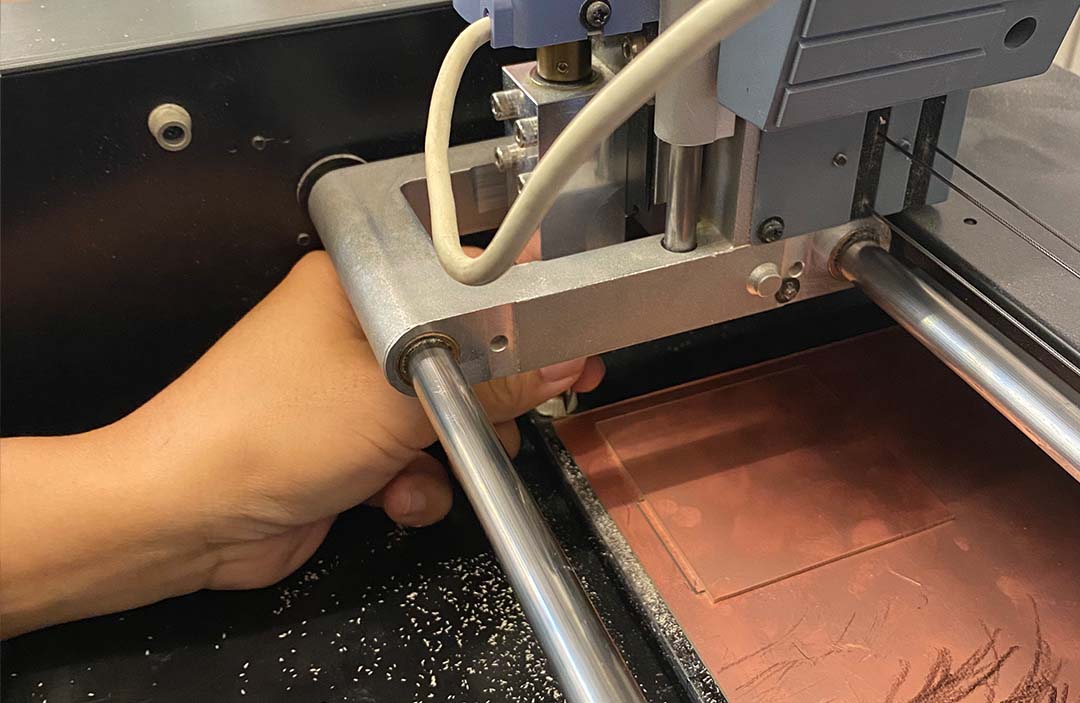

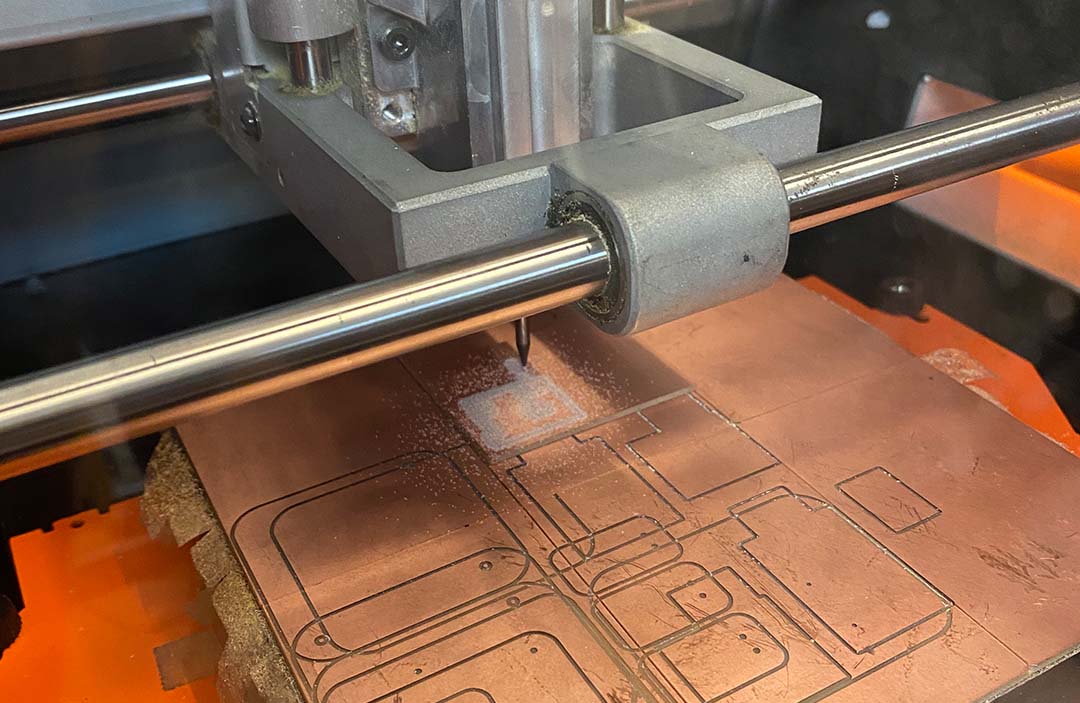

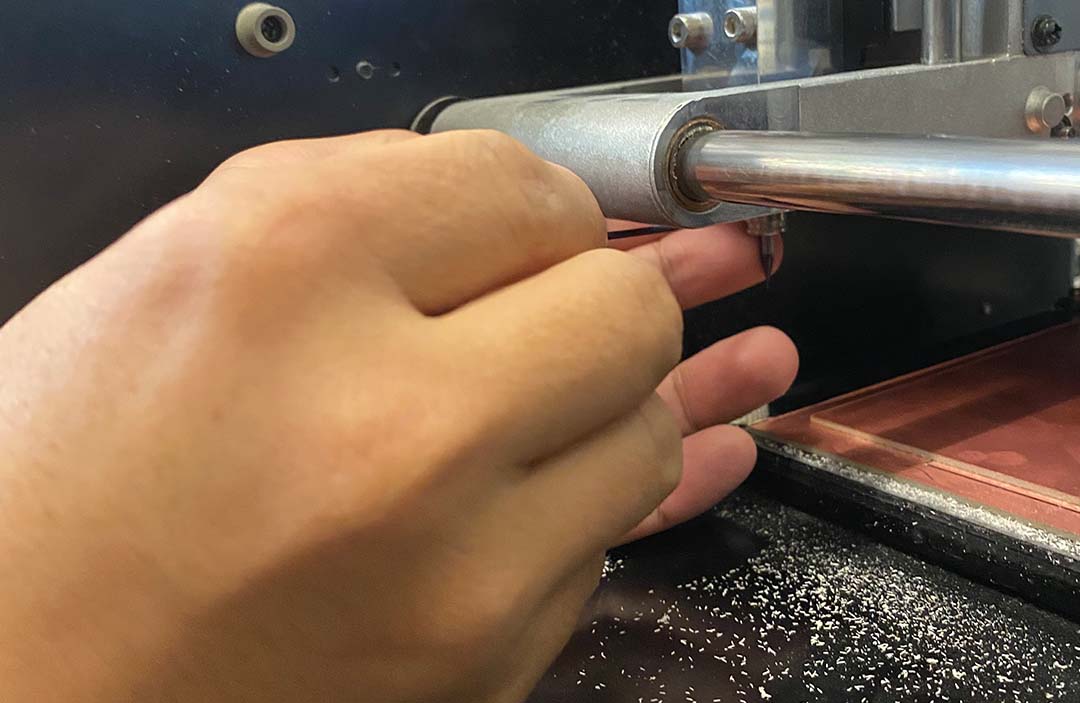

