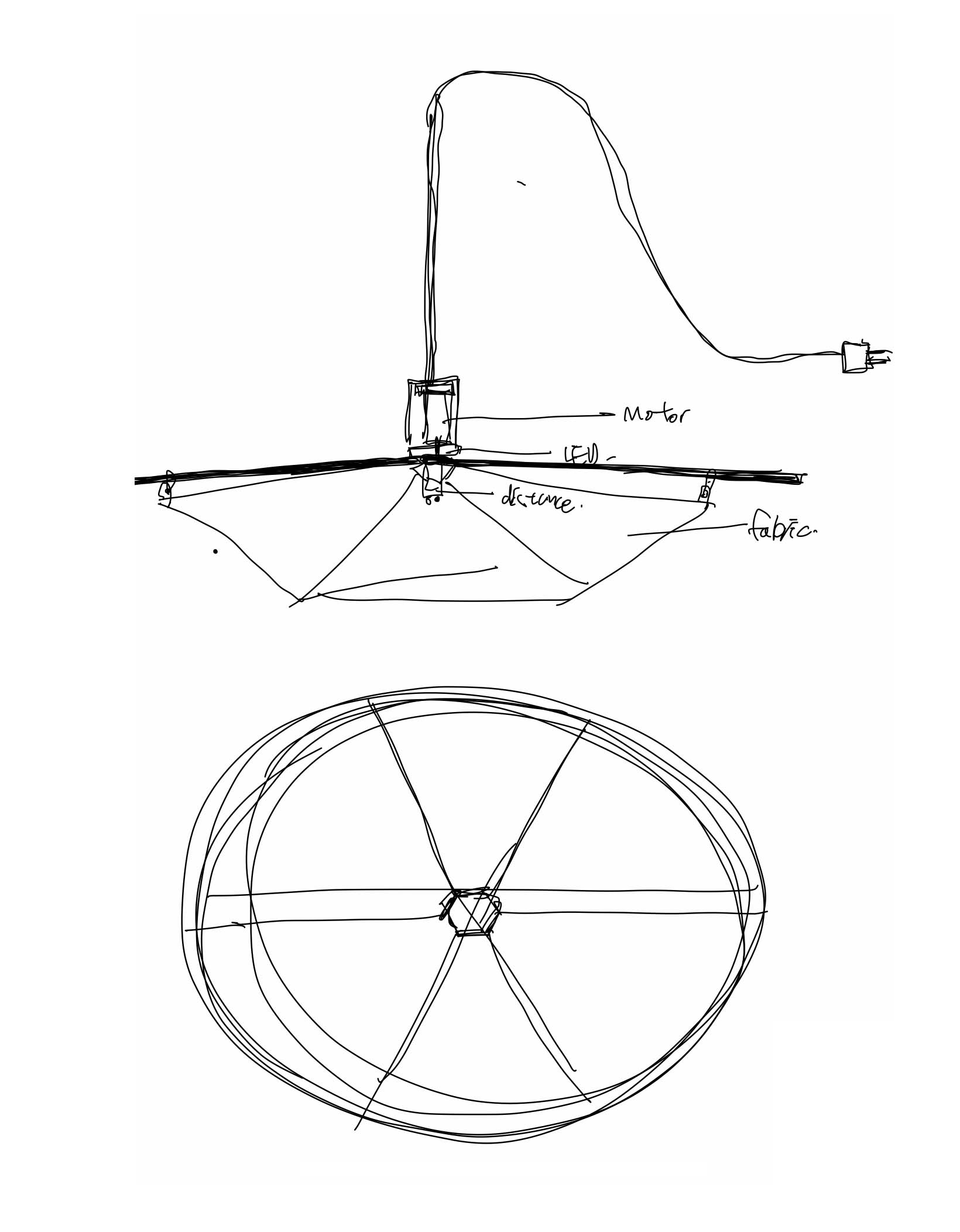

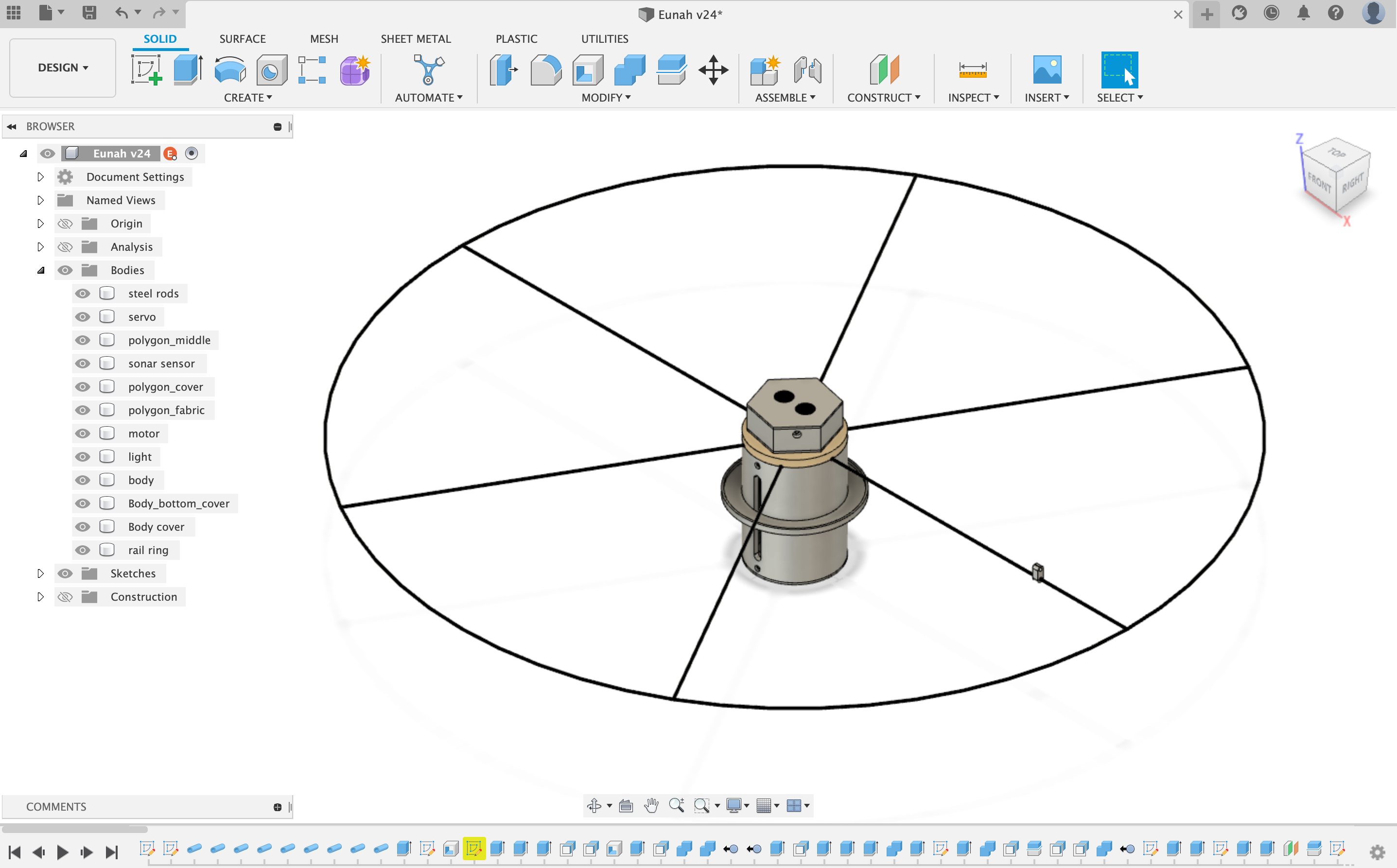

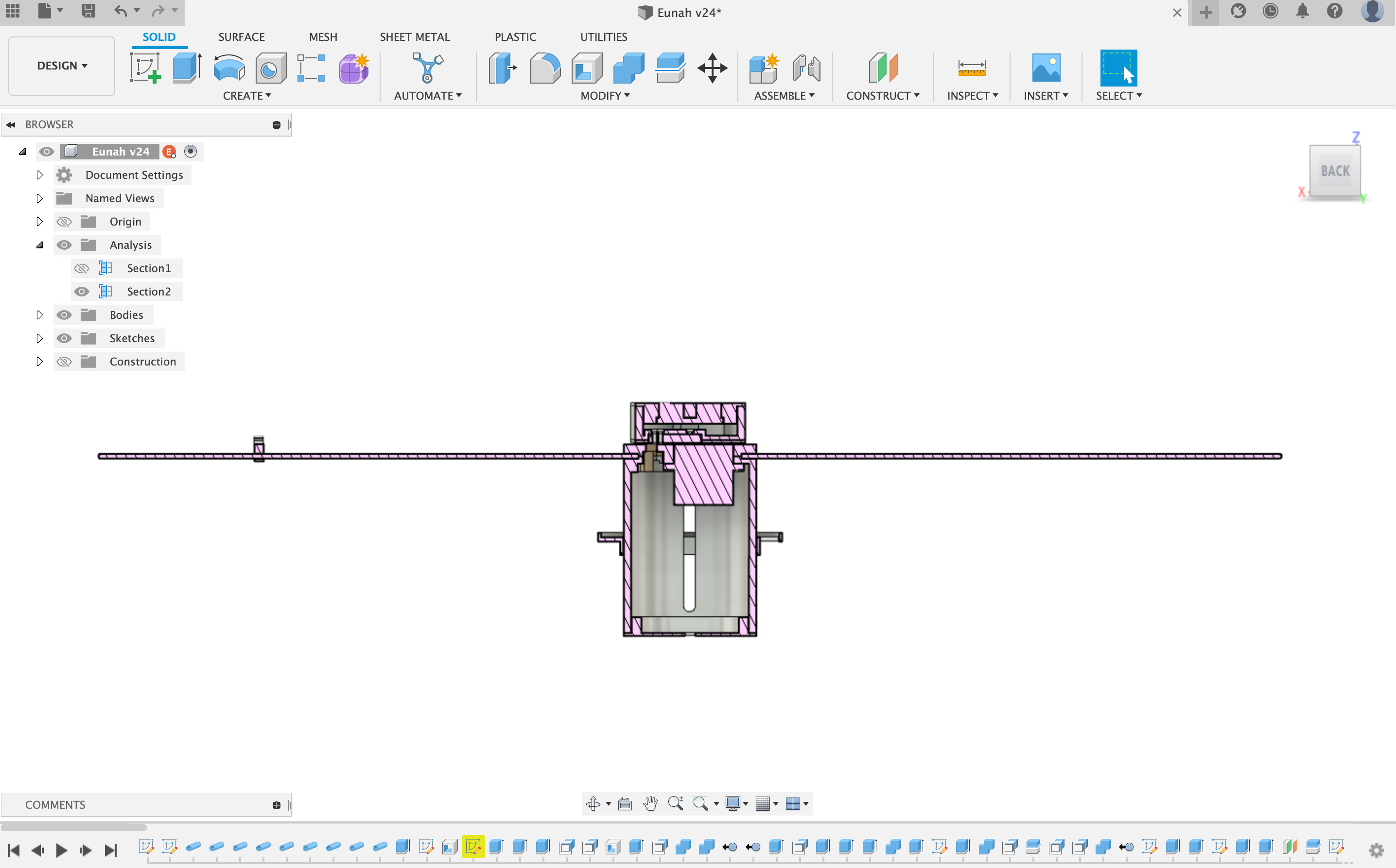

