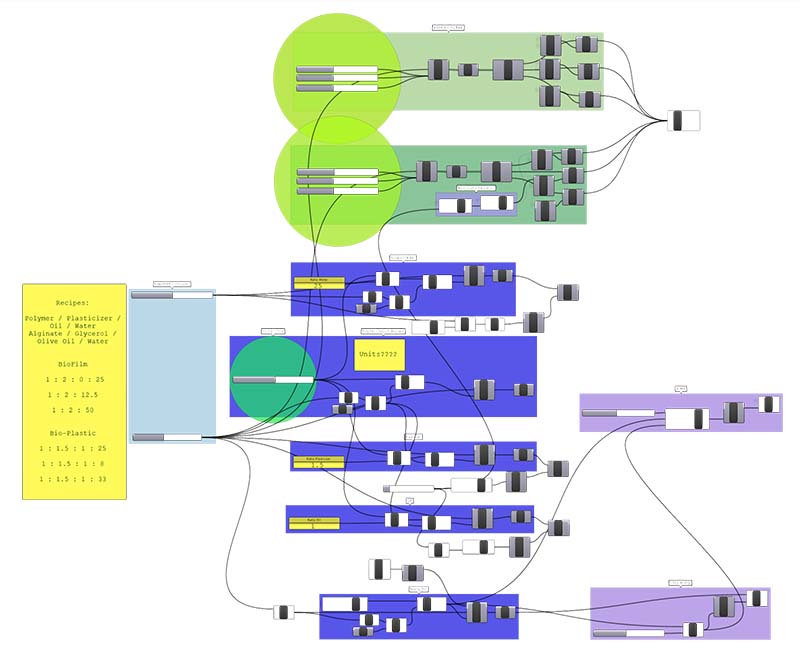

I made a gh script (sorry for the low res. image, you can find the messy script here) and built in the controls that I'd like on the user interface, essentially:

- Primary Ingredient Controls: drop down list of options

- Additive Controls: on sliders

All of the ingredients are measured according to volume, this may be a good way to visualise it in grasshopper for the model but I expect it's not the right way for the machine to measure/dispense powders for the mix? I'll have to keep my eye on this as I start designing it.

The mixing bowl and bath are currently generated from the total volume from the ingredients we've chosen from the controls. But I should really look into how much mix I'd need for my desired yeild.