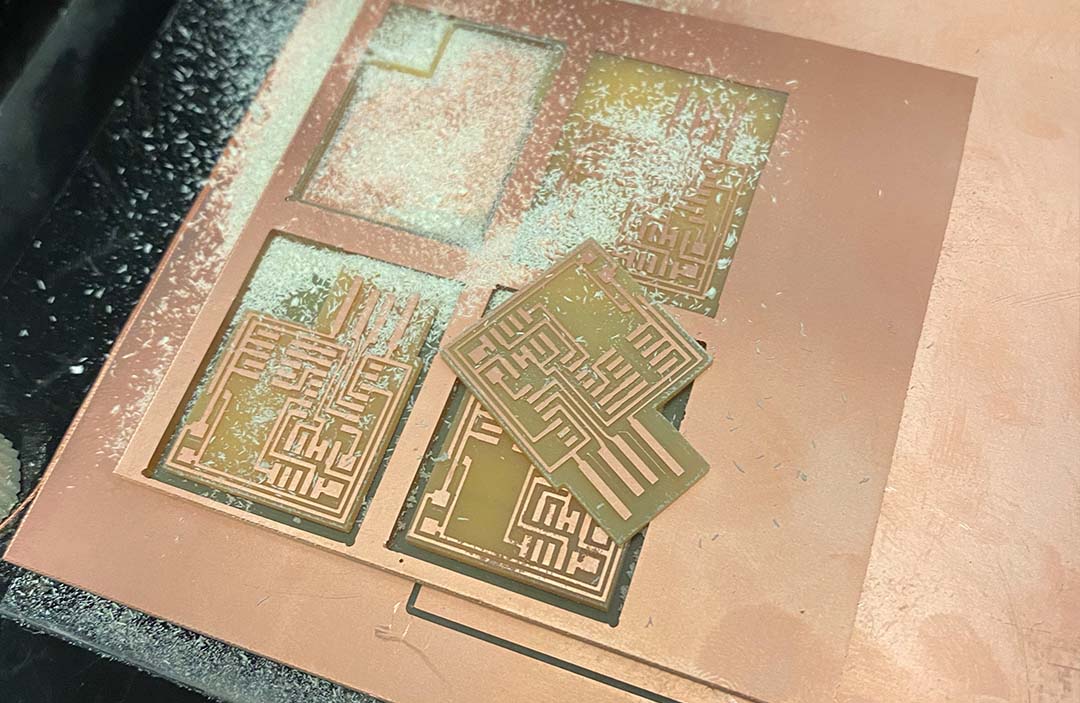

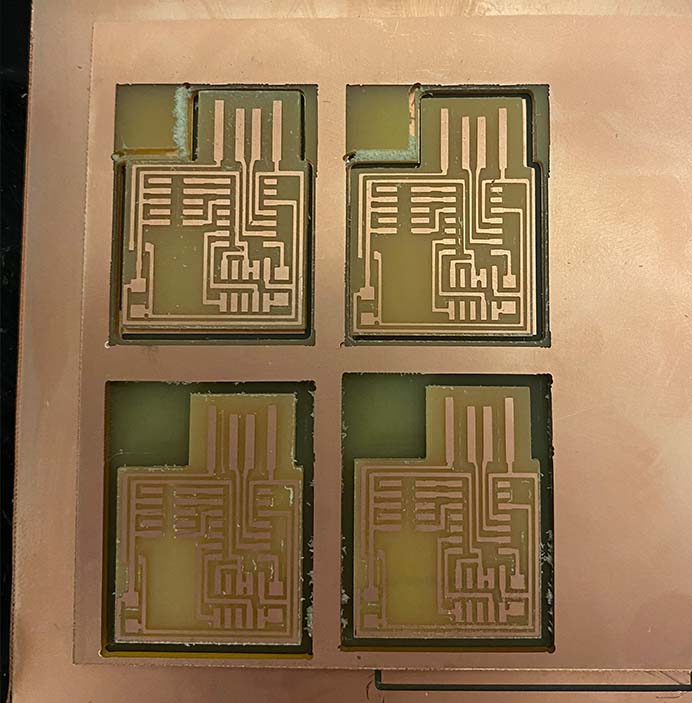

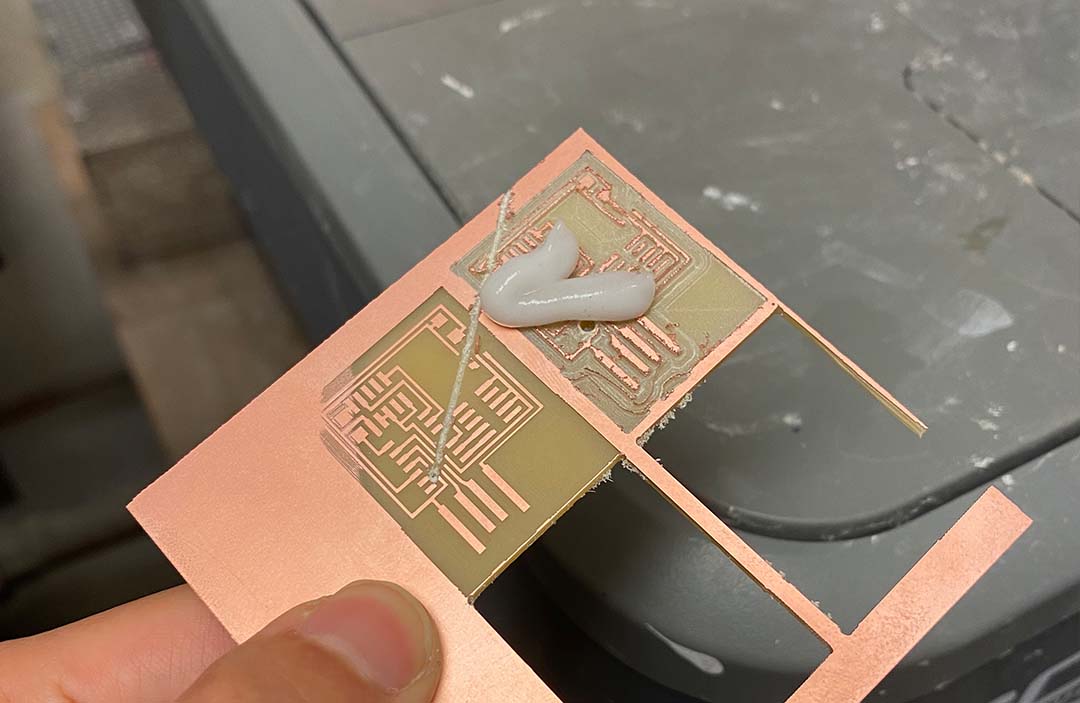