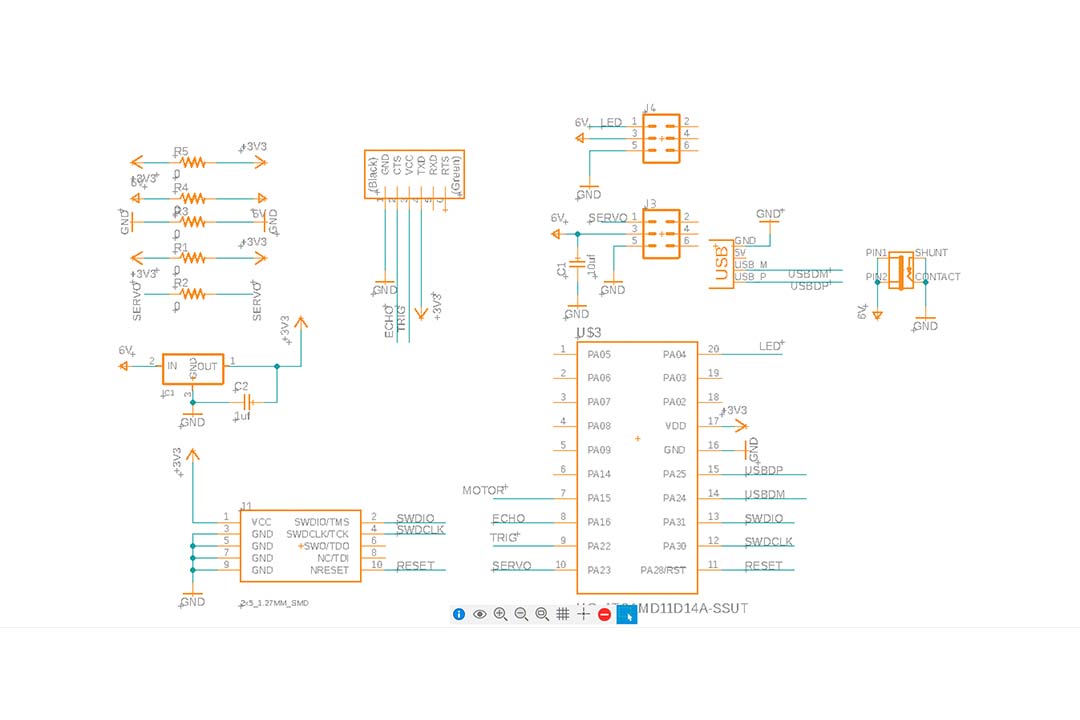

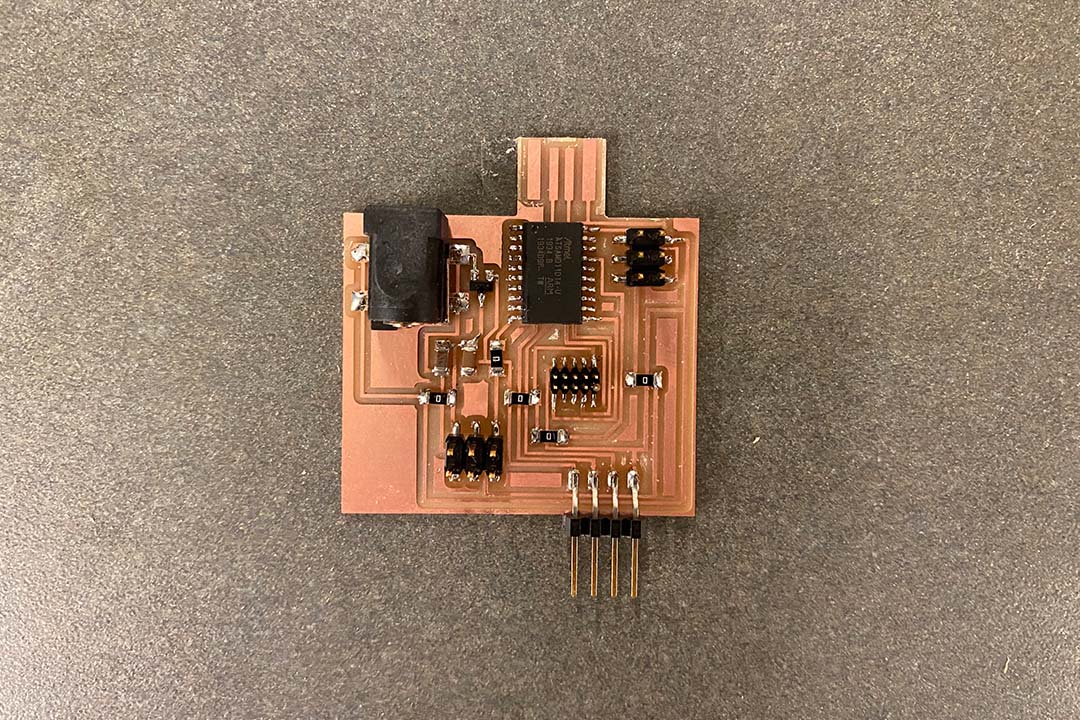

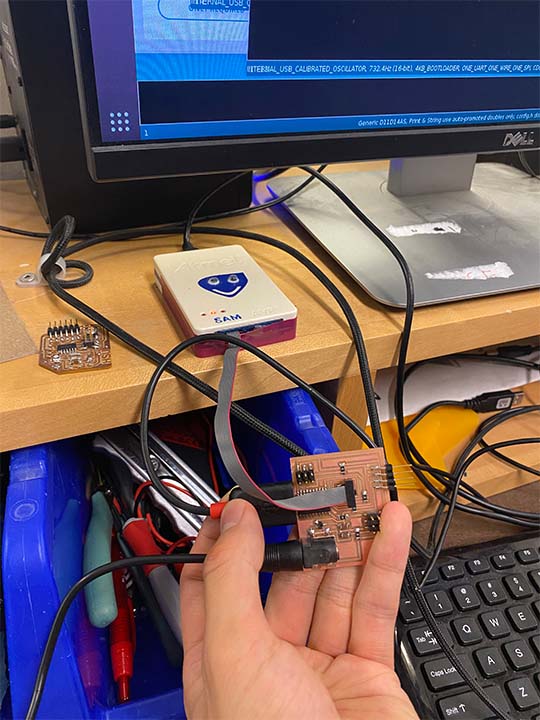

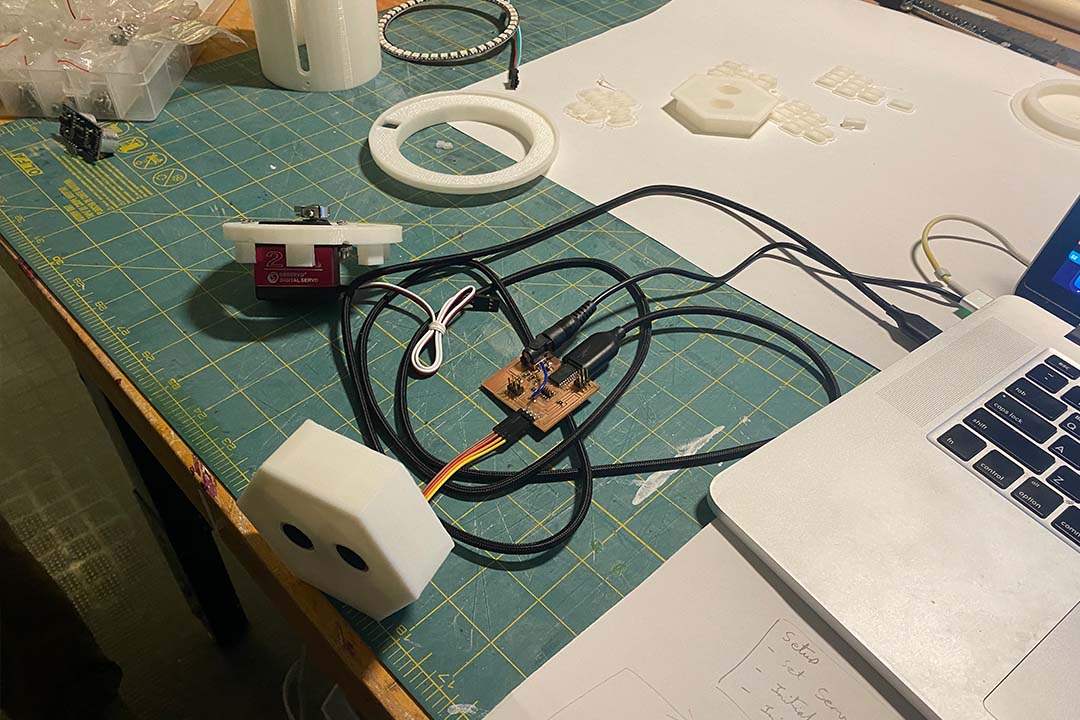