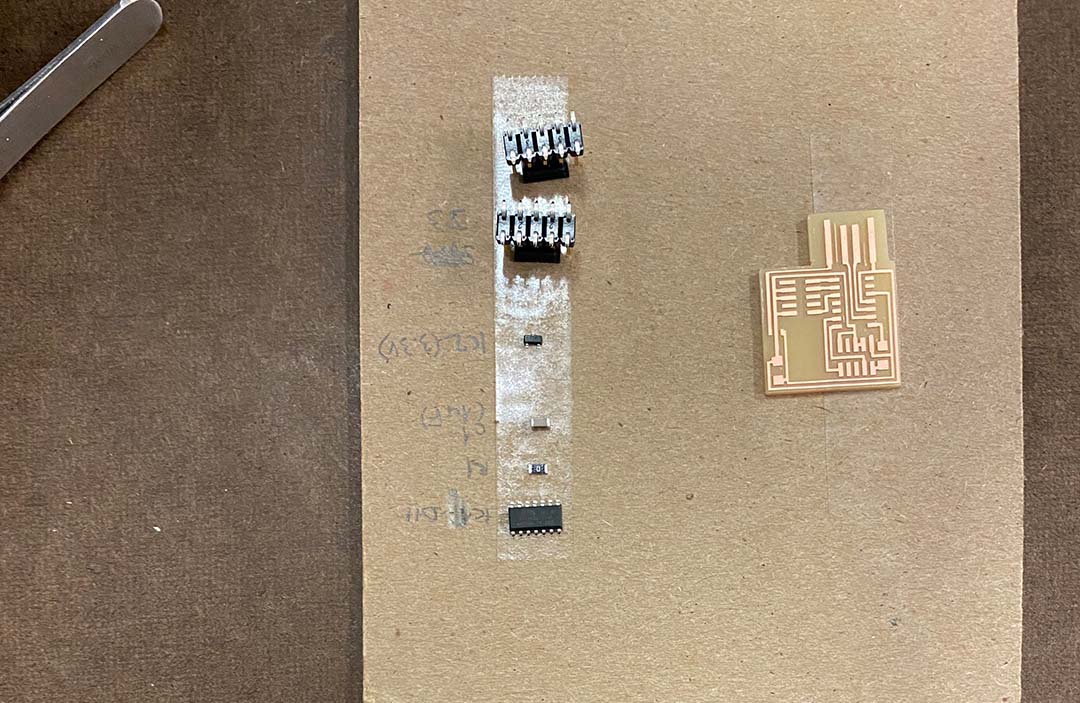

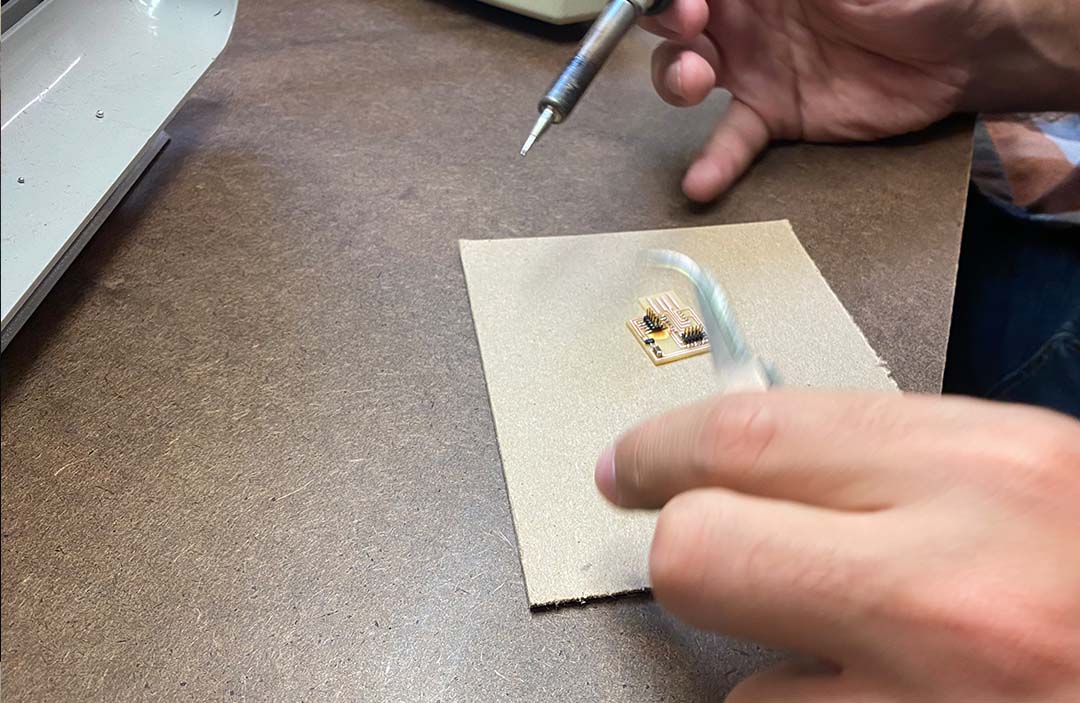

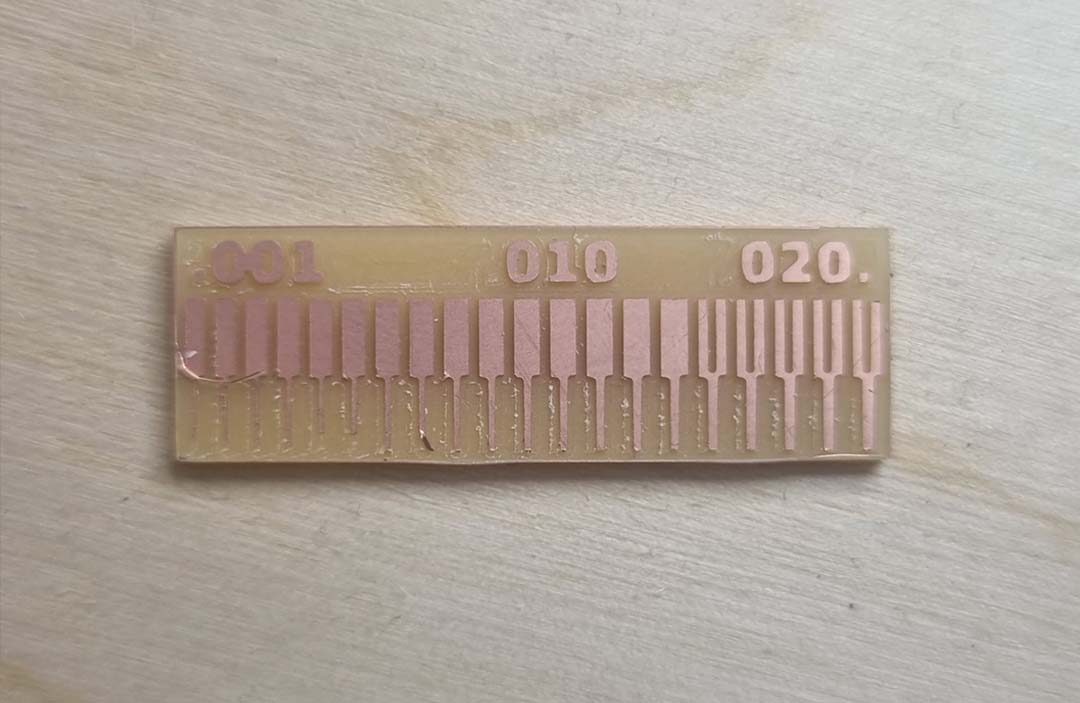

First, I attached the double-sided tape on the back of the copper

board. The copper board can also be taped perfectly flat, so it is in

the same XY plane with no gap underneath - clean, flat board layers

that were taped down very flat, very carefully, are super important.