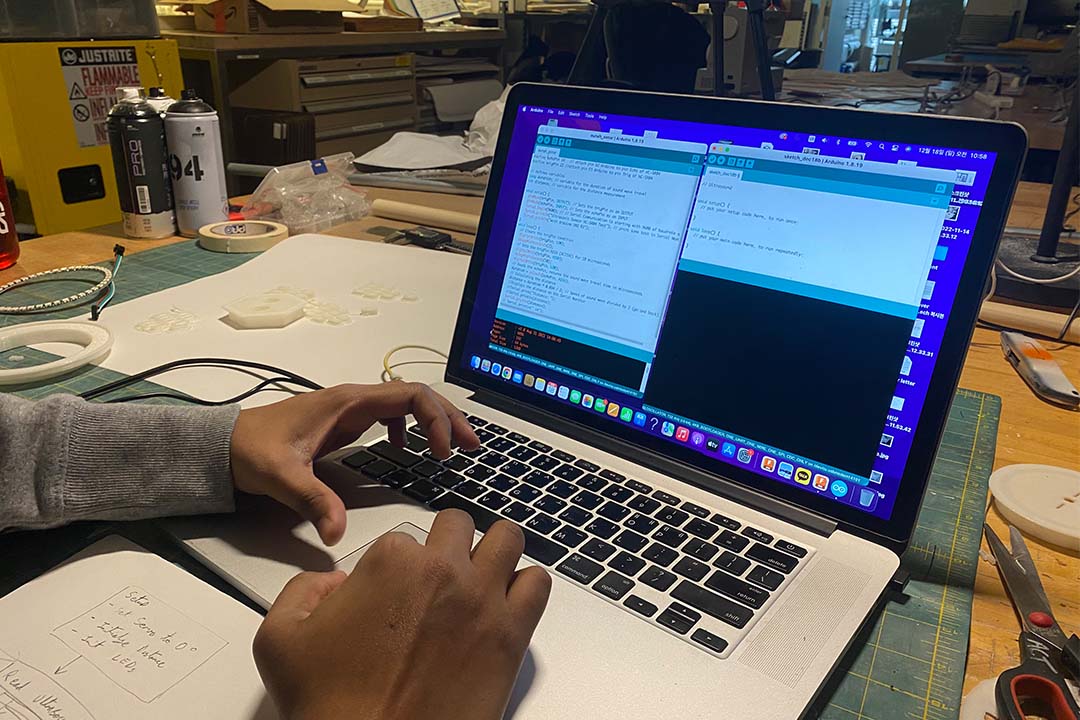

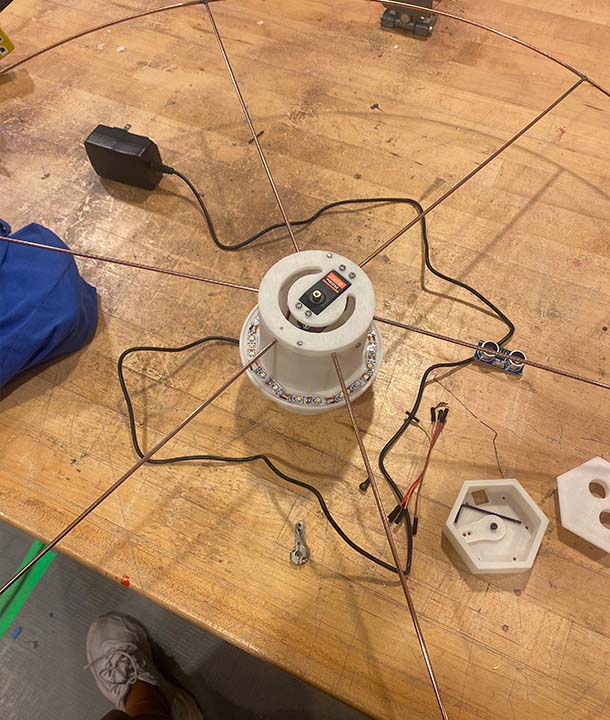

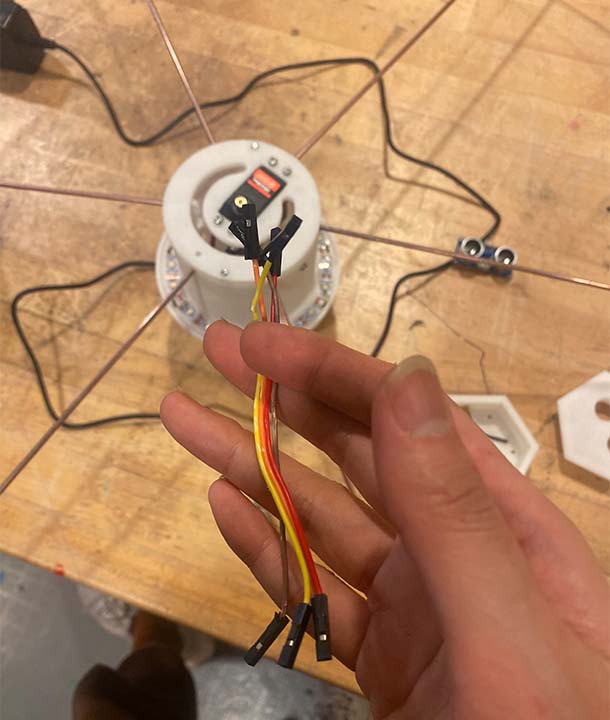

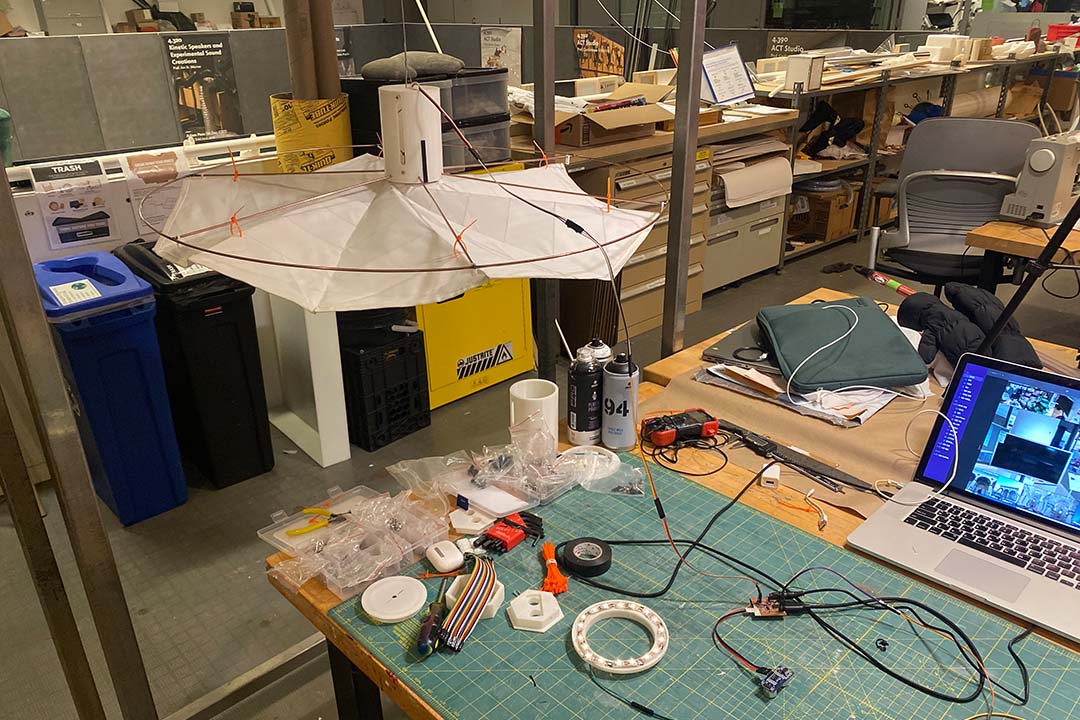

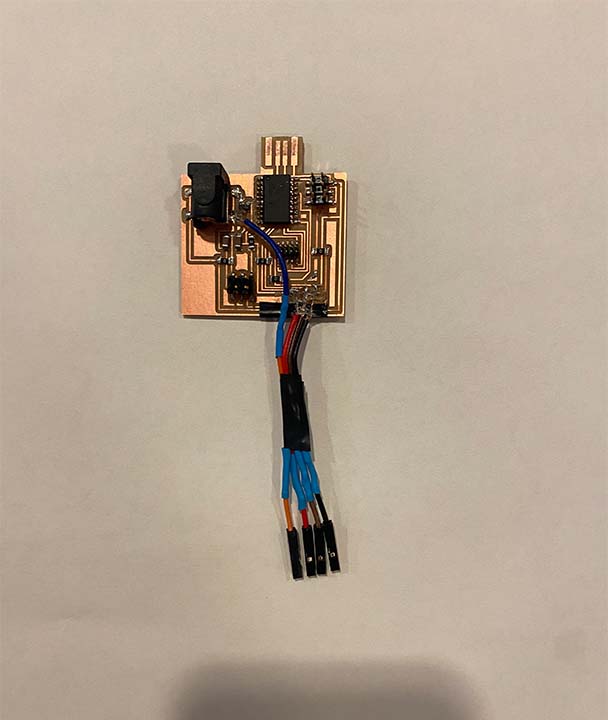

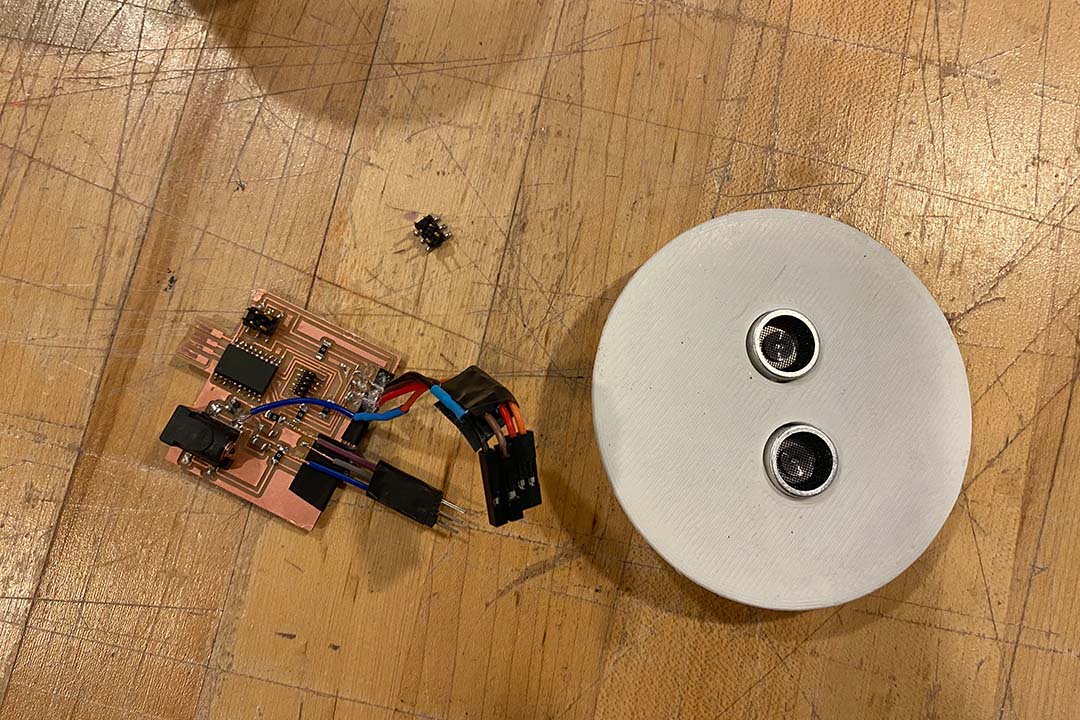

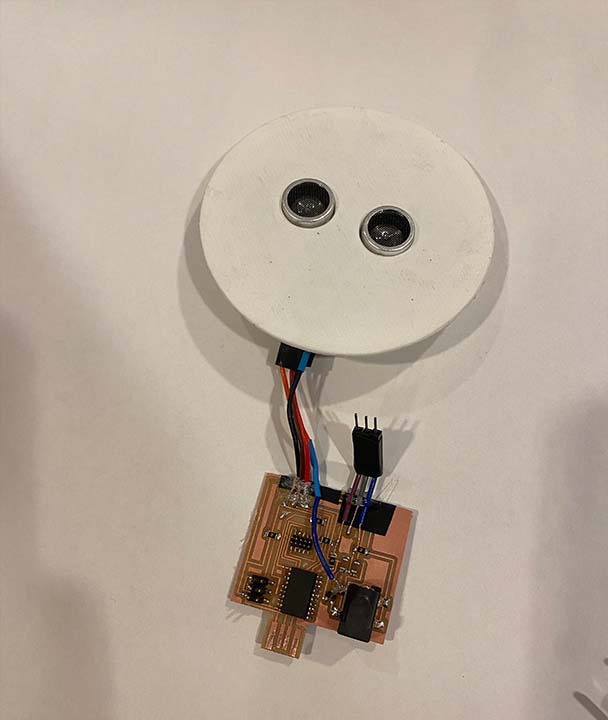

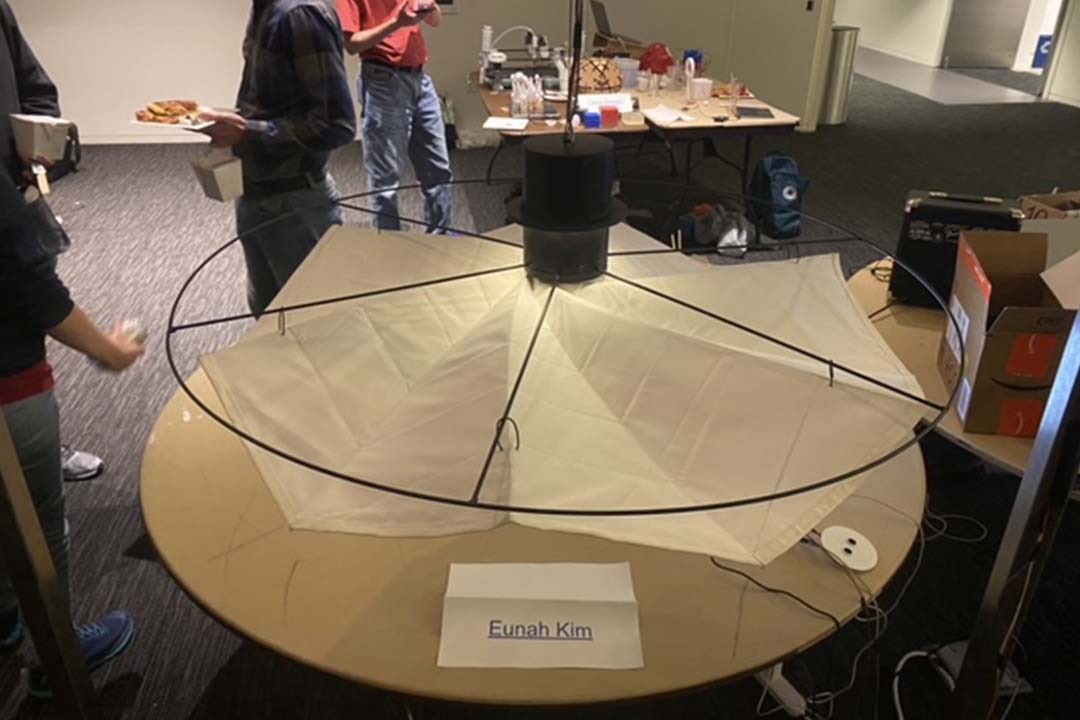

Here I found a few problems. First, the sonar sensor didn't work with my PCB schematic. Later I found out the sonar sensor requires the 5V. So I had to use a jumper wire to connect sonar power to 5V. Second, I realized the microcontroller I used, which is SAMD11D, was not compatible with Neo pixel LED. I had to change it to an LED strip. Also, I had to use PWM to program the LED strip, and one pin must be connected to the microcontroller, which uses 3.3V. So the LED brightness wasn't strong enough.